Abstract

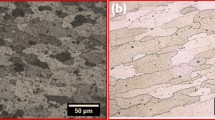

The deformation behavior of dispersion strengthened copper alloy Cu-Al2O3 was studied by TEM. The results show that nano-scaled dispersed second phase not only increases dislocation density in matrix, but also has an important influence on the dislocation substructure. The presence of fine dispersed Al2O3 particles results in a uniform and random dislocation distribution in matrix copper and causes the difficulty in formation of dislocation cell structure and the decrease in the amount of cell structure during deformation. Deformation gives rise to much more dislocations and dislocation cells form more difficultly and the decrease in the cell size with the increase of dispersion degree.

Similar content being viewed by others

References

Grundmann U, Gerner M, Heimsier M, et al. Deformation behavior of oxide-dispersion-strengthened siler[J]. Materials Science and Engineering A, 1997, 234–236: 505–508.

Lee J S, Kim Y C, Lee S. Correlation of the microstructure and mechanical properties of oxide-dispersion-strengthened coppers fabricated by internal oxidation[J]. Metallurgical and Materials Transactions A, 2004, 35A: 493–502.

Grundmann U, Heilmaier M, Martin U. Oxide dispersion-strengthened silver: manufacturing and properties[J]. Z Metallkd, 2003, 94(5): 587–592.

Takahashi T, Hashimoto Y. Preparation of dispersion-strengthened coppers with NbC and TaC by mechanical alloying[J]. Materials Transactions, JIM, 1991, 32(4): 389–397.

Reppich B. On the dispersion strengthening mechanisms in ODS materials[J]. Z Metallkd, 2002, 93(7): 605–613.

Brimhall J L, Klein M J, Huggins R A. Influence of a finely dispersed second phase on recrystallization[J]. Acta Metallurgica, 1966, 14: 459–466.

Klein M J, Huggins R A. The structure of cold worked silver and silver-magnesium oxide alloys[J]. Acta Metallurgica, 1962, 10: 55–62.

Brimhall J L, Huggins R A. Electron-microscopic observations of deformed internally oxidized alloys[J]. Trans of Metallurgical Society of AIME, 1965, 233: 1076–1085.

Kim S H, Lee D N. Annealing behavior of Alumina dispersion-strengthened copper strips rolled under different conditions [J]. Metallurgical and Materials Transactions A, 2002, 33A: 1605–1616.

Mandal D, Baker I. On the effect of fine second-phase particles on primary recrystallization as a function of strain[J]. Acta Mater, 1997, 45(2): 453–461.

Author information

Authors and Affiliations

Corresponding author

Additional information

Foundation item: Project (2002AA302505) supported by the National Advanced Materials Committee of China

Rights and permissions

About this article

Cite this article

Cheng, Jy., Wang, Mp., Cao, Jg. et al. Influence of nano-scaled dispersed second phase on substructure of deformed dispersion strengthened copper alloy. J Cent. South Univ. Technol. 12 (Suppl 1), 50–53 (2005). https://doi.org/10.1007/s11771-005-0370-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11771-005-0370-9