Abstract

In this study the effect of temperature, NaCl and oils (hydrocarbons: C8–C16) on the formation and solubilization capacity of the systems of oil/monoacylglycerols (MAG):ethoxylated fatty alcohols (CEO20)/propylene glycol (PG)/water was investigated. The effects of the surfactant mixture on the phase behavior and the concentration of water or oil in the systems were studied at three temperatures (50, 55, 60 °C) and with varied NaCl solutions (0.5; 2; 11%). Electrical conductivity measurement, FTIR spectroscopy and the DSC method were applied to determine the structure and type of the microemulsions formed. The dimension of the microemulsion droplets was characterized by dynamic light scattering. It has been stated that the concentration of CEO20 has a strong influence on the shape and extent of the microemulsion areas. Addition of a nonionic surfactant to the mixture with MAG promotes an increase in the area of microemulsion formation in the phase diagrams, and these areas of isotropic region did not change considerably depending on the temperature, NaCl solution and oil type. It was found that, depending on the concentration of the surfactant mixture, it was possible to obtain U-type microemulsions with dispersed particles size distribution ranging from 25 to 50 nm and consisting of about 30–32% of the water phase in the systems. The conditions under which the microemulsion region was found (electrolyte and temperature—insensitive, comparatively low oil and surfactant concentration) could be highly useful in detergency.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Substantial amounts of oil and water can be solubilized in the form of homogeneous, isotropic thermodynamically stable systems with the help of surfactants, these systems are called microemulsions. Their structures, dynamics, and transport properties have been well reported because of their numerous scientific and technological applications [1, 2]. Many industrial product formulations require the solubilization or dispersion of hydrophobic, water-insoluble materials in water. Solubilization is also an important element of detergency and finds various applications in micelle-enhanced separation, emulsion polymerization, and the preparation of various cosmetic, pharmaceutical, and agricultural products.

REACH is a European Community Regulation on chemicals and their safe use that deals with the registration, evaluation and restriction of chemical substances. The aim of REACH is to improve the protection of human health and the environment through the better and earlier identification of the intrinsic properties of chemical substances. Among these chemical substances are industrial cleaning products, generally composed of aqueous solutions of surfactants that contain solvents, solubilizers, stabilizers, etc. Due to their common use, these chemical substances need to be studied exhaustively in the near future, not only from the standpoint of their environmental security but also for their efficiency.

Monoacylglycerols (MAG) are a class of polar food lipids obtained from natural raw materials, namely glycerol and fatty acids and they are widely used in many products of the food industry and cosmetics [3, 4]. Ethoxylated fatty alcohols are not only highly biodegradable but also highly efficient at removing fatty soils [5]. It is with these nonionic surfactants microemulsions that we are mainly concerned here.

The growing use of non-ionic surfactants is related to their good detergent performance, which is not affected by water hardness, and, in most cases, to their low toxicity. They do not give rise to electrostatic interactions and they remove dirt from synthetic, as well as natural fibers at low temperatures. Most of the studies on ethoxylated nonionic microemulsions are based on fatty alcohols, which are ecologically suitable surfactants, since they are biodegradable and show low water toxicity. Earlier reports [6–10] indicated that hydrocarbon oils were mainly used in the formation of Brij microemulsions and reverse micelles. The characterization of the systems was restricted to the phase behavior, interfacial composition, and PIT studies. Moreover, the blend of surfactants and cosolvents that were used to form ethoxylated alcohol microemulsions have small isotropic regions in the phase diagram or sensitive to electrolyte at the experimental temperature examined.

The present report examines the solubilization process of these types of molecules using environment-friendly resources. Here, we study the phase behavior of systems prepared with water, hexadecane, PG and received from renewable sources nonionic surfactants (MAG and ethoxylated fatty alcohols C16-18EO20). Owing to their amphiphilic nature, surfactants can form monolayers between oil and water. The properties of interfacial surfactant films which are affected by a change in temperature and/or electrolyte concentration are responsible for the microstructural changes in microemulsions containing nonionic surfactants [11–13]. Along this line, our primary goal was to search for areas of water solubilization in microemulsions stabilized by nonionic surfactants received from renewable sources, at varied temperatures and electrolyte solutions, with model oil phases, preferably thermodynamically stable ones, containing reduced proportions of surfactant.

Experimental Procedures

Materials

Molecular distilled (MAG > 95%) (MYVEROL RX GMS 95P, a mixture of glycerol palmitic (57,8%) stearic (37.3%) and myristic (1.3%) acid monoesters, were purchased from KERRY BIO-SCIENCE (Netherlands). Ethoxylated fatty alcohols (average molecular formula C16-18EO20) was purchased from CHEMCO (Poland) and (PG: propane-1,2-diol, 99.5% purity) was obtained from POCH (Poland). Hexadecane, pentadecane, tetradecane, dodecane, decane, octane (model oil phases, purity >98%) were obtained from FLUKA (Poland). Sodium chloride (NaCl, purity 99,9%) was purchased from POCH (Poland). The water used for the preparation of the systems was purified in a ROpureST/NANOpure system (Barnstead, USA).

Methods

Microemulsion Formation

Microemulsions were prepared in a glass thermostated emulsor using a mechanical stirrer (Heidolph RZR 2021, Germany). Water was added dropwise to a mixture of the other components (oil phase and surfactant with cosurfactant) until its solubilization limit was reached, (the system became turbid) under continuous stirring (300 rpm). The temperatures of the microemulsion preparation were 50, 55, 60 ± 1 °C; chosen with respect to the melting temperature of the compounds, mainly MAG.

Since the behavior of four components was to be depicted on a pseudo-ternary phase diagram, the relative concentration of two of the components had to be kept constant for all the experiments. We preferred to use a fixed weight ratio of surfactants-to-cosurfactant (MAG:CEO20/PG was 1/1), to reduce the concentration of the surfactants, which is quite common. The oil:surfactants + polyol weight ratios ranging from 0:100 to 10:90 were examined.

Phase Diagrams

During the emulsification, the electrical conductivity (the conductivity cell used was a Tetra Con® 325, WTW, Germany) of the studied systems was continuously measured to determine the type of the microemulsion formed. In the case of microemulsions stabilized by nonionic surfactants, a small amount of an aqueous electrolyte must be added for electrical conduction [14, 15]. Thus, a 0.05% sodium chloride aqueous solution was used in the preparation of the microemulsion samples in place of pure water. Based on the data obtained, pseudoternary phase diagrams were formulated. The isotropic region was identified when clear and transparent systems were obtained by visual examination of samples. The amounts of water of the corresponding phases behavior in the systems were determined from three preparations and showed a maximum standard deviation of ±1%.

Calorimetric Measurements

Thermal analyses were conducted on a Mettler TA3000 calorimeter (Mettler Instrument, Switzerland) equipped with a TC 10 TA processor and a differential scanning calorimeter (DSC) with a model 30 temperature cell. The DSC measurements were carried out as follows: microemulsion samples (15–30 mg) were weighed into 40-μL aluminum pans and immediately hermetically sealed. The samples were rapidly cooled by liquid nitrogen from ambient temperature to −60 °C and then heated at a constant scanning rate (usually 5 °C/min) to 70 °C. An empty pan was used as the reference.

FT-IR Spectroscopy

Fourier transform infrared (FT-IR) spectra were recorded on a Nicolet 8700 FT-IR spectrometer and spectra acquisition was controlled by the OMNIC 7.2a software package (Thermo Electron Corporation, Madison, WI). The automatic atmospheric suppression procedures of the software were used to minimize water vapor and carbon dioxide residues in the spectra. ATR spectra in the 4,500–525 cm−1 range were measured using the Turbo mode of the EverGlo infrared source. 128 scans were made at 4 cm−1 resolution. The single-reflection Specac Golden Gate ATR system was used, equipped with a heated tungsten carbide disc fitted with a 45° horizontal diamond crystal. The liquid samples were held under a lid equipped with a Kalrez O-ring seal to minimize evaporation. The temperature of the sample was kept at 60 ± 0.5 °C with the aid of an external Specac West 6100 + controller. The sample spectra were rationed against a background with an empty, dry cell collected under the same conditions before measuring each sample series.

Droplet Size

The mean droplet size and size distribution of the microemulsions were determined using a Non-Invasive Back Scatter method (NIBS). A Zetasizer Nano ZS (Malvern Instruments, Malvern, UK) equipped with a helium neon laser with a diffraction grating operating at 633 nm was employed. Measurements were made at given temperatures of the microemulsions formation (50–60 °C).

Results and Discussion

Phase Behavior of Monoacylglycerols: Ethoxylated Fatty Alcohols Microemulsion Systems

The pseudoternary phase diagram of the hexadecane/MAG:ethoxylated alcohols/PG/water (C16H34/MAG:CEO20/PG/H2O) at 60 °C is presented in Fig. 1. The MAG:CEO20 weight ratios were 90:10 and 80:20. The phase behavior indicates the presence of an isotropic and low viscosity area which is a microemulsion one phase region (ME). It was observed that addition of 10% CEO20 to the system of oil/MAG/PG promoted an increase in the volume of solubilized water phases. A maximum concentration of 25% water could be incorporated into the microemulsion at 60 °C (Table 1). Increasing the concentration of ethoxylated fatty alcohols (20%) in those systems results in the possibility of obtaining even larger ME area in the phase diagram. These systems contained maximal amounts of water, i.e. 30.2%. It was stated that the solubilization capacity of a nonionic surfactants system can be improved by blending it with other surfactants. Addition of a second nonionic surfactant has been reported to enhance the solubilization capacity of nonionic surface agents [16–18].

The creation of a liquid crystal (LC) phase region in the systems with large amounts of stabilized mixture (MAG:CEO20/PG from 80 to 100%) was exhibited. An LC phase was distinguished by its very high viscosity and optical isotropy. MAG are able to undergo interfacial crystallization (at oil–water and air–water interfaces) and to form various liquid-crystalline phases with water, which have an influence on their wide use in many food applications, cosmetic products and pharmaceutical formulations [19–22]. The phase behavior of saturated MAG-water systems is relatively well understood [4, 23–26]. Above the Krafft temperature (the melting temperature of the hydrocarbon chains) the liquid crystalline lamellar phase is formed, which can transform into the cubic phase if the temperature is further raised. Below the Krafft point, the lamellar phase transforms into the so-called α-gel (highly hydrated structure of the MAG bilayers with ordered hydrocarbon chains), which in turn converts with time to the so-called coagel phase, a network of platelike crystals [27].

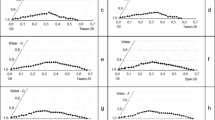

Droplet sizes are highly dependent on the quantities of the surfactants mixture. We observed that the droplet size of ME, in all cases, increased when CEO20 concentration was increased (Fig. 2a). This effect was probably due to the large size of the ethoxylated alcohol molecules. Particle size distributions were from about 25 to 50 nm for all microemulsions obtained at 60 °C.

Influence of Temperature and Electrolyte on the Phase Behavior of MAG:CEO20 Systems

We also studied the influence of temperature and added NaCl solution on the systems' behavior. The temperature of the microemulsion preparation was chosen with the respect to the melting temperature of the compounds, mainly MAG (from 50 to 60 °C). The higher temperature may promote the evaporation of water from the system. The electrolyte solutions were 2 and 11% as relatively small and high concentration [28, 29]. Additionally, in the earlier obtained systems with a maximum amount of solubilized water (water without NaCl, see Table 1), we also applied 0.5% NaCl (point in the phase diagrams). As can be see in Figs. 3 and 4 the area of the microemulsion regions changes very slightly with aqueous NaCl and temperature. This indicates temperature insensitive behavior in selected rage of temperature. Only one system with MAG:CEO20 (80:20) obtained at 50 °C contained less than the maximum water phase (beyond the statistical error) as against the rest of ME with maximum solubilization (Table 1). The observed temperature independence of these systems can be a consequence of the stabilized solubility of the MAG in the water. This means that the glycerol ester nonionic surfactant is slightly affected by temperature due to the stabilized hydration of the head groups and that the slight changes in the area of the microemulsion region as a function of temperature is due to the presence of the ethoxylated alcohols with the polyoxyethylene head group in the surfactant mixture [30–32]. It was reported earlier [33] that temperature (up to 70 °C) does not have much effect on the present pure ethoxylated nonionic surfactant microemulsion system. The only change observed was in the one-phase microemulsion area. In our case it can be concluded that the increase of temperature and also the presence of NaCl does not cause drastic changes in the pseudoternary phase diagram with mixed nonionic surfactants. It was also stated that temperature affects the droplet size slightly in the systems with MAG:CEO20. Figure 2b shows that in microemulsions stabilized by MAG and 10% of CEO20, particle size distributions were from about 25 to 40 nm.

However, in the systems with electrolyte and more than 40% of oil phase (weight ratio: oil/MAG:CEO20 40/60 ÷ 90/10) (Fig. 4) the turbid regions were observed after we had added initial amounts of the water phase. Only after adding a certain volume of water did the transparent systems occur. The cause of this situation is that the cloud point temperature of ethoxylated nonionic surfactant is affected by the concentration of the surfactant and the addition of electrolyte. The small and strongly polarizable anion (Cl−) tends to promote the water structure and dehydrate the ether oxygen of poly(oxyethylene) type nonionic surfactant. This consequently decreases the cloud point temperature by making the surfactant less hydrophilic (salting-out effect) [12]. With addition of the water phase (NaCl solution) to these systems, we changed the concentration of the surfactants to entirely ME and probably therefore, after adding a certain volume of the water phase, the transparent systems were observed. It was also found that with the increase in salinity, the hexadecane/MAG:CEO20/PG system does not become considerably more efficient in solubilizing of water (Table 2).

Thermodynamics of Water Solubilization

U-type microemulsions were formulated upon water solubilization in mixed surfactants/PG/hexadecane medium. The corresponding free energy of dissolution (ΔG os ) at a constant temperature can be obtained from the relation [34–36]:

where X d is the mole fraction of the dispersed phase (in our case water) and R is the gas constant. The estimation of ΔG os herein reported was performed based on mole fraction of dispersed water. The free energy of solubilization (ΔG os ) for water-in-oil microemulsions studied were calculated and the values are given in Table 3. It was found that the ΔG os values decrease with water content in the water-in-oil microemulsions indicating that adding water to the water-in-oil microemulsions disrupts their organization. We calculated also that ΔG os values are independent on the ethoxylated alcohols content in the mixed surfactants when the systems contained equal amount of water (not shown in the Table).

Electrical Conductivity

By using electrical conductivity measurement, the type and structure of microemulsions was determined [37, 38]. The concentration of sodium chloride in water equals 0.05%. It should be mentioned here that the addition of this small amount of electrolyte to the water used in the formulation of the microemulsions has no effect on the area of the one phase microemulsion region. The changes of electrical conductivity together with an increase in water content over the monophasic area of the hexadecane/MAG:CEO20/PG/solution of 0.05% NaCl systems at 60 °C, along the X dilution lines, are shown in Fig. 5a. As we can see from the curves obtained, in all the systems obtained (with pure MAG and MAG:CEO20 ratios of 90:10:80:20) the electrical conductivity of the microemulsions increased gradually with the increase in water content. Even after about 30 wt% solubilization of water, the system conductivity did not exceed 20 μS/cm. It seems, therefore, that the microemulsions have a microstructure that even at high water content does not invert. After reaching the maximum, conductivity decreases, probably due to the increase in the viscosity of the systems.

Figure 5b shows a plot of dlog κ/dW as a function of the water content fraction for the systems presented in Fig. 5a. Occurrence of the changes (the maximum) have been attributed to the occurrence of a percolation transition. Our systems (MAG, MAG + 10% CEO20 and MAG + 20% CEO20) did not present a maximum because they were probably already percolated, even with 1% of the aqueous phase. A model for the explanation of the behavior of the slope dlog κ/dW as a function of the water fraction was initially shown in our previous work [39]. The ethylene oxide moieties of the head group of the monomeric surfactant may already be associated with the polyol (cosurfactant) in the absence of water [40]. Addition of water may then encourage the formation of short cylinders, which further transform into water channels in an oil phase due to the attractive interaction between the spherical microdroplets of the water phase and upon further dilution system turn into bicontinuous microemulsions.

It has been found that the aggregate structure, and consequently the intrinsic geometry of an individual amphiphile, has a strong influence on the shape of the micelles and other dispersed systems [41]. The different shapes of the micellar aggregates can be characterized by the critical packing parameter defined as, CPP = v/a o l c, where a o is the effective cross-sectional area of the head group, and v and l c are the volume and critical chain length of the hydrophobic chain, respectively. The CPP values for spherical, cylindrical and lamellar particle are ~1/3, 1/3< CPP <1/2, and 1/2< CPP <1, respectively. We assume that the added water may bind with the hydrophilic CEO20 molecules. Consequently, the effective cross-sectional area of the surfactant head group increased, and hence CPP decreased and favored the structure growth. On the other hand, MAG have a relatively small polar group and a larger hydrophobic tail which may show that the CPP of these molecules is approximately 1. We also calculated the HLB (hydrophilic-lipophilic-balance) numbers of surfactants mixture according to the Davies method [42] (which is inversely related to the packing parameter). Our results show that the HLB for a mixture of the surfactant MAG:CEO20 is 90:10 and 80:20 is 9.5 and 10.7 respectively, which indicate that the bicontinuous (lamellar) structure is preferentially created in these systems.

Thermal Behavior of Systems

When describing the state of water in relation to any surface in dispersed systems, a distinction is usually made between free and bound (interfacial) water. We followed the method utilized by Senatra [43] and then Garti et al. [44], in which the endothermic scanning mode was applied and the peaks representing various states of water were identified and analyzed. Free water is assumed to have physicochemical properties not much different from those of pure water. Thus, it should, for example, freeze at approximately 0 °C [45]. The interfacial water was reported to melt at temperatures ranging from −15 to −5 °C, for microemulsions stabilized by anionic surfactants [46] or by ethoxylated alcohols [47]. Bound water is that water which is associated with hydrophilic groups and counter ions and which melts at temperatures lower than −10 °C.

Figure 5 demonstrates the thermal behavior of the pure ethoxylated surfactant and the system of hexadecane/MAG:CEO20/PG/water, with different amounts CEO20 in mixture with MAG and in which the concentration of water phase was maximum. As described above, the samples were cooled to −60 °C to freeze the microstructure. Upon heating, a series of endothermic events takes place, the temperatures and enthalpies of which are dependent on the relative amounts of amphiphile, hexadecane, and water. Pure MAG (shown in our previous work [38]) melted at 70.6 °C. When we use MAG in the W/O microemulsion system, the endothermic peak of this surfactant is shifted to a lower temperature (48.9 °C) which is similar to the CEO20 melting point temperature. The hexadecane endothermic melting peak appears at +17.5 °C. We suggest that the peaks at −4.9 and −9.3 for the system with 10 and 20% CEO20 (Fig. 5b, c) may be due to interfacial and bound water respectively. However, the range of those peaks was from about −25 to +2 °C (Fig. 6).

Thermogram for a pure CEO20, b the system of hexadecane/MAG:CEO20 (90:10)/PG/water; c the system of hexadecane/MAG:CEO20 (80:20)/PG/water. All microemulsion systems consist of the maximum amount of water (Table 1)

Propylene glycol (PG) like water forms hydrogen bonds, and has a relatively high dielectric constant. It was reported that polyols such as PG provided a ‘‘salting-in’’ effect [48–51]. It was assumed [48] that a considerable fraction of PG molecules is incorporated into the surfactant layer and thus increases the interfacial fluidity, while the other fraction of the PG molecules resides in the water bulk and decreases its polarity. In our previous work [39] we showed that water strongly binds to PG and the melting event of the binary system, e.g. water/PG is lowered. In this context we cannot clearly attribute the endothermic events to the type of water interaction that exists in those systems.

FT-IR Spectroscopy

We analyzed of the FI-IR spectra of the hexadecane/MAG:CEO20/PG/water microemulsions as a function of water content (W%wt.) to clarify the states of dissolved water in W/O microemulsions. A typical spectrum of these systems was made in the frequency range 2,600–4,400 cm−1 and also normalized to the same height of the band maximum. For comparison, the spectrum of pure water at 60 °C is also reported (3,400 cm−1). We found that with the increase in the weight fraction of water in microemulsions, no significant differences in the wavenumber of pure water were observed. It suggested that free water was present in microemulsions stabilized by MAG:CEO20.

Influence of Hydrocarbon Structure (Oils Phase) on the Solubilization of MAG:CEO20 Systems

In this study, the influence of hydrocarbon structure (C8, C10, C12, C14, C15, C16) on the solubilization of dispersed systems was evaluated. In the systems of oil phase/MAG:CEO20/PG/water, there were differences found between regions of W/O microemulsion existence. When the hydrocarbon chain length was decreased from 16 to 14, the corresponding areas of microemulsion existence were similar. Systems containing dodecane, decane and octane displayed a smaller region compared to the microemulsions with longer hydrocarbon chain oils (Fig. 7a, b). The effect of the surfactant concentration on the solubilization of water in the presence of different oil is shown in Fig. 8. For a quaternary system of surfactant (S)/oil (O)/(PG)/water (W), the following symbols were defined: α represents the weight fraction of water in oil plus water,

β is the weight fraction of a surfactant in the whole system,

We calculated that solubilization capacities are not dependent on the MAG and ethoxylated alcohols content in the mixed surfactants MAG + 10%CEO20 used, in the presence of oils with hydrocarbon chain C16, C15 and C14 (Fig. 8; Table 4). For the corresponding MAG + 20%CEO20 systems, a smaller amount of surfactant mixture was required to solubilize more water in the systems with hexa- and pentadecane. Hou and Shah [52] have reported that the emulsion solubilization capacity decreases as the hydrocarbon chain length increases. In comparison, Mehta et al. obtained the values which are in the reverse order of that expected from the above-mentioned model. In their works, the solubility increases with increased molecular volume of oil. Such an order had also been reported earlier [6, 7], where ethoxylated alcohol microemulsions solubilized larger triglycerides to a greater extent than their short-chain counterparts. This is attributed to the fact that the solubilization depends not only on the geometric parameters but also on chain stiffness, branching, etc. In the present case, it might be the mutual miscibility between the hydrophobic parts of the surfactants and the oil that affects the degree of oil penetration into the amphiphilic film as well as the spontaneous curvature.

Conclusion

Microemulsions based on (MAG) and ethoxylated fatty alcohols, safe nonionic surfactants in the presence of PG and different oil phases, concerning their ability to solubilize the water phase were formulated and characterized for the first time. The mixed surfactants systems improve the water solubilization capacity and are able to form U-type microemulsions (large continuous isotropic region in the phase diagram). The weight ratios of mixed surfactants determine the extent of water solubilization and the properties of the systems. These microemulsions form bicontinuous microstructures and the size of microemulsion droplet is dependent on the ethoxylated alcohols content. Temperature and NaCl concentration have negligible effect on the hexadecane/MAG:CEO20/PG/water systems. The conditions where the microemulsion region was found (different NaCl concentration, temperature-insensitive, comparatively low oil content and low surfactant concentration, bicontinuous structure) are similar to the conditions that may be useful in detergency. Those studies, on presented model microemulsions, are a background paper and are expected to play a key role in our further research to obtain systems with triglycerides which make solubilization more difficult.

References

Paul BK, Mouli SP (1997) Microemulsions: an overview. J Dispers Sci Technol 18:301–367

Paul BK, Moulik SP (1998) Structure, dynamics and transport properties of microemulsions. Adv Colloid Interface Sci 78:99–195

Davson SS, Hadgraft JH, Palin KJ (1985) Pharmaceutical emulsions. In: Becher P (ed) Encyclopedia of emulsion technology. Marcel Dekker, New York, p 159

Krog NJ (1997) Food emulsifiers and their chemical and physical properties. In: Friberg SE, Larsson K (eds) Food emulsions. Marcel Dekker, New York, pp 141–188

Jurado E, Bravo V, Luzon G, Fernandez-Serrano M, Garcia-Roman M, Altmajer-Vaz D, Vicaria JM (2007) Hard-surface cleaning using lipases: enzyme–surfactant. Interactions and washing tests. J Surf Deterg 10:61–70

Warisnoicharoen W, Lansley AB, Lawrence MJ (2000) Nonionic oil-in-water microemulsions: the effect of oil type on phase behavior. Int J Pharm 198:7–27

Ko CJ, Ko YJ, Kim DM, Park HJ (2003) Solution properties and PGSE-NMR self-diffusion study of C18:1E10/oil/water system. Colloids Surf A 216:55–63

Alany RG, Tucker IG, Davies NM, Rades T (2001) Characterizing colloidal structures of pseudoternary phase diagrams formed by oil/water/amphiphile systems. Drug Dev Ind Pharm 27:31–38

Ajith S, Rakshit AK (1996) Effect of NaCl on a nonionic surfactant microemulsion system. Langmuir 11:1122–1126

Paul BK, Nandy D (2007) Dilution method study on the interfacial composition, thermodynamic properties and structural parameters of W/O microemulsions stabilized by 1-pentanol and surfactants in absence and presence of sodium chloride. J Colloid Interface Sci 316:751–761

Kabalnov A, Olsson JU, Wennerstrom H (1995) Salt effects on nonionic microemulsions are driven by adsorption/depletion at the surfactant monolayer. J Phys Chem 99:6220–6230

Leontidies E (2007) Hofmeister anion effects on surfactant self-assembly and the formation of mesoporous solids. Curr Opin Colloid Interface Sci 7:81–91

Kunieda H, Aramaki K, Ishitobi M, Tagawa T (1997) Effect of added salt on three-phase behavior in a sucrose monoalkanoate system. Langmuir 13:2266–2270

Eicke HF, Meier W, Hammerich H (1994) On electric conductivity of infinite clusters in water-in-oil microemulsions. Langmuir 10:2223–2227

Garti N, Clement V, Fanun M, Leser ME (2000) Some characteristics of sugar ester nonionic microemulsions in view of possible food applications. J Agric Food Chem 48:3945–3956

Kunieda H, Yamagata M (1993) Mixing of nonionic surfactants at water-oil interfaces in microemulsions. Langmuir 9:3345–3351

Jurado E, Bravo V, Vicaria JM, Fernandez-Arteaga A, Garcia-Lopez AI (2008) Triolein solubilization using highly biodegradable non-ionic surfactants. Colloids Surf A 326:162–168

Fanun M (2008) A study of the properties of mixed nonionic surfactants microemulsions by NMR, SAXS, viscosity and conductivity. J Mol Liq 142:103–110

Krog N (1999) Food emulsifiers. In: Guneston FD, Padley FB (eds) Lipid technologies and applications, 2nd edn. Wiley-VCH, New York, pp 521–534

Krog N, Larsson K (1992) Crystallization at interfaces in food emulsions—a general phenomenon. Fat Sci Technol 94:55–57

Sagalowicz L, Leser ME, Watzke HJ, Michel M (2006) Monoglyceride self-assembly structures as delivery vehicles. Trends Food Sci Technol 17:204–214

Eccleston GM (1997) Functions of mixed emulsifiers and emulsifying waxes in dermatological lotions and creams. Colloids Surf A 123–124:169–182

Krog N, Larsson K (1968) Phase behavior and rheological properties of aqueous systems of industrial distilled monoglycerides. Chem Phys Lipids 2:129–143

Larsson K, Krog N (1972) Structural properties of the lipid–water gel phase. Chem Phys Lipids 10:177–180

Krog N, Borup AP (1973) Swelling behavior of lamellar phases of saturated monoglycerides in aqueous systems. J Sci Food Agric 24:691–701

Krog N (2001) Crystallization properties and lyotropic phase behavior of food emulsifiers: relation to technical applications. In: Garti N, Sato K (eds) Crystallization processes in fats and lipid systems. Marcel Dekker, New York, pp 505–526

Macierzanka A, Szeląg H (2010) Structuring of emulsions by tailoring the composition of crystalline emulsifier. In: Monzer F (ed) Colloids in biotechnology, surfactant science. CRC Press, Boca Raton

Polizelli MA, dos Santos AL, Feitosa E (2008) The effect of sodium chloride on the formation of W/O microemulsions in soy bean oil/surfactant/water systems and the solubilization of small hydrophilic molecules. Colloids Surf A 315:130–135

Showell MS (2006) Handbook of detergents part D: formulation. Taylor & Francis, Boca Raton

Kluge K, Stubenrauch C, Sottmann T, Strey R (2001) Temperature-insensitive microemulsions formulated from octyl monoglucoside and alcohols: potential candidates for practical applications. Tens Surf Deterg 38:30–40

Binks BP, Fletcher PDI, Taylor DJF (1997) Temperature insensitive microemulsions. Langmuir 13:7030–7038

Oh KH, Baran JR Jr, Wade WH, Weerasooriya V (1995) Temperature insensitive microemulsion phase behavior with non-ionic surfactants. J Dispers Sci Technol 16:165–188

Ajith S, Rakshit AK (1992) Properties of mixed alkane microemulsions. J Surf Sci Technol 8:365–372

Acharya A, Sanyal SK, Moulik SP (1995) Physicochemical investigations on microemulsification of eucalyptol and water in presence of polyoxyethylene(4) lauryl ether (Brij- 30) and ethanol. J Colloid Interf Sci 229:213–226

Ajith S, John AC, Rakshit AR (1994) Physicochemical studies of microemulsions. Pure Appl Chem 66:509–514

Majhi PR, Moulik SP (1999) Physicochemical studies on biological macro- and microemulsions VI: mixing behaviors of eucalyptus oil, water and polyoxyethylene sorbitan monolaurate (Tween 20) assisted by n-butanol or cinnamic alcohol. J Dispers Sci Technol 20:1407–1427

Georges J, Chen J (1986) Microemulsions studies: correlation between viscosity, electrical conductivity and electrochemical and fluorescent probe measurements. Colloid Polym Sci 264:896–902

Bumajdad A, Eastoe J (2004) Conductivity of water-in-oil microemulsions stabilized by mixed surfactants. J Colloid Interf Sci 274:268–276

Szeląg H, Szumała P (2011) Effect of alkyl sulfate on the phase behavior of microemulsions stabilized with monoacylglycerols. J Surf Deterg 14:245–255

Mehta SK, Kaur G, Mutneja R, Bhasin KK (2009) Solubilization, microstructure, and thermodynamics of fully dilutable U-type Brij microemulsion. J Colloid Interf Sci 338:542–549

Israelachvili JN, Mitchell DJ, Ninham BW (1976) Theory of self-assembly of hydrocarbon amphiphiles into micelles and bilayers. J Chem Soc Faraday Trans 72:1525–1568

Davies JT (1957) A quantitative kinetics theory of emulsion type. I. Physical chemistry of the emulsifying agent. In gas/liquid and liquid/liquid interfaces. In: Proceedings of the 2nd international congress of surface activity. Butterworths, London, pp 430–431

Senatra D, Gabrielli G, Caminati G, Guarini GGT (1989) In: Mittal KL (ed) Surfactants in solution, vol 10. Plenum, New York, pp 147–158

Garti N, Aserin A, Tiunova I, Fanun M (2000) A DSC study of water behavior in water-in-oil microemulsions stabilized by sucrose esters and butanol. Colloids Surf A 170:1–18

Kuntz ID Jr, Kauzmann W (1974) Hydration of proteins and polypeptides. Adv Protein Chem 28:239–345

Senatra D, Lendinara L, Givi GM (1991) W/O microemulsions as model systems for the study of water confined in microenvironments: low resolution 1H magnetic resonance relaxation analysis. Prog Colloid Polym Sci 84:122–128

Garti N, Aserin A, Ezrahi S, Tiunova I, Berkovic G (1996) Water behavior in nonionic surfactant systems I: subzero temperature behavior of water in nonionic microemulsions studied by DSC. J Colloid Interface Sci 178:60–68

Fanun M (2008) Phase behavior, transport, diffusion and structural parameters of nonionic surfactants microemulsions. J Mol Liq 139:14–22

Yaghmur A, Aserin A, Garti N (2002) Phase behavior of microemulsions based on food-grade nonionic surfactants: effect of polyols and short-chain alcohols. Colloids Surf A 209:71–81

Garti N, Yaghmur A, Leser M, Clement V, Watzke H (2001) Improved oil solubilization in oil/water food grade microemulsions in the presence of polyols and ethanol. J Agric Food Chem 49:2552–2562

Martino A, Kaler EW (1995) Phase behavior and microstructure of nonaqueous microemulsions 2. Langmuir 11:779–784

Hou MJ, Shah DO (1987) Effects of the molecular structure of the interface and continuous phase on solubilization of water in water/oil microemulsions. Langmuir 3:1086–1096

Acknowledgments

Support for this work provided by Polish Ministry of Science and Higher Education (Grant N N209 335237) is gratefully acknowledged. The authors thank Doctor Roman Pawłowicz (from Department of Food Chemistry, Technology and Biotechnology, Gdansk University of Technology) for his support with thermal analyses.

Open Access

This article is distributed under the terms of the Creative Commons Attribution Noncommercial License which permits any noncommercial use, distribution, and reproduction in any medium, provided the original author(s) and source are credited.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

This article is published under an open access license. Please check the 'Copyright Information' section either on this page or in the PDF for details of this license and what re-use is permitted. If your intended use exceeds what is permitted by the license or if you are unable to locate the licence and re-use information, please contact the Rights and Permissions team.

About this article

Cite this article

Szumała, P., Szeląg, H. Water Solubilization Using Nonionic Surfactants from Renewable Sources in Microemulsion Systems. J Surfact Deterg 15, 485–494 (2012). https://doi.org/10.1007/s11743-011-1323-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11743-011-1323-y