Abstract

The phase relationships in the Zn-rich corner of the Zn-Fe-Zr system at 450, 600 and 800 °C were investigated by means of x-ray powder diffraction (XRD) and scanning electron microscopy coupled with energy/wave dispersive spectroscopy (SEM-EDS/WDS). Two ternary compounds were found in the system. One of them was designated as ZrFe2Zn20 according its narrow composition range. It is a CeCr2Al20-type compound with lattice parameter a = 1.3941 nm. ZrFe2Zn20 is stable below 878.6 °C and can co-exist with all binary compounds in the Zn rich corner of the system. The other one was designated as Zr2Fe3Zn5. SEM-WDS analysis indicated that Fe was hardly detected in ZrZn22, Zr5Zn39 and ZrZn3. And no Zr was dissolved in all Fe-Zn intermetallic compounds.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Hot-dip galvanizing is a popular and mature process that offers steel components effective corrosion protection. However, galvanizing Si-containing steels remains a technical challenge as it produces dull and excessively thick coatings with poor adhesion. This phenomenon is referred to as the Sandlin effect or Si reactivity by the galvanizers.[1-3] A practical solution to this problem is galvanizing the steels in alloyed baths. At present, Zn-Ni alloys are commonly used in the galvanizing industry.[4] However, they afford control of Si reactivity only when the Si content in the steel is below 0.2 wt.%. Mackowiak and Short[5] demonstrated that Zr in the Zn bath effectively suppressed the excessive growth of Fe-Zn compounds by forming a ternary compound at the growth front of the ζ (FeZn13) layer in the coating.

The investigation of addition of Zr to Zn bath is very limited. Sebisty[6,7] reported that additions of 0.1 and 0.3 wt.%Zr decreased the coating thickness. He suggested that the limiting growth of the ζ phase is probably due to the formation of the intermetallic particles rich in Fe and Zr which involves the dissolution of the ζ phase. Zhang[6] believed that both Zr and Mn can inhibit the layer growth of active steels with high Si content. Thus, Mn and Zr might be an alternative addition to Ni for controlling the excessive reaction of the active steels in general galvanizing.

When Zr is added to the Zn bath, the bath essentially becomes a Zn-Fe-Zr ternary system. Gross et al.[8] reported a ternary compound ZrFe2Zn20 with the CeCr2Al20-type structure in the ternary system. However, no information about the phase diagram was reported. To understand the effect of Zr on Si reactivity control, determination of the phase relationship in the Zn-Fe-Zr ternary system at the galvanizing temperature is essential. In the present work, the phase equilibria in the Zn-rich corner of the Zn-Fe-Zr system at 450 and 600 °C were determined experimentally using combined techniques of x-ray diffraction (XRD), optical microscopy and scanning electron microscopy coupled with energy/wave dispersive x-ray spectroscopy (SEM-EDS/WDS).

Due to its importance to the galvanizing industry, the Fe-Zn binary system has been investigated repeatedly.[9-11] The most recent thermodynamic assessment of the system was carried out by Xiong et al.[12] There are four intermetallic compounds, the ζ (FeZn13), the δ (FeZn10), the Г1 (Fe5Zn21) and the Г (Fe3Zn10) phases, in the system.

The Zn-Zr phase diagram has been thermodynamically assessed by Arroyave and Liu[13] based on previous investigation results.[14,15] Six stoichiometric compounds exist in the system: ZrZn22, Zr5Zn39, ZrZn3, ZrZn2, ZrZn, and Zr2Zn. It needs to be mentioned that the compounds of Zn14Zr and Zn6Zr reported by Chiotti and Kilp[16] were found to be Zn22Zr and Zn39Zr5 instead, respectively, in a recent study. The crystal data of all the binary and ternary compounds relevant to the equilibria in the Zn-rich corner are listed in Table 1.

Experimental Methods

Series of alloys were prepared to determine the equilibrium phases in the Zn-Fe-Zr system. The purity of raw materials, i.e., Fe and Zr powders and Zn chips, was 99.99 wt.%. The mixture of the raw materials, with the weight of each constituent precisely measured, was put into a tantalum inner corundum crucible, and then sealed in an evacuated quartz tube. Each sample was heated to 1100 °C and kept for 24 h, then quenched in water. During the course of the work, in order to minimize Zn loss and obtain a relatively compact sample, a bottom-quenching technique[22] was used. The quenched samples were then resealed and annealed at 450, 600 and 800 °C for 40, 30 and 20 days, respectively, to ensure the establishment of an equilibrium state. The treatment was completed with rapid water quenching to preserve the equilibrium state at high temperature.

Sections of the specimens were prepared in the conventional way for metallographic examinations. A nital etching solution was used for revealing their microstructural details and a conventional optical microscope was used for the preliminary examination of all specimens. Detailed metallographic examinations and compositional analyses of various phases in the samples were performed using a JSM-6510 scanning electron microscope (SEM) equipped with an OXFORD INCA energy dispersive x-ray spectroscope (EDS). More precise determinations of the phase composition and the solubility were conducted using the wave dispersive x-ray spectroscopy (WDS). The compositions reported in this study were the averages of at least five measurements. In addition, some critical alloys were carefully studied by analyzing XRD patterns generated using a BEVKER-AXS/D8 advanced x-ray diffractometer with Cu Kα-radiation and a step increase of 0.01° in the 2θ angle.

To determine the transition point of the new compound, NETZSCH DSC 404 F3 high temperature calorimeter was used. In order to prevent oxidation and the evaporation of Zn during the heating, the specimens were sealed in evacuated quartz tubes. Vassilev[23] used this method in study of Ni-Sn-Bi system. The DTA calibration was performed by measuring the heat of melting of pure elements (Bi, Zn, Al, Ag and Au) using the same working conditions. The base line was determined by performing measurements on two empty quartz tubes. And the temperature uncertainty was about ±0.6 °C. The measurement was repeated three times.

Results and Discussion

Phase Equilibrium in Zn-Rich Corner at 450 °C

All phases and their chemical compositions detected in the three phase regions in the Zn-Fe-Zr alloys, after being annealed at 450 °C for 40 days, are summarized in Table 2. The ternary compound which had a narrow composition range of 4.3-5.1 at.%Zr, 8.4-9.9 at.%Fe and 85.1-87.1 at.%Zn was firmly identified. It can be approximately represented by stoichiometric formula of ZrFe2Zn20, which is the same as that reported by Gross et al.[8] The ternary compound is similar to those existing in the Zn-Fe-Ti,[24] Zn-Fe-Ni[25] and Zn-Fe-Nb[26] systems.

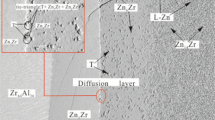

As shown in Table 2, ZrFe2Zn20 was in equilibria with all Zn-Fe binary compounds at 450 °C. Three phases were clearly distinguished in alloys A1-A5. ZrFe2Zn20 was more resistant to etching by nital and can be clearly distinguished from all Zn-Fe binary compounds. Figure 1 and 2 show the microstructures of alloys A2 and A5, which are located in the three-phase region of δ + ζ + ZrFe2Zn20 and α-Fe + Γ + ZrFe2Zn20, respectively. SEM-WDS analysis indicated that no Zr was dissolved in any of the Zn-Fe binary compounds. As can be seen from the microstructure of alloy A7 in Fig. 3, ZrFe2Zn20 coexists with ZrZn22 and Zr5Zn39. ZrFe2Zn20 was more difficult to be etched than ZrZn22, but less than Zr5Zn39 and ZrZn3. Fe was hardly detected in ZrZn22, Zr5Zn39 and ZrZn3 by SEM-WDS analysis.

To further identify the ZrFe2Zn20 phase and confirm the relative phase equilibrium states determined by SEM-WDS, the XRD patterns of some selective alloys were generated, as shown in Fig. 4-9. It needs to be noted that the patterns of single ζ, δ, Γ1 and Γ were gathered from Cook and Grant[20] and that of α-Fe, η-Zn, ZrZn22 and Zr5Zn39 were calculated from available crystal structure data from Samson[17] and from Chen and Jeitsehko[18]. However, the XRD pattern of ZrZn3 in Fig. 7 and 8(b) was generated from the Zn-25 at.%Zr alloy which was prepared by annealing the cold-pressed mixture of the Zn and Zr powders in evacuated tube at 700 °C for 30 days. Arroyave et al.[15] first-principle calculated the enthalpies of formation for ZrZn3 with the AB3-type structures. They believed that the cubic L12 structure is likely to be the ground state for the ZrZn3 composition. However, it had no experiment supporting.

The XRD pattern of ZrFe2Zn20 contained in all figures was generated from alloy A11. The alloy was prepared by the way described in Section 2 and was confirmed to be a single phase by SEM-EDS. As can be seen from Fig. 4-9, the characteristic peaks of ZrFe2Zn20 are clearly distinguished from all binary compounds in all alloys.

The TREOR program[27] was used to index and calculate the pattern automatically and finally all peaks were indexed in the cubic system, resulting in the figure of merit, M(40) = 26, F(40) = 30. The lattice parameter of the crystal was 1.3941 nm, which agreed well with that reported by Gross et al.[8] As discussed by Gross et al., both the ZrFe2Zn20 and ZrZn22 had the CeCr2Al20-type structure. Therefore, the profiles of the XRD patterns of them were similar, as shown in Fig. 6. They had a difference of 0.45° (2θ) in all peaks with ZrZn22 having the larger lattice parameter of 1.4101 nm.[17] The BSE image and XRD pattern of the alloys A7, shown in Fig. 3 and 6, respectively, indicated that ZrFe2Zn20 containing 9 at.% of Fe is a different phase from ZrZn22.

Another ternary compound was found in alloy A9, as shown in Fig. 8(a). It coexisted with ZrZn3 and ZrFe2Zn20 with a little color difference from ZrZn3. SEM-WDS analysis indicated that it contained 20 at.%Zr, 30 at.%Fe and 50 at.%Zn. Therefore, it was designated as Zr2Fe3Zn5. An XRD pattern of alloy A9 in Fig. 8(b) clearly shows that there are some peaks, denoted by dots, not belong to the patterns of ZrFe2Zn20 or ZrZn3. They can not be indexed as attributable to any of binary compound in the system.

It is important to note that 12.3 at.%Zn was detected in the Fe23Zr6 phase in alloy A10. Three phases were clearly distinguished in the BSE image of alloy A10 in Fig. 9(a). And Fe23Zr6 was successfully index in the XRD pattern (Fig. 9b) but with 2θ difference of about 0.244°. It may be a ternary compound which has a crystal structure similar to Fe23Zr6 and needs further examination. At present, it was considered as Fe23Zr6.

Based on the experimental results obtained in this study and the information of relevant binary systems in the literatures, the 450 °C isothermal section of the Zn-rich corner of the Zn-Fe-Zr system was constructed, as shown in Fig. 10. The ternary compound ZrFe2Zn20, which has a narrow composition range, is in equilibrium with all phases in the Zn-rich corner and is designated as T1.

Phase Equilibrium in Zn-Rich Corner at 600 and 800 °C

In the present work, phase equilibrium in the Zn-rich corner of the Zn-Fe-Zr system at 600 °C was also investigated. Some typical SEM images and XRD patterns are clearly shown in Fig. 11-13. For concise, the BSE images and XRD patterns of the alloys which lie in the same ternary phase field with that at 450 °C, i.e., ZrFe2Zn20 + Zr5Zn39 + ZrZn3 and α-Fe + ZrFe2Zn20 + Γ, were not shown again.

The ZrFe2Zn20 phase stably existed at 600 °C and coexisted with all the compounds in the Zn-rich corner. ZrZn22, ζ and Γ1 were not found at this temperature which agrees well with the binary boundaries. The equilibria of δ + Liq. + ZrFe2Zn20 in alloy B1 is shown in Fig. 11. It should be pointed out that the η-Zn marked in the figure was the liquid phase at the annealing temperature. The BSE image and XRD pattern of alloy B2, which show the coexistence of δ + Γ + ZrFe2Zn20, was shown in Fig. 12(a) and (b), respectively. The pattern of alloy A11 was used to index the ZrFe2Zn20 phase at 600 °C. SEM-WDS results in Table 3 suggested that Zr can not dissolve in δ and Γ at 600 °C. Besides, the XRD pattern of alloy B4 is shown in Fig. 13. Liquid, Zr5Zn39 and ZrFe2Zn20 were coexisting in the alloy. No Fe was detected in Zr5Zn39 and ZrZn3 by SEM-WDS analysis. The Zn-rich corner of the Zn-Fe-Zr system at 600 °C was outlined in Fig. 14.

As shown above, the ZrFe2Zn20 phase stably exists at 600 °C. The alloy A11, which was annealed at 450 °C for 40 days and confirmed to be a single phase, was used to determine the transition point of the ZrFe2Zn20 phase. The alloy was enclosed in an evacuated quartz tube in DTA examination to prevent oxidation and the evaporation of Zn. The DTA curve in Fig. 15 indicates that the transformation point of the ZrFe2Zn20 phase is 878.6 °C. At the same time, the equilibria of Liq. + α-Fe + ZrFe2Zn20 and Liq. + ZrFe2Zn20 + ZrZn3 at 800 °C were observed in the present work. The Zn-rich corner of the Zn-Fe-Zr system at 800 °C was outlined in Fig. 16.

Conclusions

Based on SEM-EDS and WDS analyses and x-ray diffraction studies, the phase relationship in the Zn-rich corner of Zn-Fe-Zr ternary system at 450, 600 and 800 °C was outlined in the present work. The solubility of Zr in four Fe-Zn compounds is too limited to be detected. And Fe can not be dissolved into the ZrZn22, Zr5Zn39 and ZrZn3.

Two ternary compounds, designated as ZrFe2Zn20 and Zr2Fe3Zn5 according their narrow chemical composition, were found in the system. DTA test indicated that ZrFe2Zn20 can stably exist below 878.6 °C. The XRD pattern of the single ZrFe2Zn20 phase was successfully indexed. It is a CeCr2Al20-type compound with lattice parameter a = 1.3941 nm. ZrFe2Zn20 can be in equilibrium with all phases in the Zn-rich corner of the system. Moreover, Zr2Fe3Zn5 was found coexisting with ZrFe2Zn20 and ZrZn3.

References

R.W. Sandelin, Galvanizing Characteristics of Different Types of Steel, Wire Wire Prod., 1940, 15(11-12), p 655-676

J. Foct, P. Perrot, and G. Reumont, Interpretation of the Role of Silicon on the Galvanizing Reaction Based on Kinetics, Morphology and Thermodynamics, Scr. Metall., 1993, 28(10), p 1195-1200

H. Guttman and P. Niessen, Reactivity of Silicon Steels in Hot-Dip Galvanizing, Can. Metall. Q., 1972, 11(4), p 609-615

J. Zervoudis, G.R. Adams, V.M. Duarte, M. Gilles, and R. Sokolowski, Galvanizing of Reactive Steels (Vancouver, CA), Cominco, Ltd., United States patent 6280795, 2001 p 1-11

J. Mackowiak and N.R. Short, Metallurgy of Galvanizing Coatings, Int. Met. Rev., 1979, 24(1), p 1-19

B. Zhang, Development of Corrosion Resistant Galvanizing Alloys (Birmingham), The University of Birmingham, 2005, 255 pp

J.J. Sebisty and R.H. Palmer, Hot-Dip Galvanizing with Less Common Bath Additions, Report, Department of Mines and Technical Surveys—Mines Branch, 1964, 40 pp

N. Gross, T. Nasch, and W. Jeitschko, Ternary Intermetallics with High Zinc Content: TT’2Zn20 (T = Zr, Hf, Nb; T’ = Mn, Fe, Ru, Co, Rh, Ni) with CeCr2Al20-Type Structure, J. Solid State Chem., 2001, 161(2), p 288-293

X. Su, N.-Y. Tang, and J.M. Toguri, Thermodynamic Evaluation of the Fe-Zn System, J. Alloys Compd., 2001, 325(1-2), p 129-136

J. Nakano, D.V. Malakhov, and G.R. Purdy, A Crystallographically Consistent Optimization of the Zn-Fe System, Calphad, 2005, 29(4), p 276-288

G. Reumont, P. Perrot, J. Fiorani, and J. Hertz, Thermodynamic Assessment of the Fe-Zn System, J. Phase Equilib. Diffus., 2000, 21(4), p 371-378

W. Xiong, Y. Kong, Y. Du, Z.-K. Liu, M. Selleby, and W.-H. Sun, Thermodynamic Investigation of the Galvanizing Systems, I: Refinement of the Thermodynamic Description for the Fe-Zn System, Calphad, 2009, 33(2), p 433-440

R. Arroyave and Z.K. Liu, Thermodynamic Modelling of the Zn-Zr System, Calphad, 2006, 30(1), p 1-13

P. Chiotti and G. Kilp, Vapor pressure and thermodynamic properties of Zn-Zr and Zn-U alloys, Trans. Metall. Soc. AIME, 1960, 218, p 41-44

R. Arroyave, A. van de Walle, and Z.K. Liu, First-Principles Calculations of the Zn-Zr System, Acta Mater., 2006, 54(2), p 473-482

P. Chiotti and G.R. Kilp, Zinc-Zirconium System, Trans. Metall. Soc. AIME, 1959, 215, p 892-898

B. Samson, The Crystal Structure of the Intermetallic Compound ZrZn22, Acta Crystallogr., 1961, 14, p 1229-1236

X.-A. Chen and W. Jeitschko, Preparation, Properties, and Crystal Structure of Zr5Zn39, a Vacancy Variant of the Ce5Mg41-Type, and Structure Refinement of ZrZn22, J. Solid State Chem., 1996, 121(1), p 95-104

Y. Liu, X. Su, F. Yin, Z. Li, and Y. Liu, Experimental Determination and Atomistic Simulation on the Structure of FeZn13, J. Phase Equilib. Diffus., 2008, 29(6), p 488-492

D. Cook and R. Grant, Identification of the Iron-Zinc Phases in Galvanneal Steel Coatings by Mossbauer Spectroscopy and X-ray Diffraction. Phase I: Characterization of the Fe-Zn Intermetallic Phases, ILZRO Report: ODUDCC0193, 1993, p 1-108

C.H.E. Belin and R.C.H. Belin, Synthesis and Crystal Structure Determinations in the Γ and δ Phase Domains of the Iron-Zinc System: Electronic and Bonding Analysis of Fe13Zn39 and FeZn10, a Subtle Deviation from the Hume-Rothery Standard?, J. Solid State Chem., 2000, 151(1), p 85-95

X. Su, N.-Y. Tang, and J.M. Toguri, 450 °C Isothermal Section of the Fe-Zn-Si Ternary Phase Diagram, Can. Metall. Q., 2001, 40(3), p 377-384

G.P. Vassilev, K.I. Lilova, and J.C. Gachon, Phase Diagram Investigations of the Ni-Sn-Bi System, J. Alloys Compd., 2009, 469(1-2), p 264-269

X. Tang, F. Yin, X. Wang, J. Wang, X. Su, and N.-Y. Tang, The 450 °C Isothermal Section of the Zn-Fe-Ti System, J. Phase Equilib. Diffus., 2007, 28(4), p 355-361

N.-Y. Tang, X. Su, and J.M. Toguri, Experimental Study and Thermodynamic Assessment of the Zn-Fe-Ni System, Calphad, 2001, 25(2), p 267-277

H. Tu, X. Su, F. Yin, X. Wang, and J. Wang, 450 °C Isothermal Section of the Zn-Fe-Nb Ternary System at the Zn-Rich Corner, J. Alloys Compd., 2009, 485(1-2), p 270-274

P. Werner, L. Eriksson, and M. Westdahl, TREOR, a Semi-Exhaustive Trial-and-Error Powder Indexing Program for all Symmetries, J. Appl. Crystallogr., 1985, 18(5), p 367-370

Acknowledgments

The authors gratefully acknowledge the financial support from Qinlan project, and National Natural Science Foundation of China (Nos. 50971110 and 50971111). Discussions with Dr. Nai-Yong Tang at Teck Metals are much appreciated.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

Open Access This is an open access article distributed under the terms of the Creative Commons Attribution Noncommercial License ( https://creativecommons.org/licenses/by-nc/2.0 ), which permits any noncommercial use, distribution, and reproduction in any medium, provided the original author(s) and source are credited.

About this article

Cite this article

Wu, C., Wang, X., Liu, D. et al. Phase Relationships in the Zn-Rich Corner of the Zn-Fe-Zr System. J. Phase Equilib. Diffus. 32, 271–278 (2011). https://doi.org/10.1007/s11669-011-9901-2

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11669-011-9901-2