Abstract

The shell and membrane of the egg constitute approximately 11% of the whole egg and is an important food industry waste. Eggshells can be used as an additional source of calcium to the diet because of their low cost and high bioavailability. This study aimed to design and produce the optimum formulation for the gluten-free cake using eggshell powder as rice flour and baking powder replacer by Face-Centered Composite Design. According to the results, it was determined that the optimized formulation should contain 9.85% eggshell powder as a rice flour replacer and 32.78% eggshell powder as a baking powder replacer to obtain a gluten-free cake with a desirable profile in terms of hardness, specific volume, color (\({\text{L}}_{{{\text{crust}}}}^{*}\) and \({\text{L}}_{{{\text{crumb}}}}^{*}\) values), ash content, calcium content, and overall acceptability. The gluten-free cake with eggshell powder obtained was characterized as a product rich in calcium, high in ash content, high in specific volume, with a brighter colour and good sensory acceptability. Also, the proximate properties of the gluten-free cake produced with the optimum formulation were also reported. These findings show for the first time that eggshell powder can be used as a rice flour and a baking powder replacer for the formulation of gluten-free cake.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

The eggshell is the part of the egg, which protects the egg from external influences and consists mostly of calcium carbonate [1]. The eggshell is an important structure for the developing embryo, as it provides mechanical protection, controls gas exchange, prevents the contamination of bacteria, viruses, and other pathogens to the egg, and has many nutrient sources, primarily calcium [1, 2]. Due to the vitamins and minerals in its structure, it renews skin cells and heals skin irritations. Apart from these, it prevents bone resorption owing to the protein and calcium in its structure [2].

Dietary calcium deficiency is a common problem. Calcium intake from dairy products is an affordable way to meet calcium requirements. However, people often cannot consume them in sufficient quantities. Eggshell calcium is both a good source of dietary calcium and an excellent replacer [3].

Calcium is an essential mineral for the body for various physiological functions and maintenance of bone tissues throughout life [4]. If adequate calcium intake is not provided, the risk of developing diseases such as hypertension, osteoporosis, and colon cancer increase. Eggshell powder with a calcium content of up to 38% is promising in terms of human nutrition. Approximately 90% absorbable eggshell increases bone density and reduces pain in patients with osteoporosis [3]. It has an important role, especially in the treatment and prevention of bone demineralization [5].

Celiac disease is an immune-mediated ailment triggered by the consumption of gluten [6]. The only known treatment for celiac disease is a lifelong gluten-free diet [7]. The limited number of foods that can be used in a gluten-free diet, their high cost, and less availability create various difficulties for individuals on a gluten-free diet [8]. For this reason, there is a need to develop alternative products both to create an alternative for people who consume gluten-free foods and to prevent them from experiencing calcium deficiency.

Food waste is one of the most important problems in the food industry [9]. In many countries of the world, food companies that use eggs in their products generate tons of eggshell waste. Eggshell is also one of the most important waste materials that are formed in domestic sources such as poultry farms, hatcheries, restaurants, and even houses [3, 10]. Therefore, eggshell wastes constitute a serious environmental problem [3]. This egg-processing waste can be used in different fields such as feed production, a catalyst, an agent increasing soil pH, and a dietary calcium supplement [11, 12]. In addition, eggshell powder can be used in the formulations of calcium-fortified foods to increase daily calcium intake.

In previous studies on the use of eggshells in foods, it has been observed that eggshell powder was used as a replacer for synthetic phosphate in cooked ground pork products or flour [3, 13,14,15,16,17,18]. The eggshell powder was utilized as flour replacer in bread, cookie, biscuit, and chocolate cake [3, 13, 15,16,17,18]. There is no study in which eggshell powder is used as a baking powder replacer. It is thought that eggshells can be used as a replacer for both rice flour and baking powder in gluten-free cake production, and therefore this calcium-rich waste can be evaluated. To the best our knowledge eggshells have not been used in gluten-free cake formulation as rice flour and baking powder replacer and this cake formulation is also not optimized by the response surface methodology. The aim of this study is to use eggshells as a rice flour and baking powder replacer in the gluten-free cake. Also, it is to produce a healthier and alternative gluten-free cake with increased calcium content as a result of determining the optimum usage ratio of eggshell powders in the formulation in order to obtain the cake preferred by the consumer with its physical and sensory properties.

Materials and methods

Materials

The rice flour, baking powder, whole milk, whole eggs, sugar, and sunflower oil were purchased from a local market in Izmir, Turkey. Hydrochloric acid, lanthanum chloride, petroleum ether were also supplied from Sigma Chemical Co. (St. Louis, MO, USA).

Eggshell powder production

A-grade waste eggshells with their membranes were first cleaned by washing in tap water and dried in an incubator at 40 °C. They were then ground in a laboratory-type blender (Waring, USA) to increase their surface area and sieved through a 500 μm mesh sieve. They were placed in the extractor and subjected to soxhlet extraction with 1:10 (w/v) ethyl alcohol (70%) for 4 h. With this method used, eggshells are sterilized by removing organic contaminants [18]. Eggshells were dried in the incubator again after sterilization and stored at − 18 °C until analysis.

Microbiologic analysis

Total aerobic mesophilic bacteria count, yeast and mold count and Salmonella spp. detection in eggshells powder were performed according to ISO 4833 (2013), ISO 21527–2 (2008), and ISO 6579 (2017) methods, respectively [19].

Preparation of gluten-free cake formulations with eggshell powders

A method by Gularte et al. [20] was applied in the preparation of gluten-free cakes. The basic recipe below has been modified by using different amounts of eggshell powders (Table 1) as a replacer for rice flour and baking powder in the formulation. Also, malic acid was added to each formulation to be 1.34 times the calcium carbonate content (95.73 g/100 g) of the eggshell powder to be used as a baking powder replacer. One hundred and fifty grams of rice flour, 5.63 g of baking powder, 112.5 g of whole milk, 93.75 g of eggs, 168.75 g of sugar, and 56.25 g of sunflower oil were weighed separately. In a bowl, eggs and sugar were mixed with a Fakir Professional mixer (Fakir, Germany) at speed 1 for 2 min. After the other ingredients were added to it, gluten-free cake batter was formed by mixing for 5 min at speed 2. The cake batter obtained was poured into a baton cake mold (21 cm × 11 cm). It was baked at 190 °C for 40 min in a preheated home-type oven (Arçelik, Turkey) and cooled at room temperature for 1 h.

Experimental design

An RSM was utilized to determine the experimental design and the optimum levels of eggshell powder as a rice flour and baking powder replacer in the production of gluten-free cake samples. Two-factors central composite (face-centered) design (FCCD) was obtained using Design-Expert software version 11 (Stat-Ease Co., Minneapolis, MN, USA). These two factors used as independent variables in optimization were the rice flour replacer ratio and the baking powder replacer ratio. The levels of these factors were 0%, 5%, and 10% for the rice flour replacer (X1) and 0%, 50%, and 100% for the baking powder replacer (X2). Specific volume (R1), colour (\({\text{L}}_{{{\text{crust}}}}^{*}\) (Y2) and \({\text{L}}_{{{\text{crumb}}}}^{*}\) (Y3) values), hardness (Y4), ash content (Y5), calcium content (Y6), and overall acceptability (Y7) were determined as dependent variables. The complete design consisted of 13 combinations including five replicates of the center point (Table 1).

The effect of these two independent variables X1 and X2 on the responses (Y) was modelled using the general polynomial model equation. The equation used for the prediction of the dependent variables is as follows:

In the equation, Xi and Xj are the independent variables, Y is the predicted dependent variable, β0 is the constant, βi, is the linear, βii is the quadratic, and βij is the interaction terms, and ε is the error value. The optimum use of eggshell powder as rice flour and baking powder replacer was determined according to the desirability function approach by utilizing the simultaneous optimization of multiple dependent variables. Thus, the replacement ratio of rice flour and baking powder in the formulation of gluten-free cake with minimum hardness and maximum specific volume, color (\({\text{L}}_{{{\text{crust}}}}^{*}\) and \({\text{L}}_{{{\text{crumb}}}}^{*}\) values), ash content, calcium content, and overall acceptability values was determined as the optimum usage levels of eggshell powder. One sample t-test was applied using the SPSS v.20.0 statistical program for verification the optimization. All gluten-free cake productions and analyses were performed in triplicate and the results were averaged.

Moisture, ash, fat, and protein content of gluten-free cakes were measured by AACC [21] method number 44.40, and AOAC [22] method number 923.03, 945.16, and 968.06, respectively. Carbohydrate content was calculated as total carbohydrate according to Pearson [23] by subtraction method. The proximate composition of gluten-free cakes was expressed as a percentage. Energy value was determined as kcal per 100 g sample according to the method suggested by Birch et al. [24].

Calcium content of gluten-free cakes

Approximately 2.5 g of gluten-free cakes was dry-ashed in a muffle oven at 550 °C. The ash obtained was dissolved in 2 mL of 6 N HCl, and this solution was transferred to a 25 mL volumetric flask after filtration. This process was repeated three times. The volume of the volumetric flask was then adjusted to the marked volume with deionized water [25]. Lanthanum chloride (1%) was put in the solutions to prevent interference from phosphorus. The calcium contents of the sample and standard solutions were analysed by flame atomic absorption spectrophotometry (AAS) (ContrAA 700, Analytik Jena, Germany). They were expressed as mg of calcium per 100 g for cake.

Physical properties of gluten-free cakes

Colour values of crust and crumb in the gluten-free cakes were measured using a CR-400 chromameter (Konica Minolta, Japan). In the CIE Lab colour system, L*, a*, and b* values indicate black-white, red-green, and yellow-blue colour values, respectively.

Specific volume was measured by Volscan Profiler volume analyser (Stable Microsystems, Surrey, UK). It was obtained by dividing the volume of cakes by their weights and expressed in cm3/g [26].

Hardness of gluten-free cakes (2 × 2 × 2 cm) was measured by a TAXT Plus Texture Analyzer (Stable Micro Systems Ltd., Godalming, UK) with a 36 mm diameter cylindrical probe and a 5 kg load cell using the method described by Dadalı and Elmacı [27]. The hardness values of samples were determined as Newton (N).

Baking loss (%) of gluten-free cakes was determined by calculating the difference between the weight of the cake batter and the baked cake and then dividing it by the weight of cake batter [28]. Symmetry index, and uniformity index of the gluten-free cakes were also evaluated by AACC 10-91 [29]. The cake samples were cut vertically from their center and the respective lengths were determined by the template according to method.

Sensory analysis of gluten-free cakes

Sensory evaluation of gluten-free cakes was performed with the participation of 56 panellists. Panellists assessed the samples on a 9-point hedonic scale (9 = like extremely; 1 = dislike extremely) to decide the degree of liking for five sensory characteristics, including colour, flavour, appearance, texture, and overall acceptability.

Results and discussion

Microbiologic analysis

Total aerobic mesophilic bacteria count, yeast and mold count and Salmonella spp. detection analyses were performed in ground eggshells. Total aerobic mesophilic bacteria count was < 10 log cfu/g, yeast and mold count was < 10 log cfu/g, and Salmonella spp. not detected in 25 g of analysed eggshells powder. Zerek et al. [18] used same sterilization method used in this study and obtained similar results in eggshell powder.

Model fitting

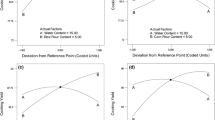

The effect of rice flour replacer and baking powder replacer on specific volume, \({\text{L}}_{{{\text{crust}}}}^{*}\), \({\text{L}}_{{{\text{crumb}}}}^{*}\), hardness, ash content, calcium content and overall acceptability are given in Table 1. The effects of rice flour replacer and baking powder replacer on specific volume, \({\text{L}}_{{{\text{crust}}}}^{*}\), \({\text{L}}_{{{\text{crumb}}}}^{*}\), hardness, ash content, calcium content and overall acceptability were determined by Analysis of Variance (ANOVA). The statistical significances of rice flour replacer and baking powder replacer, their interactions, and square influences are shown in Table 2. While specific volume, \({\text{L}}_{{{\text{crust}}}}^{*}\), hardness and overall acceptability were defined with quadratic model, \({\text{L}}_{{{\text{crumb}}}}^{*}\), ash content and calcium content were defined with linear model (Fig. 1, Fig. 2). All models were significant at 99% confidence level (p < 0.01) for specific volume, \({\text{L}}_{{{\text{crust}}}}^{*}\), \({\text{L}}_{{{\text{crumb}}}}^{*}\), hardness, ash content, calcium content, and overall acceptability. ANOVA results showed that lack of fit values were statistically insignificant (p < 0.05) for all models and indicated that data had well reproducibility (Table 2) [30]. The R2 values and coefficient of variation were defined to determine the adequacy of created models. All models had high R2 values and were in range of 0.8480–0.9987 (Table 2, Table 3).

The effect of rice flour replacer and baking powder replacer on cake properties

The specific volume of gluten-free cakes affected linearly by the use of eggshell powder as a baking powder replacer, and quadratically by the use of rice flour as a replacer (p < 0.05). The gluten-free cake containing 5% rice flour replacer had the highest specific volume (1.15 cm3/g), which was also higher than the control sample (1.46 cm3/g). The specific volume of gluten-free cakes containing 100% baking powder replacer is in the range of 1.15–1.19 cm3/g, was lower than the other samples. The specific volume values of gluten-free cakes produced centre point experiments of the design containing 5% rice flour replacer and 50% baking powder replacer are close to the control cake. The calcium carbonate in the eggshell reacts with the acids and provides the formation of CO2. As a result, the volume of the product increases with heating. Similarly with this study an increase in the volume of bread fortified with eggshell was also detected [31]. Also, Khan et al. [32] determined that the volume values of breads containing 3% eggshell calcium extract were the same as control bread.

There were linear effects of rice flour replacer and baking powder replacer on the \({\text{L}}_{{{\text{crust}}}}^{*}\) value of gluten-free cake samples (p < 0.05). In addition, \({\text{L}}_{{{\text{crust}}}}^{*}\) value is affected quadratically by using eggshell powder as baking powder (p < 0.05). The inclusion of eggshell powder as rice flour and baking powder replacer in the gluten-free cake formulation resulted in an increase in \({\text{L}}_{{{\text{crust}}}}^{*}\) value. Whilst \({\text{L}}_{{{\text{crust}}}}^{*}\) value of the control gluten-free cake was 44.83, \({\text{L}}_{{{\text{crust}}}}^{*}\) value of the gluten-free cake with %10 rice flour replacer and %100 baking powder replacer was 65.03 (Exp no. 7). The brightness of the gluten-free cake crumb was affected by the linear change of the rice flour and baking powder replacer (p < 0.05). The brightness change of the gluten-free cake crumb showed a similar trend with the gluten-free cake crust. As a result, the brightness of the gluten-free cake crumb (81.73) with the highest amount of rice flour and baking powder replacer was higher than other samples. Likewise, this study Chilek et al. [33] measured brighter colour value from bread supplemented with %3 and %5 eggshell powder.

The use of rice flour and baking powder replacer in gluten-free cake had linear effects on cake hardness (p < 0.05). At the same time, there was also a quadratic effect of using eggshell powder as a baking powder replacer on cake hardness (p < 0.05). The use of eggshell as for both rice flour and baking powder replacer increased the hardness of the gluten-free cakes. The hardness of the gluten-free cake without rice flour and baking powder replacer was 19.07 N, while the hardness of the cake containing 10% rice flour and 100% baking powder replacer was 108.75 N. The hardness results obtained were compatible with the hardness results determined by Zulkeflee et al. [17], and an increase in the hardness data was observed as a result of enrichment of bread with eggshell up to 6%. The increase in hardness in the product is explained by the hard structure of the eggshell powder and the increase in the hardness as a result of the increase in the mineral content of the product.

The ash content of gluten-free cakes was changed depend on rice flour replacer ratio at a statistically significant level (p < 0.05). The ash content of gluten-free cakes positively influenced by rice flour replacer. The control cake, cakes containing 50% and 100% baking powder contain 1.03%, 1.05% and 1.06% ash, respectively, and these ash content values were lower than the other samples. The ash content of the cake with eggshell powder as 10% rice flour replacer and 100% baking powder replacer was the highest (2.79%). The calcium content of gluten-free cakes enriched with eggshell powder increased linearly with the increase of rice flour and baking powder replacement ratio (p < 0.05). Since eggshell is an important source of calcium, the calcium content of the cake, which had the highest usage rate in gluten-free cake formulation, was higher than other gluten-free cake samples (exp. no 7). While the calcium content of the gluten-free cake without eggshell powder was 34.19 mg/100 g, the highest calcium content was determined as 1425 mg/100 and an increase of approximately 40 times was achieved. Ash content and calcium content showed a similar increasing trend depending on the replacer rates. The increase in the ash content of gluten-free cakes with rice flour and baking powder replacer was associated with the high mineral content of the eggshell. In previous studies, the increase was detected in ash and calcium content in biscuit, cookie, bread, gingerbread, and muffins enriched with eggshell powder, depending on the ratio of eggshell use [13, 18, 34,35,36].

There was a linear and quadratic effect of baking powder replacer on general acceptability scores of gluten-free cakes containing eggshell powder. Gluten-free cakes containing 5% rice flour and 50% baking powder substitute had higher overall acceptability scores than other samples (Exp no. 3, 6, 9, 10). However, when 100% baking powder replacer was used in gluten-free cake formulation, a decrease in overall acceptability scores was observed.

Optimization of gluten-free cake formulation and verification of predicted model

The optimization of gluten-free cake formulation was implemented using Design-Expert software by maximizing specific volume, \({\text{L}}_{{{\text{crust}}}}^{*}\), \({\text{L}}_{{{\text{crumb}}}}^{*}\), ash content, calcium content, overall acceptability values and minimizing hardness values. Simultaneous optimization of multiple responses was implemented by desirability function method. As a result of the optimization, it was determined that the optimum formulation was a gluten-free cake containing eggshell as 9.85% rice flour and 32.78% baking powder replacer. Gluten-free cakes with optimum formulation were produced in five replicates and experimentally measured response values were compared with the data predicted from the model. The one sample T test was performed to determine significant differences between experimental values and the estimated values from model. The experimental and estimated values agreed and there was no statistically significant difference (p < 0.05) (Table 4). Thus, model obtained by optimization was experimentally successful.

Characterization of optimum gluten-free cake with eggshell and control gluten-free cake

Physical, chemical, and sensory properties of control gluten-free cake and optimum gluten-free cake with eggshell powder is shown in Table 5. The eggshell fortification significantly affected moisture content of gluten-free cake samples (p < 0.05). The moisture content of optimum gluten-free cake was lower than control gluten-free cake (p < 0.05). Thus, cooking loss of optimum gluten-free cake with eggshell was higher than control gluten-free cake at a statistically significant level (p < 0.05). Similar moisture content reduction depend on eggshell addition was observed in gingerbread with 3% eggshell and bread with 6% eggshell [33, 36]. There was a statistically significant difference between ash content of control and optimum gluten-free cake (p < 0.05). The ash content of optimum gluten-free cake increased due to the high calcium content of eggshell. Also, the addition of eggshell increased the calcium content of the optimum gluten-free cake (1162.79 mg/100 g) by approximately 3.5 times compared to the control gluten-free cake (34.19 mg/100 g). However, the addition of eggshell did not affect fat, protein, carbohydrate, and energy content (p < 0.05). Similarly, protein and fat content of biscuits did not influence by eggshell powder supplementation [13].

The specific volume of the optimum gluten-free cake was lower than the control gluten-free cake (p < 0.05). The capacity of CO2 formation of eggshell powder is not same as the baking powder. When eggshell powder was used as baking powder replacer, the formation of CO2 was reduced compared to control gluten-free cake. As a result, specific volume of optimum gluten-free cake was determined as lower (p < 0.05). \({\text{L}}_{{{\text{crust}}}}^{*}\) and \({\text{L}}_{{{\text{crumb}}}}^{*}\) values of optimum gluten-free cake were higher than control gluten-free cake (p < 0.05). As result the crust and crumb of the optimum gluten-free cake appeared brighter. However, the use of eggshell powder in gluten-free cake formulation did not significantly change a* and b* values (p < 0.05). Positive a* values in the cake crust were indicative of redness, while negative a* values in the cake were indicative of greenness. Positive b* values detected in both the cake crust and crumb showed yellow colour. The symmetry index values of both cakes were greater than zero, and the symmetry index of the optimum gluten-free cake was higher than the control cake (p < 0.05). Symmetry index shows the contour of the gluten-free cake [37]. Positive symmetry index means that the central of the cake is higher than the lateral parts [38]. The symmetry index value of optimum gluten-free cake is consistent with specific volume values. Due to the higher specific volume of control gluten-free cake sample, its symmetry index was higher compared to optimum gluten-free cake. The uniformity index of control and optimum gluten-free cake was − 0.5 and − 0.3 cm, respectively and very close to zero. The uniformity index shows lateral symmetry of the cake and must be as close to zero as possible. These indexes affect consumer acceptance of the cake [27, 39]. The uniformity index value of optimum gluten-free cake was closer to zero than control gluten-free cake. So optimum gluten-free cake showed more uniform and symmetrical structure.

As in the other samples in the experimental design, the use of eggshell powder in gluten-free cake in the optimum concentration caused an increase in the hardness value (72.62 N) (p < 0.05). The overall acceptability gives information about overall impression including appearance, texture, and flavour of food. For this reason, overall acceptability shows an important role in acceptability of food by consumers. According to the sensory evaluation results, the optimum gluten-free cake was liked more by the panellists and the overall acceptability scores were statistically higher (p < 0.05). Optimum gluten-free cake has the potential to be more preferred by panellists. The addition of eggshell powder as rice flour and baking powder replacer to the gluten-free cake formulation positively affected its sensory properties.

Conclusion

In recent years, zero waste practices that contribute to the environment and economy have become widespread all over the world. Animal wastes threaten both the environment and human health, and eggshell is one of these wastes. In this study, eggshell powder was used as rice flour and baking powder replacer in gluten-free cake, and it was determined that the optimum gluten-free cake formulation contained 9.85% rice flour and 32.78% baking powder replacer. The inclusion of eggshell waste as replacer for rice flour and baking powder in the gluten-free cake formulation increased the cake specific volume, brightness, calcium content and overall acceptability scores. At the same time, a new product rich in calcium was obtained for individuals suffer from celiac disease and prefer a gluten-free diet. The use of eggshell powder as replacer for rice flour and baking powder in gluten-free cake also contributes to zero waste practices.

Data Availability

The data is available upon a reasonable request from the corresponding author.

References

P. Hunton, Research on eggshell structure and quality: an historical overview. Rev. Bras. Cienc. Avic. 7, 67–71 (2005)

D.A. Oliveira, P. Benelli, E.R. Amante, A literature review on adding value to solid residues: eggshells. J. Clean. Prod. 46, 42–47 (2013)

S. Ray, A. Kumar Barman, P. Kumar Roy, B. Kumar Singh, Chicken eggshell powder as dietary calcium source in chocolate cakes. Pharma Innov. J. 6(9), 01–04 (2017)

G.D. Miller, J.J.B. Anderson, The role of calcium in prevention of chronic diseases. J. Am. Coll. Nutr. 18, 371S-372S (1999)

G.D. Miller, J.K. Jarvis, L.D. McBean, The importance of meeting calcium needs with foods. J. Am. Coll. Nutr. 20, 168S-185S (2001)

K.A. Bascuñán, M.C. Vespa, M. Araya, Celiac disease: understanding the gluten-free diet. Eur. J. Nutr. 56, 449–459 (2017)

J. Miranda, A. Lasa, M.A. Bustamante, I. Churruca, E. Simon, Nutritional differences between a gluten-free diet and a diet containing equivalent products with gluten. Plant Foods Hum. Nutr. 69, 182–187 (2014)

C. Kupper, Dietary guidelines and implementation for celiac disease. Gastroenterology 128, S121–S127 (2005)

S. Aditya, J. Stephen, M. Radhakrishnan, Utilization of eggshell waste in calcium-fortified foods and other industrial applications: a review. Trends Food Sci. Technol. 115, 422–432 (2021)

O.O. Amu, A.B. Fajobi, B.O. Oke, Effect of eggshell powder on the stabilizing potential of lime on an expansive clay soil. Res. J. Agric. Biol. Sci. 1(1), 80–84 (2005)

A. Laca, A. Laca, M. Díaz, Eggshell waste as catalyst: a review. J. Environ. Manage. 197, 351–359 (2017)

V. Vandeginste, Food waste eggshell valorization through development of new composites: a review. Sustain. Mater. Technol. 29, e00317 (2021)

N.M.M. Hassan, Chicken eggshell powder as dietary calcium source in biscuits. World J. Dairy Food Sci. 10, 199–206 (2015)

M.G. Cho, S.M. Bae, J.Y. Jeong, Egg shell and oyster shell powder as alternatives for synthetic phosphate: effects on the quality of cooked ground pork products. Korean J. Food Sci. Anim. Resour. 37, 571–578 (2017)

J. Kobus-Cisowska, D. Szymanowska-Powałowska, K. Szymandera-Buszka, R. Rezler, M. Jarzębski, O. Szczepaniak, G. Marciniak, A. Jędrusek-Golińska, M. Kobus-Moryson, Effect of fortification with calcium from eggshells on bioavailability, quality, and rheological characteristics of traditional Polish bread spread. J. Dairy Sci. 103, 6918–6929 (2020)

N. Platon, V.A. Arus, A.M. Georgescu, I. Denisa Nistor, N. Barsan, white bread fortified with calcium from eggshell powder. Rev. Chim. 71, 299–306 (2020)

W. Zulkeflee, P. Chompoorat, R. Siva, Physicochemical and sensory properties of bread added with chicken eggshell powder. Malay. J. Anal. Sci. 24(6), 873–881 (2020)

E. Zerek, N. Ersoy, G. Ersoy, Determination of some nutritional and quality properties of eggshell powder added cookies: properties of eggshell powder added cookies. J. Food Meas. Charact. 16, 3315–3320 (2022)

ISO 4833-1, Microbiology of the Food Chain—Horizontal Method for the Enumeration of Microorganisms—Part 1: Colony Count at 30 Degrees C by the Pour Plate Technique (International Organization for Standardization, Geneva, 2013)

M.A. Gularte, E. de la Hera, M. Gómez, C.M. Rosell, Effect of different fibers on batter and gluten-free layer cake properties. LWT Food Sci. Technol. 48, 209–214 (2012)

L. Lamberts, E. De Bie, G.E. Vandeputte, W.S. Veraverbeke, V. Derycke, W. De Man, J.A. Delcour, Effect of milling on colour and nutritional properties of rice. Food Chem. 100, 1496–1503 (2007)

AOAC, Official Methods of Analysis (Association of Official Analytical Chemists, Gaithersburg, 2007)

D. Pearson, The Dictionary of Nutrition and Food Technology (Butter Warth Publication, London, 1976)

G.G. Birch, M. Spencer, A.G. Cameron, Food Science (Pergamon Press, Oxford, 1980)

A. López, P. García, A. Garrido, Multivariate characterization of table olives according to their mineral nutrient composition. Food Chem. 106, 369–378 (2008)

C. Segundo, L. Román, M. Gómez, M.M. Martínez, Mechanically fractionated flour isolated from green bananas (M. cavendishii var. nanica) as a tool to increase the dietary fiber and phytochemical bioactivity of layer and sponge cakes. Food Chem. 219, 240–248 (2017)

C. Dadalı, Y. Elmacı, Reduction of sucrose by inhomogeneous distribution in cake formulation. J. Food Meas. Charact. 13, 2563–2570 (2019)

S. Martínez-Cervera, A. Salvador, T. Sanz, Cellulose ether emulsions as fat replacers in muffins: rheological, thermal, and textural properties. LWT 63, 1083–1090 (2015)

AACC, AACC International Approved Methods (American Association of Cereal Chemist, St Paul, 2000)

E. Nakilcioğlu, S. Ötleş, Multiresponse optimization of physical, chemical, and sensory properties of the gluten-free cake made with whole white quinoa flour. J. Food Sci. Technol. 59, 3836–3847 (2022)

V. Bradauskiene, K. Montrimaite, E. Moscenkova, Facilities of bread enrichment with calcium by using eggshell powder, in 11th Baltic Conference on Food Science and Technology April 27, pp. 91–95 (2017).

F.A. Khan, K. Ameer, M.A. Qaiser, I. Pasha, Q. Mahmood, F.M. Anjum, A. Riaz, R.M. Amir, Development and analysis of bread fortified with calcium extracted from chick eggshells of Pakistani market. Food Sci. Technol. 41, 14–20 (2021)

T. Zainazor, T. Chilek, N. Ayuni Kairuaman, F. Ahmad, A. Wahab, A. Mahmood, Development of white bread fortified with calcium derived from eggshell powder. Malays. Appl. Biol. 47(6), 29–39 (2018)

A.M.A. Alsuhaibani, Rheological and nutritional properties and sensory evaluation of bread fortified with natural sources of calcium. J. Food Qual. (2018). https://doi.org/10.1155/2018/8308361

F. Afzal, G. Mueen-ud-Din, M. Nadeem, M.A. Murtaza, S. Mahmood, Effect of eggshell powder fortification on the physicochemical and organoleptic characteristics of muffins. Pure Appl Biol. 9(2), 1488–1496 (2020)

M. Arnold, Y.V. Rajagukguk, A. Sidor, B. Kulczyński, A. Brzozowska, J. Suliburska, N. Wawrzyniak, A. Gramza-Michałowska, Innovative application of chicken eggshell calcium to improve the functional value of gingerbread. Int. J. Environ. Res. Public Health 19(7), 4195 (2022)

M. Majzoobi, Z.V. Poor, J. Jamalian, A. Farahnaky, Improvement of the quality of gluten-free sponge cake using different levels and particle sizes of carrot pomace powder. Int. J. Food Sci. Technol. 51, 1369–1377 (2016)

E. de la Hera, M. Martinez, M. Gómez, Influence of flour particle size on quality of gluten-free rice bread. LWT Food Sci. Technol. 54, 199–206 (2013)

M.H.F. Felisberto, A.L. Wahanik, C.R. Gomes-Ruffi, M.T.P.S. Clerici, Y.K. Chang, C.J. Steel, Use of chia (Salvia hispanica L.) mucilage gel to reduce fat in pound cakes. LWT Food Sci. Technol. 63(2), 1049–1055 (2015)

Acknowledgements

The authors thank Gizem Tiryaki for her technical support. This work was supported by Ege University Scientific Research Projects Coordination Unit. Project Number: FM-GAP-2023-27408.

Funding

Open access funding provided by the Scientific and Technological Research Council of Türkiye (TÜBİTAK).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The author declares no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Nakilcioglu, E., Dadalı, C. Optimization of gluten-free cake formulation by replacement of rice flour and baking powder with different levels of eggshell powder using response surface methodology. Food Measure (2024). https://doi.org/10.1007/s11694-024-02586-8

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11694-024-02586-8