Abstract

This paper presents the use of computed tomography for the evaluation of hardfacing. The method used in this research is hardfacing by tungsten inert gas using alloy wires of wear resistant layers. This paper discusses the latest materials used for hardfacing and their application. It characterizes the defects of obtained hardfacing and impact of the type of wire on the concentration of defects. It further, the basic mechanical properties of coatings were determined. The results are subjected to qualitative and quantitative analysis. The smallest average percentage of defects in relation to the overall surface is observed for the hardfacing EL-600 HB, which amounts to 1.5%. The highest average percentage of defects in relation to the overall surface is observed for the hardfacing EL-500 HB, which amounts to 7.2%. The chemical composition of hardfacing has been presented.

摘要

本文采用计算机断层扫描技术对堆焊效果进行评估。采用钨极惰性气体保护进行堆焊,焊料为 耐磨涂层的合金线。讨论了最新的堆焊材料及其应用。对堆焊涂层的缺陷进行表征,并研究焊料线材 对缺陷浓度的影响。此外,测试了涂层的基本力学性能,对测试结果进行定性和定量分析。结果表明, EL-600 HB 堆焊涂层总表面的平均缺陷百分数最小,为1.5%。EL-600 HB 堆焊涂层总表面的平均缺陷 百分数最大,为7.2%。获得了堆焊涂层的化学成分。

Similar content being viewed by others

References

LEHOCKA D, KLICH J, FOLDYNA J, HLOCH S, KROLCZYK J B, CARACH J, KROLCZYK G M. Copper alloys disintegration using pulsating water jet [J]. Measurement, 2016, 82: 375–383. DOI: 10.1016/j.measurement.2016.01.014.

GLOWACZ A, GLOWACZ A, KOROHODA P. Recognition of monochrome thermal images of synchronous motor with the application of binarization and nearest mean classifier [J]. Archives of Metallurgy and Materials, 2014, 59(1): 31–34. DOI: 10.2478/amm-2014-0005.

WOJCIECHOWSKI S, MARUDA R W, KROLCZYK G M, NIESLONY P. Application of signal to noise ratio and grey relational analysis to minimize forces and vibrations during precise ball end milling [J]. Precision Engineering, 2016, 51: 582–596. DOI: 10.1016/j.precisioneng.2017.10.014.

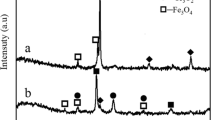

YANG K, YANG K, BAO Y F, JIANG Y F. Formation mechanism of titanium and niobium carbides in hardfacing alloy [J]. Rare Metals, 2017: 36(8): 640–644. DOI: 10.1007/s12598-016-0777-5.

DA SILVA L J, D'OLIVEIRA A. NiCrSiBC coatings: Effect of dilution on microstructure and high temperature tribological behaviour [J]. Wear, 2016, 350: 130–140. DOI: 10.1016/j.wear.2016.01.015.

CHAKRABORTY G, DAS C R, ALBERT S K, BHADURI A K, MURUGESAN S, DASGUPTA A. Effect of alloy 625 buffer layer on Hardfacing of modified 9Cr-1Mo steel using nickel base Hardfacing alloy [J]. Journal of Materials Engineering and Performance, 2016, 25(4): 1663–1672. DOI: 10.1007/s11665-016-1965-z.

WANG X H, ZOU Z D, QU S Y. Microstructure of Fe-based alloy hardfacing coating reinforced by TiC-VC particle [J]. Journal of Iron and Steel Research, 2006, 13(4): 51–55. DOI: 10.1016/S1006-706X(06)60078-2.

PASHECHKO M, DZIEDZIC K, BARSZCZ M. Study of the structure and properties of wear-resistant eutectic Fe-Mn-C-B-Si-Ni-Cr coatings [J]. Powder Metallurgy and Metal Ceramics, 2013, 7–8(52): 469–476. DOI: 10.1007/s11106-013-9549-z.

YUKSEL N, SAHIN S. Wear behavior–hardness–microstructure relation of Fe–Cr–C and Fe–Cr–C–B based hardfacing alloys [J]. Materials and Design, 2016, 58: 491–498. DOI: 10.1016/j.matdes.2014.02.032.

CORREA E O, ALCANTARA N G, VALERIANO L C, BARBEDO N D, CHAVES R R. The effect of microstructure on abrasive wear of a Fe–Cr–C–Nb hardfacing alloy deposited by the open arc welding process [J]. Surface & Coatings Technology, 2015, 276: 479–484. DOI: 10.1016/j.surf coat.2015. 06.026.

BADISCH E, KATSICH C, WINKELMANN H, FRANEK F, MANISH R. Wear behavior of hardfaced Fe-Cr-C alloy and austenitic steel under 2-body and 3-body conditions at elevated temperature [J]. Tribology International, 2010, 43: 1234–1244. DOI: 10.1016/j.trib oint.2010.01.008.

VALAVANIS I, KOSMOPOULOS D. Multiclass defect detection and classification in weld radiographic images using geometric and texture features [J]. Expert Systems with Applications, 2010, 37: 7606–7614. DOI: 10.1016/j.eswa.2010.04.082.

ZAPATA J, VILAR R, RUIZ R. Performance evaluation of an automatic inspection system of weld defects in radiographic images based on neuro-classifiers [J]. Expert Systems with Applications, 2011, 38: 8812–8824. DOI: 10.1016/j.eswa.2011.01.092.

TABATABAEIPOUR M, HETTLER J, DELRUE S, ABEELE K. Non-destructive ultrasonic examination of root defects in friction stir welded butt-joints [J]. NDT&E International, 2016, 80: 23–34. DOI: 10.1016/j.ndteint. 2016.02.007.

KROLCZYK J B, GAPINSKI B, KROLCZYK G M, SAMARDZIC I, MARUDA R W, SOUCEK K, JAVADI Y, LEGUTKO S, NIESLONY P, STAS L. Topographic inspection as a method of weld joint diagnostic [J]. Tehnicki Vjesnik–Technical Gazette, 2016, 23(1): 301–306. DOI: 10.17559/TV-20141230182054.

DINDA S K, WARNETT J M, WILLIAMS M A, ROYA G, SRIRANGAM P. 3D imaging and quantification of porosity in electron beam welded dissimilar steel to Fe-Al alloy joints by X-ray tomography [J]. Materials and Design, 2016, 96: 224–231. DOI: 10.1016/j.matdes. 2016.02.010.

YANG M, XIONG S M, GUO Z. Characterization of the 3-D dendrite morphology of magnesium alloys using synchrotron X-ray tomography and 3-D phase-field modelling [J]. Acta Materialia, 2015, 92: 8–17. DOI: 10.1016/j.actamat.2015.03.044.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Jozwik, J., Dziedzic, K., Usydus, I. et al. Assessment of internal defects of hardfacing coatings in regeneration of machine parts. J. Cent. South Univ. 25, 1144–1153 (2018). https://doi.org/10.1007/s11771-018-3813-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11771-018-3813-9