Abstract

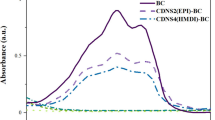

The article investigated the encapsulation and characterization of commercial green tea extracts with green encapsulation methods such as inclusion complexation (IC) and ion gelation (IG). Catechin extracts were isolated first by hot water extraction and then by vacuum filtration and the extracts were encapsulated by inclusion complexation and ion gelation methods. Maltodextrin and sodium alginate were used as wall material for inclusion complexation and ion gelation, respectively. The prepared encapsulates were characterized for their encapsulation efficiency and as with FESEM, DSC, XRD, DLS, and FTIR analyses. The IC-encapsulated catechin extracts exhibited high encapsulation yield and encapsulation efficiency at 90.53, and 88.4%, respectively. IG catechin extracts had a high encapsulation yield (86.86%) but exhibited resistance to the release of catechins during encapsulation efficiency study. Characterization of the encapsulated catechin extracts affirmed promising thermal and crystalline properties for future applications as fortificants in functional food products. The IC catechin extracts had superior crystalline properties with a 56.6% increase in relative crystallinity. The thermal property, namely melting temperature enhanced significantly for both IC and IG-based catechin extracts at 118.3–214 °C and 118.6–225.3 °C, respectively. The IC catechin extracts also exhibited better encapsulation yield and efficiency.

Highlights

Green encapsulation methods were deployed to encapsulate green tea extract bioactive and thereby have applicability as a functional beverage additive.

Both processes of encapsulation produced catechin encapsulate with enhanced thermal characteristics, namely melting temperatures and Cp.

The relative crystallinity of catechin encapsulate prepared with the method increased significantly with respect to raw catechin extracts.

While both methods ensured high encapsulation yield, the encapsulation efficiency was the best for IC-based encapsulated catechin extracts.

Similar content being viewed by others

Data Availability

The datasets generated during and analysed during the current study are available from the corresponding author upon reasonable request.

References

L.F. Wang, D.M. Kim, C.Y. Lee, Effects of heat processing and storage on flavanols and sensory qualities of green tea beverage. J. Agric. Food Chem. 48(9), 4227–4232 (2000). https://doi.org/10.1021/jf0003597

Y.R. Liang et al., Chemical and instrumental assessment of green tea sensory preference. Int. J. Food Prop. 11(2), 258–272 (2008). https://doi.org/10.1080/10942910701299430

H. Zhu, Y. Ye, H. He, C. Dong, Evaluation of green tea sensory quality via process characteristics and image information. Food Bioprod. Process. 102(9), 116–122 (2017). https://doi.org/10.1016/j.fbp.2016.12.004

M.S. Westerterp-Plantenga, Green tea catechins, caffeine and body-weight regulation. Physiol. Behav. 100(1), 42–46 (2010). https://doi.org/10.1016/j.physbeh.2010.02.005

S.P.J. Namal Senanayake, Green tea extract: Chemistry, antioxidant properties and food applications - a review. J. Funct. Foods. 5(4), 1529–1541 (2013). https://doi.org/10.1016/j.jff.2013.08.011

V. Verardo, Y. Riciputi, M.C. Trivisonno, E. Marconi, M.F. Caboni, Effect of the addition of air-classified barley flours on the lipid stability of bakery products. Eur. Food Res. Technol. 231(2), 309–319 (2010). https://doi.org/10.1007/s00217-010-1288-5

T. Goto, Y. Yoshida, M. Kiso, H. Nagashima, Simultaneous analysis of individual catechins and caffeine in green tea. J. Chromatogr. A 749, 1–2 (1996). https://doi.org/10.1016/0021-9673(96)00456-6

J. Hu, D. Zhou, Y. Chen, Preparation and antioxidant activity of green tea extract enriched in epigallocatechin (EGC) and epigallocatechin gallate (EGCG). J. Agric. Food Chem. 57(4), 1349–1353 (2009). https://doi.org/10.1021/jf803143n

K.H. Row, Y. Jin, Recovery of catechin compounds from Korean tea by solvent extraction. Bioresour Technol. 97(5), 790–793 (2006). https://doi.org/10.1016/j.biortech.2005.04.001

H. Liang, Y. Liang, J. Dong, J. Lu, H. Xu, H. Wang, Decaffeination of fresh green tea leaf (Camellia sinensis) by hot water treatment. Food Chem. 101(4), 1451–1456 (2007). https://doi.org/10.1016/j.foodchem.2006.03.054

S. Leclercq, K.R. Harlander, G.A. Reineccius, Formation and characterization of microcapsules by complex coacervation with liquid or solid aroma cores. Flavour. Fragr. J. 24(1), 17–24 (2009). https://doi.org/10.1002/ffj.1911

ACS Food Sci. & Technol, vol. 3, no. 4, pp. 626–634, Mar. 2023, doi: 10.1021/acsfoodscitech.2c00369

A. Schoubben, P. Blasi, S. Giovagnoli, C. Rossi, M. Ricci, Development of a scalable procedure for fine calcium alginate particle preparation. Chem. Eng. J. 160(1), 363–369 (2010). https://doi.org/10.1016/j.cej.2010.02.062

L.X. Song, L. Bai, X.M. Xu, J. He, S.Z. Pan, Inclusion complexation, encapsulation interaction and inclusion number in cyclodextrin chemistry. Coord. Chem. Rev. 253, 9–10 (2009). https://doi.org/10.1016/j.ccr.2008.08.011

J. Zhou, J. Guo, I. Gladden, A. Contreras, L. Kong, “Complexation ability and physicochemical properties of starch inclusion complexes with C18 fatty acids,” Food Hydrocoll, vol. 123, no. September 2021, p. 107175, 2022, https://doi.org/10.1016/j.foodhyd.2021.107175

E.S. Kim, J.S. Lee, H.G. Lee, Calcium-alginate microparticles for sustained release of catechin prepared via an emulsion gelation technique. Food Sci. Biotechnol. 25(5), 1337–1343 (2016). https://doi.org/10.1007/s10068-016-0210-8

P.H. Campelo, A.S. Sant’Ana, M.T. Pedrosa Silva Clerici, “Starch nanoparticles: production methods, structure, and properties for food applications,” Curr. Opin. Food Sci, vol. 33, no. i, pp. 136–140, 2020, https://doi.org/10.1016/j.cofs.2020.04.007

K. Krishnaswamy, V. Orsat, K. Thangavel, Synthesis and characterization of nano-encapsulated catechin by molecular inclusion with beta-cyclodextrin. J. Food Eng. 111(2), 255–264 (2012). https://doi.org/10.1016/j.jfoodeng.2012.02.024

S. Ho, Y.Y. Thoo, D.J. Young, L.F. Siow, Inclusion complexation of catechin by β-cyclodextrins: characterization and storage stability. Lwt. 86, 555–565 (2017). https://doi.org/10.1016/j.lwt.2017.08.041

S.K. Chandini, L.J. Rao, M.K. Gowthaman, D.J. Haware, R. Subramanian, Enzymatic treatment to improve the quality of black tea extracts. Food Chem. 127(3), 1039–1045 (2011). https://doi.org/10.1016/j.foodchem.2011.01.078

K.M. Wani, R.V.S. Uppaluri, Pulsed ultrasound-assisted extraction of bioactive compounds from papaya pulp and papaya peel using response surface methodology: optimization and comparison with hot water extraction. Appl. Food Res. 2(2), 100178 (2022). https://doi.org/10.1016/j.afres.2022.100178

K.M. Wani, R.V.S. Uppaluri, Continuous and pulsed ultrasound-assisted extraction of pectin from pomelo fruit peel using citric acid. Biomass Convers. Biorefinery. (2022). https://doi.org/10.1007/s13399-022-03513-x

A. Rashidinejad, E.J. Birch, D. Sun-Waterhouse, D.W. Everett, Delivery of green tea catechin and epigallocatechin gallate in liposomes incorporated into low-fat hard cheese. Food Chem. 156, 176–183 (2014). https://doi.org/10.1016/j.foodchem.2014.01.115

S. Ho, Y.Y. Thoo, D.J. Young, L.F. Siow, “Stability and recovery of cyclodextrin encapsulated catechin in various food matrices,” Food Chem, vol. 275, no. July 2018, pp. 594–599, 2019, https://doi.org/10.1016/j.foodchem.2018.09.117

S. Ahmed et al., Environmental factors variably Impact Tea secondary metabolites in the Context of Climate Change. Front. Plant. Sci. 10, 1–16 (2019). https://doi.org/10.3389/fpls.2019.00939

A.B.D. Nandiyanto, R. Oktiani, R. Ragadhita, How to read and interpret ftir spectroscope of organic material. Indones J. Sci. Technol. 4(1), 97–118 (2019). https://doi.org/10.17509/ijost.v4i1.15806

N.D.A. Arriola et al., “Encapsulation of stevia rebaudiana Bertoni aqueous crude extracts by ionic gelation – Effects of alginate blends and gelling solutions on the polyphenolic profile,” Food Chem, vol. 275, no. August 2018, pp. 123–134, 2019, https://doi.org/10.1016/j.foodchem.2018.09.086

Y.S.R. Elnaggar, M.A. El-Massik, O.Y. Abdallah, A.E.R. Ebian, Maltodextrin: a novel excipient used in sugar-based orally disintegrating tablets and phase transition process. AAPS PharmSciTech. 11(2), 645–651 (2010). https://doi.org/10.1208/s12249-010-9423-y

S.S. Seda Bekin, Dielectric, Thermal, and Swelling properties of Calcium Ion-Crosslinked Sodium Alginate Film. Society. 1–10 (2006). https://doi.org/10.1002/pen

W. Zhao et al., Morphology and thermal properties of calcium alginate/reduced graphene oxide composites. Polym. (Basel). 10, 1–11 (2018). https://doi.org/10.3390/polym10090990

C.K. Reddy, E.S. Jung, S.Y. Son, C.H. Lee, Inclusion complexation of catechins-rich green tea extract by β-cyclodextrin: Preparation, physicochemical, thermal, and antioxidant properties. Lwt. 131, 109723 (2020). https://doi.org/10.1016/j.lwt.2020.109723

Acknowledgements

The authors thankfully acknowledge the Department of Chemical Engineering, School of Agro & Rural Technology, Central Instrumentation Facility, IITG, and Indian Institute of Technology Guwahati, India, for providing the necessary facilities for carrying out this research.

Funding

The authors did not receive support from any organization for the submitted work.

Author information

Authors and Affiliations

Contributions

The study’s inception and design involved input from all authors. Paushali Mukherjee prepared the material, collected the data, and carried out the analysis. Kamal Narayan Baruah also performed experimental analysis. The first draft of the manuscript was written by Paushali Mukherjee, and all authors commented on previous versions of the manuscript. The final manuscript was read and approved by all writers.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no competing interests.

Ethics approval and consent to participate

This article does not contain any studies with human participants or animals performed by any of the authors.

Informed consent

Not applicable.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Mukherjee, P., Baruah, K.N. & Uppaluri, R.V.S. Encapsulation and characterization of commercial green tea extracts using green methods: a comparative study of inclusion complexation and ion gelation. Food Measure 18, 916–929 (2024). https://doi.org/10.1007/s11694-023-02250-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11694-023-02250-7