Abstract

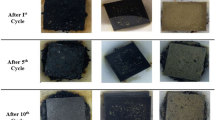

This study investigates the hot corrosion resistance characteristics of plasma-sprayed WC-CoCr coatings deposited on AISI 316L stainless steel. Coated and uncoated samples were exposed to a fused Na2SO4-25%NaCl salt deposit at 700 °C in cyclic conditions for fifty thermal cycles. The corrosion kinetics were determined using a thermogravimetric method. To determine the hot corrosion rate, weight-change measurements were taken after every cycle. X-ray diffraction, energy dispersive spectroscopy, and scanning electron microscopy were performed on samples to examine the hot corrosion characteristics. With a fused salt deposit at 700 °C, the uncoated AISI 316L steel substrate samples experienced faster high-temperature oxidation as compared to coated samples. It was noticed that the uncoated steel substrate gained a little weight during the first few cycles, afterwards as the number of thermal cycles increased, the weight gain followed a linear kinetics. The WC-CoCr coating reduced the weight gain of steel substrate by about 75% in a corrosive salt environment. The plasma-sprayed WC-CoCr coatings had adhesion strength and microhardness of 10.8 ± 2.4 MPa and 410 ± 25 HV0.5, respectively. The hot corrosion-affected coatings displayed slow-scaling kinetics. The oxides of the coatings, formed at the surface were rich in chromium and tungsten. These oxides helped in providing hot corrosion resistance in the corrosive environment as they worked as obstacles to the penetration/diffusion of corrosive elements through coatings. The higher content of tungsten inside the coating promoted WO3 formation, which improved resistance to corrosion at elevated temperatures. Chromium in the coating caused the formation of spinel CoCr2O4 and Cr2O3 the spinel CoCr2O4 that emerged as an intermediate phase also contributes to the maintenance of corrosion resistance. Some oxides such as Fe2O3, FeCr2O4, and CoSO4 were found. Apart from that some traces of Na were also found.

Similar content being viewed by others

References

S. Buchholz, Z. N. Farhat, G. J. Kipouros, and K. P. Plucknett, The reciprocating wear behaviour of TiC–Ni3Al cermets. International Journal of Refractory Metals and Hard Materials. 33, 2012 (44–52).

B. S. Mann and B. Prakash, High temperature friction and wear characteristics of various coating materials for steam valve spindle application. Wear. 240, 2000 (223–230).

L. Jaworska, M. Rozmus, B. Królicka, and A. Twardowska, Functionally graded cermets. Journal of Achievements in Materials and Manufacturing Engineering. 17, 2006 (73).

C. Huang, L. Du, and W. Zhang, Effects of solid lubricant content on the microstructure and properties of NiCr/Cr3C2–BaF2·CaF2 composite coatings. J Alloys Compd. 479, 2009 (777–784).

R. A. Rapp and Y.-S. Zhang, Hot corrosion of materials: fundamental studies. JOM. 46, 1994 (47–55).

N. Eliaz, G. Shemesh, and R. M. Latanision, Hot corrosion in gas turbine components. Engineering Failure Analysis. 9, 2002 (31–43).

L. Baiamonte, F. Marra, S. Gazzola, et al., Thermal sprayed coatings for hot corrosion protection of exhaust valves in naval diesel engines. Surface and Coatings Technology. 295, 2016 (78–87).

T. S. Sidhu, A. Malik, S. Prakash, and R. D. Agrawal, Oxidation and hot corrosion resistance of HVOF WC-NiCrFeSiB coating on Ni- and Fe-based superalloys at 800 °C. Journal of Thermal Spray Technology. 16, 2007 (844–849).

I. Gurrappa and Rao A. Sambasiva, Thermal barrier coatings for enhanced efficiency of gas turbine engines. Surface and Coatings Technology. 201, 2006 (3016–3029).

W. Tillmann, L. Hagen, C. Schaak, et al., Adhesion of HVOF-sprayed WC-Co coatings on 316L substrates processed by SLM. Journal of Thermal Spray Technology. 29, 2020 (1396–1409).

J. K. N. Murthy and B. Venkataraman, Abrasive wear behaviour of WC–CoCr and Cr3C2–20(NiCr) deposited by HVOF and detonation spray processes. Surface and Coatings Technology. 200, 2006 (2642–2652).

M. S. Alam and A. K. Das, Advancement in cermet based coating on steel substrate: a review. Materials Today: Proceedings. 56, 2022 (805–810).

R. B. Heimann, Plasma-spray coating: principles and applications, (Wiley, 2008).

H. Singh, B. S. Sidhu, D. Puri, and S. Prakash, Use of plasma spray technology for deposition of high temperature oxidation/corrosion resistant coatings—a review. Materials and Corrosion. 58, 2007 (92–102).

S. Hu, H. Finklea, and X. Liu, A review on molten sulfate salts induced hot corrosion. Journal of Materials Science and Technology. 90, 2021 (243–254).

N. Arivazhagan, S. Narayanan, S. Singh, Satya Prakash, and G.M. Reddy, High temperature corrosion studies on friction welded low alloy steel and stainless steel in air and molten salt environment at 6500C, Materials and Design. 34, 459-468 (2012).

Mortezaie, M. Shamanian, An assessment of microstructure, mechanical properties and corrosion resistance of dissimilar welds between Inconel 718 and 310S austenitic stainless steel, International Journal of Pressure Vessels and Piping. 116, p 37-46 (2014).

Q. Gao, Y. Lu, Q. Yu, Y. Wu, C. Zhang, and R. Zhi, High-temperature corrosion behavior of austenitic stainless steel in quaternary nitrate molten salt nanofluids for concentrated solar power. Solar Energy Materials and Solar Cells. 245, 2022 111851.

Z. Xu, W. Jinchu, Y. Zonghui, Z. Hui, P. Cong, C. Yajie and L. Xiaoquan, Hot corrosion behavior of Fe–Cr–Ni-based austenitic heat-resistant steel weld metal (2023).

W. Zhou, K. Zhou, C. Deng, K. Zeng and Y. Li, Hot corrosion behaviour of HVOF-sprayed Cr3C2-NiCrMoNbAl coating. Surface and Coatings Technology. 309, (2017).

J. Singh and J. P. Singh, Performance analysis of erosion resistant Mo2C reinforced WC-CoCr coating for pump impeller with Taguchi’s method. Industrial (2022).

B. Song, J. W. Murray, R. G. Wellman, Z. Pala and T. Hussain, Dry sliding wear behaviour of HVOF thermal sprayed WC-Co-Cr and WC-CrxCy-Ni (2020)

H. V. Ozkavak, S. Sahin, M. F. Sarac and Z. Alkan, Wear properties of WC–Co and WC–CoCr coatings applied by HVOF technique on different steel (2020).

Y. Zhang, S. Hong, J. Lin and Y. Zheng, Influence of ultrasonic excitation sealing on the corrosion resistance of HVOF-sprayed nanostructured WC-CoCr (2019).

J. A. Picas, M. Punset, E. Rupérez, S. Menargues, E. Martin and M. T. Baile, Corrosion mechanism of HVOF thermal sprayed WC-CoCr coatings in acidic (2019).

V. P. S. Sidhu, K. Goyal and R. Goyal, Comparative evaluation of hot corrosion resistance of 83WC–17CO and 86WC–10CO–4Cr coatings on some boiler steels (2017).

M. S. Alam and A. K. Das, Study on microstructure and cyclic oxidation behaviour of WC-CoCr cermet-based plasma-sprayed coatings developed on the austenite steel. High Temperature Corrosion of Materials. 1–11 (2023).

I. Gurappa, Development of appropriate thickness ceramic coatings on 316 L stainless steel for biomedical applications. Surface and Coatings Technology. 161, 2002 (70–78).

A. Saboori, A. Aversa, G. Marchese, S. Biamino, M. Lombardi, and P. Fino, Microstructure and mechanical properties of AISI 316L produced by directed energy deposition-based additive manufacturing: a review. Applied Sciences. 10, 2020 (3310).

S. Kamal, R. Jayaganthan, and S. Prakash, High temperature cyclic oxidation and hot corrosion behaviours of superalloys at 900°C. Bulletin of Materials Science. 33, (3), 2010 (299–306). https://doi.org/10.1007/s12034-010-0046-4.

Y. S. Hwang and D. B. Lee, High-temperature oxidation of WC-20%TiC-10%Co carbides. Advanced Materials Research. 811, 2013 (93–97).

I. Gurrappa, Hot corrosion behavior of CM 247 LC alloy in Na2SO4 and NaCl environments. Oxidation of Metals. 51, 1999 (353–382).

I. Gurrappa, Identification of hot corrosion resistant MCrAlY based bond coatings for gas turbine engine applications. Surface and Coatings Technology. 139, 2001 (272–283).

T. Zhang, C. Huang, H. Lan, L. Du, and W. Zhang, Oxidation and hot corrosion behavior of plasma-sprayed MCrAlY–Cr2O3 coatings. Journal of Thermal Spray Technology. 25, 2016 (1208–1216).

Acknowledgements

The authors would like to express their appreciation to the Thapar Institute of Engineering & Technology in Patiala, India, for their XRD, EDS and, SEM facilities. We are grateful to Metallizing Equipment Pvt. Ltd., Jodhpur, India, for their assistance in carrying out the trials.

Funding

For the current research, there is no funding to report.

Author information

Authors and Affiliations

Contributions

MSA contributed to investigation of experimental work, formal analysis, and preparation of the manuscript. AKD contributed to conceptualization and supervision of research work, review and editing of the manuscript.

Corresponding author

Ethics declarations

Conflict of interest

There are no conflicts of interest to report for any of the authors.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Alam, M.S., Das, A.K. Hot Corrosion Behavior of Plasma-Sprayed WC-CoCr Coatings on AISI 316L Steel Substrate in Na2SO4-25% NaCl Salt Environment. High Temperature Corrosion of mater. 99, 415–430 (2023). https://doi.org/10.1007/s11085-023-10162-6

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11085-023-10162-6