Abstract

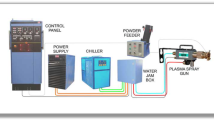

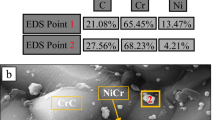

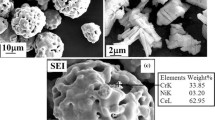

Austenitic stainless steel used in power plants and chemical industries is susceptible to corrosion in high-temperature environments. The corrosion is accelerated in high-temperature applications due to chemical substances like sodium, sulfur, and vanadium. The current investigation involves the assessment of the hot corrosion performance of two distinct coatings, namely 8 wt.% yttria-stabilized zirconia (8YSZ) and chromium carbide (Cr3C2), which have been applied using air plasma spraying onto SS316. Coatings were analysed after being heated in the furnace for 50 h at 700 °C at 5 h/cycle with a salt mixture of Na2SO4− 60 wt.% of V2O5 (30 mg/cm2). Elemental analysis of the hot corroded specimen was performed using scanning electron microscopy (SEM), x-ray diffraction analysis (XRD), and energy-dispersive spectroscopy (EDS). The findings indicate that the 8YSZ coating exhibited enhanced adherence to the substrate for the entire duration of the hot corrosion test. In contrast, it was observed that the Cr3C2 coating underwent total delamination subsequent to the fifth cycle of the hot corrosion test. Bare material shows a substantial degradation surface that peels off without substantial formation of strong surface adherence corrosion products.

Similar content being viewed by others

References

P.S. Rajendran, High temperature corrosion of austenitic stainless steels, in H.S. Khatak, B. Raj (eds.), Woodhead Publishing Series in Metals and Surface Engineering. Corrosion of Austenitic Stainless Steels, pp. 265–286 (2002). https://doi.org/10.1533/9780857094018.287

Z. Lin, P. Ren, R. Zhu, X. Tang, Y. Zheng, T. Xu, Y. Wang, J. Yang, J. Cai, The effect of molten phosphate on corrosion of 316 stainless steel, alloy 625, and titanium TA8 in supercritical water oxidation conditions. Materials. 16, 395 (2023). https://doi.org/10.3390/ma16010395

G.M. Yi, Y.H. Cheng, L. Ren, J. Yang, Q. Wang, X. Li, Corrosion behavior of 316 stainless steel for advanced high-temperature water-cooled nuclear plant. Surf. Interface Anal. 54(7), 767–774 (2022). https://doi.org/10.1002/sia.7089

H. Zhou, Z. Tian, C. Liao, Corrosion behaviour characterization of 316L stainless steel and Inconel 625 in supercritical water containing hydrochloric acid and high oxygen. Corros. Eng. Sci. Technol.. Eng. Sci. Technol. 57(7), 640–647 (2022). https://doi.org/10.1080/1478422X.2022.2112931

X. Huang, K. Xiao, X. Fang, Z. Xiong, L. Wei, P. Zhu, X. Li, Oxidation behavior of 316L austenitic stainless steel in high temperature air with long-term exposure. Mater. Res. Express. 7(6), 066517 (2020). https://doi.org/10.1088/2053-1591/ab96fa

R. Vaben, E. Bakan, D.E. Mack, A perspective on thermally sprayed thermal barrier coatings: current status and trends. J. Therm. Spray Tech. 31, 685–698 (2022). https://doi.org/10.1007/s11666-022-01330-2

H. Singh, B.S. Sidhu, D. Puri, S. Prakash, Use of plasma spray technology for deposition of high temperature oxidation/corrosion resistant coatings—a review. Mater. Corros.Corros. 58(2), 92–102 (2007). https://doi.org/10.1002/maco.200603985

D. Mudgal, S. Kumar, S. Singh, S. Prakash, Corrosion behavior of bare, Cr3C2-25%(NiCr), and Cr3C2-25%(NiCr) + 0.4%CeO2—coated Superni 600 under molten salt at 900 °C. J. Mater. Eng. Perform. 23, 3805–3818 (2014). https://doi.org/10.1007/s11665-014-1177-3

D. Mudgal, S. Singh, S. Prakash, Hot corrosion behavior of bare, Cr3C2-(NiCr) and Cr3C2-(NiCr) + 0.2 wt.% Zr coated SuperNi 718 at 900 °C. J. Mater. Eng. Perform. 24, 1–15 (2015). https://doi.org/10.1007/s11665-014-1279-y

H. Singh, M. Kaur, S. Prakash, High-temperature exposure studies of HVOF-sprayed Cr3C2-25(NiCr)/(WC-Co) coating. J. Therm. Spray Technol. 25, 1192–1207 (2016). https://doi.org/10.1007/s11666-016-0424-6

K. Lencova, F. Netrvalova, M. Vostrak, M. Lukac, F.R. Musalek, esanek C, Houdkova ZS, Hot corrosion behavior of TWAS and HVOF NiCr-based coatings in molten salt. Materials. 16, 1712 (2023). https://doi.org/10.3390/ma16041712

M. Shi, Z. Xue, H. Liang, Z. Yan, X. Liu, S. Zhang, High velocity oxygen fuel sprayed Cr3C2-NiCr coatings against Na2SO4 hot corrosion at different temperatures. Ceram. Int. 46(15), 23629–23635 (2020). https://doi.org/10.1016/j.ceramint.2020.06.135

S. Saladi, J. Menghani, S. Prakash, Hot corrosion behaviour of detonation-gun sprayed Cr3C2–NiCr coating on inconel-718 in molten salt environment at 900 °C. Trans. Indian Inst. Met. 67, 623–627 (2014). https://doi.org/10.1007/s12666-014-0383-x

I.A. Alnaser, M. Yunus, R. Alfattani, T. Alamro, High-temperature corrosion of APS and HVOF-coated nickel-based super alloy under air oxidation and melted salt domains. Materials. 14, 5119 (2021). https://doi.org/10.3390/ma14185119

M. Kaur, H. Singh, S. Prakash, High-temperature corrosion studies of HVOF-sprayed Cr3C2-NiCr coating on SAE-347H boiler steel. J. Therm. Spray Technol. 18, 619–632 (2009). https://doi.org/10.1007/s11666-009-9371-9

T.S. Sidhu, S. Prakash, R.D. Agrawal, Performance of high-velocity oxyfuel-sprayed coatings on an Fe-based superalloy in Na2SO4-60%V2O5 environment at 900 °C part II: hot corrosion behavior of the coatings. J. Mater. Eng. Perform. 15, 130–138 (2006). https://doi.org/10.1361/105994906X83411

T.S. Sidhu, S. Prakash, R.D. Agrawal, Characterizations and hot corrosion resistance of Cr3C2-NiCr coating on Ni-base superalloys in an aggressive environment. J. Therm. Spray Tech. 15, 811–816 (2006). https://doi.org/10.1361/105996306X147162

M. Kuruba, G. Gaikwad, D. Shivalingappa, Hot-corrosion behaviour of CNT reinforced Cr3C2-NiCr coatings working under high-temperature sprayed by HVOF method. Proc. Inst. Mech. Eng. L. (2022). https://doi.org/10.1177/14644207221082237

N. Dharuman, M. Arulmozhi, M.S. Babu, Investigations on oxidation, hot corrosion and thermal gradient performance of low k-La2Mo2O9 thermal barrier coating. Bull. Mater. Sci. 44, 8 (2021). https://doi.org/10.1007/s12034-020-02279-0

D. Gond, D. Puri, S. Prakash, Hot corrosion behaviour of yttria-stabilized zirconia as plasma sprayed coated boiler steel in air and salt at 900 °C under cyclic condition. J. Min. Mater. Charact. Eng. 10(5), 463–478 (2011). https://doi.org/10.4236/jmmce.2012.113021

N. Ejaz, L. Ali, F. Ahmed, G. Awan, K.M.A. Ghauri, Hot corrosion behavior of double ceramic layered CaZrO3/Yttria-stabilized zirconia coatings. Int. J. Appl. Ceram. 15(1), 53–62 (2018). https://doi.org/10.1111/ijac.12767

A.G. Gonzalez-Hernandez, H. Ageorges, M.E. Lopez-Gomez, Evaluation of hot corrosion of 8YSZ coatings elaborated by suspension plasma spraying. J. Phys. Conf. Ser. 786(01), 0112018 (2017). https://doi.org/10.1088/1742-6596/786/1/012018

H. Habibi, S. Guo, Evolution of hot corrosion behavior of YSZ-Ta2O5 composites with different YSZ/Ta2O5 ratios. Int. J. Appl. Ceram. 12(3), 542–550 (2015). https://doi.org/10.1111/ijac.12224

I.N. Qureshi, M. Shahid, N.A. Nusair Khan, Hot corrosion of yttria-stabilized zirconia coating, in a mixture of sodium sulfate and vanadium oxide at 950 °C. J. Therm. Spray Tech. 25, 567–579 (2016). https://doi.org/10.1007/s11666-015-0374-4

M. Karabaş, E. Bal, Y. Taptik, Hot corrosion behaviour of plasma sprayed alumina + YSZ particle composite coating. Prot. Met. Phys. Chem. Surf. 53, 859–863 (2017). https://doi.org/10.1134/S2070205117050069

K.P. Jonnalagadda, S. Mahade, N. Curry, Hot corrosion mechanism in multi-layer suspension plasma sprayed Gd2Zr2O7/YSZ thermal barrier coatings in the presence of V2O5 + Na2SO4. J. Therm. Spray Tech. 26, 140–149 (2017). https://doi.org/10.1007/s11666-016-0486-5

A. Avci, M. Karabaş, A. Akdogan Eker, E. Akman, C. Aslan, Hot corrosion and CMAS degradation of laser-glazed YSZ coating with optimum parameter. Proc. Inst. Mech. Eng. L. (2023). https://doi.org/10.1177/14644207231178174

Acknowledgment

The authors would like to express their gratitude to Spraymet Technologies, Bangalore, for providing the coating facility, as well as Ramco Institute of Technology, Rajapalayam, Kalasalingam Academy of Research and Education, Krishnan Koil, and National Engineering College, Kovilpatti, for their assistance with experimental work and microstructural characterization studies.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Maharajan, S., Rex, F.M.T. Hot Corrosion Evaluation of Cr3C2/8YSZ-Based Plasma-Sprayed Coatings on SS316 in Na2SO4–V2O5 Molten Salt Environment at 700 °C. J Fail. Anal. and Preven. 24, 769–778 (2024). https://doi.org/10.1007/s11668-024-01880-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11668-024-01880-3