Abstract

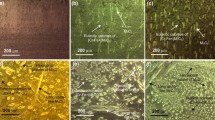

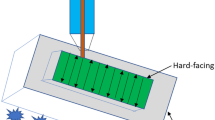

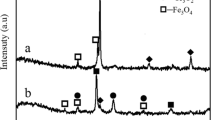

Raw material handling areas in an integrated steel plant experience severe wear of engineering components. The use of hardfacing plates is one of the ways to combat this problem. Three commercial hardfacing Fe-Cr-C alloys of varying Cr content were deposited on mild steel base plate and studied in this work. Abrasive wear tests were conducted by using pin-on-disk tribometer in accordance with the ASTM G99. Microstructural characterization was done by using optical and scanning electron microscopes. Energy- and wavelength-dispersive spectroscopies were carried out to study the carbide type and distribution in the hardfaced deposit. It was observed that wear resistance increases with increasing Cr content in the alloy. Along with hardness, morphology and type of carbide are also important factors to decide the wear resistance. An attempt has been made to corelate the chemical composition, carbide morphology, and macrostructural features with wear properties of hardfacing alloys.

Similar content being viewed by others

Change history

21 May 2018

In the original article, Aman Kumar Jha was inadvertently omitted as a co-author.

References

D. Kotechi, Hardfacing benefits maintenance and repair welding. Weld. J. 25, 51–55 (1992)

D. Cortie, J. McEwan, Materials selection in the mining industry: old issues and new challenges. J. South Afr. Inst. Min. Metall. 96(4), 145–157 (1996)

A. Roberts, M. Ooms, S. Wiche, Concepts of boundary friction, adhesion and wear in bulk solids handling operations, in Third International Conference on Bulk Materials, Storage, Handling and Transportation, Institution of engineers. (Australia, 1989)

K. Tuckey, Intelligent selection of engineered wear linings in iron ore plant. Mineral Process. Extr. Metall. 112(1), 33–38 (2003)

O. Scott, P. Choules, The use of impact plates in conveyor transfers. Tribol. Int. 26(5), 353–359 (1993)

I. Hutchings, Mechanisms of wear in powder technology: a review. Powder Technol. 76(1), 3–13 (1993)

S. Wiche, S. Keys, A. Roberts, Abrasion wear tester for bulk solids handling applications. Wear 258(1), 251–257 (2005)

S. Biswas, A. Cenna, K. Williams, M. Jones, Subsurface behavior of ductile material by particle impacts and its influence on wear mechanism. Process Eng. 90, 160–165 (2014)

A. Cenna, K. Williams, M. Jones, Analysis of impact energy factors in ductile materials using single particle impact tests on gas gun. Tribol. Int. 44(12), 1920–1925 (2011)

E. Gregory, Surfacing by welding. Weld. Inst. Res. Bull. 21, 9–13 (1980)

ASM, ASM Materials Park, in Metals Handbook, 9th ed, vol. 7, (1972) pp. 770–786

M. Carvalho, Y. Wangb, J. Souza, E. Braga, L. Li, Characterization of phases and defects in chromium carbide overlays deposited by SAW process. Eng. Fail. Anal. 60, 374–382 (2016)

J. Gates, Wear plate and materials selection for sliding abrasion. Aust. J. Min. 2, 26–32 (2003)

Z.H. Wang, Q.B. Wang, L. Cui, A.D. Yang, D.Y. He, Influence of cooling rate and composition on orientation of primary carbides of Fe-Cr-C hardfacing alloys. Sci. Technol. Weld. Join. 13(7), 656–662 (2008)

J. Hornung, A. Zikin, K. Pichelbauer, M. Kalin, M. Kirchgabner, Influence of cooling speed on the microstructure and wear behaviour of hypereutectic Fe-Cr-C hardfacings. Mater. Sci. Eng. 576, 243–251 (2013)

E. Correa, N.A. Ntara, D. Tecco, R. Kumar, The Relationship between the microstructure and abrasive resistance of a hardfacing alloy in the Fe-Cr-C-Nb-V system. Metall. Mater. Trans. 38(A), 1671–1680 (2007)

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Pawar, S., Mukhopadhyay, G. Metallurgical and Tribological Evaluation of Fe-Cr-C Hardfacing Alloys. J Fail. Anal. and Preven. 18, 868–876 (2018). https://doi.org/10.1007/s11668-018-0475-8

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11668-018-0475-8