Abstract

Color-based time-temperature indicators (TTIs) can show the time and temperature changes of an environment with a visually recognizable color change. Made from natural dyes, these TTIs are simple, inexpensive and sustainable. In this study, cellulose-based TTI labels were prepared with red cabbage extract of pH2, pH7 and pH9 to determine how pH alter the response of the labels to time and temperature changes. This study also aimed to determine the relationship between color change and time at different temperatures. The color responses of the labels were followed spectrophotometrically by measuring the CIE Lab color coordinates and by giving the total color difference at 4 °C, 23 °C, 40 °C, 80 and 100 °C after increments of time. The best fitting linear or nonlinear regression models of the CIE Lab coordinates, total color difference and time data as a function of temperature were also determined. The labels prepared with red cabbage extract at different pH behaved differently. Opposite to expectations, the acidic, pink colored labels did not have the highest color stability. Our finding was, that the label prepared with the acidic red cabbage extract is the most suitable as time-temperature label for indicating long-term temperature storage and the label prepared with the neutral red cabbage extract is the most suitable as time-temperature label for indicating short-term storage by color change. According to the results the color changes of the labels are predictable with the fitted models with a correlation coefficient between 0.96 and 1.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Temperature and time are two of the main parameters that effect the shelf-life of a product, especially food products. Heating, cooling or storing a product above or below a critical temperature for a certain time can cause its deterioration [1,2,3]. Inadequate storage temperatures favors the growth of food spoiling microorganisms, among them food-borne pathogens as well [3]. As representatives of smart solutions, time-temperature indicators (TTIs) are being developed to respond to time and temperature, thus monitoring the conditions of the surrounding environment. In general, TTIs shows the changes in temperature and time by visually observable color changes. There are different kinds of TTIs, such as color-based, acidity-based, diffusion length based or electrical signal based TTIs [4]. The importance of TTIs clearly demonstrated by the fact that they are expected to be integrated into a Hazard Analysis and Critical Control Point (HACCP) plan [5], which requires a continuous control and monitoring of parameters such as temperature throughout the entire food chain [6]. The components of TTIs used for food products must comply with certain regulations in the European Union described by Commission Regulation (EC) No 450/2009 and should be approved by European Food Safety Authority [7]. Color-based TTIs can also be prepared from natural dyes, such as anthocyanins, which help to keep the indicators safe for food contact, simple, inexpensive, user-friendly and sustainable [8,9,10].

The flavonoid anthocyanins are water-soluble plant pigments, which are responsible for the red, blue, purple color of leaves, flowers, fruits and vegetables. The color of anthocyanins is pH dependent. They show different structures at different pH, which are associated with different colors (Fig. 1). In acidic environments (pH ≤ 3) the anthocyanin is protonated and the dominance of flavylium cation results in a red color; at pH 4–5, through hydration the anthocyanins have the colorless carbinol pseudobase and chalcone forms; at a slightly acidic or neutral pH (6–7) deprotonation occurs and the neutral quinonoid base form causes a purple color; at around pH 8–9 the deprotonation proceeds and the formed anionic quinonoid base causes bluish color. When pH is further increased, chalcone form occur which provides a greenish and yellowish color. [11,12,13,14].

In general, anthocyanins are sensitive to relatively high temperatures, pH, UV-radiation, the presence of oxygen, other phenolics, metal ion and sugar content [15,16,17,18,19]. Temperature and pH most strongly affect the stability of anthocyanins [18, 20]. Studies showed the anthocyanins have the highest color stability at lower pH, and at neutral or alkaline pH they have less stability [18, 21, 22]. It was also found that increasing pH decreases the thermal stability [18, 23, 24]. The instability of the anthocyanins promotes degradation mechanisms and the discoloration and browning of the extract [25]. Whilst color changes induced by pH are reversible, heat induced discoloration is permanent. While the low stability of anthocyanins in food products during processing or storage is a disadvantage for the food industry, it is a useful feature for TTIs.

Although there are a large number of papers about the advantages of using anthocyanins in pH indicators, there is limited number of papers about their use as time-temperature indicators. Maciel et al. [8] coated cardboard with anthocyanin loaded chitosan and examined its responsivity at 10–70 °C after 72 h storage. They reported that the developed TTI could irreversibly respond to temperature between 40 and 70 °C. Their TTI gradually turned yellow when exposed to 40 °C and the TTI darkened above 50 °C, independently of luminosity (0 or 1000 lx). Saengpanya et al. [26] coated paper with red cabbage extract of pH9 and examined the color change over time at room temperature, at 40 °C and at 60 °C. They reported that there were no differences in visual color changes of the coated paper during the tested 100 min time interval. However, it was also observed that lightness and b* values slightly decreased and a* value slightly increased as time increased. Rachmelia et al. [9] prepared TTI label with black corn extract incorporated into chitosan and examined the properties of the label at 10, 25 and 40 °C. They observed the fastest color change at 40 °C (purple to blue in 6 h, to dark green after 360 h) and the lowest at 10 °C. The color change was irreversible. Amiri et al. [10] developed a black carrot anthocyanin-paper-paraffin wax as an indicator label. The color change was analyzed at -5, 5, 15 and 25 °C for 48 h. Their TTIs showed color change at 15 and 25 °C. A well-recognizable change, a color transition from blue to red, appeared after 8 h for label at 25 °C, and after 12 h at 15 °C.

Although the creation of TTI labels was not intended, Prietto et al. [27] studied the stability of pH indicator films made from black been seed coat and red cabbage extract incorporated into glycerol-plasticized corn starch. They exposed the films in pH 1–10 buffers, stored at room temperature and under refrigeration (the exact temperature was not given), with and without light. They reported that black been anthocyanins were more sensitive to the 28-day storage and showed increased yellowness, while red cabbage anthocyanins remained stable (although, a color difference of 5 was considered a visible color difference). Prietto et al. reported that the strongest color change occurred at pH 8, 9 and 10, regardless of the source of the anthocyanin.

The aim of our study was to examine the response of simply prepared red cabbage extract-cellulose labels from the perspective of TTIs at specific temperatures and time, after adjusting pH to acidic, neutral and slightly alkaline. We also aimed to investigate the relationship between the color change of red cabbage anthocyanins and time at different temperatures using statistical methods to determine the visually observable color difference stages.

Red cabbage is a rich source of anthocyanins, has a long shelf-life, and its extract is easy to prepare making red cabbage a sustainable and potential material for smart packaging [14, 28]. The anthocyanin profile of red cabbage is very complex, more than 20 anthocyanin pigments can be identified [14, 29, 30], which is due to the glycosylation of the cyanidin with two different sugars and acylation with different aromatic acids [31]. The main anthocyanin found to be cyanidin-3-O-diglucoside-5-O-glucoside, which can be mono-or diacylated with the presenting sinapic, ferulic, caffeic and p-coumaric acids [14]. The acylated cyanidins can offer a broader color spectrum and a higher stability [30]. Greater stability might impair the applicability of red cabbage extract as a TTI material, but at the same time, red cabbage can be considered as one of the most economical source of anthocyanins, so its extract is also worth researching in the field of TTIs. Figure 1 shows the structures of cyanidin-3-O-diglucoside-5-O-glucoside and the color of red cabbage extract at pH2, pH7 and pH9 14.

Structural change of cyanidin-3-O-diglucoside-5-O-glucoside (drawn by MolView [32]), the color of red cabbage extract and the prepared cellulose samples at pH2 (A), pH7 (B) and pH9 (C)

Materials and methods

Materials

The indicator dye was extracted from red cabbage, obtained from a local market. 96% ethanol, potassium chloride, sodium acetate and pH buffers (2,7 and 9) were supplied by Molar Chemicals Ltd. (Hungary). Whatman No. 1 filter paper was used as an indicator base material.

Methods

Extraction and determination of total monomeric anthocyanin content

To obtain the indicator dye solution 100 g fresh weight of red cabbage was mixed with 200 ml of a mixture of 1:1 ethanol:water in a blender. The mixture was stirred for 6 h at room temperature without heating to prevent any loss of anthocyanin or formation of by-products caused by thermal degradation. The mixture was filtered, and the resulting extract was kept closed in a dark, cool (4 °C) place until use. The total monomeric anthocyanin content (TMAC) of the red cabbage extract was determined by pH differential method according to the Official AOAC Method 2005.02 [33]. Buffers of pH 1 (0.025 M potassium chloride) and pH 4.5 (0.4 M sodium acetate) were prepared and added to the extract. After storing the solutions for 15 min in the dark, the absorbance was measured at 500 nm (λvis−max) and 700 nm with a UV/VIS spectrophotometer (AquaLog UV-800). Its TMAC was calculated from the absorbance difference according to the following, and expressed as a cyanidin-3-glucoside equivalent (CGE, cyanidin-3-glucoside equivalent):

where, Mw: molecular weight of cyanidin-3-glucoside (Mw = 449.2 g mol− 1), DF : dilution factor, ε: molar absorptivity (ε = 26 900), L: cell path length (L = 1 cm).

Red cabbage-cellulose indicator label preparation

Samples of 4 × 4 cm were cut from the filter paper and were impregnated with 1 ml of extract with pH of 2, 7 and 9. The wet cellulose-based labels were dried in a ventilated oven at 23 °C. LpH2, LpH9 and LpH7 label notation refer to the pH2, pH7 and pH9 labels, respectively.

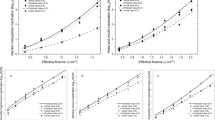

Color response to time and temperature

The color response of the indicator labels to time-temperature changes were examined at 4 °C, 23 °C, 40 °C, 80 and 100 °C were determined by the CIE (Commission Internationale d’Eclairage) Lab method. The experiment was limited to measuring the color change without exposure to light or oxygen. The color coordinates (lightness: L*, redness or greenness: a*, yellowness or blueness: b*) were measured with a Datacolor Elrepho 2000 spectrophotometer (D65/10°) at three different points of each label. Three individual samples were tested from each kind of label. (The change in CIE Lab coordinates, and the best fit regression models can be found in the Supporting Information). The total color difference (ΔE) compared to the original label colors was calculated according to the following Eq. (2):

where, Li*, ai* and bi* are the original color coordinates of the LpH2, LpH9 and LpH7 labels before the heat treatments.

Based on Mokrzycki and Tatol [34] the following ranges were applied to determine notability of the color difference to the human eye: E1: 0 < ∆E < 1, observer does not notice the difference; E2: 1 < ∆E < 2, only experienced observers can notice the difference; E3: 2 < ∆E < 3.5, unexperienced observer also notice the difference; E4: 3.5 < ∆E < 5, a clear difference in color is noticed; E5: 5 < ∆E, observers notices two different colors.

To visually show the color change of the red cabbage extract-cellulose labels as a function of temperature and time, the measured colors of the labels were converted to RGB.

Determination of best fitting models

The best fitting linear or nonlinear regression models of the CIE Lab coordinates (see Supplementary Information), total color difference and time data as a function of temperature were generated with a CurveExpert Basic 2.1.0 software [35]. The software is validated against the Statistical Reference Datasets Project of the National Institute of Standards and Technology. The CurveExpert Basic compares data to each of 60 models to choose the best curve. The best fitting model was determined by the highest ranking of correlation coefficient.

Results and discussions

Figure 1 shows the prepared red cabbage extract and the TTI labels at pH values of 2, 7 and 9. Based on the TMAC results the anthocyanin content of the labels was 3.2 mg g− 1. The results of the pH differential method gave a total monomeric anthocyanin content of 439 mg L− 1 CGE. The CIE Lab color values (L*,a*,b*) of the freshly prepared samples were LpH2 (71.8, 38.2,-4.3), LpH7 (70.2, 19.3, -16.2) and LpH9 (72.8,11.3,-11.4). The converted RGB color values: LpH2 (239,149,185), LpH7 (194,161,201) and LpH9 (190,173,200).

Color response to storage at 4 °C

TTI labels which were kept at 4 °C showed stable color (Fig. 2). Among CIE Lab color coordinates the a* value showed the highest change. For LpH2 labels the a* value decreased, for LpH9 and LpH7 labels it increased (by 13 and 9% at the end of the testing period) (see Supporting Fig. 1). No total color difference higher than 2 (noticeable color difference for inexperienced observers) was measured for either the LpH2, or for the LpH9 label. The color of the LpH2 label changed the least, followed by the LpH9 and LpH7. Prieto et al., who studied the stability of red cabbage/starch films, showed similar behavior that the films exposed to pH2 and pH7 have similar stability, although the color difference of the film at pH2 exceeded the value 2. On contrary to our findings their data showed that the film at pH9 had a much high color difference, it approached and then exceeded the value at the 12th and at the 25th test day. An alternation of ∆E between approximately 2 and 5 can be observed for some reason at pH9, but also at pH9 and pH2. We did not observe such change of the ∆E. Based on the best fitted model (Fig. 2; Table 1) of the total color difference and the elapsed time, which was the Weibull model for all the three labels (with correlation coefficients of 0.9975, 0.9833 and 0.9877 for LpH2, LpH9 and LpH7 labels, respectively), the ∆E of 2 is reached after 43.4 days for LpH7. These results show that the labels have high color stability when kept at 4 °C, which indicates that the labels are less suitable for TTI applications at lower temperatures examined in the time range of this study. Maintaining the original label color increases the shelf-life of the indicator labels, although we did not study how the labels would behave after 60 days of storage at 4 °C. Amiri et al. [10] reported the color stability of a TTI label made from paraffin wax, black carrot and cellulose at 5 °C (no information was provided on whether the labels were exposed to light or oxygen). The labels showed no color change after 48 h. A purple to blue color transition was reported by Rachmelia et al. [9], who studied the color change of chitosan labels made with black corn extract at a lower temperature (10 °C) for 360 h (there was lack of information about the presence of light or oxygen). Such a color change did not occur with our labels prepared with red cabbage extract and cellulose. The color transition was probably due to the interactions formed between the matrix and the extract. No interactions were observed between the red cabbage extract and the cellulose fibers of such a form or to such an extent as to cause an observable color change. It can be assumed that not only the type of anthocyanin but also the type of matrix have a strong influence on the color change of the anthocyanin-based TTIs.

Color response to storage at 23 °C

When the labels were kept at room temperature in the dark, the difference in the color stability of the labels became more pronounced (Fig. 3.). It was expected that the red LpH2 would have the most stable color. However, the color of the purple LpH7 label was the most stable, and there was no observable difference in the color compared to its original color during the test period. Linear regression provided the best fit to the data for LpH2 label (with a R2 of 0.9936), for LpH9 label yield-density model (exponential plus linear, with a R [2] of 0.9903) and for LpH7 label a sigmoidal model (MMF (Morgan-Mercer-Flodin model), with a R [2] of 0.9929) gave the best fit (Table 2). According to the models, the ∆E of 2 is reached after 21 and 2 days for LpH2 and LpH9 labels, respectively (Fig. 3). The ∆E of 3.5 occurred after 37 and 4 days and the ∆E of 5 after 54 and 21 days for LpH2 and LpH9 labels, respectively. The color difference that occurred over time was due to the increase of L* value, all samples became lighter. For lpH2 the color value a* (redness) decreased and for lpH9 the b* (yellowness) increased remarkably. Analyzing the results of Prietto et al. [27], our results are somewhat similar. Their starch/red cabbage extract film at pH 9 showed also remarkably higher ∆E during the test period, and the color difference of the film at pH 7 remained under the value ~ 2 at room temperature under dark. Unlike our label at pH2, the color difference of their film at pH2 was below 2 during the stability test. Prieto et al. reported same tendency for films made from black been anthocyanins.

Overall, our finding is that the pink LpH2 and the blue LpH9 labels kept at room temperature in the dark can show the elapsed time through their color fading, however LpH7 label is not suitable for TTI under these conditions in the examined time range.

Color response to storage at 40 °C

The results showed that the color of the LpH9 and LpH7 labels are more stable in the tested time range than the color of the LpH2 label. However, based on the measurements and the fitted model an observable color difference (∆E = 2) can be detected for LpH9 from 1.2 h. A total color difference of 5 (two different colors are observed) was not reached within the test period (14 days) for LpH7 and lpH9 either, while it occurred for lpH2 after the 43rd hour (Fig. 4), Table 3). The fitted model gave an observable color difference after 9.4 h for LpH2. For the neutral and alkaline labels, the best fitting models were more complex (Table 3) than for acidic label. Moreover, for lpH7 at the beginning of the treatment there was a rise in the total difference compared to the original color and then a lower observed ∆E was followed by a rising ∆E. The higher color difference of the LpH2 labels is due to the decrease of the a* (redness) value (see Supporting Fig. 3).

Similarly to the findings of Maciel et al. [8], who coated cardboard with anthocyanin-chitosan mixture, and to the findings of Saengpanya et al. [26], who coated paper with red cabbage extract of pH9, at 40 °C slight darkening of the samples was observed for the purple LpH7 label in the beginning of the test. We also experienced the same tendency for the blue lpH9 label. After the slight decrease of L* value it began to increase, and both the labels became lighter in time (see Supporting Fig. 3). This phenomenon at 40 °C is in agreement with the finding of Rachmelia et al. [9], who prepared TTI from black corn extract and chitosan. Although they also observed a purple-blue-green transition, the cause of which is not specified, probably due to the interactions between chitosan and the extract that altered the color change of the anthocyanin. No darkening was observed for the red LpH2 sample, the label became gradually lighter. Based on the results, the label with red cabbage extract of pH2 can best show the elapsed time at 40 °C, although the alkaline label responds earlier to a 40 °C storage.

Color response to storage at 80 °C

A similar phenomenon was observed at 80 °C as at 40 °C. The color difference of the LpH2 can be described with a single Weibull model (R2 = 0.9993), whilst the LpH9 and LpH7 labels with complex models due to the higher total color difference at the beginning followed by a backslide, and again a raising value (Fig. 5; Table 5). Although the difference between the labels at 80 °C is not as pronounced as at 40 °C, if we consider the whole tested time period the pink label had a lower color stability compared to the blue and purple LpH9 and LpH7 labels. If we consider the time required to reach total color difference of 2, based on the models it occurs after 2 h for LpH2, after 0.1 h for LpH9 and 0.04 h for LpH7, ∆E of 3.5 occurs after 7, 0.2 and 16.1 and ∆E of 5 occurs after 11, 0.7 and 31 h for LpH2, LpH9 and LpH7 labels, respectively. It was reported by Dyrby et al. [31] that the thermal degradation of anthocyanins of red cabbage was not detectable at 40 °C, only at 80 °C within 6 h. Although the anthocyanins might behave differently in dry form than in solutions, we also observed that storage at 40 °C did not cause browning during the test period, whilst samples at 80 °C showed browning (Fig. 5). The initial b* values became positive, the colors shifted towards yellowish (see Supporting Fig. 4), which is in accordance with the measurements of Maciel et al. [8] at 70 °C. The increase in the b* value relates to the thermal degradation of the anthocyanins and phenolics and also to the formation of polymerics [36]. The thermal degradation mechanism of anthocyanins is not yet fully understood, but it is assumed that the first step in the thermal degradation of anthocyanins is the opening of the pyrylium ring leading to formation of the yellow chalcone [17].

As the results showed among the labels the LpH9 is the most usable to show a short storage time at 80 °C LpH9, followed by the LpH2 and LpH7.

Color response to storage at 100 °C

Storing the labels at a higher temperature, at 100 °C, a faster color change was observed. LpH2 did not show a clearly noticeable color change until 30 min, whilst LpH9 showed a clearly noticeable change at the 5th and LpH7 at the 10th testing minute (Fig. 6). The lightness of the LpH2 did not change remarkably. The difference compared to the original lightness was only 1%. Their b* values increased from negative values to positive ones, which induced a brownish color due to the heat-induced degradation of the anthocyanins, also observed at 80 °C (see Supporting Fig. 5). Browning occurred for the blue and purple labels as well, however for LpH7 labels there was an increasing lightness (up to 8%) from the 24th hour. The relationship between the elapsed time and the total color difference was best described with a sigmoidal model (MMF) for all the labels, where the correlation coefficients were between 0.9957 and 0.9990 (Table 5). According to the fitted model the ∆E > 2 is reached after 12, 2.4 and 0.6 min for LpH2, LpH9 and LpH7 labels; the ∆E > 3.5 24, 5.4 and 12.6 min; and ∆E > 5 after 36, 9.6 and 20.4 min. The LpH9 label proved to be the most suitable as a TTI to show elapsed time at 100 °C temperature.

Conclusions

The color change of red cabbage extract containing cellulose based labels were examined at 4 °C, 23 °C, 40 °C, 80 and 100 °C over the function of time. According to the results the color changes of the labels were predictable with the fitted models with a correlation coefficient between 0.96 and 1. The labels had high stability at 4 °C. The noticeable color difference was not observed for LpH2 and LpH9 labels within 60 days of storage. The LpH7 showed a slightly higher total color difference compared to the acidic and neutral labels because, a noticeable color change occurred after 43 days, based on the fitted model. The labels are less suitable as TTIs at 4 °C, but these results showed that the color of the labels can be maintained when they are kept in cold and dark conditions. Although it has been reported that the color of anthocyanins is more stable at acidic pH and less stable at alkaline pH, the cellulose-based labels with the dehydrated extract showed a somewhat different behavior. At 23 °C the most color stable label was the alkaline followed by the acidic, and then the neutral one. The LpH2 and LpH9 labels showed the elapsed time by their color fading. LpH9 and LpH7 labels did not reach the total color difference of “two different colors” within the examined time range, however, noticeable color change occurred for LpH9 label after 1.2 h of storage, making the alkaline label suitable to indicate short-term storage at 40 °C. On the other hand, long-term storage at 40 °C can be monitored with the LpH2 label, as it showed a high color difference (∆E > 15) at the end of the test period. During the tested time range, similarly to the 40 °C storage, the highest ∆E at 80 °C occurred for LpH2, although the labels showed a noticeable color change (∆E > 2) after 2 h, whilst LpH9 labels changed after 6 min and LpH7 labels after 2.4 min based on the fitted models. The LpH2 labels showed passage of time by fading, then by browning. The LpH9 labels darkened and browned, whilst the LpH7 label, darkened, faded then browned. The LpH9 label had the most recognizable color change. At 100 °C, the LpH2 label was the most stable for the first 35 min, then after 28 h it showed the highest color difference, whilst LpH7 was the most stable during the whole test period. Overall, the blue LpH9 label prepared with the neutral red cabbage extract is the most suitable as time-temperature label for indicating short-term storage and the pink LpH2 prepared with the acidic red cabbage extract for long-term temperature storage by color change.

These simple red cabbage-based indicators could be suitable to indicate inappropriate transport or storage temperatures, in case of products (like eggs or UHT milk) that can be stored at room temperature, but spoilage can occur around 40 °C due to microbial activity. The labels could also show whether a product was subjected to a heat treatment (100 °C and above) such as a sterilization process. However, further characterization is needed to determine the pH dependent color change that occurs with exposure to light or oxygen, which could affect the label’s use.

References

K.L. Yam, P.T. Takhistov, J. Miltz, Intelligent packaging: concepts and applications. J. Food Sci. 70(1), R1–R10 (2005)

M. Sohail, D.-W. Sun, Z. Zhu, Recent developments in intelligent packaging for enhancing food quality and safety. Crit. Rev. Food Sci. Nutr. 58(15), 2650–2662 (2018)

M. Mataragas, V.C. Bikouli, M. Korre, A. Sterioti, P.N. Skandamis, Development of a microbial time temperature Indicator for monitoring the shelf life of meat. Innov. Food Sci. Emerg. Technol. 52, 89–99 (2019)

T. Gao, Y. Tian, Z. Zhu, D.-W. Sun, Modelling, responses and applications of time-temperature indicators (TTIs) in monitoring fresh food quality. Trends Food Sci Technol. 2020

F1416-96(2019) A. Standard Guide for Selection of Time-Temperature Indicators. 2019. doi:https://doi.org/10.1520/F1416-96R19

K. Pennanen, C. Focas, V. Kumpusalo-Sanna et al., European consumers’ perceptions of time–temperature indicators in food packaging. Packag Technol. Sci. 28(4), 303–323 (2015)

EFSA Panel on Food Contact Materials Flavourings and Processing Aids (CEF) E, Scientific opinion on the safety evaluation of a time-temperature indicator system, based on Carnobacterium maltaromaticum and acid fuchsin for use in food contact materials. EFSA J. 11(7), 3307 (2013)

V.B.V. Maciel, C.M.P. Yoshida, T.T. Franco, Development of a prototype of a colourimetric temperature indicator for monitoring food quality. J. Food Eng. 111(1), 21–27 (2012)

D. Rachmelia, C. Imawan. Time Temperature Indicator Label using Black Corn Extract and Chitosan Matrix. In: Journal of Physics: Conference Series. Vol 1120. IOP Publishing; 2018:12041

R. Amiri, H. Piri, M. Akbari, G. Moradi, The fabrication and kinetic modeling of a new time–temperature label based on paraffin wax and black carrot anthocyanin for monitoring fish products. Anal. Methods 12(4), 544–551 (2020)

P.S. Vankar, D. Shukla, Natural dyeing with anthocyanins from Hibiscus rosa sinensis flowers. J. Appl. Polym. Sci. 122(5), 3361–3368 (2011)

A. Castañeda-Ovando, M. de Lourdes Pacheco-Hernández, M.E. Páez-Hernández, J.A. Rodríguez, C.A. Galán-Vidal, Chemical studies of anthocyanins: a review. Food Chem. 113(4), 859–871 (2009)

G.T. Sigurdson, P. Tang, M.M. Giusti, Natural colorants: Food colorants from natural sources. Annu. Rev. Food Sci. Technol. 8, 261–280 (2017)

W. Wiczkowski, D. Szawara-Nowak, J. Topolska, Red cabbage anthocyanins: Profile, isolation, identification, and antioxidant activity. Food Res. Int. 51(1), 303–309 (2013)

C.R. Sonar, B. Rasco, J. Tang, S.S. Sablani, Natural color pigments: oxidative stability and degradation kinetics during storage in thermally pasteurized vegetable purees. J. Sci. Food Agric. 99(13), 5934–5945 (2019)

J.-W. Rhim, Kinetics of thermal degradation of anthocyanin pigment solutions driven from red flower cabbage. Food Sci. Biotechnol. 11(4), 361–364 (2002)

A. Patras, N.P. Brunton, C. O’Donnell, B.K. Tiwari, Effect of thermal processing on anthocyanin stability in foods; mechanisms and kinetics of degradation. Trends Food Sci Technol 21(1), 3–11 (2010)

L. Ekici, Z. Simsek, I. Ozturk, O. Sagdic, H. Yetim, Effects of temperature, time, and pH on the stability of anthocyanin extracts: prediction of total anthocyanin content using nonlinear models. Food Anal. Methods 7(6), 1328–1336 (2014)

S. Singh, K.K. Gaikwad, J.S. Lee, Anthocyanin—A natural dye for Smart Food Packaging Systems. Korean J. Packag Sci. Technol. 24, 167–180 (2018)

B. Moldovan, L. David, C. Chişbora, C. Cimpoiu, Degradation kinetics of anthocyanins from european cranberrybush (Viburnum opulus L.) fruit extracts. Effects of temperature, pH and storage solvent. Molecules 17(10), 11655–11666 (2012)

T. Fossen, L. Cabrita, O.M. Andersen, Colour and stability of pure anthocyanins influenced by pH including the alkaline region. Food Chem. 63(4), 435–440 (1998)

H.E. Khoo, A. Azlan, S.T. Tang, S.M. Lim, Anthocyanidins and anthocyanins: colored pigments as food, pharmaceutical ingredients, and the potential health benefits. Food Nutr. Res. 61(1), 1361779 (2017)

A. Kırca, M. Özkan, B. Cemeroğlu, Effects of temperature, solid content and pH on the stability of black carrot anthocyanins. Food Chem. 101(1), 212–218 (2007)

K. Torskangerpoll, ØM. Andersen, Colour stability of anthocyanins in aqueous solutions at various pH values. Food Chem. 89(3), 427–440 (2005)

S. Roy, J.-W. Rhim, Anthocyanin food colorant and its application in pH-responsive color change indicator films. Crit Rev Food Sci Nutr. 2020:1–29

K. Saengpanya, W. Nopotha, L. Thiraphattaraphun. Temperature indicator based on paper coated with anthocyanins extracted from red cabbage. In: 8th IUPAC International Conference on Green Chemistry Organized by The Chemical Society of Thailand under the Patronage of Professor Dr. HRH Princess Chulabhorn.; 2018:34

L. Prietto, T.C. Mirapalhete, V.Z. Pinto et al., pH-sensitive films containing anthocyanins extracted from black bean seed coat and red cabbage. LWT 80, 492–500 (2017). doi:https://doi.org/10.1016/j.lwt.2017.03.006

M. Cheng, X. Yan, Y. Cui et al., An eco-friendly film of pH-responsive indicators for smart packaging. J. Food Eng. 321, 110943 (2022). doi:https://doi.org/10.1016/j.jfoodeng.2022.110943

X. Wu, G.R. Beecher, J.M. Holden, D.B. Haytowitz, S.E. Gebhardt, R.L. Prior, Concentrations of anthocyanins in common foods in the United States and estimation of normal consumption. J. Agric. Food Chem. 54(11), 4069–4075 (2006)

N. Ghareaghajlou, S. Hallaj-Nezhadi, Z. Ghasempour, Red cabbage anthocyanins: Stability, extraction, biological activities and applications in food systems. Food Chem. 365, 130482 (2021). doi:https://doi.org/10.1016/j.foodchem.2021.130482

M. Dyrby, N. Westergaard, H. Stapelfeldt, Light and heat sensitivity of red cabbage extract in soft drink model systems. Food Chem. 72(4), 431–437 (2001). doi:https://doi.org/10.1016/S0308-8146(00)00251-X

H. Bergwerf MolView. 2014. molview.org

J. Lee, R. Durst, R. Wrolstad, AOAC official method 2005.02: total monomeric anthocyanin pigment content of fruit juices, beverages, natural colorants, and wines by the pH differential method. Off methods Anal AOAC Int. 2005;2

W.S. Mokrzycki, M. Tatol, Colour difference∆ E-A survey. Mach Graph Vis. 2012;8

D.G. Hyams. CurveExpert Professional. 2020

C.B. Casati, R. Baeza, V. Sanchez, A. Catalano, P. López, M.C. Zamora, Thermal degradation kinetics of monomeric anthocyanins, colour changes and storage effect in elderberry juices. J. Berry Res. 5(1), 29–39 (2015)

Funding

The research described in this article/study was carried out as part of the project GINOP-2.3.3-15-2016-00038, “Further processing of wood and wood products based on green chemistry and technology, through creating modern research infrastructure” in the framework of the Széchenyi2020 Programme. The implementation of this project is supported by the European Union, co-financed by the European Regional Development Fund.

Open access funding provided by University of Sopron.

Author information

Authors and Affiliations

Contributions

Conceptualization: Katalin Halász; Methodology: Katalin Halász, Zsófia Kóczán; Formal analysis and investigation: Katalin Halász, Zsófia Kóczán, Edina Preklet; Writing - original draft preparation: Katalin Halász; Writing - review and editing: Edina Preklet.

Corresponding author

Ethics declarations

Conflict of interest

The authors have no relevant financial or non-financial interests to disclose.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Halász, K., Kóczán, Z. & Joóbné Preklet, E. pH-dependent color response of cellulose-based time-temperature indicators impregnated with red cabbage extract. Food Measure 17, 2555–2565 (2023). https://doi.org/10.1007/s11694-023-01805-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11694-023-01805-y