Abstract

Alloys with composition Ti25(Fe50 − x Ni x )Al25 (0 ≤ x ≤ 50) were investigated employing electron probe microanalysis (EPMA) and X-ray powder diffraction (XPD). For TiFe2Al, in situ neutron powder diffraction (ND) was used for the inspection of phase constitution covering the temperature range from 27 °C (300 K) to 1277 °C (1550 K). Combined Rietveld refinement of ND and XPD data for TiFe2Al revealed that Fe atoms occupy the 8c site in space group \( Fm\bar{3}m ,\) Ti with a small amount of Al sharing the 4a site, and the remaining Ti and Al atoms adopting the 4b site. This structural model was successfully applied in the refinement of all alloys Ti25(Fe50 − x Ni x )Al25 (0 ≤ x ≤ 50). Partial atom order exists on the Fe-rich side while complete order is observed for the Ni-rich side. Profiles recorded by in situ neutron powder diffraction for TiFe2Al in the range of investigated temperatures show two phases, namely Heusler phase and MgZn2-type Laves phase. Diffraction peaks from the Heusler phase dominate the profiles at lower temperatures but at higher temperatures the MgZn2-type Laves phase is the main phase. No CsCl-type phase was found in the alloy in the investigated temperature range. The thermal expansion coefficient of TiFe2Al is 1.4552 × 10−5 K−1.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

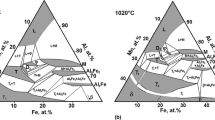

Since the first Heusler alloy was identified by Heusler[1] in 1903, intermetallic compounds with Heusler-type structure are attracting considerable interest due to their unique magnetic, mechanical, thermoelectric and other physical properties. FeAl-base and NiAl-base alloys with Heusler type are considered as potential high temperature structural materials with high strength in combination with excellent oxidation resistance.[2-8] It is well known that intermetallic alloys with CsCl-type structure, for example NiAl aluminides,[5-10] are important candidates for high temperature structural application. However, shortages exist such as poor ductility at room temperature and the loss of strength at high temperature because of the open structure of the ordered bcc lattice. Alloying with elements that form Heusler phase precipitates has been demonstrated as a useful way to solve this problem.[2,6,7,11-14] Particularly the control of the two-phase microstructure of the CsCl and the Heusler phases turned out to be very important.[5] Isopleths were established for the sections NiAl-TiNi2Al,[5] FeAl-TiFe2Al,[15] Fe3Al-TiFe2Al-FeAl,[16,17] NiAl-TiNi2Al-TiNi,[15,18,19] TiNi2Al-TiNi,[20] and (Fe, Ni)Al-Ti (Fe, Ni).[15] The influences of the replacement of X or Z in X2YZ by a fourth element[15,21-23] on (i) the critical boundaries of the CsCl/Heusler phase, (ii) the transition temperature from Heusler to CsCl phase, and (iii) the stability of Heusler phase were well investigated and discussed.[24] The lattice misfit between the two coherent phases, CsCl and Heusler phase, was also thought to be an important factor to affect the mechanical properties by influencing the shape of the precipitates, the spatial distribution in the alloy and the coarsening behavior.[6,12,19,25,26] On the other hand, atom substitution in binary alloys can drastically increase the transition temperature to enlarge the range of the Heusler phase, specifically, in binary Fe3Al with BiF3-type structure and/or in ternary MnCu2Al-type by substitution of Al by Si[27] or of Fe by M (M = Ti,[4,16] V, Cr, Mn, and Mo[26,28]), respectively. For the ternary alloys, TiFe2Al and TiNi2Al, past efforts focused on physical properties,[3,8,11,12,29-31] lattice parameters,[6,19,32-40] and structure evaluations.[36] However, no investigation is known dealing with detailed atomic site preference in the Heusler phase of the quaternary system Ti-Fe-Ni-Al. Since the atom’s environment in the unit cell (the atom species and position of the nearest neighbors) is of significance to the stability of the ordered phase[24] and to the material properties,[41] the present work provides detailed structural information for the Heusler phase in the quaternary system Ti-Fe-Ni-Al along the section TiFe2Al-TiNi2Al.

It is worthwhile to note the structural differences among the related structure types of W, CsCl, BiF3, and MnCu2Al. Figure 1 shows the crystal structures and corresponding simulated X-ray diffraction patterns with Miller indices for Ti-Fe-Al phases. For the structure type of W and CsCl, 8 conventional unit cells are used in Fig. 1(a) and (b) for convenient comparison with the larger cell of the BiF3, and MnCu2Al types. Replacing the central atom in the W-type structure by an atom of a different species we arrive at the CsCl-type (Fig. 1b). As a consequence, the substitution changes the Bravais lattice from body-centered to primitive and thus triggers the appearance of “primitive” peaks in the diffraction patterns (e.g., (100) in the CsCl-cell corresponds to (200) in the unit cell with double lattice dimension; see Fig. 1b). The BiF3 structure (formula X3Y) consists of 8 W-type cells where 4 of the central atoms in tetrahedral position are replaced by a different element species all together revealing a face-centered symmetry (see Fig. 1c). The MnCu2Al-type structure can be constructed by substitution of the second tetrahedral set of central atoms by a third atom species without reduction of the fcc symmetry (see Fig. 1d). Nonzero intensities of (111), (311) and (331) differentiate the Heusler type (BiF3 and MnCu2Al) from the CsCl-type (see Fig. 1b) but note that the Miller indices for the CsCl-type refer to a block of 8 conventional unit cells (a = 2a 0) in order to compare with the Heusler type).

Experimental Details

A series of alloys with nominal composition Ti25(Fe50−x Ni x )Al25 (x = 0, 10, 20, 25, 30, 40, and 50) were prepared by argon arc-melting, from high-purity materials (more than 99.9 mass%), on a water-cooled copper hearth. To insure homogenization, all alloys (1 g for each alloy) were re-melted three times. Part of each sample was vacuum sealed in quartz tubes and annealed at 900 °C for 10 days before being quenched in cold water. X-ray powder diffraction data from as-cast and annealed alloys were collected employing a Guinier-Huber image plate system with Cu-Kα1 or Fe-Kα1 (8° < 2θ < 100°). Precise lattice parameters were calculated by least-squares fits to indexed 4θ-values employing Ge as internal standard (a Ge = 0.5657906 nm). X-ray powder intensity data for the determination of structural parameters were collected on a Siemens D5000 instrument with Cu-Kα1,2 (10° < 2θ < 110°, step (2θ) = 0.02°) equipped with an energy dispersive SOLX detector.

Neutron diffraction was performed at room temperature for the alloy TiFe2Al annealed at 900 °C in high intensity mode (Δd/d ≥ 2 × 10−3) and on heating in the temperature range 27 ≤ T ≤ 1277 °C (300 ≤ T ≤ 1550 K; heating rate: 5 °C/min and dwell time for diffraction run at isothermal temperature: 180 min) on the high-resolution HRPT diffractometer[42] at the SINQ spallation source of Paul Scherrer Institute, Switzerland. To reduce preferential orientation effects, the alloy was powdered to a grain size below 60 μm. The powder was contained in a Nb-can sealed under argon, the neutron wavelength is λneutron = 0.1494 nm and the θ range was 5° ≤ 2θ ≤ 165°. After neutron diffraction the powder appeared to be densely sintered into a rod-shaped body that easily separated from the Nb-container. With respect to a possibly slow kinetic in reaching phase equilibrium during the relative short dwell time in neutron diffraction, discs were cut from the rod and were sealed individually and annealed at 800 °C for 10 days, 900 °C for 7 days, 1000 °C for 4 days, 1100 °C for 24 h and 1200 °C for 12 h. After this long term annealing the phase constitutions in the discs were measured by XPD and EPMA and should insure equilibrium conditions.

Quantitative Rietveld refinement of the X-ray and neutron powder diffraction data was performed with the FULLPROF program,[43] employing internal tables for neutron scattering lengths and X-ray atomic form factors.

All as-cast and annealed samples were polished via standard procedures and have been examined by optical metallography and scanning electron microscopy (SEM). Specimen compositions were determined by Electron Probe Microanalysis (EPMA). Compositions of quaternary Ti-Fe-Ni-Al alloys were established on a Carl Zeiss DSM 962 instrument equipped with a link EDS system operated at 20 kV and 60 μA. Compositions of phases in the TiFe2Al alloy after ND and after annealing at various temperatures between 800 and 1200 °C have been measured on a Cameca SX 50 and a Jeol JXA-8100 at 15 kV and 20 nA using the pure elements as standards.

Results and Discussion

The Alloy Series Ti25(Fe50−x Ni x )Al25 (0 ≤ x ≤ 50)

X-ray diffraction patterns in Fig. 2(a) were collected from samples annealed at 900 °C with nominal compositions Ti25(Fe50−x Ni x )Al25 (0 ≤ x ≤ 50). In all cases a single Heusler-type structure was recorded except for TiFe2Al, which besides the Heusler phase revealed a tiny amount of Laves phase, showing consistency with the phase diagram reported by Palm et al.[44,45] For 1000 °C a similar phase constitution was found by Fu et al.[41] in this alloy series. Lattice parameters a as a function of Ni content (x) are plotted in Fig. 3 in comparison with all literature data available for the Heusler-type phase. The small differences of lattice parameters for Ti25(Fe50−x Ni x )Al25 (0 ≤ x ≤ 50) are attributed to the comparable radii of Fe and Ni atoms.

Experimental X-ray diffraction patterns for the alloys Ti25(Fe50−x Ni x )Al25 (0 ≤ x ≤ 50) annealed at 900 °C (a) and Rietveld refinements for TiFe2Al from XPD (b) and ND (c) with respect to different structure types (for refinements with CsCl-type model, only the Yobs.–Ycal. curves and Bragg positions are presented in both cases)

As indicated in Fig. 1, the nonzero intensity of the (111) reflection is a strong evidence for the Heusler-type structure with respect to a CsCl or W-type structure (a detailed description of the characteristics of each structure type and corresponding X-ray powder diffractograms are presented in the Introduction). For TiFe2Al, the weakness of the (111) XPD reflection prompted us to compare refinements for a CsCl-type with respect to a Heusler type. From the difference curves of the refinements (which yield close residual values for both structure types) in Fig. 2(b) it is not easy to recognize the proper structural type. However, the clearly exposed ND intensity of (111) compared to XPD and the significant difference for the (111) reflection in the Yobs.–Ycal. curves (see Fig. 2c) unambiguously indicated the Heusler type as the proper structure. The location of the heavy Fe atoms in the unit cell (8c-site) were easily defined by X-ray diffraction, while those of Ti can be found unambiguously by neutron diffraction due to the negative neutron scattering length of natural titanium. Therefore the combined Rietveld refinement of neutron and X-ray data for TiFe2Al clearly revealed: (i) Fe in the 8c positions, (ii) Ti atoms share with a small amount of Al the 4a sites and (iii) the remaining Ti and Al occupy the 4b sites. Due to centro-symmetry the intensity calculations with the 4a and 4b sites interchanged are equivalent, i.e., exchange of atom occupation in these two positions does not influence the R-values in the Rietveld refinements. Although the deviation from a fully ordered Heusler-type atom arrangement is small, the random distribution significantly reduces I(111). This structure model was successfully employed on the other compounds of the alloy series Ti25(Fe50 − x Ni x )Al25. All results from Rietveld refinements are summarized in Table 1. However, due to only slight differences for the X-ray scattering factors of Ni and Fe atoms, the occupation of Ni and Fe in the 8c site could not be defined, and therefore the Fe/Ni ratio was fixed from EPMA. The obvious increase of the intensity I(111) throughout the alloy series (as seen in Fig. 2a) corresponds to a monotonous decrease of the partial atom disorder in the 4a and 4b sites. Particularly for the alloys with 0 ≤ x ≤ 30 (see Table 1 and Fig. 2), any attempts to attain more ordered arrangements failed yielding higher residual values or negative temperature factors (see Fig. 4). For x = 40 and 50, the 4a and 4b sites show full atom order in consistency with literature data.[36] It shall be noted that compositions derived from Rietveld refinements are in good agreement with nominal compositions as well as with the compositions obtained from EPMA (see Table 1).

In Situ Neutron Diffraction for TiFe2Al (RT < T < 1277 °C)

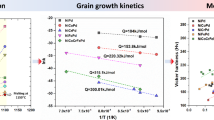

A sequence of plots of neutron diffraction patterns recorded for various temperatures for TiFe2Al are shown in Fig. 5. The corresponding reflections from the Laves phase and the Heusler phase as well as temperature axes were indicated and also those peaks that stem from the Nb-sample holder. Apparently, diffraction patterns from the Heusler phase dominated the profiles covering the temperature range from 27 °C (300 K) to 1027 °C (1300 K) (the profiles recorded at 1027 °C (1300 K) and 1077 °C (1350 K) were emphasized in Fig. 5 by a dashed line and a dotted line, respectively), while the MgZn2-type Laves phase dominates above 1077 °C (1350 K). This indicates that at higher temperature the Laves phase is the main phase. Both cubic phases (Heusler or CsCl phase) and Laves phase coexist in the alloy at all the investigated temperatures. The presented profiles can not prove or reject visually the fact that the cubic phase is Heusler type or CsCl type at temperatures above 1077 °C. Although the characteristic peak (111) of the Heusler phase disappeared completely at about 1177 °C (1450 K), this cannot be taken as evidence that the CsCl-type phase appears, since the strongest peak (220) of the Heusler phase already was very weak. The characteristic peaks probably turned undetectable. Figure 6 shows the ratio of integrated intensities for the reflections (111)/(200) and (311)/(222) as a function of temperature. Both ratios seem to be constant below 527 °C (800 K) but increase with temperature in the range 527-727 °C (800-1000 K) and turn to be constant again up to 1027 °C (1300 K). Integration above 1027 °C (1300 K) was not considered because the precision of the intensity ratio is questionable. Since the CsCl phase generally forms preferentially at high temperature, the mixture of two phases will lead to a decrease of the intensity ratios (111)/(200) and (311)/(222) because both intensities (200) and (222) not only benefit from the Heusler phase but also from the CsCl phase. The increase of the intensity ratios shown in Fig. 6 suggests that the CsCl phase does not exist in this temperature range.

The atom arrangement in TiFe2Al as derived from Rietveld refinement of in situ neutron diffraction data shows consistency with that obtained at room temperature. The temperature dependence of the occupancies for Ti in 4a and Ti in 4b is shown in Fig. 7. As no structural voids were found during the refinements, the temperature dependence of the occupancy for Al in both sites (not shown in Fig. 7) can be easily obtained by subtracting the Ti occupancy from 4. The occupancy of Ti in the 4a site is almost constant below 527 °C (800 K) and increases slightly from 527 °C (800 K) to 727 °C (1000 K) but decreases drastically above 1027 °C (1300 K). This trend seems to correspond to that of the intensity ratio (111)/(200) and (311/222) which indicates that the intensities of (111) and (311) reflect the Ti occupancy in 4a. Accordingly, at high temperature, the refined compositions of the Heusler phase significantly deviate from the stoichiometric composition TiFe2Al.

The temperature dependence of the site preference for TiFe2Al (Fig. 7) was analyzed in terms of two boundary models for a possible transformation of the Heusler-type into the CsCl-type structure. As already discussed in Fig. 1, such a transition occurs in case the scattering power of 4a and 4b sites becomes equivalent. Therefore model A would comply with a CsCl-type structure for composition TiFe2Al at around 1200 °C (point a, Fig. 7, Fe8c(0.5Ti0.5Al)4a(0.5Ti0.5Al)4b), while the site preference according to model B would reveal the CsCl type lattice at ~1300 °C with a composition for binary FeAl (point b, Fe8cAl4aAl4b , Fig. 7). Attempts to force refinements in model A fixing appropriate amounts of Ti in the 4b site were ruled out due to high residual values. Model B disqualifies by an unacceptable composition (CsCl-type structure only possible at point b).

The isotropic displacement factors, B, for all sites in the Heusler unit cell were plotted in Fig. 7(inset) as a function of temperature. A significant rise of B at around 1100 °C indicates the occurrence of a transition. As indicated in Fig. 5, at around this temperature, the amount of Heusler phase in the alloy starts to be reduced greatly on heating.

Analyzing in situ neutron diffraction data we have to consider a slow equilibration rate in the sample at low temperature. One can see from Fig. 5 and 7 that data obtained in the range RT (Room temperature) < T < 900 °C represent almost the same state of the sample, while at higher temperatures significant changes are observed due to an enhanced diffusion rate. In order to elucidate equilibrium conditions for TiFe2Al, the sample was cut into several discs after the neutron diffraction experiment and annealed at various temperatures in the range from 800 to 1200 °C.

The samples after ND diffraction and after annealing at 1200 °C show almost a single Laves phase with a tiny amount of Heusler phase. The volume fraction of the Heusler phase increases with decreasing annealing temperature. Accordingly the sample heat treated at 800 °C reveals major amounts of Heusler phase close to the nominal composition (Fig. 8, 9). The microstructures of the sample after neutron diffraction and after annealing at 800 °C are shown in Fig. 9, indicating an almost single Laves phase at 1277 °C and grain growth and precipitation of Heusler phase after annealing at 800 °C. The ratio of Heusler phase to Laves phase versus annealing temperature is plotted in Fig. 10. A polynomial equation was used to fit the data and an extrapolation derives the threshold temperature as T = 1217 °C. It is interesting to note, that this value is close to the temperature, which was interpreted by Ohnuma et al.[16] (from thermal effects) as a structural transformation of TiFe2Al with Heusler type into CsCl-type. In this context it is important to stress that the TiFe2Al sample at high temperatures mainly consists of Laves phase in equilibrium with a Ti-depleted Heusler phase Ti~0.5Fe2Al~1.5.

Finally, the thermal expansion coefficient α a of the Heusler phase TiFe2Al was calculated through a polynomial fitting of lattice parameters from Rietveld refinements using the relation:

where α a is the linear thermal expansion coefficient, a 298 K is the lattice parameter value at room temperature, and a T is the lattice parameter value at the measured temperature. Discarding low precision data extracted from the dwindling amount of the Heusler phase at high temperatures, only the lattice parameters below 827 °C (1100 K) were employed for the analysis. The relation of lattice parameter with temperature can be described by a linear equation (see Fig. 11) as: a, nm = 0.5852 + 0.8498 × 10−6 T. Then α a = 1.4552 × 10−5 K−1, which is very close to the expansion coefficients of αFe[47,48] and Fe-40 at.% Al (CsCl-type).[49,50]

Conclusions

Combined Rietveld refinement of X-ray and neutron diffraction data for TiFe2Al revealed the structural details of the ternary Heusler phase as a function of temperature and Fe/Ni substitution, i.e., Fe atoms occupy the 8c site, Ti with a small amount of Al shares the 4a site and the rests of Ti and Al atoms are situated in the 4a site. This structural model holds for all alloys Ti25(Fe50−x Ni x )Al25 (0 ≤ x ≤ 50) revealing partial order in the Fe-rich side but complete order in the Ni-rich side. Profiles recorded by in situ neutron powder diffraction for TiFe2Al in the range of investigated temperatures show two phases, namely Heusler phase and MgZn2-type Laves phase. The fraction of Heusler phase in the alloy decreases with temperature. No CsCl-type phase was found in the alloy in the investigated temperature range.

The thermal expansion coefficient of the TiFe2Al Heusler phase was calculated for the temperature range 300-1100 K (27-827 °C) to be 1.4552 × 10−5 K−1.

References

F. Heusler, Ueber Magnetische Manganlegierungen (On Magnetic Manganese Alloys), Verh. Dtsch. Phys. Ges., 1903, 5, p 219, in German

R.S. Polvani, S.T. Wen, P.R. Strutt (1976) High Temperature Creep in a Semi-coherent NiAl-Ni2AlTi Alloy, Metall. Mater. Trans. A. 7(1), 33-40

P.R. Strutt, R.S. Polvani, J.C. Ingram 1976. Creep Behavior of the Heusler Type Structure Alloy Ni2AlTi, Metall. Mater. Trans. A, 7(1), 23-31

M.G. Mendiratta, S.K. Ehlers, H.A. Lipsitt 1987. DO3-B2-α Phase Relations in Fe-Al-Ti Alloys, Metall. Mater. Trans. A, 18, 509–518

R.D. Field, R. Darolia, D.F. Lahrma. 1989. Precipitation in NiAl/Ni2AlTi Alloys. Scr. Metall. 23(9) 1469-1474

W. Lin, A.J. Freeman, (1992) Cohesive Properties and Electronic Structure of Heusler L21-phase Compounds Ni2XAl (X=Ti, V, Zr, Nb, Hf, and Ta). Phy. Rev. B: Condens. Matter. 45, 4561-4569

Y. Mishima, E.H. Lee, C.T. Liu 1995. Microstructure, Phase Constitution and Tensile Properties of Co-Ni-Ti-Al Base Multi-phase Intermetallic Alloys. Mater. Trans., JIM, 36(8), 1031-40

U. Prakash, G. Sauthoff 2001. Structure and Properties of Fe-Al-Ti Intermetallic Alloys. Intermetallics, 9, 107-112

J. Bauer, P. Rogl, A. Pewin, M. Boh, W. Wolf, R. Podloucky, Y. LeFriec, D. Antoine 1996. TiAl-Based Alloys with Nickel. Intermetallics, 4, 71-76

P.H. Kitabjian, W.D. Nix, 1998. Atomic Size Effects in Ni-Al Based Solid Solutions, Acta Mater. 46(2), 701-710

M. Yamaguchi, Y. Umakoshi, T. Yamane 1984. Plastic Deformation of Ni2AlTi, Philos. Mag. A50, 205-220

Y. Umakoshi, M. Yamaguchi, T. Yamane 1985. Effects of Non-Stoichiometry on the High-temperature Deformation of Ni2AlTi, Philos. Mag. A52, 357-367

C.T. Liu, C.L. White, J.A. Horton. 1985. Effect of Boron on Grain-Boundaries in Ni3Al. Acta Metall., 33, 213

G. Bozzolo, R. Noebe, J. Ferrante, A. Garg, F. Hongecy, C. Amador 1999. BFS Simulation and Experimental Analysis of the Effect of Ti Additions on the Structure of NiAl, J. Comput. Aided Mater. Des., 6, 33-68

R. Kainuma, K. Urushiyama, K. Ishikawa, C.C. Jia, I. Ohnuma, and K. Ishida, Ordering and Phase Separation in b.c.c. Aluminides of the Ni-Fe-Al-Ti System, Mater. Sci. Eng., A, 1997, 239-240, p 235-244

I. Ohnuma, C.G. Schön, R. Kainuma, G. Inden, K. Ishida 1998. Ordering and Phase Separation in the b.c.c. Phase of the Fe-Al-Ti System. Acta Mater. 46(6), 2083-2091

R. Ducher, “Contribution à l’étude du diagramme de phase ternaire Fe-Ti-Al et des équilibres Fe-TiAl,” Dr. Thesis, ENSIACET Toulouse, 2003, p 1-171

W.J. Boettinger, L.A. Bendersky, F.S. Biancaniello, J. W. Cahn, 1988. Rapid Solidification and Ordering of B2 and L21 Phases in the NiAl-NiTi System. Mater. Sci. Eng. 98, 273-276

J. Jung, G. Ghosh, G.B. Olson, 2003. A Comparative Study of Precipitation Behavior of Heusler Phase (Ni2TiAl) from B2-TiNi in Ni–Ti–Al and Ni–Ti–Al–X (X = Hf, Pd, Pt, Zr) Alloys. Acta Mater. 51, 6341–6357

M. Enomoto, T. Kumeta, 1997. Analysis of the β′ Ni2TiAl/βNiTi Equilibrium in Ni-Ti-Al Alloys by the Cluster Variation Method. Intermetallics, 5, 103-109

K. Ishikawa, H. Mitsui, I. Ohnuma, R. Kainuma, K. Aoki, and K. Ishida, Ordering and Phase Separation of BCC Aluminides in (Ni, Co)-Al-Ti System, Mater. Sci. Eng., A, 2002, 329-331, p 276-281

K. Ishikawa, R. Kainuma, I. Ohnuma, K. Aoki, K. Ishida, 2002. Phase Stability of the X2AlTi (X: Fe, Co, Ni and Cu) Heusler and B2-type Intermetallic Compounds, Acta Mater. 50, 2233-2243

K. Ishikawa, I. Ohnuma, R. Kainuma, K. Aoki, K. Ishida, 2004. Phase Equilibria and Stability of Heusler-Type Aluminides in the NiAl–Ni2AlTi–Ni2AlY (Y: V, Cr or Mn) System, J. Alloys Compd. 367, 2–9

A.W. Wilson, J.M. Howe, 2001. Effect of Alloying Additions on β′ Precipitation in NiAl-Ti Base Alloys. Acta Mater. 49, 2653-2660

G. Bozzolo, R.D. Noebe, J. Ferrante, and A. Garg, Atomistic Simulations of Alloying Additions to NiAl, Mater. Sci. Eng., A, 1997, 239-240, p 769-776

Y. Nishino, C. Kumada, S. Asano, 1997. Phase Stability of Fe3Al with Addition of 3d Transition Elements. Scr. Mater. 36(4), 461–466

S.K. Ehlers, M.G. Mendiratta, 1984. Tensile Behaviour of Two DO3-Ordered: Fe3Si and Fe-20 at% Al-5 at% Si. J. Mater. Sci. 19, 2203-2210.

Y. Nishino, Electrical Resistance Anomaly in Fe3Al-Based Alloys, Mater. Sci. Eng., A, 1998, 258, p 50-58

J.G. Cabañas-Moreno, T. Itsukaichi, and M. Umemoto, A New Phase in Al-Ni-Ti Alloys Made from Mechanically Alloyed Powders, Mater. Sci. Eng., A, 1994, 181-182, p 1202-1206

S·H. Mahmood, M.A. Gharaibeh, A.S. Saleh, 1995. Mössbauer and Structural Studies of FeAl1-xTix. Solid State Commun. 95(4), 263–266

P.O. Suzuki, T. Kyono, 2004. Thermoelectric Properties of Fe2TiAl Heusler Alloys, J. Alloys Compd. 377, 38–42

W.B. Pearson, Chapter II: Tabulated Lattice Parameters and Data on Elemental Metals and Metalloids, Handbook of Lattice Spacings and Structures of Metals, 2nd ed., W.B. Pearson, Ed. (New York), Pergamon Press, 1967, p 127

A.E. Dwight, Body-Centered Cubic Derivative Structures, Intermetallic Compounds, J.H. Westbrook Ed. (New York), Wiley Press, 1967, p 174

P.D. Parsons, J. Nutting, 1969. Electron Metallography of an Austentic Steel Containing Aluminal and Titanium, J. Iron Steel Inst. 207, 230

K.H.J. Buschow, P.G. Van Engen, 1981. Magnetic and Magneto-Optical Properties of Heusler Alloys Based on Aluminum and Gallium. J. Magn. Magn. Mater. 25, 90–96

S. Sridharan, H. Nowotny, S.F. Wayne, 1983. Investigations within the Quaternary System Titanium-Nickel-Aluminium-Carbon. Monatsh. Chem. 114, 127–135

K.H.J. Buschow, P.G. Van Engen, R. Jongebreur 1983. Magneto-Optical Properties of Metallic Ferromagnetic Materials. J. Magn. Magn. Mater. 38, 1–22

D.E. Okpalugo, J.G. Booth, and C.A. Faunce, Onset of Ferromagnetism in 3d-Substituted FeAl Alloys. I: Ti, V and Cr Substitution, J. Phys. F: Metal Phys., 1985, 15, p 681-692

B. Huneau, P. Rogl, K. Zeng, R. Schmid-Fetzer, M. Bohn, J. Bauer. 1999. The Ternary System Al-Ni-Ti Part I: Isothermal Section at 900°C: Experimental Investigation and Thermodynamic Calculation, Intermetallics 7, 1337–1345

F.S. da Rocha, G.L.F. Fraga, D.E. Brandão, C.M. da Silva, A.A. Gomes, 1999. Specific Heat and Electronic Structure of Heusler Compounds Ni2TAl (T=Ti, Zr, Hf, V, Nb, Ta). Physica B. 269, 154–162

H. Fu, D. Chen, X. Cheng, T. Gao, X. Yang, 2007. The Influence of the X Atoms and Al 3p Occupied States in AlTiX2 (X = Fe, Cu, Co, Ni). Intermetallics, Physica B. 388, 303–311

P. Fischer, G. Frey, M. Koch, M. Koennecke, V. Pomjakushin, J. Schefer, R. Thut, N. Schlumpf, R. Buerge, U. Greuter, S. Bondt, and E. Berruyer, High-Resolution Powder Diffractiometer HRPT for Thermal Neutrons at SINQ, Physica B, 2000, 276-278, p 146-147

T. Roisnel and J. Rodríquez-Carvajal, WinPLOTR: A Windows Tool for Powder Diffraction Pattern Analysis, Mater. Sci. Forum, 2001, 378-381, p 118

M. Palm, G. Inden, N. Thomas 1995. The Fe-Al-Ti System, J. Phase Equil. 16, 209-222

M. Palm, J. Lacaze, 2006. Assessment of the Al-Fe-Ti system, Intermetallics, 14, 1291-1303

E. Parthé, L. Gelato, B. Chabot, M. Penzo, K. Cenzual, and R. Gladyshevskii, TYPIX Standardized Data and Crystal Chemical Characterization of Inorganic Structure Types, Gmelin Handbook of Inorganic and Organometallic Chemistry, 8th ed. (Berlin), Springer-Verlag, 1994

C.Y. Ho, Thermal Expansion of Solids, CINDAS Data Series on Material Properties, Vol. 1-4 (Ohio), ASM International, 1998

N.A. Dubrovinskaia, L.S. Dubrovinsky, A. Karisson, S.K. Saxena 1999. Experimental Study of Thermal Expansion and Phase Transformations in Iron-Rich Fe-Al Alloys, CALPHAD. 23(1), 69–84

B.V. Reddy, S.C. Deevi 2000. Thermophysical Properties of FeAl (Fe-40 at.%Al). Intermetallics. 8, 1369–1376

S.C. Deevi, 2000. Powder Processing of FeAl Sheets by Roll Compaction, Intermetallics. 8, 679–685

Acknowledgments

This work was supported by the Austrian National Science Foundation FWF projects no. P16957, P16778 and was partially performed at the Laboratory for Neutron Scattering, ETH Zurich & Paul Scherrer Institut, Nilligen PSI, Switzerland. X. Y. and P. R. are grateful to the OEAD for stipends within the bilateral WTZ Austria-China, project VII.A.16.

Open Access

This article is distributed under the terms of the Creative Commons Attribution Noncommercial License which permits any noncommercial use, distribution, and reproduction in any medium, provided the original author(s) and source are credited.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

Open Access This is an open access article distributed under the terms of the Creative Commons Attribution Noncommercial License (https://creativecommons.org/licenses/by-nc/2.0), which permits any noncommercial use, distribution, and reproduction in any medium, provided the original author(s) and source are credited.

About this article

Cite this article

Yan, X., Grytsiv, A., Rogl, P. et al. The Heusler Phase Ti25(Fe50 − x Ni x )Al25 (0 ≤ x ≤ 50); Structure and Constitution. J Phs Eqil and Diff 29, 500–508 (2008). https://doi.org/10.1007/s11669-008-9389-6

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11669-008-9389-6