Abstract

The Alkemade theorem goes back to a very fundamental paper on the graphical description of thermodynamic equilibrium problems from 1893 (van Rijn van Alkemade in Z Phys Chem 11: 289-327, 1893). It is one of the most helpful implements for the construction of the liquidus surface of ternary phase diagrams. In its original form, it allows to find the direction of falling or increasing temperature along the monovariant reaction lines forming the boundaries of the primary crystallization fields. The theorem is valid for systems with any number of phases; however, its geometrical construction rule is only defined for the case of stoichiometric phases and it is not clear how to apply the theorem in the case of phases with extended homogeneity ranges. Some examples from a ternary, transition-metal-based system containing phases with large homogeneity ranges are presented, and the usefulness and limits of applicability of the theorem are discussed.

Similar content being viewed by others

1 Introduction

The design of novel materials requires the knowledge of the amount and composition of coexisting phases, which is information that can be obtained from phase diagrams. However, this information is not sufficient to predict the properties of the material. A factor that is essential to the behavior of the material–especially in the case of alloys for structural applications–is the microstructure resulting from the production process. In most cases, such kind of materials are produced by solidification from the liquid state (e.g., by casting or additive manufacturing), because usually (ignoring the rare cases of coexistence of two or more immiscible liquid phases) all components can be mixed to form a homogeneous (liquid) phase. The corresponding solidification path then is the most important factor that determines how the microstructure of the material will look. This information is available from the phase diagram of the corresponding alloy system, where the relevant part is the boundary separating the liquid phase from the region containing solid phase(s). For the following discussion we will focus on the ternary case, where this boundary is the liquidus surface of the system. This liquidus surface is a three-dimensional surface that usually is shown as a projection on the composition triangle. It is divided by a number of lines into different fields each of which indicates the composition range of primary crystallization of a particular phase. The lines emanating from the invariant reactions in the binary boundary systems and separating the primary crystallization fields correspond to the monovariant equilibria between the phases of the two adjacent primary crystallization fields and the liquid. The traces of the composition of the liquid in these monovariant equilibria will be called boundary lines, and the particular points where three such boundary lines meet mark the invariant reactions of the ternary system. Experimentally, the determination of the primary phases often can be easily done from the as-solidified microstructure, from which the position of the monovariant boundary lines can be fixed. A crucial piece of information to then infer the course of the solidification path is the temperature change along the boundary lines, where the temperature can both increase and decrease. This is usually very difficult to determine experimentally. A great help can be the so-called Alkemade theorem.

After introducing this Alkemade theorem in its original form in the following section, the shortcomings of the theorem in the case of phases with extended homogeneity ranges are explained in the third section and demonstrated in the subsequent section using the example of a real, thermodynamically well-described ternary system. In the final discussion section, an attempt is made to show to what extent the theorem still allows conclusions to be drawn about the liquidus surface and the solidification path even in the case of phases with extended homogeneity ranges. It should be noted here that it is in no way the aim of this article to replace the existing computational tools such as the Calphad method. Rather, the purpose is to discuss the theorem as such and its validity and usefulness in establishing reliable experimental liquidus surfaces of ternary systems.

2 The Alkemade Theorem

In 1876 and 1878, J. Willard Gibbs published his seminal two-part work “On the Equilibrium of Heterogeneous Substances”.[1] This treatise, in which he described his ideas on the geometric representation of thermodynamic quantities, forms the basis for the description of phase equilibria by phase diagrams. Motivated by Gibbs’ work, A. C. van Rijn van Alkemade, a teacher at the higher civil school in Apeldoorn in the Netherlands, published an extensive discussion about equilibria of salt solutions with solid phases (originally written in Dutch,[2] and soon thereafter also published in a German version).[3] The paper contained a finding that was cited a few years later by Wilder D. Bancroft in his book “The Phase Rule”[4] in a formulation still used today as the ‘Alkemade theorem’. Let us assume a ternary system with any number of stoichiometric phases. Then the theorem states that the point of intersection of a straight line on the liquidus surface projection connecting the compositions of any two phases (the so-called Alkemade line) with the boundary line (or its extension) between the primary crystallization fields of these two phases corresponds to a temperature maximum on this boundary line. This means that along the boundary line of two primary crystallization fields, the direction of decreasing temperature is always away from the Alkemade line of the corresponding phases. At the same time, this point of intersection is a temperature minimum for the liquidus on the Alkemade line. As a side note and before this theorem is explained in the following with the help of two simple examples, it should be briefly mentioned here that Bancroft was not really sure when writing his book whether the theorem actually has general validity. This is obvious from his text, where he writes “Until the number of contradictions is somewhat increased or until it has been shown under what circumstances the theorem does not apply, it may be accepted provisionally as accurate”.[4] It took more than 100 years until the Alkemade theorem was finally proven by Malakhov.[5]

Figure 1 illustrates the Alkemade theorem using as example a simple ternary system formed by three immiscible components A, B, and C and one binary compound AB. The invariant reactions of the binary boundary systems, all of which are of the eutectic type, are projected onto the boundaries of the ternary triangle and marked as e1-4. The monovariant lines emanating from these points divide the composition triangle into the four primary crystallization fields A, B, C, and AB. If we now connect the compositions of the phases C and AB, this gives the Alkemade line of these two phases (red dotted line in Fig. 1). It intersects the boundary line of the primary crystallization fields C and AB at the point X. As indicated by the green arrows, the Alkemade theorem now implies that the temperature along the boundary line decreases in both directions away from the point X. At the same time, this point marks a temperature minimum on the Alkemade line.

Illustration of the application of the Alkemade theorem on a liquidus surface projection of a ternary system A-B-C with only one, congruently melting binary compound AB (points e1-4 and I1-2 mark the binary and ternary invariant reactions, respectively; the arrows indicate the direction of decreasing temperature)

It is important to note that the theorem holds for any two phases of the system, i.e., it can be applied for the other boundary lines A/C, A/AB, AB/B, and B/C as well. In these cases, the respective Alkemade lines are always along the binary boundaries of the composition triangle. For example, the Alkemade line A-C meets the boundary line of the two primary crystallization fields A and C (line connecting e4 and I1) at point e4, which is why according to the Alkemade theorem the temperature decreases from e4 towards I1. Moreover, and in agreement with the fact that e4 is a binary eutectic, a conclusion of the Alkemade theorem is that the liquidus temperature in the binary boundary system A-C increases on both sides of e4, since this point is a temperature minimum on the Alkemade line.

Thus, the Alkemade theorem leads to two important general conclusions for systems with phases with negligible homogeneity range:

-

The addition of one or more components (B, C, ...) which are not soluble in a phase A always results in a lowering of the melting point or liquidus temperature.

-

All invariant temperatures of a binary system are lowered by the addition of a non-miscible third component.

In the simple example presented in Fig. 1, the Alkemade line AB-C intersects the corresponding boundary line. However, the theorem also applies in cases where this is not true. A corresponding, again very simple example is shown in Fig. 2. Here, the binary phase AB forms peritectically in the binary system A-B and its Alkemade line does not intersect with the AB-C boundary line (connecting I1 and I2). In this case, the extension of the boundary line is used, which meets the Alkemade line at the point X. Then again the theorem can be applied saying that the temperature along the boundary line decreases in the direction away from the point X, i.e., it decreases from I2 to I1. Consequently, the ternary invariant reaction I2 is a transition-type reaction (L + B ↔ AB + C) and I1 is of the eutectic type (L ↔ A + AB + C), while in the example of Fig. 1 both ternary invariant reactions are of the eutectic type.

Application of the Alkemade theorem for the case that the Alkemade line does not intersect the corresponding boundary line (designations as in Fig. 1)

3 The ‘Problem’ of Solid Solubility

The original formulation of the theorem applies only to phases with fixed compositions, i.e., there is no statement about its validity in the case of phases with (extended) homogeneity ranges and how it might then be applied. The theorem is mentioned frequently in the literature especially in the fields of mineralogy and ceramics,[6, 7] where the occurring phases in most cases can be well described as approximate ‘point phases’ and the theorem becomes very useful for the determination of the often complex liquidus surfaces. The problem that all phases have to be ‘point phases’ with no solubility range as a prerequisite for the application of the Alkemade theorem was, to the best of our knowledge, mentioned only once in the literature. In his extended work about “Eutectic-like and peritectic-like reactions in ternary systems”, J. van den Boomgaard mentioned that “the "van Rijn van Alkemade" theorem only holds in boundary cases in which the composition of the solid phases is practically restricted to points in the composition triangle”.[8] As this kind of point phases “does not exist in a great number of systems”, he concluded that the theorem is not applicable in most cases as there is no defined Alkemade line.[8]

Indeed, it is this lack of a rule on how to draw the Alkemade line that starts the difficulties. This problem is illustrated in Fig. 3. Here, the two phases C and AB exhibit certain homogeneity ranges and it is no longer obvious what should be the Alkemade line in this case. The set of possible connecting lines between the two phases covers the entire intermediate region bounded by the two dashed gray lines in Fig. 3 (for simplification, we neglect here a possible temperature dependence of the extension of the homogeneity range; the shown size shall correspond to that in the temperature range of the boundary line). Obviously, an Alkemade line as introduced in the original theorem does not exist. There are various particular compositions that might be chosen as starting and end point of a hypothetical Alkemade line. This could be, for example, the two stoichiometric compositions of the phases C and AB, which give line 1 in Fig. 3. Or, since often the composition with the highest stability (highest melting point) of a phase is not identical to the stoichiometric composition (as in the later example of a real system; see Section 4), one could alternatively choose the line connecting these stability maxima (line 2 in Fig. 3). Another, third possible pair of special compositions would be the points at the two phase boundaries whose connection gives the shortest possible line between the two phases (line 3 in Fig. 3). In all these three cases, the theorem would at least allow the conclusion that there must be a temperature maximum on the line I1-I2 (which means that both invariant points I1 and I2 belong to ternary eutectics). However, the position of the maximum on this boundary line remains unclear. It may even be the case that there is no maximum: If the Alkemade line were near the left boundary of the shaded region to the left of point I1 (line 4), application of the theorem would indicate that the invariant reaction at I1 is not eutectic, but is a transition-type reaction, and there would be no maximum on the AB/C boundary curve, but the temperature along I1-I2 would continuously decrease. Obviously, not only the position, but also the very existence of a maximum on the boundary curve is unclear.

Liquidus surface projection of a simple ternary system similar to that shown in Fig. 1, but with solubility ranges for the phases C and AB. The shaded area bounded by the dashed gray lines marks the region of possible connecting lines between C and AB. The two points marked Tmax (C) and Tmax (AB) are arbitrarily chosen compositions that should mark the points of maximum stability of the two phases. The four red lines 1-4 are examples of particular lines, which connect some special points of the system as discussed in the text

In the following section we will first present an example of an experimentally well-studied ternary system demonstrating the difficulty to apply the theorem to real systems. After that we will have a closer look on the development of the equilibria at temperatures near maxima on different boundary curves.

4 Real Systems

In contrast to most mineralogical and ceramic compounds, intermetallic phases often have an extended homogeneity range. As an example, Fig. 4(a) shows an experimentally obtained isothermal section of the Al-Fe-Nb system (redrawn from Ref 9), where several intermetallic phases such as Nb(Fe,Al)2, Nb6(Fe,Al)7, and Nb2Al extend far into the ternary system. Moreover, in the Al-Fe binary boundary system, the single-phase region of the (αFe) solid solution and its B2-ordered superstructure phase FeAl cover a composition range of more than 50 at.% Al.[10,11,12] On the other hand, the system also contains some phases with only very low solubility for the third element such as NbAl3 and the Al-rich Al-Fe phases Fe5Al8, FeAl2, Fe2Al5, and Fe4Al13, making the Al-Fe-Nb system a well-suited candidate to investigate the applicability of the Alkemade theorem.

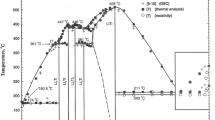

Figure 4(b) shows the liquidus surface projection of the Al-Fe-Nb ternary system as obtained from the experimental work in (Ref 9, 13). Along the monovariant lines (red lines), there are several temperature maxima (denoted by blue dots as M1 to M5, numbered from the highest to the lowest temperature), which allow to present and discuss the above described problems in a real system.

The three most interesting cases are the maxima M1, M2, and M3 on the boundary lines of the primary crystallization field of the Laves phase Nb(Fe,Al)2, which has the largest homogeneity range of all phases. Before we focus on them, let us briefly discuss the other two maxima, M4 and M5. In these cases, the Alkemade theorem can be applied (more or less well) in its classical form. M5 is the maximum on the boundary line between the congruently melting compounds NbAl3 and Fe2Al5, which both have small composition ranges. As predicted by the Alkemade theorem, the maximum is located at the intersection of the boundary line and the line connecting both phases. In contrast to Fe2Al5, the two neighboring compounds FeAl2 and Fe4Al13 both melt peritectically and in both cases the situation is as shown in Fig. 2, i.e., there is no maximum on the boundary line, but the direction of falling temperature along the boundary lines can be derived from the Alkemade theorem. The fourth Al-rich Al-Fe compound Fe5Al8 also melts peritectically. However, in this case the composition of the peritectic point is well within the homogeneity range of the phase and the intermediate region between Fe5Al8 and NbAl3 intersects their boundary line leading to the maximum M4. It should be noted, however, that due to the non-negligible homogeneity range of Fe5Al8, the position of the maximum is not exactly defined, but may also be slightly shifted on the boundary line to the left or right. Now let us focus on the other three maxima.

The position of the maximum M3 in the Fe-rich corner, which belongs to the boundary curve between the primary crystallization fields of the Laves phase Nb(Fe,Al)2 and the Fe solid solution (αFe)/FeAl, is well-established experimentally, and, moreover, in this case the liquidus temperatures of two series of single-phase samples of both phases involved were determined. Figure 5 shows the measured liquidus temperatures of Nb(Fe,Al)2 (Fig. 5b) and (αFe)/FeAl (Fig. 5c) as a function of the Al content (for constant Nb content, i.e., in a direction parallel to the Al-Fe boundary as illustrated in Fig. 5a). For both series of single-phase alloys, there is a clearly visible temperature maximum. The monovariant boundary line between the two phases is a eutectic valley running approximately parallel to the Al-Fe boundary. The corresponding compositions and temperatures are well determined, and a plot of the obtained eutectic temperatures as function of the Al content (Fig. 5d) clearly reveals the temperature maximum M3. The Alkemade theorem, however, can obviously not be applied in this case. Figure 5(a) indicates that the position M3 is not related to the liquidus maxima of the two phases. Likewise, a hypothetical Alkemade line connecting the stoichiometric compositions of the two phases (which should be NbFe2 and αFe) would not give the position of the maximum. The situation is similar in case of the maxima M1 and M2, where, however, the much lower number of available experimental data does not allow a precise determination of the positions of the maxima.

(a) Fe-rich corner of the Al-Fe-Nb liquidus surface (a), liquidus temperatures as a function of the Al content for the ternary Laves phase Nb(Fe,Al)2 (b), the Fe solid solution (αFe)/FeAl, and the eutectic formed by these two phases (d). The red points in (a) mark the temperature maxima observed in (b-d) (redrawn from Ref 9)

However, a thermodynamic description of the entire ternary system is also available and has been published in (Ref 14) Calphad-type modelling of the system resulted in a very good description of the experimental data. Using the set of optimized parameters, we have now calculated a series of isothermal sections focusing on the temperature ranges near the three maxima M1-M3 (for details of the calculations and the list of the optimized parameters, see Ref 14).

Starting from a temperature of 1680 °C, which is above the melting maximum of the Laves phase Nb(Fe,Al)2 (1669 °C), we now follow the development of the shape of the liquid phase field with decreasing temperature focusing on the constriction of this phase field near the three maxima and its separation into two liquid phase fields below the maxima. At 1680 °C (Fig. 6a), the liquid phase covers the entire ternary triangle below 50 at.% Nb (with the exception of a small two-phase field with the high-melting NbAl3 phase). At 1665 °C (Fig. 6b), i.e., just below the melting maximum of the Laves phase Nb(Fe,Al)2, there is a small island of this phase centered around 35 at.% Al (see also Fig. 5b). Lowering the temperature to 1640 °C leads to a growth of its composition range, and the beginning of a constriction of the liquid phase field on the Nb-rich side (in the direction of Nb2Al) is already visible (Fig. 6c). Just below the temperature of the maximum M1 (Fig. 6d), the liquid phase field has split into two parts. The direction of the very narrow two-phase field Nb(Fe,Al)2 + Nb2Al indicates where the first tie line between Nb(Fe,Al)2 and Nb2Al has formed at the maximum temperature. In the case of point phases, this first connection between the two phases would have been the Alkemade line. Here, as is obvious from the position of the respective composition of the Nb(Fe,Al)2 phase, there is no relation neither to the point of maximum stability of Nb(Fe,Al)2 (marked with the red triangle) nor to the stoichiometric composition NbFe2, and also a connection of the two points resulting in the shortest distance between the two phases (Al-rich end of the Nb(Fe,Al)2 phase field and Nb-poor end of the Nb2Al phase field) would have resulted in a tie line clearly different from the actual one.

Calculated isothermal sections of the Al-Fe-Nb system at (a) 1680 °C, (b) 1665 °C, (c) 1640 °C, and (d) 1598.9 °C (just below the temperature of the maximum M1). The small red triangle in the center of the Nb(Fe,Al)2 phase field marks the composition of maximum stability of the ternary Laves phase Nb(Fe,Al)2, the two small red triangles on the binary boundary lines correspond to the temperature maxima of the congruently melting compounds NbFe2 and NbAl3

With further reduction in temperature, the Nb(Fe,Al)2 + Nb2Al two-phase field grows as the two three-phase equilibria L + Nb(Fe,Al)2 + Nb2Al on the left and right side move away from each other in opposite directions, accompanied by shrinking of the two separated liquid phase fields. In addition, a second constriction of the liquid phase field can be observed in the region near the Al-Nb boundary, which finally results in the maximum M2 and a first equilibrium between Nb(Fe,Al)2 and NbAl3 (Fig. 7a). In this case, the system chooses the shortest distance between both phases (as in case 3 in Fig. 3), i.e. a connection of the Al-rich end of the Nb(Fe,Al)2 phase field with the narrow composition range of NbAl3.

Then, as the temperature continues to fall, the small, disconnected phase field of liquid above M2 disappears at 1550 °C (Fig. 7b) in a eutectic reaction resulting in the three-phase equilibrium Nb(Fe,Al)2 + Nb2Al + NbAl3. The still extended liquid phase field near the Al-Fe boundary continuously shrinks and starts to detach from the Al-Fe boundary at 1530 °C in the Fe corner (Fig. 7c, see also Fig. 5c). At 1450 and 1400 °C, a third constriction of the liquid phase field becomes obvious at its Fe-rich end (Fig. 8a and b). This results in another splitting of the liquid phase field at the temperature of M3 resulting in a tie line between Nb(Fe,Al)2 and (αFe) as indicated in Fig. 8c. As already described above when presenting the experimental results related to this maximum (Fig. 5), there is no apparent relation between the position of the maximum, the calculated phase compositions, and any particular composition points of the two involved phases. The remaining Fe-rich liquid phase field disappears at the binary Fe-Nb boundary at 1373 °C (reaction e3, Fig. 4b and 5d), while the Al-rich liquid recedes further and further into the Al corner (Fig. 8d), where it finally disappears at 654 °C in a binary eutectic at the Al-Fe boundary very near to the Al corner.[11]

5 Discussion

In discussing the validity, usefulness, and applicability of the Alkemade theorem, one must distinguish between different goals that the theorem is intended to accomplish. Either one is interested in the solidification path of a material and what the microstructure will look like in the solidified state, or one is interested in studying the liquidus surface itself.

If we are thinking about the first topic, i.e., the solidification path, the equilibrium phases and the microstructure, we can say the following: In the case of a system with (any number of) only point phases, i.e., in the situation for which the Alkemade theorem was actually defined, there are exclusively three-phase fields in the solidified state (two-phase equilibria exist only for the special compositions lying along the Alkemade lines, i.e., the two-phase range is not a field but a line, which is actually obvious already for geometric reasons). In this case, the knowledge of the position of the maximum is very useful, because this decides about the third phase, which will be in equilibrium with the two phases connected by the Alkemade line. Application of the theorem does not only yield the temperature maxima and/or direction of falling temperature on the boundary lines, but the Alkemade lines also divide the system into different triangles, which for any alloy composition define the three equilibrium phases. In the simple examples shown in Fig. 1 and 2, these are the two three-phase fields A + AB + C and AB + B + C. However, the theorem can also be applied in much more complex systems under the only condition that the respective phases are point phases (or have only narrow composition ranges), examples are the above described maxima M4 and M5 in the Al-Fe-Nb system.

Staying with the topic of solidification path, equilibrium phases and microstructure, let us now consider the case of non-negligible extended homogeneity regions. This situation is very different from the one above, and the Alkemade theorem is not needed at all. In contrast to the above-described condition of point phases, the position of a maximum does not play a role for the prediction of the finally solidified equilibrium phases, because there will be a two-phase field composed of the respective phases the existence and extension of which is not affected by the position of the maximum. If the intermediate region between the homogeneity ranges of two of such phases intersects their boundary line, then for any alloy composition in this range the solidification will start with the primary crystallization of one of the two phases (depending in which primary crystallization field the alloy composition lies) and the composition of the remaining, continuously solidifying liquid will shift until it reaches the boundary line where the solidification is finished. Consequently, the direction of falling temperature on the boundary line is of no importance for the solidified microstructure, since solidification is already complete just at the moment when the liquid composition arrives at the boundary line. The irrelevance of the direction of falling temperature for the microstructure of two-phase alloys can also be well illustrated by the Al-Fe-Nb system presented above. The most extended two-phase region in this system is the (αFe)/FeAl + Nb(Fe,Al)2 two-phase field (see Fig. 4a). The situation is particularly simple because both phase fields and the eutectic valley (Fig. 5a) extend approximately parallel to the Al-Fe axis, i.e., at approximately constant Nb contents. In this situation, the solidified microstructure of an alloy of any composition in this two-phase field only depends on its Nb content, while the Al content is (more or less) irrelevant. The microstructure will consist of a eutectic (αFe)/FeAl + Nb(Fe,Al)2 matrix and primary particles that are either (αFe)/FeAl or Nb(Fe,Al)2 depending on whether the Nb content is below or above the eutectic boundary line. For a fixed Nb content, alloys with different Al contents will exhibit the same microstructure (a situation which provides an ideal playground for material development, since the material properties will considerably change in dependence of the Al content while the microstructure does not). Here it becomes obvious that the position of the maximum M3 does not play any role for the microstructure.

If we are interested in studying the liquidus surface itself, the situation is a bit different. As was already pointed out by Boomgaard,[8] the Alkemade theorem only holds for point phases, because in the case of extended homogeneity ranges the problem already is that the Alkemade line is not defined. He already suggested that this line should be replaced by the intermediate region between the homogeneity ranges of the phases (as introduced in Fig. 3). For the sake of abbreviation, we will now briefly refer to this intermediate region between the phases as the “Alkemade region”. The occurrence of a temperature maximum depends on the positions (i.e., compositions) of the two invariant reaction points at the ends of the boundary line. If the intersection line between the boundary curve of the two phases and their Alkemade region is completely between these two invariant reaction points, then there must be a temperature maximum on the boundary curve in the intersected region (Fig. 9a). The exact position of the maximum, however, cannot be determined by this procedure. In the case that the Alkemade region of the two phases also covers one of the invariant reaction points, it cannot be concluded if there is a maximum on the boundary curve or not (Fig. 9b). Finally, if there is no intersection of the Alkemade region with the boundary line, there will be no maximum on the curve, just as in the case of point phases (Fig. 9c). But what is especially important: Regarding the directions of falling temperature along the boundary line, the idea of the Alkemade theorem still works if we simply replace the ‘Alkemade line’ by the ‘Alkemade region‘. Just as in the case of the Alkemade line, it is also true for the Alkemade region that the temperatures to the left and right of this region will always decrease along the boundary line in the direction away from the Alkemade region (red arrows in Fig. 9).

Liquidus surface projection of a simple ternary system with the phases C and AB showing some non-negligible homogeneity range. Shown are different possibilities how the Alkemade region (the shaded area bounded by the dashed gray lines) can intersect the C/AB boundary line: (a) the intersection lies completely between the invariant reaction points at the ends of the boundary line; then there must be a temperature maximum on the boundary line with, however, unknown position, and on both sides of the Alkemade region the temperature decreases away from this region (red arrows), which is why both invariant reactions will be ternary eutectics; (b) in this case, it is not clear whether there is a maximum on the boundary line, but at least it can be concluded that the temperature decreases on the right side (red arrow), which determines the character of the invariant reaction as eutectic; (c) if the Alkemade region does not intersect with the boundary line, there is no maximum and the temperature must decrease as indicated by the red arrow, which also defines the character of the two invariant reactions (one is a transition-type and the other one is a eutectic reaction) (Color figure online)

It is now interesting to see how and if this more generalized view of the Alkemade theorem can be applied to the above described maxima M1-M3 of the Al-Fe-Nb system. Starting with the maximum M1 on the boundary line between Nb(Fe,Al)2 and Nb2Al (see Fig. 4b), we can see that the above introduced Alkemade region extends over a wide area that covers a large part of the boundary line between these phases (but not the entire boundary line as the Al-rich end would remain uncovered) and in addition covers the invariant reaction point P1 as well as parts of the monovariant lines starting from this point (Fig. 10, blue shaded area). Obviously, in this case the Alkemade theorem does not give any information about the existence of a maximum on the boundary line and we only learn that the temperature at the right end of the boundary line decreases to the right. This is different in the case of the maxima M2 and M3. The entire intersection of the Alkemade region of the two phases Nb(Fe,Al)2 and NbAl3 (yellow shaded area in Fig. 10) with their boundary line is within the limiting invariant reactions E1 and E2, and therefore the Alkemade theorem predicts that there must be a maximum M2 in this intersecting composition range. The only missing information is the exact position of M2 in the intersecting range. Finally, the situation is again a little different for M3. Although the Alkemade region of the two phases Nb(Fe,Al)2 and (αFe)/FeAl is very large (brown shaded area in Fig. 10), it only intersects with its own boundary line that extends from the binary invariant reaction point e3 at the Fe-Nb boundary to the ternary reaction U3 at about 60 at.% Al. Again, the theorem predicts the existence of a temperature maximum on the boundary line, but in this case it could also be located at the binary boundary, i.e., at e3.

Alkemade regions between Nb(Fe,Al)2 and Nb2Al (blue shaded area), Nb(Fe,Al)2 and NbAl3 (yellow shade area), and Nb(Fe,Al)2 and (αFe)/FeAl (brown shaded area). In the first case, it is not clear if there is a maximum on the respective boundary line (blue line); in the second case (yellow line), there must be a maximum and also the range of possible composition is comparably small; in the third case (brown line), there must also be a maximum, but it might also be located at the binary endpoint e3 in the Fe-Nb boundary system (Color figure online)

As the examples show, the position of the maximum is not predictable from simple geometric considerations. Instead, the position of the temperature maximum is determined by the position of the two-phase field, which continuously narrows with increasing temperature until it becomes a single tie line just at the maximum temperature and composition. The direction of this special tie line, i.e., the corresponding compositions of the two phases are not related to the stoichiometric phase composition or to their composition of maximum stability.

6 Conclusions

The Alkemade theorem allows to find the direction of falling temperature along the monovariant reaction lines on liquidus surfaces and can be very useful for the construction of liquidus surface projections, especially when an only insufficient or unreliable database exists that does not allow a proper Calphad calculation. Although in its classical form it is only applicable to phases with negligible homogeneity range, it can still be very useful for systems with phases that extend over wide composition ranges. If the Alkemade line, which is only defined for point phases, is replaced by an ‘Alkemade region’, then the theorem can still give valuable information about the direction of falling temperatures and even the presence or absence of temperature maxima can be predicted under special conditions. However, the position of the maximum and the direction of the respective tie line between the two corresponding phases at the maximum temperature cannot be derived from the Alkemade theorem.

References

J.W. Gibbs, On the Equilibrium of Heterogeneous Substances. Trans. Conn. Acad. Arts Sci., 1874-1878, 3, p 108–248, 343–524.

A.C. van Rijn van Alkemade, Toepassingen der theorie van Gibbs op evenwichtstoestanden van zoutoplossingen met vaste fasen [1892] (Applications of Gibbs’ Theory to Equilibrium States of Salt Solutions with Solid Phases), Verh. Akad. Wet. Amst. Sect. 1, 1893, 1(5), p 1-65.

A.C. van Rijn van Alkemade, Graphische Behandlung einiger thermodynamischen Probleme über Gleichgewichtszustände von Salzlösungen mit festen Phasen (Graphical Treatment of some Thermodynamic Problems with Equilibrium States of Salt Solutions with Solid Phases), Z. Phys. Chem., 1893, 11(3), p 289-327.

W.D. Bancroft, The Phase Rule Journal of Physical Chemistry, Ithaca, NY, 1897, p149

D.V. Malakhov, A Rigorous Proof of the Alkemade Theorem, Calphad, 2004, 28(2), p 209-211. https://doi.org/10.1016/j.calphad.2004.08.002

F.P. Hall, H. Insley, E.M. Levin, H.F. McMurdie, and C.R. Robbins, General Discussion of Phase Diagrams, in Phase Diagrams For Ceramists, Vol. I. E.M. Levin, C.R. Robbins, and H.F. McMurdie, Eds., American Ceramic Society, Columbus, OH, 1964, p5-36

A.E. McHale, Three or More Component Equilibria, in Phase Diagrams and Ceramic Processes. A.E. McHale, Ed., Springer, Dordrecht, 1997, p110-130

J. van den Boomgaard, Eutectic-Like and Peritectic-Like Reactions in Ternary Systems at a Constant Pressure. Part III–Ternary Systems Containing more than Three Solid Phases, Philips. J. Res., 1979, 34(5/6), p 211-237.

F. Stein, C. He, O. Prymak, S. Voß, and I. Wossack, Phase Equilibria in the Fe-Al-Nb System: Solidification Behaviour, Liquidus Surface and Isothermal Sections, Intermetallics, 2015, 59, p 43-58. https://doi.org/10.1016/j.intermet.2014.12.008

U.R. Kattner, Al-Fe, in Binary Alloy Phase Diagrams, 2nd edn. T.B. Massalski, Ed., ASM International, Materials Park, OH, USA, 1990, p147-149

F. Stein, Al-Fe (Aluminium-Iron), in Selected Al-Fe-X Ternary Systems for Industrial Applications. F. Stein and M. Palm, Eds., Materials Science International Services GmbH, Stuttgart, Germany, 2022, p1-38

U.R. Kattner and B.P. Burton, Al-Fe, in Phase Diagrams of Binary Iron Alloys. H. Okamoto, Ed., ASM International, Materials Park, OH, 1993, p12-28

F. Stein and N. Philips, Nb-based Nb-Al-Fe Alloys: Solidification Behavior and High-Temperature Phase Equilibria, Metall. Mater. Trans. A, 2018, 49(3), p 752-762. https://doi.org/10.1007/s11661-017-4334-0

C. He, Y. Qin, and F. Stein, Thermodynamic Assessment of the Fe-Al-Nb System with Updated Fe-Nb Description, J. Phase Equilib. Diffus., 2017, 38, p 771-787. https://doi.org/10.1007/s11669-017-0566-3

Funding

Open Access funding enabled and organized by Projekt DEAL.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

This invited article is part of a special tribute issue of the Journal of Phase Equilibria and Diffusion dedicated to the memory of Thaddeus B. “Ted” Massalski. The issue was organized by David E. Laughlin, Carnegie Mellon University; John H. Perepezko, University of Wisconsin–Madison; Wei Xiong, University of Pittsburgh; and JPED Editor-in-Chief Ursula Kattner, National Institute of Standards and Technology (NIST).

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Stein, F., He, C. About the Alkemade Theorem and the Limits of its Applicability for the Construction of Ternary Liquidus Surfaces. J. Phase Equilib. Diffus. (2024). https://doi.org/10.1007/s11669-024-01097-9

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11669-024-01097-9