Abstract

This study addressed pesticide contamination in beeswax, explicitly focusing on detecting Amitraz using innovative spectroscopy quantification. Beeswax’s susceptibility to pesticides poses risks to colony health, prompting the need for efficient detection methods. Current offline techniques, notably gas chromatography-mass spectrometry (GC-MS), are accurate but financially burdensome. Honeybees’ significance as global pollinators underscores the need to protect colonies from pesticides. Colony collapse disorder, triggered by pesticide exposure, is a widespread threat. This study proposes a cost-effective spectroscopy method for online hive monitoring, addressing gaps in existing identification methods. A systematic laboratory approach assessed the pesticide detection limit, targeting Amitraz in beeswax through online point spectroscopy and leveraging the short-wave infrared (SWIR) spectral range enhanced sensitivity to pesticide-induced color changes. The model, combining methods, proved reliable for estimating amitraz contamination, significantly exceeding one ppm, using Analytical Spectral Devices (ASD) sensors. Statistical analysis included. The study demonstrates the effectiveness of the AIW/BIW ratio in identifying amitraz concentrations above 1 ppm, particularly in the SWIR spectral range. Statistical analysis revealed a significant correlation between the AIW/BIW ratio and Amitraz concentrations, with a coefficient of determination (R2) of 0.9976. The proposed model, integrating methods, emerges as a dependable means for estimating amitraz contamination in beeswax, especially at concentrations exceeding 1 ppm, as validated through ASD sensors. Comparative analysis highlights the financial constraints associated with GC-MS and the impracticality of FTIR for online hive monitoring.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Honeybees have cultural, economic, and ecological significance to human beings as pollinators and producers of honey, propolis, and pollen. While honey is used for nutritional and medicinal purposes, propolis and wax are utilized in manufacturing a variety of cosmetics and health products [1]. By transferring pollen from one flower to another, honeybees facilitate and enhance food production, contributing to nutrition and food security [2]. As global pollinators of approximately 100 significant crops, they oversee approximately 9.5% of the overall agricultural production value, amounting to approximately $200 billion. In addition to commercial crops, honeybees pollinate numerous wild plants (some of which are endangered) that are a vital genetic reservoir [3] and, as such, play an essential role in every part of the ecosystem by enabling the growth of flowers, trees, and other plants, which serve as shelter and food for numerous small and large creatures [3].

Beeswax’s chemical structure is composed of a viscous saturated hydrocarbon (oxygen 7.5%, hydrogen 13.2%, and carbon 73.3%) that enables its essential role as a beehive natural building material [4]. Other chemical components in beeswax comprise an ester of higher fatty acids with higher monohydric alcohols, water, stains, aromatics, and free fatty acids [5]. Beeswax forms the beehive structure, which further serves as a honey and pollen storage facility for larval protection inside the beehive. A beeswax honeycomb of perfect hexagon-shaped cells is created by worker bees around the brood nest, where the queen lays eggs and raises the offspring [5]. To generate a pound of beeswax, female worker bees need to ingest approximately 6 to 8 pounds of honey from approximately 1600 to 2000 flowers [6].

Bees huddle together to raise the temperature in the hive to a minimum of 33 degrees Celsius, which enables the special wax-producing glands in the bees’ abdomen to change the sugar from honey into beeswax that oozes via tiny pores to create scales on their abdomen. Female worker bees or other hive worker bees chew these small scales to convert them into beeswax of the appropriate consistency to create the honeycomb. The bees maintain a warm ambient temperature to ensure beeswax can be worked into hexagon cylinders[7]. After several use cycles, beeswax can be recycled and used again to make new honeycombs [8]. Moreover, since beeswax is a natural biodegradable commodity, it can be recycled to create nature-friendly items such as candles, perfumes, and soaps.

Nonetheless, pesticides tend to accumulate in beeswax more than in any other beekeeping, threatening bee larvae growth [9]. The pesticide problem in beeswax is manifested by high acrinathrin, fluvalinate, chlorfenvinphos, and coumaphos [10]. According to Calatayud-Vernich et al. [11], beeswax has a higher content of lipids than honey and pollen, which makes it a better pesticide accumulation extraction and accumulation agent.

Amitraz, coumaphos, and fluvalinate are commonly used in agriculture for pest control, and Amitraz is utilized globally for crops and animals. Amitraz controls aphids, scale insects, leaf miners, and other infestations in crops. It also controls red spider mites in fruit crops and psylla infection in pears [12]. Amitraz controls various pests in animals, encompassing generalized demodicosis in canines, mites, and ticks in sheep and cattle. Walsh et al. [13] reported that Amitraz shows insecticidal and acaricidal activity and is often utilized by beekeepers to protect honeybee colonies against Varroa destructor mites. Coumaphos is an organophosphorus pesticide that regulates arthropod pests, mites, lice, and ticks on swine, dairy cows, beef cattle, and other farm animals. Unlike Amitraz, coumaphos has limited usage in controlling mites in honeybee hives [14]. Fluvalinate is a synthetic pyrethroid chemical compound used as an active agent in Minadox, Klartan, and Apistan. Fluvalinate is frequently utilized in honeybee colonies to control Varroa destructor mites [13].

Pesticides such as Amitraz, coumaphos, and fluvalinate also have a positive effect, as they are used to protect honeybees from Varroa destructor mites. These mites are harmful since they weaken bees, shorten their lives, and lead to death from viral infections, which otherwise would cause little harm. Severe Varroa mite infestation leads to crippled and crawling bees, a decrease in the honeybee population, and eventual colony breakdown and death of the hive [13]. Pesticides protect bees from infestation by Varroa mites and hence safeguard bees from the negative consequences and diseases caused by these mites. Nevertheless, they are known to disrupt honeybees’ cognitive capabilities [15, 16] High pesticide levels reduce sperm viability and impair reproduction, resulting in fewer bee broods [16]. Fikadu [15] reports that the uncontrolled utilization and inappropriate practice of pesticides cause honeybee poisoning and ultimately bee colony loss. Hillier et al. [17] showed that a high amitraz and fluvalinate concentration of 0.1 ppm in bee tissues corresponding to 400 ppm in beeswax may cause elevated bee mortality within 24 h of exposure.

Different methodologies have been developed to detect and remove pesticide contamination from honeybee hives. For instance, Calatayud-Vernich et al. [9] examined whether the technique employed to clean sheep wool wax from pesticides could be used to clean beeswax. An aggregate sample of brood comb wax was made from three diverse beekeepers and analyzed for pesticide contamination. The wax was dissolved into a hexane solution and run through four consecutive washings with N and N-dimethylformamide (DMF), reducing pesticide contamination by an average of 95%. Only three pesticides out of the initial 24 were detected after DMF extraction [9]. Luna et al. [18] developed a batch-mode process to remove pesticides from beeswax. The extraction procedure relied on methanol at 65 °C, and the beeswax was purified by a volatilization procedure with hot water (70 °C). The study showed that the batch mode procedure reduced the beeswax contamination load by 80% and 90% for the acaricide pesticides, usually in wax, such as clathrin, tau-fluvalinate, chlorfenvinphos, and coumaphos.

Several tests and methods have been developed to help identify pesticides in beeswax. Gas chromatography (GC) is the most applied analysis for detecting pesticides in beeswax [19]. The GC approach is based on a mixture of compounds separated by the different adsorption properties of each compound on a solid phase and moving the compounds on the solid phase by a mobile gas phase. Calatayud-Vernich et al. [9] used GC to identify DMF as a pesticide group and eradicate pesticide indicators in a beeswax sample, with only three out of the potential 24 pesticides identified after the DMF extraction process. Other analytical methods, such as liquid chromatography, are also used for bee-wax pesticide detection. For example, ultrahigh-performance liquid chromatography was applied to identify pesticides in beeswax. This approach helped to identify 17 pesticides and to determine the concentrations of 13 pesticides in the beeswax sample. The most abundant pesticides were tau-fluvalinate and coumaphos [20].

A different direct and reagent-free method used an absorbance peak at 332 nm to determine the presence of Amitraz in honey with spectroscopy, and this spectroscopic method detection limits for Amitraz were in the range of 0.1 – 1.5 ppm [21]. From this perspective, the main objective of this study was to determine the amitraz content in beeswax and to assess the point spectroscopy method limit of detection. To achieve this objective, a systematically controlled laboratory examination and spectral imaging of the amitraz content in the visible spectral range (350–850 nm), the NIR-near infrared range (850–900 nm), and the SWIR-short wave infrared region (SWIR) (900–2500 nm) were applied to extend existing imaging technologies and thus bring about online comprehensive, reliable and affordable (economically) remote sensing beekeeping technology.

Materials and methods

Beeswax sample and laboratory measurements

Pure beeswax (yellow) was purchased from Sigma-Aldrich (CAS Number 8012-89-3) (Sigma-Aldrich, n.d.).

The pesticide amitraz was purchased from Fisher Scientific Products (100 μg/mL amitraz in acetonitrile, Fisher Chemical™, No. 12923154).

Sigma-Aldrich supplied the chemicals used throughout this study and were of analytical grade.

GC-MS analysis was performed using a Shimadzu GC MS-QP2010 SE gas chromatograph equipped with a J&W DB-5 column (30 m × 0.25 mm × 0.25 µm). The temperature programmed for the separation in the column was:

80 °C (3 min) → 180 °C (6 min, 30 °C/min) → 250 °C (5 min, 20 °C/min) → 300 °C (5 min, 10 °C/min). The sample injection volume was 1 µl mixed with a helium gas carrier. Data were analyzed by the A7890 program (Agilent Technologies, Santa Clara, USA) [6].

A Waters Pipette + single channel was used for sampling liquids. An electronic Semi-Micro analytical balance Mettler Toledano MS105 with a standard deviation of less than ± 0.00004 g was used for weight measurements. An MRC DNO-20 oven was used to melt the solid beeswax. Advanced Vortex Mixer- ZX3 was used to mix the melted beeswax with Amitraz.

Spectral measurements were performed using a portable Analytical Spectral Devices spectrometer ASD Field Spec 4. The spectrometer has three detectors with 1 nm interpolated spectral resolution that supply 2151 bands in the VNIR (350–1000 nm), SWIR1 (1000–1800 nm), and SWIR2 (1800–2500 nm) regions.

Sample preparation

The pure solid beeswax was heated in an oven (UF55 Plus, Memmert) to a temperature of 85 °C for 90 min to create a melted mixture. For mixing the melted beeswax and Amitraz, 10 ml beeswax was added to a 50 ml PP tube (product 1-0276 from Simada.co.il), and amitraz concentrations (100, 500, and 1000 ppm) were added to the tube, and mixed in Advanced Vortex Mixer – ZX3 at power 24 for 10 s. Mixing was performed next to the heater to keep the sample liquid. Ten seconds of mixing is required to release acetonitrile from the sample completely. Mixed samples were prepared in Petri plates (diameter of 5.35 cm). This is in contrast to beeswax, which is solid at room temperature. Amitraz is in liquid form.

For this reason, it is impossible to compare pure beeswax and pure Amitraz directly, and it was necessary to compare beeswax with a high concentration of Amitraz. Since 500 ppm, according to the literature survey, is the lowest dose that damages the colony, 1000 ppm was chosen as the highest concentration in beeswax. The Amitraz concentrations, number of samples, and quantities are given in Appendix A. Two separated mixtures from each sample were used to compare the GC results.

Sensor configuration and spectral data correction

The spectrum of each sample was measured by the point spectrometer and set to a designated model [22, 23]. The protocol uses an average spectral range that characterizes the desired property and not just discrete wavelengths. The point spectrometer is a portable Analytical Spectral Devices spectrometer ASD Field Spec 4 of the Remote Sensing Laboratory at Ariel University, Israel.

Preprocessing and spectral analysis

To construct an amitraz concentration prediction model, both the beeswax spectral variance and the amitraz effect were predicted by the following procedure:

-

i.

A first derivative Savitzky‒Golay (S-G) smoothing [24]

-

ii.

Identification of beeswax-indicative wavelength (BIW) and amitraz-indicative wavelength (AIW).

-

iii.

Calculate the AIW/BIW ratio, mean (x), and standard deviation (a) for each mixed amitraz-Beeswax concertation.

-

iv.

A linear correlation curve was created between the AIW/BIW ratio and the added amitraz amounts.

-

v.

The determination coefficient (R2) between the AIW/BIW ratio and the added amitraz amounts was calculated.

-

vi.

The pure beeswax spectrum was subtracted from the mixed amitraz-beeswax spectrum to empower the amitraz effect.

-

vii.

Specific wavelengths that allow the detection of a difference between the concentrations were selected for further model development.

-

viii.

The linear equation was selected since it reflected the highest correlation.

-

ix.

A factor-based partial least squares regression (PLSR) method was used to determine the prediction strength of the model.

-

x.

An investigation was conducted with 15 comb foundations with unknown chemical backgrounds, and GC-MS analysis was performed to confirm the model's validity.

-

xi.

Model calibration performance and accuracy were evaluated using a coefficient of determination (R2) and mean squared error (MSE) value.

Results

Detecting amitraz contamination via the BIW and AIW

To identify the indicative wavelength for amitraz presence detection, the first derivative (the slope) was determined and expressed for Amitraz only, followed by a different slope being identified. The absorptions at 1704 to 1730 nm were chosen for the amitraz values (AIW range) range, and 2050 to 2107 nm were chosen for the beeswax values (BIW range) (Fig. 1). To obtain the expression intensity of the first derivative, the value of the first derivative in the BIW range was divided by the value of the first derivative in the AIW range. The AIW/BIW value in all samples (n = 10) was suitable for detecting Amitraz and estimating the amount of Amitraz in the sample (Table 1).

The AIW/BIW range can give an initial amitraz presence detection represented by a transition from a negative to a positive value. The relationship between the concentrations can be represented by a linear relationship, as shown in Fig. 2.

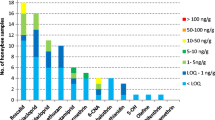

The methodology’s effectiveness in detecting amitraz contamination in beeswax through the BIW and AIW ranges is evident from the calculated AIW/BIW ratio, showcasing a transition from negative to positive values indicative of amitraz presence. The linear relationship observed in Fig. 2 underscores the method’s capability to accurately estimate amitraz concentrations, providing a practical means for quantifying contamination levels in beeswax samples. The chosen indicative wavelengths, coupled with using the first derivative, enhance the method’s sensitivity, enabling reliable detection even at low concentrations. The consistency in AIW/BIW ratio determination across different concentrations, as reflected in Table 1’s standard deviation values, further attests to the method’s precision. Detecting amitraz concentration via the spectral features of beeswax/amitraz mixtures.`To improve the amitraz detection sensitivity, different beeswax/amitraz mixture spectra were measured for different amitraz contents (0, 100, 500, and 1000 ppm) (Fig. 3). The results indicate the feasibility of a linear decrease in the spectral region of 645–1138 nm [hydrocarbons: reflectance minimum at 930 nm and 1037 nm (IRUG)] [esters: absorption maximum (reflectance minimum) at 860 nm and 1138 nm (IRUG)]. A linear decrease in the reflectance was also observed at 1235–1650 nm [esters, free fatty acids: 1328, 1490, and 1640 nm (IRUG)]. The spectra after subtracting the reflectance of the pure beeswax are given in Fig. 3.

The effect of subtracting the beeswax reflectance spectrum contribution was measured for different amitraz contents (100 to 1000 ppm, every 100 ppm). It showed an excellent linear correlation that may represent amitraz concentration differences (Fig. 4).

the observed linear decrease in reflectance across specific wavelength ranges (645–1138 nm and 1235–1650 nm) for different amitraz concentrations demonstrates the sensitivity of these spectral features to variations in hydrocarbons, esters, and free fatty acids. Post-subtracting the pure beeswax reflectance further enhances the distinction of mixed samples. The notable linear correlation between reflectance and amitraz concentration differences, as depicted in Fig. 4, underscores the potential utility of this approach for precise and quantitative amitraz detection in beeswax. Evaluation of amitraz concentration in unknown samples and a demonstration of the model’s ability to detect Amitraz in beeswax.

Hyperspectral analysis was compared to the GC-MS method for different mixtures with unknown amitraz concentrations to evaluate the amitraz concentration in beeswax samples. The different amitraz concentration prediction methods were then evaluated and compared using PLSR modeling. The samples’ spectral reflectance for various amitraz concentrations (Fig. 5) was as expected (Fig. 1), and when a reversal experiment was conducted at the high absorption intensity within the 1650–2250 nm range, spanning from the AIW to the BIW (refer to Fig. 5, circled area). This section was assessed utilizing the PLSR model, considering it as an initial variable that indicates variations in the presence or absence of Amitraz based on the slopes. To enhance the distinction in light reflection intensity caused by Amitraz, the pure beeswax spectrum was subtracted from the spectrum of the mixed samples. Figure 6 illustrates the resulting spectra of the mixed beeswax–amitraz after the beeswax spectra were reduced.

An amitraz concentration assessment PLS model was constructed after evaluating the characteristic wavelengths and obtaining the linear correlations from the selected wavelengths and the AIW/BIW ratio (PLS_Toolbox, 2016) [25], modeling results are given in Table 2, where the AIW and BIW relationship values and the linear correlation between the different concentrations support an amitraz concentration prediction by the combined PLSR model over selected wavelengths. The model evaluates Amitraz’s presence by monitoring the AIW/BIW ratio. According to this ratio, the initial noticeable concentration is determined. When the system detects the presence of Amitraz, the model selects the appropriate wavelengths according to the AIW/BIW data and uses the equations obtained to determine the amitraz concentration. Figure 7 shows that the PLSR model linear correlation is R2 = 0.9976.

The ASD’s high spectral resolution and accuracy made distinguishing the amitraz concentrations in the samples possible. In each of the wavelengths individually or together, data predicting a deviation of up to 6.32% with threshold concentrations (100 and 1000 ppm) showing the highest deviations were obtained. In the AIW/BIW ratio, the deviation reached up to 5.2%. Compared to these two methods, the PLSR method was able to give a prediction at a higher level of standard deviation of 2.3% and was able to give a prediction even for values lower than 100 ppm. Gas chromatography (GC-MS) is a widely used technique to identify pesticides in beeswax. The process involves separating the different compounds in the sample (based on different adsorption properties of the compounds on a solid phase), such as pesticides, and analyzing them using a detector to identify their presence. GC is a reliable technique for food environmental contamination analysis. While this technique is considered accurate, it is expensive and performed offline [26].

Advanced technologies such as surface-enhanced Raman spectroscopy (SERS) have also been used to identify pesticides in beeswax. These techniques offer several advantages over GC-MS, including higher sensitivity and specificity and the ability to identify compounds in complex mixtures. SERS is a more recent technology that can identify the presence of pesticides in a sample by analyzing the unique Raman spectrum of the compounds [27]. While these offline technologies are expensive and require specialized equipment and trained personnel to perform the analysis, several recent studies have attempted to identify pesticides in beeswax using more efficient and cost-effective methods. Tanner and Kragg [28] used infrared spectroscopy (FTIR) to determine the concentration of pesticides as a contaminant in beeswax. Luna et al. [18] used the same technique to identify pesticides and their removal methods at 1800–2600 ppm concentration ranges.

Brazas et al. [21] used visible spectrometry to identify pesticides using the absorption peak at 332 nm. The everyday use of VIS spectrometry for pesticide identification in beeswax utilizes a visible spectral range (350–850 nm). This complicates the analysis, as a beeswax sample must undergo physical cleaning from visible absorbing compounds, so it cannot be used for online monitoring. To overcome this, it is proposed to refer to the ratio between different amitraz typical spectral regions independent of the pure wax source. The combined model used in this study integrates the AIW to BIW ratio to identify the presence of Amitraz.

The sensitivity reaches an amitraz identification limit of 1 ppm, and the AIB/BIW ratio is affected by the spectral offset changes from negative to positive values. Using the AIB/BIW method, the detection limit of Amitraz was 100 ppm. The second method found indicative wavelengths suitable for detecting Amitraz in pure bee wax. A lower coefficient of determination was obtained, but the identification limit was improved, and ten ppm could be detected. The PSLR model was used in the third method to obtain more uniform and accurate information between the two methods. Using this model, the detection limit was one ppm with the best coefficient of determination. This method is the most accurate for detecting Amitraz in beeswax.

Conclusions

In conclusion, this study highlights the effectiveness of the AIW/BIW ratio in detecting amitraz concentrations above 1 ppm, particularly in the SWIR spectral range. Combining these methods, the developed model proves reliable for estimating amitraz contamination in beeswax, especially for concentrations exceeding one ppm using ASD sensors. A comparison with traditional GC-MS, and FTIR methods underscores the financial constraints of GC-MS and the requirement for direct hive contact. While the FTIR method shows similar accuracy, its incompatibility with online hive monitoring systems emphasizes the unique advantages of the proposed approach for real-time and cost-effective amitraz detection in beekeeping contexts.

Data availability

The authors declare that the data supporting the findings of this study are available within the paper and its Supplementary Information files. Should any raw data files be needed in another format they are available from the corresponding author upon reasonable request. Source data are provided with this paper.

References

A. Ullah, I.T. Gajger, A. Majoros, S.A. Dar, S. Khan, A.H. Shah et al., Viral impacts on honey bee populations: a review. Saudi J. Biol. Sci. 28(1), 523–530 (2021). https://doi.org/10.1016/j.sjbs.2020.10.037

A.M. Klein, V. Boreux, F. Fornoff, A.C. Mupepele, G. Pufal, Relevance of wild and managed bees for human well-being. Curr. Opin. Insect Sci. 26, 82–88 (2018). https://doi.org/10.1016/J.COIS.2018.02.011

P. Hristov, B. Neov, R. Shumkova, N. Palova, Significance of Apoidea as main pollinators. Ecological and economic impact and implications for human nutrition. Diversity 12(7), 280 (2020). https://doi.org/10.3390/d12070280

X.Y. Liu, M.C. Timar, A.M. Varodi, A comparative study on the artificial UV and natural aging of beeswax and Chinese wax and the influence of wax finishing on the aging of Chinese Ash (Fraxinus mandshurica) wood surfaces. J. Photochem. Photobiol. B 201, 111607 (2019). https://doi.org/10.1016/j.jphotobiol.2019.111607

F. Fratini, G. Cilia, B. Turchi, A. Felicioli, Beeswax: a minireview of its antimicrobial activity and its application in medicine. Asian Pac. J. Trop. Med. 9(9), 839–843 (2016). https://doi.org/10.1016/j.apjtm.2016.07.003

R. Ullah, F.A. Jan, H. Gulab, S. Saleem, N. Ullah, Metals contents in honey, beeswax and bees, and human health risk assessment due to consumption of honey: a case study from selected districts in Khyber Pakhtunkhwa, Pakistan. Arch. Environ. Contam. Toxicol. 82(3), 341–354 (2022). https://doi.org/10.1007/s00244-021-00910-7

L. Svečnjak, L.A. Chesson, A. Gallina, M. Maia, M. Martinello, F. Martinelli, M.N. Muz, F.M. Nunes, F. Saucy, B.J. Tipple, K. Wallner, E. Waś, T.A. Waters, Standard methods for Apis mellifera beeswax research. J. Apic. Res. 58(2), 1–108 (2019). https://doi.org/10.1080/00218839.2019.1571556

F. Giampieri, J.L. Quiles, F.J. Orantes-Bermejo, M. Gasparrini, T.Y. Forbes-Hernandez, C. Sánchez-González, J. Llopis, L. Rivas-García, S. Afrin, A. Varela-López, D. Cianciosi, P. Reboredo-Rodriguez, C.T. Fernández-Piñar, R.C. Iglesias, R. Ruiz, S. Aparicio, J. Crespo, L. Dzul Lopez, J. Xiao, M. Battino, Are by-products from the beeswax recycling process a new promising source of bioactive compounds with biomedical properties? Food Chem. Toxicol. 112, 126–133 (2018). https://doi.org/10.1016/j.fct.2017.12.041

P. Calatayud-Vernich, D. VanEngelsdorp, Y. Picó, Beeswax cleaning by solvent extraction of pesticides. MethodsX 6, 980–985 (2019). https://doi.org/10.1016/j.mex.2019.04.022Get

A.N. Payne, E.M. Walsh, J. Rangel, Initial exposure of wax foundation to agrochemicals causes negligible effects on the growth and winter survival of incipient honeybee (Apis mellifera) colonies. Insects 10(1), 19 (2019). https://doi.org/10.3390/insects10010019

P. Calatayud-Vernich, F. Calatayud, E. Simó, Y. Picó, Occurrence of pesticide residues in Spanish beeswax. Sci. Tot. Environ. 605, 745–754 (2017). https://doi.org/10.1016/j.scitotenv.2017.06.174

H.B. Česnik, V. Kmecl, Investigating Amitraz, coumaphos, and thymol concentrations in honey produced by Slovenian beekeepers in 2020. Acta Agric. Slov. 117(2), 1–7 (2021). https://doi.org/10.14720/aas.2021.117.2.1833

E.M. Walsh, M.A. Janowiecki, K. Zhu, N.H. Ing, E.L. Vargo, J. Rangel, Elevated mating frequency in honeybee (Hymenoptera: Apidae) queens exposed to the miticide amitraz during development. Ann. Entomol. Soc. Am. 114(5), 620–626 (2021). https://doi.org/10.1093/aesa/saaa041

A. Gregorc, M. Alburaki, N. Rinderer et al., Effects of coumaphos and imidacloprid on honeybee (Hymenoptera: Apidae) lifespan and antioxidant gene regulations in laboratory experiments. Sci. Rep. 8, 15003 (2018). https://doi.org/10.1038/s41598-018-33348-4

Z. Fikadu, Pesticides use, practice and its effect on honeybee in Ethiopia: a review. Int. J. Trop. Insect Sci. 40, 473–481 (2020). https://doi.org/10.1007/s42690-020-00114-x

F. Sanchez-Bayo, K. Goka, Impacts of pesticides on honey bees, beekeeping and bee conservation. Adv. Res. (2016). https://doi.org/10.5772/62487

N.K. Hillier, E.H. Frost, D. Shutler, Fate of dermally applied miticides fluvalinate and amitraz within honey bee (Hymenoptera: Apidae) bodies. J. Econ. Entomol. 106, 558–565 (2013). https://doi.org/10.1603/EC12300

A. Luna, R. Alonso, V.M. Cutillas, C.M. Ferrer, M.J. Gómez-Ramos, D. Hernando et al., Removal of pesticide residues from beeswax using a methanol extraction-based procedure: a pilot-scale study. Environ. Technol. Innov. 23, 101606 (2021). https://doi.org/10.1016/j.eti.2021.101606

M.J. Nozal, E. Imaz, J.L. Bernal, J.L. Nieto, M. Higes, J. Bernal, An optimized extraction procedure for determining acaricide residues in foundation sheets of beeswax by using gas chromatography-mass spectrometry. Agronomy 11(4), 804 (2021). https://doi.org/10.3390/agronomy11040804

J.N.G. Marti, V. Kilchenmann, C. Kast, Evaluation of pesticide residues in commercial Swiss beeswax collected in 2019 using ultra-high performance liquid chromatographic analysis. Environ. Sci. Pollut. Res. 29, 32054–32064 (2022). https://doi.org/10.1007/s11356-021-18363-9

J.J. Brazas Navado, M.C. Mahedero, J.A. Olibares, F. Salinas, Determination of Amitraz in honey by first-derivative spectrophotometry. Int. J. Environ. Anal. Chem. 43, 187–194 (1991). https://doi.org/10.1080/03067319108026975

M. Maia, I.R.N.A. Barros, F.M. Nunes, A novel, direct, reagent-free method for the detection of beeswax adulteration by single-reflection attenuated total reflectance mid-infrared spectroscopy. Talanta 107, 74–80 (2013). https://doi.org/10.1016/j.talanta.2012.09.052

Y. Ogen, C. Neumann, S. Chabrillat, N. Goldshlager, E. Ben-Dor, Evaluating the detection limit of organic matter using point and imaging spectroscopy. Geoderma 321, 100–109 (2018). https://doi.org/10.1016/j.geoderma.2018.02.011

S. Goldrick, E. Mercer, G. Montague, D. Lovett, B. Lennox, Control of an industrial scale bioreactor using a PAT analyser. IFAC Proc. 47, 6222–6227 (2014). https://doi.org/10.3182/20140824-6-ZA-1003.02589

B.M. Wise, N.B. Gallagher, The process chemometrics approach to process monitoring and fault detection. J. Process Control 6, 329–348 (1996). https://doi.org/10.1016/0959-1524(96)00009-1

A.P. Ferreira de Souza, N.R. Rodrigues, A.R. Fernández-Alba, F.G.R. Reyes, Occurrence of pesticide residues in Brazilian Apis mellifera beeswax by gas chromatography-tandem mass spectrometry and pesticide hazard evaluation. J. Apic. Res. (2022). https://doi.org/10.1080/00218839.2022.2043228

L. Salvador, M. Guijarro, D. Rubio, B. Aucatoma, T. Guillén, P. Vargas Jentzsch, V. Ciobotă, L. Stolker, S. Ulic, L. Vásquez, P. Garrido, J. Bravo, L. Ramos Guerrero, Exploratory monitoring of the quality and authenticity of commercial honey in Ecuador. Foods 8, 105 (2019). https://doi.org/10.3390/foods8030105

N. Tanner, B. Lichtenberg-Kraag, Identification and quantification of single and multi-adulteration of beeswax by FTIR-ATR spectroscopy. Eur. J. Lipid Sci. Technol. 121(12), 1900245 (2019). https://doi.org/10.1002/ejlt.201900245

Funding

Open access funding provided by Ariel University.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Zohar, E., Cohen, H., Goldshlager, N. et al. Detection of the amitraz pesticide in bee wax by hyperspectral imaging. Food Measure 18, 3008–3017 (2024). https://doi.org/10.1007/s11694-024-02382-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11694-024-02382-4