Abstract

Partial and integral enthalpies of mixing of ternary Li-Pb-Sb alloys were measured at 923 and 1023 K with drop calorimetry. In total 12 sections were studied of fixed molar ratios of Li to Pb equal to 1/9, 1/3, 2/3, 1, 3/2, 3, Pb to Sb equal to 3/1, 1, 1/3 and Li to Sb equal to 1/4, 2/3, 1. The measurements were performed by consecutive dropping solid metal samples (Li, Pb or Sb) from ambient temperature into calorimeter chamber. In the first step calibration was performed, in the second binary starting alloy was formed, and finally enthalpies of liquid ternary alloys were measured. Integral enthalpies of mixing are negative in the whole concentration range studied, and tend to a minimum associated with a minimum in Li-Sb system.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

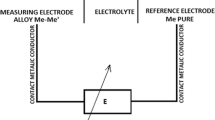

Novel rechargeable liquid metal batteries (LMB), invented in 2009 by MIT research group led by Donald Sadoway,[1,1,2,3,3] where both electrodes and electrolyte are in a liquid form, have an ability to store a large amount of electricity from renewable energy sources such as wind or solar, and to deliver this electricity when it is required. Wang et al.[3] proposed the Li-Pb-Sb alloys as a potential electrode candidate for LMB technology, due to relatively high cell voltage (about 0.9 V open-circuit voltage), low self-discharge and long-term stability. However, phase relations in the Li-Pb-Sb system and thermodynamic data for constituent phases has not yet been reported. High temperature drop calorimetry readily provides partial and integral enthalpies of mixing, which may be further used to develop a thermodynamic description of the liquid phase in the Li-Pb-Sb system. Therefore the aim of this work is to measure enthalpies of mixing in liquid Li-Pb-Sb alloys.

Although there are no reports on thermodynamic properties of liquid Li-Pb-Sb alloys, the enthalpies of mixing of constituent binary alloys are well studied. Integral enthalpies of mixing of liquid Pb-Sb alloys were studied by many, as summarized by Gierlotka et al.[4] All of the reported integral enthalpies are close to zero and thermodynamic properties of liquid Pb-Sb alloys only slightly deviate from ideal solution.[4] Integral enthalpies of mixing of Li-Pb alloys at 1000 K reported in Ref 5 are negative in the whole concentration range with a minimum of ~− 29 kJ/mol at 0.25 mol fraction Pb. Recent measurements of integral enthalpies carried out at between 817 and 1023 K,[6] are close to Ref 5 and indicate that the integral enthalpies of mixing of liquid Li-Pb alloys are temperature independent. Enthalpies of mixing of liquid Li-Sb alloys were measured calorimetrically by the present authors at 922 K over 0.46–0.87 mol fraction Sb.[7] These were recently confirmed experimentally by Li et al.[8] over Sb concentration range 0.43–0.97 mol fraction Sb at 929 and 979 K. According to both sets of data,[7,8] integral enthalpies of mixing do not show temperature dependency and, in the concentration range studied, decrease with decreasing content of Sb to reach ~− 55 kJ/mol at 0.44 mol fraction of Sb.

2 Materials and Method

All of the substances used in present study, without further purification, are listed in Table 1. All measurements were carried out with the use of the Setaram MHTC 96 Line Evo calorimeter under the protective atmosphere of high purity argon. This calorimeter has a thermopile constructed of 20 thermocouples, graphite tube resistance furnace, and manual drop device in which each piece of metal is loaded separately, evacuated and flushed with argon before being dropped to the calorimeter chamber. The drop device has detachable antechamber allowing transfer of Li pieces from argon filled glovebox. The liquid alloys, in all measurements, were held in tungsten crucibles (internal dimensions: 69 mm × 7.6 mm in dia.) because W neither dissolves nor reacts with Sb.[9] Crucibles could be reused after their content was removed by dissolving in nitric acid. Before running of each experiment and dropping samples, the calorimeter was evacuated several times by a rotary vacuum pump, and flushed with high purity argon. At the beginning of each experiment, after stabilising the temperature and the baseline (more than 3 h from the start of heating and before the first drop), the calibration constant was determined by dropping the six calibration pieces of Li, Pb or Sb (depending on the starting ratio of Li to Pb, Pb to Sb, or Li to Sb,). Once calibration was completed, appropriate amount of the second component (in a single piece) was dropped to the calorimeter to form the binary starting alloy of respective Li to Pb, Li to Sb and Pb to Sb molar ratio. Then, the main experiments were started, when the pieces of third component were dropped to the liquid binary alloys in the crucible. The voltage signal from the thermopile was registered in a digital form, and then the heat effects and the mixing enthalpies were calculated according to Eq 1-4. The heat effects were measured up to the moment when the baseline achieved the same constant value as that before the reaction (in average about 40 min per drop). Due to the high reactivity of Li with air components such as nitrogen, oxygen, carbon dioxide or water vapor, the Li pieces were prepared and locked in calorimetric antechamber inside the glove box in a high purity argon atmosphere with trace amounts of moisture, O2 and nitrogen. Then, this antechamber was removed from the glovebox, and connected to the calorimeter.

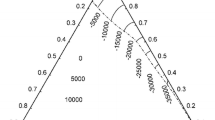

Integral enthalpies of mixing for binary Pb-Sb alloys, needed as a starting point for ternary enthalpy determination, were calculated from the thermodynamic description of the liquid phase of Pb-Sb system.[4] Integral enthalpies of binary Li-Pb alloys were directly taken from the recent paper,[6] whereas integral enthalpies of Li-Sb alloys were determined in this work and found to be consistent with those published earlier.[7,8] Then enthalpies of ternary alloys were measured along 12 sections of fixed molar ratios of Li to Pb equal to 1/9, 1/3, 2/3, 1, 3/2, 3, Pb to Sb equal to 3/1, 1, 1/3 and Li to Sb equal to 1/4, 2/3, 1, as illustrated in Fig. 1. Measurements were performed at 923 K, except for sections of Li to Pb equal to 3, 3/2 where measurement temperature was 1023 K.

The integral and partial enthalpies of mixing (∆mixH, ΔHX) of the Li-Pb-Sb liquid alloys can be described using the equations listed below:

where \(\Delta H_{\text{Signal}}\) is the heat effect of each dropped metal (Li, Pb or Sb) which equalled the added drop enthalpy; K is the calorimeter constant; \(\Delta H_{\text{X}}^{{{\text{T}}_{\text{R}} \to {\text{T}}_{\text{M}} }}\) is the molar enthalpy difference of X pure element (X = Li, Pb, Sb) between room temperature (TR = 298 K) and temperature of measurement (TM), calculated using SGTE v4.4 database;[10] \(n_{\text{X}}\) (\(n_{\text{Li}} , n_{\text{Pb}} , n_{\text{Sb}}\)) are the number of moles of lithium, lead and antimony, respectively; \(H_{{{\text{DISS}} - {\text{X}}}}\) is the enthalpy of dissolution of pure lithium, lead or antimony; nj is a number of moles of components in the crucible before the starting of the main integral molar mixing enthalpy measurements; \(\Delta H_{\text{Calibration}}\) is the heat effect of dropped metal, which was used for calibration.

3 Results and Discussion

Tables 2, 3, and 4 contain partial and integral enthalpies of mixing of Li-Pb-Sb alloys, together with all the experimental information needed i.e. temperatures, starting amounts, dropped amounts, the corresponding heat effects, enthalpies of dropped components calculated using SGTE data,[10] and binary starting points of the integral enthalpy of mixing. Integral enthalpies of mixing are graphically presented in Fig. 2(a)-(c).

Starting from the Li-Pb side (sections A-F) the enthalpies were measured up to ~ 0.45 mol fraction Sb, from Li-Sb side (sections G-I) up to ~ 0.3 mol fraction of Pb, and from Pb-Sb side (sections J-L) up to ~ 0.6 mol fraction Li. The integral enthalpies of mixing in the Li-Pb-Sb system are negative in the whole concentration range studied, and strongly depend on concentration. In the case of enthalpies measured from Li-Pb (sections A-F) and Li-Sb (sections G-I) side, the integral enthalpies are lower for starting binary alloys, which contain more lithium. As illustrated in Fig. 2(a), integral enthalpies measured from the Li-Pb side for each experimental section decrease initially until they reach a minimum, then further increase with increasing Sb concentration. For sections B, C, D two individual measurement series were performed, the second with smaller concentration step, and the results were repeatable. As the Li to Pb molar ratio increases in the series A-F, the integral enthalpies are lower, the minima get deeper and shift towards higher Sb concentrations. For example, in section B (Li to Pb ratio equal to 1/3) the minimum of integral mixing enthalpy (~ − 23 kJ/mol) occurs at 0.08 mol fractions Sb. In the case of section F (Li to Pb ratio equal to 3) the minimum of integral mixing enthalpy (~ − 62 kJ/mol) corresponds to 0.19 mol fraction of Sb. Integral enthalpies measured from the Pb-Sb (Fig. 2c) side decrease with increasing concentration of Li, in the concentration range studied, only for section L (Pb to Sb molar ratio 3) the minimum is observed at ~ 0.55 mol fraction Li. Since the difference between enthalpy values for starting points on the Pb-Sb side is negligible, there are no significant differences between sections of different Pb to Sb ratio. The decreasing trend in integral enthalpies of mixing measured by dropping Li from Pb-Sb (Fig. 2c) side strongly resembles the trend of integral enthalpies in liquid Li-Sb alloys measured from the Sb side.[7,8] On the other hand, integral enthalpies of mixing measured by dropping Pb from the Li-Sb side (Fig. 2b) do not show similar behaviour, instead they increase nearly monotonically with increasing Pb concentration.

In Table 5, integral enthalpies of mixing measured near the points of intersection of experimental sections are compared. The greatest difference is observed between sections J and F (5.6 kJ/mol), and K and C (4.5 kJ/mol), whereas on average the difference is 2.4 kJ/mol. The differences between data from intersecting sections are generally larger than uncertainties of integral enthalpy of mixing reported in Tables 2, 3, and 4, which do not exceed 0.9 kJ/mol. In any ternary system integral enthalpies of mixing depend on enthalpies of starting binary alloys. Literature integral enthalpies of mixing of Pb-Sb alloys, as summarized in Ref 4, are close to each other within the margin of 0.2 kJ/mol. Whereas different sets of integral enthalpies of mixing of Li-Sb (Table 3 and Ref 7, 8) as well as Li-Pb[5,6] alloys are close within the margin of 3 kJ/mol. It should be noted that values of starting points in the Li-Pb and Li-Sb systems used in the present study are generally more negative than those of other authors (within the 3 kJ/mol margins), thus changing the starting points values would not improve the agreement of experimental sections near the points of intersection. Considering the magnitude of integral enthalpies of mixing (tens of kJ/mol) in the Li-Pb-Sb ternary and that they change strongly with composition, the differences between the experimental values of integral enthalpies of mixing near the points of intersection are acceptable, and it can be concluded that the data measured from different sides of Gibbs triangle are coherent.

Partial enthalpies of Sb measured from Li-Pb side (sections A-F) jump suddenly from very negative values (~ − 160 kJ/mol for section B, and ~ − 200 kJ/mol for section F) to positive ones at relatively low concentrations of Sb. This is particularly well visible for sections B, C, D where two runs were performed, the second run with a substantially smaller increment of Sb concentration (Fig. 3a). The concentration range in which the jump occurs for each section corresponds to the position of integral enthalpy minima observed in Fig. 2(a). Such an abrupt increase in partial enthalpies of the added component was earlier observed in a number of liquid binary lithium alloys, such as Li-Pb[5] and Li-Sn,[11] when the second component was dropped to Li at temperatures close to melting temperature of the highest melting intermetallic phase. As long as associates (Li4Pb in Ref 12 and Li4Sn in Ref 13) are formed in the liquid phase partial enthalpies are low, sharp increase in partial enthalpies means that associates are not formed anymore and no longer contribute to partial enthalpies, as a result integral mixing enthalpies start to increase. Also in the Li-Sb system, the Li3Sb associate is included in thermodynamic description of Li-Sb liquid phase.[8] On the other hand, partial enthalpies of Pb measured from Li-Sb side (Fig. 3b) do not show similar jumps up, instead, for sections H, I they change rather monotonously (regardless some scatter) in the concentration range studied. Only in the case of section G there is ~ 16 kJ/mol decrease of partial enthalpies between 0.05 and 0.12 mol fraction Pb. Changes of partial enthalpies of Li, measured from Pb-Sb side (Fig. 3c), with Li concentration are difficult to track, because of very big concentration step between individual drops. Nevertheless, for section L (Pb to Sb molar ratio equal to 3) it can be noticed that partial enthalpy of Li increases after concentration of Li exceeded 0.44 mol fraction, whereas for section K (Pb to Sb ratio equal to 1) partial enthalpy of Li increases above 0.6 mol fraction Li.

The observed variation of integral enthalpies of mixing of ternary Li-Pb-Sb alloys (Fig. 2) can be explained by differences in integral enthalpies of mixing of limiting binary systems. Integral enthalpy of mixing of liquid Pb-Sb alloys is close to zero, which is characteristic for a system showing near ideal behavior. As concentration of Li increases, integral enthalpy of mixing decreases similarly to Li-Pb and Li-Sb systems, as Li interacts strongly with Pb and Sb. The minimum of integral mixing enthalpy in ternary Li-Pb-Sb alloys (~ − 63 kJ/mol) is much deeper than the minimum in the Li-Pb system (~ − 29 kJ/mol),[5] which indicates that that the interactions between Li and Sb are much stronger than between Li and Pb, and dominate in the ternary Li-Pb-Sb alloys.

This does not mean that all of the reported enthalpies of mixing of ternary Li-Pb-Sb alloys represent fully liquid concentrations range. The present measurements were conducted at 923 and 1023 K to ensure that starting alloys for each measured section were fully liquid at the beginning of measurement. It should be noted, though, that in the Li-Sb system in the concentration range of 0.58 and 0.97 mol fraction of Li the liquidus is much higher than 1023 K, in particular at 0.75 mol fraction Li it reaches 1580 K.[8] Therefore it can be expected that at 923 K the semi-liquid concentration range extends deep into the ternary Li-Pb-Sb alloys. The minima of integral enthalpies of mixing measured by dropping Sb from Li-Pb side and Li from Pb-Sb side (sections L, K) are roughly on one line connecting Li3Sb and Pb-corner of composition triangle. Possibly, when Sb is added to liquid Li-Pb alloys then solid Li3Sb precipitates and heat effects from precipitation further decrease integral enthalpies. Once concentration of Sb crosses the abovementioned line and no more Li3Sb precipitates the integral enthalpies start to increase. This is similar to what was reported in the Li-Sb system,[8] and well explains the sharp increase of partial enthalpies discussed above.

Because there is no phase diagram of the Li-Pb-Sb system it is not possible to say what the range of homogenous liquid at 923 K should be. Calorimetric measurements make it possible to detect liquidus limit, based on kinks of integral enthalpies and discontinuity of partial enthalpies with a concentration of added component,[14] accompanying crossing from homogenous liquid into two-phase concentration range. It helps if the data points are dense (concentration change between the points is small) otherwise any change of trend in integral enthalpies can go unnoticed. However, in the case of enthalpies measured by dropping Li from Pb-Sb side (series L, K, J) large concentration step between the drops of Li makes the data difficult to interpret. No obvious change of slope of integral enthalpies of mixing measured by dropping Pb (series G, H, I) is observed. It is similar in the case of integral enthalpies measured by dropping Sb from Li-Pb side (series A-F), except for minima explained above. Based on the gathered data it is not possible to give even tentative liquidus position. Nevertheless, it can be assumed that ternary Li-Pb-Sb alloys of low Li content (i.e. below 0.4 mol fraction Li) in Sb-rich corner are fully liquid at 923 K.

4 Conclusion

Calorimetric measurements of the mixing enthalpies of Li-Pb-Sb alloys were performed at 923 and 1023 K over broad composition range. Twelve sections were studied by Li, Pb and Sb drop dissolution calorimetry. The integral enthalpies of mixing of Li-Pb-Sb alloys were negative in the entire composition range studied. The integral enthalpies dependence on composition in the Li-Pb-Sb ternary alloys can be explained by strong interactions between Li and Sb in the Li-Sb binary, which dominate in the ternary alloys.

References

D.J. Bradwell, H. Kim, A.H.C. Sirk, and D.R. Sadoway, Magnesium-Antimony Liquid Metal Battery for Stationary Energy Storage, J. Am. Chem. Soc., 2012, 134(4), p 1895-1897

H. Kim, D.A. Boysen, J.M. Newhouse, B.L. Spatocco, B. Chung, P.J. Burke, D.J. Bradwell, K.J. Alina, A. Tomaszowska, K. Wang, W. Wei, L.A. Ortiz, S.A. Barriga, S.M. Poizeau, and D.R. Sadoway, Liquid metal Batteries: Past, Present, and Future, Chem. Rev., 2013, 113, p 2075-2099

K. Wang, K. Jiang, B. Chung, W. Ouchi, P.J. Burke, D.A. Boysen, D.J. Bradwell, H. Kim, U. Muecke, and D.R. Sadoway, Lithium–Antimony–Lead Liquid Metal Battery for Grid-Level Energy Storage, Nature, 2014, 514(7522), p 348-350

W. Gierlotka, C. Lee, P. Chumpanaya, M.A. Rahman, and T.-N. Ko, Thermodynamic Re-Optimization of the Binary Pb-Sb System, J. Phase Equilib. Diffus., 2013, 34, p 421-424

B. Predel and G. Oehme, Calorimetric Investigation of Liquid Li-Pb-Alloys, Z. Metallkd., 1979, 70, p 450-453, in German

S. Terlicka, A. Dębski, and W. Gąsior, W, Thermodynamic Properties of Li-Pb system, J. Mol. Liq., 2018, 249, p 66-72

S. Terlicka, A. Dębski, and P. Fima, Enthalpy of Formation of Li2Sb and Li3Sb and Mixing Enthalpy of Liquid Li-Sb Alloys, J. Alloy. Compd., 2017, 673, p 272-277

D. Li, A. Beutl, H. Flandorfer, and D.M. Cupid, The Li-Sb Phase Diagram Part II: Calorimetry and Thermodynamic Assessment, J. Alloy. Compd., 2017, 701, p 186-199

B. Predel, Crystallographic and Thermodynamic Data of Binary Alloys Pu-Re…Zn-Zr, in: The Landolt–Börnstein Phase Equlibria, IV-5 J, Springer Materials, Germany, 1998.

A.T. Dinsdale, SGTE Data for Pure Elements, Calphad, 1991, 15, p 317-425

S. Furtauer, E. Tserenjav, A. Yakymovych, and H. Flandorfer, Calorimetric Studies of Cu-Li, Li-Sn, and Cu-Li-Sn, J. Chem. Thermodyn., 2013, 61, p 105-116

C. Zhou, C. Guo, C. Li, and Z. Du, Thermodynamic Optimization of the Li-Pb System Aided by First-Principles Calculations, J. Nucl. Mater., 2016, 477, p 95-101

D. Li, S. Furtauer, H. Flandorfer, and D.M. Cupid, Thermodynamic Assessment and Experimental Investigation of the Li-Sn System, Calphad, 2014, 47, p 181-195

Y. Plevachuk, A. Yakymovych, S. Furtauer, H. Ipser, and H. Flandorfer, The Enthalpies of Mixing of Liquid Ni-Sn-Zn Alloys, J. Phase Equilib. Diff., 2014, 35(4), p 359-368

Acknowledgments

Investigations were performed thanks to the statutory funds of Institute of Metallurgy and Materials Science, Polish Academy of Sciences (Z-9/1).

Author information

Authors and Affiliations

Contributions

ST, AD carried out enthalpy measurements, ST, PF analyzed results, PF had the idea for this project, wrote the manuscript.

Corresponding author

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution 4.0 International License (http://creativecommons.org/licenses/by/4.0/), which permits unrestricted use, distribution, and reproduction in any medium, provided you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made.

About this article

Cite this article

Terlicka, S., Dębski, A. & Fima, P. Enthalpy of Mixing of Ternary Li-Pb-Sb Alloys. J. Phase Equilib. Diffus. 39, 412–425 (2018). https://doi.org/10.1007/s11669-018-0652-1

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11669-018-0652-1