Abstract

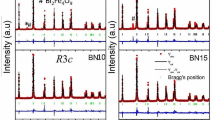

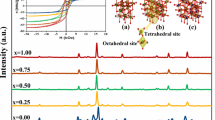

The nanocomposite xCoFe2O4-(1−x)BaTiO3 (x=0.2, 0.3, 0.4, 0.5, molar fraction) fibers with fine diameters and high aspect ratios (length to diameter ratios) were prepared by the organic gel-thermal decomposition process from citric acid and metal salts. The structures and morphologies of gel precursors and fibers derived from thermal decomposition of the gel precursors were characterized by Fourier transform infrared spectroscopy, X-ray diffractometry and scanning electron microscopy. The magnetic properties of the nanocomposite fibers were measured by vibrating sample magnetometer. The nanocomposite fibers consisting of ferrite (CoFe2O4) and perovskite (BaTiO3) are formed at the calcination temperature of 900 °C for 2 h. The average grain sizes of CoFe2O4 and BaTiO3 in the nanocomposite fibers increase from 25 to 65 nm with the calcination temperature from 900 to 1 180 °C. The single fiber constructed from these nanograins of CoFe2O4 and BaTiO3 has a necklace-like morphology. The saturation magnetization of the nanocomposite 0.4CoFe2O4-0.6BaTiO3 fibers increases with the increase of CoFe2O4 grain size, while the coercivity reaches a maximum value when the average grain size of CoFe2O4 is around the critical single-domain size of 45 nm obtained at 1 000 °C. The saturation magnetization and remanence of the nanocomposite xCoFe2O4-(1−x)BaTiO3 (x=0.2, 0.3, 0.4, 0.5) fibers almost exhibit a linear relationship with the molar fraction of CoFe2O4 in the nanocomposites.

Similar content being viewed by others

References

IIJIMA S. Helical microtubules of graphitic carbon [J]. Nature, 1991, 354: 56–58.

MORALES A M, LIEBER C M. A laser ablation method for the synthesis of crystalline semiconductor nanowires [J]. Science, 1998, 279(5348): 208–211.

MARTIN C R. Nanomaterials: A membrane-based synthetic approach [J]. Science, 1994, 266(5193): 1961–1966.

HAN Wei-qiang, FAN Shou-shan, LI Qun-qing, HU Yong-dan. Synthesis of gallium nitride nanorods through a carbon nanotube-confined reaction [J]. Science, 1997, 277(5330): 1287–1289.

PAN Zheng-wei, DAI Zu-rong, WANG Zhong-lin. Nanobelts of semiconducting oxides [J]. Science, 2001, 291(5510): 1947–1949.

JU Y W, PARK J H, JUNG H R, CHO S J, LEE W J. Electrospun MnFe2O4 nanofibers: preparation and morphology [J]. Composites Science and Technology, 2008, 68(7/8): 1704–1709.

CAO Kai, SHEN Xiang-qian, JING Mao-xiang, ZHOU Jian-xin. Preparation of ferromagnetic metal fine fibers by organic gel-thermal reduction process [J]. Journal of Central South University of Technology, 2007, 14(5): 607–611.

WANG Wen-zhong, LIU Ying-kai, XU Cong-kang, ZHENG Chang-lin, WANG Guang-hou. Synthesis of NiO nanorods by a novel simple precursor thermal decomposition approach [J]. Chemical Physics Letters, 2002, 362(1/2): 119–122.

ZHANG Chun-ye, SHEN Xiang-qian, ZHOU Jian-xin, JING Mao-xiang, CAO Kai. Preparation of spinel ferrite NiFe2O4 fibres by organic gel-thermal decomposition process [J]. Journal of Sol-Gel Science and Technology, 2007, 42(1): 95–100.

XIANG Jun, SHEN Xiang-qian, MENG Xian-feng. Preparation of Co-substituted MnZn ferrite fibers and their magnetic properties [J]. Materials Chemistry and Physics, 2009, 114: 362–366.

SRINIYAS S, LI J Y. The effective magnetoelectric coefficients of polycrystalline multiferroic composites [J]. Acta Materialia, 2005, 53: 4135–4142.

HUA Z, YANG P, HUANG H. Sol-gel template synthesis and characterization of magnetoelectric CoFe2O4/Pb(Zr0.52Ti0.48)O3 nanotubes [J]. Materials Chemistry and Physics, 2008, 107: 541–546.

XIE S H, LI J Y, LIU Y Y, LAN L N, JIN G, ZHOU Y C. Electrospinning and multiferroic properties of NiFe2O4-Pb(Zr0.52Ti0.48)O3 composite nanofibers [J]. Journal of Applied Physics, 2008, 104: 024115.

XIAO Shun-hua, JIANG Wei-fen, LI Long-yu, LI Xin-Jian. Low-temperature auto-combustion synthesis and magnetic properties of cobalt ferrite nanopowder [J]. Materials Chemistry and Physics, 2007, 106: 82–87.

ZHANG Shu-ping, DONG Da-wei, SUI Yu, LIU Zhi-guo, WANG Hong-xia, QIAN Zheng-nan, SU Wen-hui. Preparation of core shell particles consisting of cobalt ferrite and silica by sol-gel process [J]. Journal of Alloys and Compounds, 2006, 415: 257–260.

RAMAJO L, PARRA R, REBOREDO M. Heating rate and temperature effects on the BaTiO3 formation by thermal decomposition of (Ba,Ti) organic precursors during the Pechini process [J]. Materials Chemistry and Physics, 2008, 107: 110–114.

RADWAN N R E, ELSHOBAKY H G. Solid-solid interactions between ferric and cobalt oxides as influenced by Al2O3-doping [J]. Thermochimica Acta, 2000, 360: 147–156.

WANG Li-qiu, LIU Liang, XUE Dong-feng. Wet routes of high purity BaTiO3 nanopowders [J]. Journal of Alloys and Compounds, 2007, 440: 78–83.

GARCIA C L A, MONTEMAYOR S M. Synthesis of CoFe2O4 nanoparticles embedded in a silica matrix by the citrate precursor technique [J]. Journal of Magnetism and Magnetic Materials, 2005, 294: e43–e46.

RAMAJO L, CASTRO M S, REBOREDO M M. Effect of silane as coupling agent on the dielectric properties of BaTiO3-epoxy composites [J]. Composites (Part A): Applied Science and Manufacturing, 2007, 32: 1852–1859.

KASAPOGLU N, BAYKAL A, KOSEOGLUAND Y. Microwave-assisted combustion synthesis of CoFe2O4 with urea, and its magnetic characterization [J]. Scripta Materialia, 2007, 57: 441–444.

CHIU W S, RADIMAN S, ABDSHUKOR R, ABDULLAH M H, KHIEW P S. Tunable coercivity of CoFe2O4 nanoparticles via thermal annealing treatment [J]. Journal of Alloys and Compounds, 2008, 459: 291–297.

STONER E C, WOHLFARTH E P A. Mechanism of magnetic hysteresis in heterogeneous alloys [J]. IEEE Transactions on Magnetics, 1991, 27(4): 3475–3518.

MAAZ K, MUMTAZ A, HASANSIN S K, CEYLAN A. Synthesis and magnetic properties of cobalt ferrite (CoFe2O4) nanoparticles prepared by wet chemical route [J]. Journal of Magnetism and Magnetic Materials, 2007, 308: 289–295.

CHINNASAMY C N, JEYADEVAN B, SHINODA K, TOHJI K, DJAYAPRAWIRA D J, TAKAHASHI M, JOSEYPHUS R J, NARAYANASAMY A. Unusually high coercivity and critical single-domain size of nearly monodispersed CoFe2O4 nanoparticles [J]. Applied Physics Letters, 2003, 83: 2862–2864.

Author information

Authors and Affiliations

Corresponding author

Additional information

Foundation item: Project(50674048) supported by the National Natural Science Foundation of China; Project(20080431069) supported by China Postdoctoral Science Foundation; Project(CX10B-257Z) supported by Postgraduate Cultivation and Innovation Foundation of Jiangsu Province, China

Rights and permissions

About this article

Cite this article

Zhou, Z., Shen, Xq., Song, Fz. et al. Structures and magnetic properties of nanocomposite CoFe2O4-BaTiO3 fibers by organic gel-thermal decomposition process. J. Cent. South Univ. Technol. 17, 1172–1176 (2010). https://doi.org/10.1007/s11771-010-0614-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11771-010-0614-1