Abstract

The current study evaluated the structural, physicochemical, and rheological characteristics of flaxseed gum (FSG). Two commercially recognized xanthan gum (XG) and gum Arabic (GA) were used for comparison. FSG showed different monosaccharides composition from GA and XG. The average molecular weight of FSG was observed to be lower than XG and was closer to GA. Bulk and tap density, and oil holding capacity were found significantly higher in FSG as compared to XG and GA while water holding capacity, solubility index, swelling power, and emulsion properties of FSG were closer to GA but lower than XG. Rheological data revealed that FSG exhibited lower viscosity than XG and GA. Viscoelastic properties revealed that loss modulus (G″) was higher than storage modulus (Gʹ) for FSG thus suggesting the viscous behavior. Comparatively, XG exhibited elastic properties and GA showed viscous properties at lower frequency range and elastic properties at a higher frequency. However, Gʹ and G″ modulus values of FSG were lower than XG and GA. Thermal analysis revealed that all FSG samples was thermally stable, and the degradation rate occurred at higher temperature that was closer to XG and GA.

Practical applications

FSG has noteworthy composition and functional properties. The physicochemical and functional properties of polysaccharide gums are substantial for their selection and appropriate utilization in different food products. Thus, a comparative analysis of FSG was performed to determine its characteristics against extensively used commercial gums (GA and XG) that could assist in expanding its utilization in various food formulations on industrial scale.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Gums are hydrocolloids that are highly hydrophilic biopolymers and exist widely in plants, seaweeds, animals, and microorganisms [1, 2]. There is a growing interest in using natural gums in the food and pharmaceutical industries. In the food industries, the use of polysaccharides is related to “clean label” and sustainability due to their biosafety, biocompatibility, and biodegradability than synthetic materials [3,4,5]. Recently, the polysaccharide market has been emerging and their use raised by ~ 17% in the years between 2017 and 2021 and in the first half of 2021, the international market hit $10 billion [3]. Polysaccharide gums extracted from seeds are commonly used as dietary fiber, flavor encapsulator, texture modifier, foaming agent, thickener, stabilizer, and emulsifier [2, 6]. Food products during processing operations are exposed to different thermal treatments including drying, sterilization, pasteurization, evaporation, cooking, and baking, where polysaccharides can be used in those food products enduring high temperatures because of their heat stability [7]. The growing demands for ready-to-serve meals and progressive public awareness about the role of fiber in the diet and low-fat food products have raised the intake of numerous natural gums in food formulations [8, 9].

Flaxseed gum (FSG) is a hetero-polysaccharide obtained from flaxseeds (Linum usitatissimum) and composed of acidic and neutral components [10]. FSG possesses notable functional properties [11] with the potential to be used in the food industry as a thickener, emulsifier, stabilizer, and water-holding agent [6, 12]. The exploitation of gums mainly depends on functional characteristics that are markedly related to chemical composition, monosaccharide configuration, and on their bioactive role associated with certain health benefits [13]. FSG has nutritional value as a dietary fiber, which may help in curing certain diseases such as diabetes, colorectal cancers, risk of coronary heart disease, and controlling obesity [14].

Xanthan gum (XG) and gum Arabic (GA) were selected in this study for comparison with FSG since both are well recognized as commercial gums worldwide, having numerous food applications on industrial scale. Wherein, XG is an extracellular hetero-polysaccharide produced by Xanthomonas species and extensively used in various foods due to its good emulsion properties, temperature stability, and food ingredients compatibility [15]. Whereas, GA is a biopolymer isolated from mature trees of Acacia species as exudates and widely used as an emulsifier, thickening agent, and stabilizer in the food industry [16]. Additionally, the functional properties of FSG were reported to closely resemble gum Arabic [17]. FSG has not been extensively used on industrial scale [12]. Thus, the characteristics of FSG were compared with widely used commercial gums (i.e. XG and GA) that may broader its application in the diet or food products.

The current study aimed to evaluate the monosaccharide composition by HPLC (high-performance liquid chromatography), molecular weight by HPGPC (high-performance gel permeation chromatography), functional, physicochemical, rheological, and thermal properties by DSC (differential scanning calorimetry) of FSG. GA and XG were used as a comparison.

Materials and methods

Flaxseeds were purchased from Beijing supermarket and extracted by the hot water extraction method as described previously [18]. XG and GA were purchased from Azelis (Shanghai) Co., Ltd. PMP 1-phenyl-3-methyl-5-pyrazolone was purchased from Machlin (Shanghai Macklin biochemical co. Ltd). Trichloroacetic acid (TCA), monosaccharide standards (xylose, arabinose, glucose, galactose, mannose, fucose, rhamnose, galacturonic acid, and glucuronic acid) and dextran standards were purchased from Sigma-Aldrich (USA). All other chemicals used were of analytical grade.

Monosaccharide composition analysis

The monosaccharide composition of FSG was investigated as proposed by Dai et al. [19]. XG and GA were used as a comparison. Briefly, before HPLC analysis gum samples were hydrolyzed into monosaccharides by 4 M trifluoroacetic acid (TFA) under a nitrogen atmosphere at 110 °C, for 2 h followed by 1-Phenyl-3-methyl-5-pyrazolone (PMP) derivatization. Then PMP-monosaccharide derivatives were subjected to HPLC system (Agilent 1260, USA) equipped with a capillary column of Xtimate C18 (5 μm, 4.6*200 mm). The mobile phase was 0.1 M phosphate buffer (pH 6.7) and acetonitrile in a ratio of 83:17 (v/v, %) at a flow rate of 1 ml min−1. The sample injection volume was 20 µl and UV absorbance was monitored at 250 nm. The monosaccharide identification was processed by comparing them with the standard monosaccharide reagents (rhamnose, glucose, galactose, xylose, arabinose, fucose, mannose, ribose, glucuronic and galacturonic acid).

Molecular weight distribution (MWD) analysis

MWD of FSG (including weight average molecular weight, z-average molecular weight, viscosity average molecular weight, number average molecular weight, and polydispersity) was determined in accordance with Wu et al. [20], using High-performance gel permeation chromatography (HPGPC) (Shimadzu, Japan). XG and GA were evaluated for comparison. The chromatographic experiments were conducted using a TSK-GEL-GMPWXL aqueous gel column (30 cm × 7.8 mm) (Tosoh, Tokyo, Japan). A standard curve was acquired using various dextran standards (T-10 to T-1000).

Rheology

Rheological measurements of FSG solutions were carried out using a rheometer (ARES, TA Instruments, New Castle, DE, USA), using cone plate geometry (40 mm, 2.0°). The linear viscoelastic region (LVR) was determined for each sample through strain sweeps at 1 Hz (data not shown) and Viscoelastic properties of FSG solutions were carried out within the linear viscoelastic region. Flow curves (shear rate versus shear stress and shear rate versus apparent viscosity) of FSG in comparison with XG and GA were measured as depicted by Qian et al. [10] at shear rates ranging from 0.01 to 100 s−1 (25 °C, 1000 μm gap). The experimental data (shear stress–shear rate) were fitted according to the Power Law (Eq. 1) and Herschel–Bulkley (Eq. 2) models.

where τ = shear stress (Pa), K = consistency index (Pa Sn), \(\dot{ {\upgamma } }\) = shear rate (S−1), n = flow behavior index (dimensionless) and σ0 = yield stress.

The shear flow curves attained in the measurements of apparent viscosity were examined using the following Carreau Eq. 10 [21].

where \({\eta }_{a }\) = apparent viscosity (Pa s) at any shear rate, \({\eta }_{\infty }\) = infinite shear rate viscosity, \({\eta }_{0}\) = zero-shear rate viscosity, \({\lambda }_{c }\) = time constant (s), \(\dot{\gamma }\) = shear rate and N = dimensionless constant.

Furthermore, the viscoelastic behavior of FSG in comparison with XG and GA was examined following Kaur et al. [22] over the angular frequency range of 0.01–10 rad s−1 (25 °C, 1000 μm gap).

Micrometric properties

The bulk density (BD) and tap density (TD) of FSG were determined in accordance with Haseeb et al. [23] and compared with XG and GA. Briefly, BD was determined by taking 1.5 g of each gum powder in a 10 ml graduated cylinder, and occupied volume by all the samples was noted. TD was measured after 100 tapings of 1.5 g of sample in a 10 ml graduated cylinder and the volume was recorded. BD and TD were calculated as follows:

where Wp = weight of gum powder, Vb = bulk volume, Vt = Tapped volume.

Whereas Compressibility or Carr’s index (CI) and Hausner ratio (HR) were measured from the obtained values of BD and TD by the following formula:

The angle of repose (AR) of FSG, XG, and GA were measured by using the funnel fixed method in accordance with Bagchi and Kumar [24] and calculated by following Eq.

where h = height, r = radius of the formed pile.

The pH of 1.0% solution of gums was measured by using a digital pH meter (Mettler Toledo).

Hydration properties

The water holding capacity (WHC) and oil holding capacity (OHC) of gum samples were evaluated as reported by Kaur et al. [22] with some modifications. Briefly, for WHC, 0.5 g of all samples were dispersed in 50 ml of distilled water. The resultant solutions were stirred for 10 s every 15 min for 1 h at ambient temperature. For OHC, 0.5 g of each gum powder and 10 ml of soybean oil were stirred for 1 h. Then, both water and oil mixtures were centrifuged at 10,000 rpm for 20 min. The supernatant was removed, and the precipitate was weighed. The results were presented as the amount of water or oil (g) held per gram of the sample. Swelling power (SP) and solubility index (SI) of gums were analyzed by using the method proposed by Kaewmanee et al. [12] with slight changes. Briefly, 25 mg of each gum sample was mixed with 2 ml of distilled water in a centrifuge tube, shaken for 10 min followed by centrifugation for 15 min at 3000 rpm. The supernatant was dried in an oven at 105 °C to constant weight. Then the dried supernatant and precipitated paste were weighed. The SP and SI were calculated using the following formula and expressed as g g−1 and g/100 g of gum samples, respectively.

where Wpp, W0, and Wds are the weight of precipitate paste, sample, and dried supernatant, respectively.

Emulsion properties

The oil-in-water emulsions of gum samples were prepared by blending soybean oil in the water phase containing 0.5% gum (w v−1), followed by homogenization (10,000 rpm, 2 min). Emulsion properties as a function of time (after 1, 6, 12, 24, 48, and 168 h) were determined as reported by Slima et al. [25] and expressed in percentage (%). Particle size (Z-average) and zeta potential (ZP) of diluted emulsions were observed through laser light scattering Zeta sizer (ZS-90, Malvern Instruments, UK) as described by Tirgar et al. [26]. The influence of temperature (40 °C, 60 °C, 80 °C, and 100 °C) and autoclaving (100 °C and 121 °C) on gum emulsions were also investigated.

Zeta potential measurement

The zeta-potential (ZP) of 0.1% gum solutions (in distilled water) was measured through Zeta sizer (ZS-90, Malvern Instruments, Worcestershire, UK) following Kaushik et al. [27]. ZP as a function of pH (2.0 to 9.0) was also measured. The pH of the solutions was adjusted by 1 M NaOH and 1 M HCl solutions. The particle size of all the gums (0.05% solution in water) was also quantified using the same instrument.

Differential scanning calorimetric (DSC) analysis

Thermal behavior was examined as described by Kaur et al. [22] by using a differential scanning calorimeter (Shimadzu, TA-60 WS) from 30 to 400 °C with 10 °C min−1 rate. The nitrogen flow rate was 50 ml min−1.

Statistical analysis

All analysis was performed in triplicates. All results were analyzed by using analysis of variance (ANOVA) and Tukey’s test at 5% probability using Origin Pro 9.2. Results were considered significant at p < 0.05.

Results and discussion

Monosaccharide composition

The separation of PMP-monosaccharide derivatives of FSG was evaluated by HPLC and compared with XG and GA. As shown in Table 1, the monosaccharide composition of FSG was significantly different from XG and GA. Based on the monosaccharide composition of FSG, rhamnose (204.23 mg g−1), glucose (180.47 mg g−1), galactose (174.5 mg g−1), xylose (133.6 mg g−1), arabinose (113.82 mg g−1), galacturonic acid (93.79 mg g−1) and fucose (68.7 mg g−1) appeared as major sugars. Other sugar components, such as mannose, ribose, and glucuronic acid were also detected in trace amounts. In contrast, the monosaccharide composition of XG was found to be mannose (321.04 mg g−1), glucose (431.91 mg g−1), and glucuronic acid (238.31 mg g−1). Whereas, GA was composed of galactose (393 mg g−1), arabinose (180.55 mg g−1), rhamnose (82.03 mg g−1) and glucuronic acid (156.76 mg g−1). Results showed that FSG is a heteropolysaccharide containing acidic and neutral monosaccharides. The compositional dissimilarity in FSG from XG and GA is accountable for presenting different thermal and functional properties [16].

Molecular weight distribution

Molecular weight distribution has a strong impact on the functional properties of polysaccharide gums [8]. The molecular weight distribution including average molecular weight (Mw), number average molecular weight (Mn), Z-average molecular weight (Mz), viscosity average molecular mass (Mη), and polydispersity index (Mw/Mn) of FSG was evaluated in comparison with XG and GA and is tabulated in Table 2. The results showed that the molecular weight distribution of FSG varied from XG and GA. Mw of FSG (1.33 × 106 g mol−1) was found lower than XG (5.98 × 106 g mol−1) and higher than GA (1.05 × 106 g mol−1). Obtained values of Mn and Mz for FSG, GA and XG were 7.81 × 105 and 1.87 × 106 g mol−1, 1.37 × 105 and 2.33 × 106 g mol−1 and 3.24 × 106 and 8.28 × 106 g mol−1, respectively. Furthermore, Mη value of FSG (1.24 × 106 g mol−1) was found lower than XG (8.28 × 106 g mol−1) and GA (8.76 × 106 g mol−1). FSG was found relatively heteromolecular with a polydispersity value of 1.70 was closer to XG (1.85), while GA achieved a comparatively higher value (7.67) that represents a wider distribution of different size molecules [28].

Rheology

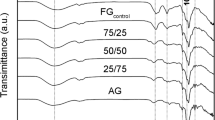

Investigation of the rheological properties is essential for the application of polysaccharide gums as a food additive, mainly in food preparation which involves certain rheological properties, for instance as stabilizer and thickener [29]. Therefore, rheological behavior including flow and viscoelastic properties of FSG were investigated and compared with XG and GA. Flow curves of FSG in comparison with XG and GA are presented in Fig. 1. As seen in the curves, shear stress was increased by increasing shear rate and was found lower in FSG compared to XG and GA (Fig. 1a). The plot of FSG showed weak dependency on shear rate. Comparatively, the same trend was observed in XG with relatively higher values. While GA gradually increased with increasing shear rate, and shear stress values were higher than FSG. The flow curves in terms of shear stress versus shear rate were fitted to Power Law and Herschel–Bulkley models (Table 3). For Power law, the n value of FSG was relatively lower than XG (0.194) and GA (0.394). n value lower than unity demonstrates the non-Newtonian pseudoplastic fluid behavior. K value of FSG was observed to be 0.147 Pa Sn which was comparatively lower than XG (5.507 Pa Sn) and GA (8.621 Pa Sn). The K value represents the viscosity whereas and n value reveals the shear-shinning characteristics of the materials [30]. Lower K and higher n value of FSG solution represents the low viscosity and higher shear-thinning behavior, respectively compared to XG and GA. Furthermore, the yield stress, Consistency coefficient (K) and flow behavior index (n) values of the Herschel–Bulkley model FSG, XG and GA are tabulated in Table 3. The R2 was 0.99 for FSG and GA while 0.95 for XG reflecting the suitability of the Herschel–Bulkley model for gum solutions. As indicated in the results, the yield stress of FSG was 0.068 Pa which was relatively higher than XG (− 7695 Pa) and GA. K value of FSG was found to be 0.129 Pa Sn was comparatively lower than XG (7695 Pa Sn) and GA (18.57 Pa Sn). “n” value of FSG (0.759) was higher than GA (0.276) and lower than XG (0.976). The n value of FSG and GA was observed to be lower than unity, indicating shear thinning behavior. Figure 1b demonstrates the variation in apparent viscosity versus the shear rate of FSG in comparison with XG and GA. 1% FSG solutions showed non-Newtonian pseudoplastic behavior where apparent viscosity decreased with increasing shear rate. In comparison with FSG, XG and GA showed the same viscosity decreasing trend. However, apparent viscosity of FSG was found to be lower than that of GA and XG over the whole tested shear rate range. The shear-thinning properties attributed to the alteration in molecular network that leads to the polysaccharide chains alignment in the shear direction and the interruption of molecular entanglements when shear applied. Difference in shear properties is mainly dependent on the molecular weight and the capability of water molecules coalescence [30, 31]. Qian et al. [10] also reported the low viscosity of flaxseed gum that is favored in the fortification of dietary fiber without leading to over-texturization of food products, when a considerable amount of fiber is needed to show certain health benefits. The apparent viscosity curve data were fitted to the Carreau model and the resulting parameters are presented in Table 4. The predicted R2 (correlation coefficients) using the Carreau model was found to be > 0.99 for all gum samples, demonstrating that it was a good fit to the obtained data from the apparent viscosity curve. As results indicated that FSG exhibited lower η0 value (0.0568 Pa s) than GA (61.0319 Pa s) and XG (61.031 Pa s) while FSG was higher in negative value of ηꝏ (− 0.041 Pa s) than XG (− 0.039 Pa s) and lower than GA (− 0.0865 Pa s). λc was found to be 3.528s in FSG which was lower than XG (6.089 s) and higher than GA (1.539 s). A lower λc value indicates that little time is required for the formation of new interactions between polymer molecules [32]. As λc is related to the breakdown of fluid–structure linkages that represents the onset of shear thinning behavior. Wherein, a higher λc value specifies the pseudoplastic behavior onset at low shear rate range [6]. The N value of FSG (0.915) was higher than GA (0.320) and XG (0.296). The pseudoplastic behavior is associated with the N value i.e., 0 < N < 1. Where N = 0 indicates a Newtonian fluid. The shear-thinning rises with increasing N value from 0 to unity [33].

Viscoelastic properties of 1% FSG solution in comparison with XG and GA were measured in the linear viscoelastic range. Figure 1c represents the variation in Gʹ and G″ as a function of angular frequency. FSG revealed the viscous behavior as G″ was higher than Gʹ. However, both moduli remained steady with increasing frequency. In comparison, the Gʹ of XG was greater than G″, indicating elastic properties (solid-like behavior) of XG solution and for GA, G″ was higher than Gʹ at a low-frequency range, then cross-over occurred at a higher frequency range and Gʹ became higher than G″ which revealed viscous properties at lower frequency range and elastic properties at a higher frequency. However, Gʹ and G″ values of FSG were lower than XG and GA. Consequently, the viscoelastic properties of FSG are nearly similar to GA at a lower frequency range but different than XG.

Micrometrics properties

Micrometrics is the science of small particles. The size and surface area of a particle can be related to its physical and chemical properties [34]. These properties are also accountable for the quality of compounds and may influence their functionality [35]. As shown in Table 5, the micrometric properties of FSG were found to be different from XG and GA. Bulk density (BD) is a function of particle size and packing proportion, which represents the volume occupied by the gum particles. It indicates the storage or packaging capacity that may assist in the transportion. While, tapped density (TD) is the maximum compaction that can be endured under the action of external forces [35, 36]. The BD and TD values were found maximum in FSG (0.701 and 1.016 g ml−1) and significantly different from XG (0.6887 and 0.986 g ml−1) and GA (0.622 and 0.943 g ml−1). This difference may refer to the particle size and swelling capacity of gums. As the water rises by capillary action through pores and activates the disintegrant to bring about collapse [37]. Hausner ratio (HR) and Carr’s index (CI) were acquired from BD and TD. The HR represents the flowability of gums, wherein 1.0–1.25, 1.25–1.4, and > 1.4 illustrates the free, fairly, cohesive, and poor flowing capability of powders, respectively [16]. The flow property of powder is obligatory to be considered for the industrial application of excipients [38]. The HR value was found significantly higher in GA (1.516) followed by FSG (1.449) and XG (1.433). Whereas, there was no significant difference among all gums in terms of CI i.e. 31, 33, and 30 for FSG, GA, and XG, respectively, demonstrating all the gums have fairly good compressibility and flow properties [38]. The angle of repose (AR) is indicative of the resistance of gums provided by frictional forces, caused by the surface properties of particles [39]. AR of GA (34°) and XG (33°) was observed to be greater, than FSG (30°), presenting more cohesive properties. As the powders with higher AR values are more cohesive and are reported to be non-cohesive with lower AR values [37]. Moreover, the particle size of a powder is always accompanied by a decrease in cohesiveness. Wherein, powders change their state from cohesive to more free-flowing with the increase of particle size [40]. FSG appeared with a higher particle size (1795 nm) whereas particle size obtained from XG, and GA was 855.5 and 607.4 nm, respectively. pH determination of gums is important because formulation and stability of food products largely depends on the pH of the gum or other ingredients. The pH of 1.0% aqueous solutions of FSG, GA, and XG was found as 4.52, 4.66, and 5.46, respectively, indicating the acidic nature of gums (Table 5).

Hydration properties

The functional properties of polysaccharide gums are important in determining their suitable applications in different food products. The functional properties of FSG were found comparatively different from GA and XG. According to the obtained results, the WHC value of FSG was 13.01 g g−1 that was closer to GA (13.45 g g−1) and relatively lesser than XG (15.29 g g−1) (Fig. 2a). Rapid dissolution of gum in water is might be responsible for lower WHC [16]. Moreover, gum source, particle size, and molecular structure also influence the WHC [25]. Furthermore, the OHC of FSG was a little lower (1.42 g g−1) than GA (1.56 g g−1) and XG (1.89 g g−1) (Fig. 2a). WHC and OHC mostly rely on the protein and carbohydrate contents of gum. OHC is a prominent factor for various food applications that induce better flavor withholding, consistency attributes, and improved mouth feels [5]. This difference may be ascribed to the presence of non-polar molecules (lipophilic in nature) of gums that are responsible for binding oil droplets [41]. The type and number of hydrophobic fractions existing in the food material composition determine its degree of oil absorption [39]. Furthermore, the SP value of FSG was observed as 20.87 g g−1 with varied values of GA (25.11 g g−1) and XG (19.93 g g−1) (Fig. 2c). Additionally, the SI value of FSG was 27.92 g g−1 that was closer to GA (28.16 g g−1) and lower than XG (33.91 g g−1) (Fig. 1c). Solubility might be affected by the particle size and cohesive properties of gums, describes the proportional correlation between SP and SI. SI and SP are important in terms of food applications and are associated with soluble molecules that exist in the gum [15, 25].

Emulsion properties

The particle size (Z-Average) of the emulsions prepared by FSG was evaluated in comparison with GA and XG (Table 6). It was noted that the particle size of FSG (20,453 nm) was not significantly different from GA (21,640 nm) and XG (21,630 nm). Particle size of emulsion is dependent on the amount of gum adsorbed onto the oil droplets [42]. The emulsion stability of FSG emulsion was also examined as a function of time and compared with GA and XG (Fig. 3a). The results indicated that FSG exhibited emulsion stability (ES) value up to 50.89%. Whereas ES values for GA and XG were noted to be 55% and 70.9% after 1 h, respectively. The ES showed a significant decline in all emulsion samples from 1 to 168 h. Change in ES values of all gums was attributed to the viscosity of gums that can control or avoid creaming of emulsions with the passage of time [27]. Protein contents also play an important role in the emulsification properties because of their amphiphilic nature (i.e., containing both hydrophilic and hydrophobic groups) and as such are able to adsorb strongly at the oil-water interface. The adsorbed protein molecules can stabilize emulsions by inhibiting droplet aggregation and coalescence through electrostatic or steric repulsive forces [43]. Thus, the mechanism behind the increase in emulsion properties with higher protein contents is linked to the electrostatic interface between charged groups of polysaccharides and protein. In addition, hydrophobic compounds and particle size in an emulsion reduce the interfacial tension of water and oil droplets [44]. Besides, arabinose and galactose content present in the side chains may contribute in emulsion properties [25].

Additionally, ZP of gum emulsions as a function of temperature (40 °C, 60 °C, 80 °C, and 100 °C) and autoclaving (at 100 °C and 121 °C) is presented in Fig. 3b. ZP of untreated emulsion samples of FSG was observed to be − 20.5. While ZP values of GA and XG emulsions were noted as − 41.2 and − 29.9 mV, respectively. A temperature-dependent manner was found for all gum emulsions. ZP of FSG emulsions was increased from − 23.9 to − 29 mV up to 60 °C. Then decreased and remained stable (− 25.1 to − 25.5 mV) at 80 °C and 90 °C. Similarly, the ZP of XG emulsions was also increased (− 36.1 to − 40 mV) from 40 to 60 °C and then found − 37.8 to − 39.9 mV at 80 °C and 100 °C. In the case of GA emulsion, ZP was decreased (− 34.3 to − 26.3 mV) at 40 °C and 60 °C, and at 80 °C and 100 °C it was noted as − 30.6 to − 35 mV. Moreover, emulsion samples autoclaved at 100 and 121 °C had the same ZP values for FSG (− 28.9 to − 28.8) in comparison with GA (− 30 to − 39.3mV) and XG (− 39.1 to − 36.4mV). It might be occurred due to the heat-induced unfolding of gum molecules incorporated into the oil in water association [6].

Zeta potential and particle size measurements

Zeta potential (ZP) is the measure of the strength of attractive and repulsive forces that lies among large particles or molecules that are responsible for the stability of the solution. The greater ZP value whether positive or negative, indicate the greater stability of the solution system [45]. ZP of FSG (0.1% aqueous solution) was observed as − 34.9 which was found comparatively lower than GA (− 40.7 mV) and XG (− 49.5 mV) (Table 6). Generally, the threshold between stable and unstable suspensions is taken at either + 30 or − 30 mV. If the solution has a large negative or positive ZP, they tend to repel each other and no tendency for the aggregation of particles can be observed. However, if the particles have a low zeta potential value, aggregation and flocculation are favored [44]. ZP values are the expression of structural charge densities, this discrepancy might be due to several factors that could affect the electrical characteristics of mucilage samples. The method of extraction, the sugar & protein, and the pH value could interfere, hence inducing variations in Z-potential values [12, 17].

Furthermore, the ZP of FSG solution was evaluated as a function of pH 2.0–9.0 and compared with GA and XG solutions (Fig. 4). All gum samples showed a negative value at all pH ranges. The negative values specify that the dispersed particles in the solution are negatively charged. It is noted from the results that ZP values were increasing with the rise of pH. At the pH 2.0, the ZP value of FSG was observed to be lowest i.e., − 1.51 which was closer to GA (− 1.8) and lower than XG (− 15.2 mV). The maximum ZP value was found at pH 9.0 for FSG (− 49.7 mV) that was relatively lower than XG (− 51.5 mV) and higher than GA (− 41.2 mV). ZP of FSG solution raised rapidly from − 12.61 to − 36.3 mV at pH range of 2.0 to 5.0, and steadily increased from − 37.8 to − 39.0 mV at pH 6.0–9.0 range. Hence indicating the stability of FSG in basic solutions. Comparatively, similar behavior was observed for GA and XG from pH 2.0 to 9.0. Negative ZP values of gums whether in the acidic or basic solutions is an indication of acidic polysaccharide conjugates. The protein present in gum exhibits isoelectric point (PI) because of its acid and base ionization [45]. Increasing values of ZP might be related to the rise in the molecule chain size of the gum [27]. Additionally, Kaewmanee et al. [12] stated that neutral or acidic sugar contents of gum might influence ZP i.e. ZP of a gum solution increase when the negative surface charge raised with higher pH. Moreover, the structural charge densities, carbohydrate and protein contents, electrolytes of solution, and pH might interfere with polysaccharide solution electrical characteristics [11, 43].

Differential scanning calorimetry (DSC) analysis

DSC has been widely used to observe the response of polymer and the occurrence of exothermal or endothermal changes on heating at increasing temperatures because of its sensitivity and accuracy [37, 45]. The obtained data indicated that heating from 30 to 400 °C at a rate of 10 °C min−1 resulted in two mass loss events for FSG that was somehow similar in behavior to GA and XG [46]. Figure 5; Table 7 summarize the data of thermal behavior including peak temperature (Tp), onset temperature (To), endset temperature (Te), and heat enthalpy (ΔH) of gum samples. Two endothermic peaks occurred at 81.28 °C and 270.80 °C for FSG. Whereas, for GA and XG, endothermic peaks were observed at 81.60 °C and 306.48 °C and 83.25 °C and 282.88 °C respectively. The endothermic peaks found around 100 °C were associated with loss of water (free or bound) on heating or due to changes in molecular state. Peak (demonstrating the decomposition or oxidation onset) at 270 °C to 306 °C proposed that gums have good thermal stability. Moreover, the moisture and to some extent the particle size of gum led to the endotherm event which is associated with variation in the physiological state [15, 16]. Structural features and functional groups difference among the gums may affect the thermal behavior and the transition temperature [47].

Conclusion

The current study was conducted to analyze the nature of FSG, and its characteristics were compared with commercial gums (GA and XG) in order to stipulate its use in the food system. It was observed that there were significant differences among the gums in terms of chemical composition, physicochemical and rheological properties. FSG presented significant functional properties that were much closer to GA and comparable with XG. However, 1% FSG solution presented different viscous properties and observed more shear thinning with lower viscosity compared to XG and GA. The obtained results revealed that FSG can be considered as a suitable choice for food applications that might replace commercial gums.

References

H. Mirhosseini, B.T. Amid, Food Res. Int 46, 387 (2012)

H.D. Goff, Q. Guo, Food Chem. Funct. Anal. pp. 3–28 (2020)

M.A. de Souza, I.T. Vilas-Boas, J.M. Leite-da-Silva, P.N. Abrahão, B.E. Teixeira-Costa, V.F. Veiga-Junior, Polysaccharides 3, 95 (2022)

R. Elboutachfaiti, C. Delattre, A. Quéro, R. Roulard, J. Duchêne, F. Mesnard, E. Petit, Food Hydrocoll. 62, 273 (2017)

G.A. Nevara, S.K. Syed Muhammad, N. Zawawi, N.A. Mustapha, R. Karim, Int. J. Food Sci. Technol. 57, 258 (2022)

Q. Guo, X. Zhu, W. Zhen, Z. Li, J. Kang, X. Sun, S. Wang, S.W. Cui, Food Hydrocoll. 112, 106289 (2021)

S. Naji, S.M.A. Razavi, H. Karazhiyan, Food Hydrocoll. 28, 75 (2012)

M. Hamidabadi Sherahi, M. Fathi, F. Zhandari, S.M.B. Hashemi, A. Rashidi, Food Hydrocoll. 66, 82 (2017)

S. Karaman, Y. Kesler, M. Goksel, M. Dogan, A. Kayacier, Int. J. Food Prop. 17, 1655 (2014)

K.Y. Qian, S.W. Cui, Y. Wu, H.D. Goff, Food Hydrocoll. 28, 275 (2012)

J. Liu, Y.Y. Shim, J. Shen, Y. Wang, S. Ghosh, M.J.T. Reaney, Int. J. Food Sci. Technol. 51, 2313 (2016)

T. Kaewmanee, L. Bagnasco, S. Benjakul, S. Lanteri, C.F. Morelli, G. Speranza, M.E. Cosulich, Food Chem. 148, 60 (2014)

P. Puligundla, S. Lim, Foods 11, 1677 (2022)

J.M. Vieira, C.C.P. Andrade, T.P. Santos, P.K. Okuro, S.T. Garcia, M.I. Rodrigues, A.A. Vicente, R.L. Cunha, Food Hydrocoll. 111, 106257 (2021)

M. Pilevaran, H. Tavakolipour, S. Naji-Tabasi, A.H. Elhamirad, J. Sol-Gel Sci. Technol 98, 76 (2021)

P.R. Bhushette, U.S. Annapure, Int. J. Biol. Macromol 102, 266 (2017)

Y. Wang, D. Li, L.J. Wang, S.J. Li, B. Adhikari, Carbohydr. Polym 81, 128 (2010)

B. Safdar, Z. Pang, X. Liu, M.A. Jatoi, M.T. Rashid, Int. J. Food Sci. Technol 55, 2481 (2020)

J. Dai, Y. Wu, S.W. Chen, S. Zhu, H.P. Yin, M. Wang, J. Tang, Carbohydr. Polym 82, 629 (2010)

F. Wu, C. Zhou, D. Zhou, S. Ou, H. Huang, J. Funct. Foods 37, 574 (2017)

P.J. Carreau, Trans. Soc. Rheol. 16, 99 (1972)

M. Kaur, R. Kaur, S. Punia, Int. J. Biol. Macromol. 117, 919 (2018)

M.T. Haseeb, M.A. Hussain, S.H. Yuk, S. Bashir, M. Nauman, Carbohydr. Polym. 136, 750 (2016)

S. Bagchi, K. Jayaram Kumar, Carbohydr. Polym. 138, 88 (2016)

S. Ben Slima, N. Ktari, I. Trabelsi, H. Moussa, I. Makni, R. Ben, Salah, Int. J. Biol. Macromol 106, 168 (2018)

M. Tirgar, P. Silcock, A. Carne, E.J. Birch, Food Chem 215, 417 (2017)

P. Kaushik, K. Dowling, R. Adhikari, C.J. Barrow, B. Adhikari, Food Chem 215, 333 (2017)

Y. Yuan, D. Macquarrie, Carbohydr. Polym 129, 101 (2015)

M.I. Capitani, L.J. Corzo-Rios, L.A. Chel-Guerrero, D.A. Betancur-Ancona, S.M. Nolasco, M.C. Tomás, J. Food Eng 149, 70 (2015)

Q. Miao, H. Jiang, L. Gao, Y. Cheng, J. Xu, X. Fu, X. Gao, Am. J. Anal. Chem 09, 210 (2018)

A.I. Bourbon, A.C. Pinheiro, C. Ribeiro, C. Miranda, J.M. Maia, J.A. Teixeira, A.A. Vicente, Food Hydrocoll 24, 184 (2010)

M. Cruz, F. Freitas, C.A.V. Torres, M.A.M. Reis, V.D. Alves, Int. J. Biol. Macromol 48, 695 (2011)

M. Anvari, M. Tabarsa, R. Cao, S. You, H.S. Joyner Melito, S. Behnam, M. Rezaei, Food Hydrocoll 52, 766 (2016)

P.K. Samal, J.S. Dangi, Carbohydr. Polym 102, 1 (2014)

H. Mirhosseini, B.T. Amid, Food Res. Int 52, 429 (2013)

G.K. Sandhu, S. Simsek, F.A. Manthey, J. Food Process. Eng 38, 426 (2015)

M. Emeje, C. Isimi, S. Byrn, J. Fortunak, O. Kunle, S. Ofoefule, Iran. J Pharm Res IJPR 10, 237 (2011)

C. Malsawmtluangi, K. Thanzami, H. Lalhlenmawia, V. Selvan, S. Palanisamy, R. Kandasamy, L. Pachuau, Int. J. Biol. Macromol 69, 192 (2014)

M. Bashir, S. Haripriya, Int. J. Biol. Macromol 93, 476 (2016)

D. Geldart, E.C. Abdullah, A. Hassanpour, L.C. Nwoke, I. Wouters, China Particuol. 4, 104 (2006)

F. Rashid, S. Hussain, Z. Ahmed, Carbohydr. Polym. 180, 88 (2018)

I. Gashua, P. Williams, Food Hydrocoll. 61, 514 (2016)

J. Liu, H.L. Pedersen, L. Knarreborg, R. Ipsen, W.L.P. Bredie, Food Sci. Nutr. 8, 6433 (2020)

Z. Ren, X. Li, F. Ma, Y. Zhang, W. Hu, M.Z.H. Khan, X. Liu, LWT 162, 113468 (2022)

G. Chen, F. Bu, X. Chen, C. Li, S. Wang, J. Kan, Int. J. Biol. Macromol. 112, 656 (2018)

S. Hadad, S.A.H. Goli, Int. J. Biol. Macromol. 114, 408 (2018)

D. Suvakanta, M.P. Narsimha, D. Pulak, C. Joshabir, D. Biswajit, Food Chem. 149, 76 (2014)

Acknowledgements

The authors wish to express their deep gratitude and appreciation for the support obtained from the National Key R&D program of China (Grant No. 2016YFD0400401).

Author information

Authors and Affiliations

Contributions

BS carried out experiments and wrote manuscript. ZP provide critical comments on draft of manuscript and supervision. XL supervised the project. MTR and MAJ revised the manuscript.

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare no conflicts of interest.

Research involving human and animal rights

This article does not contain any study related to human or animal subjects.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Safdar, B., Pang, Z., Liu, X. et al. Structural characterization, physicochemical and rheological characteristics of flaxseed gum in comparison with gum Arabic and xanthan gum. Food Measure 17, 2193–2203 (2023). https://doi.org/10.1007/s11694-022-01750-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11694-022-01750-2