Abstract

This paper describes how to discuss the uncertainty of diameter tolerance by using interval analysis. Firstly, the interval relationship among reliability, diameter tolerance and process capability index (PCI) is obtained. Considering the reasonable PCI range, then reliability range is calculated and compared by using universal gray method and combinational method, respectively. Finally, the ranges of improved tolerance and other uncertain variables are obtained. The results show that the reliability and tolerance ranges obtained by universal gray method are more reasonable. This paper provides a research thought for the uncertainty of diameter tolerance.

Similar content being viewed by others

References

W. Wu, S.S. Rao, Fuzzy analysis of geometric tolerances using interval method. Proc. Inst. Mech. Eng. C J. Mech. 220(4), 489–497 (2006)

K.G. Swift, M. Raines, J.D. Booker, Tolerance optimization in assembly stacks based on capable design. Proc. Inst. Mech. Eng. B J. Mech. 213(7), 677–693 (1999)

A. Tiwari, P.C. Chang, M.K. Tiwari, A highly optimised tolerance-based approach for multi-stage, multi-product supply chain network design. Int. J. Prod. Res. 50(19), 5430–5444 (2012)

M.F. Huang, Y.R. Zhong, Z.G. Xu, Concurrent process tolerance design based on minimum product manufacturing cost and quality loss. Int. J. Adv. Manuf. Technol. 25(7), 714–722 (2005)

K. Dems, W. Gutkowski, Manufacturing tolerances and multiple loading conditions in structural configuration optimization. Int. J. Numer. Meth. Eng. 57(10), 1341–1350 (2003)

A.S. Tahan, J. Cauvier, Capability estimation of geometrical tolerance with a material modifier by a Hasofer–Lind index. J. Manuf. Sci. E Trans. ASME 134(2), 1–11 (2012)

J.N. Wu, S.Z. Yan, J.L. Li, Y.X. Gu, Mechanism reliability of bistable compliant mechanisms considering degradation and uncertainties: modeling and evaluation method. Appl. Math. Model. 40(23), 10377–10388 (2016)

S.S. Rao, Description and optimum design of fuzzy mechanical systems. J. Mech. Trans. Autom. Des. 109(1), 126–132 (1987)

C. Jiang, Q.F. Zhang, X. Han, J. Liu, D.A. Hu, Multidimensional parallelepiped model—a new type of non-probabilistic convex model for structural uncertainty analysis. Int. J. Numer. Meth. Eng. 103(1), 31–59 (2015)

W.C. Qi, Z.P. Qiu, A collocation interval analysis method for interval structural parameters and stochastic excitation. Sci. China Phys. Mech. Astron. 55(1), 66–77 (2012)

J. Guo, X.P. Du, Reliability sensitivity analysis with random and interval variables. Int. J. Numer. Meth. Eng. 78(13), 1585–1617 (2009)

J.L. Deng, Introduction to grey system theory. J Grey Syst UK 1(1), 1–24 (1989)

Q.Y. Wang, H.Q. Wu, J.S. Xue, K.D. Lin, On grey number: basic element of grey mathematics and its relations with fuzzy and real numbers. J. Grey Syst. UK 1(1), 69–77 (1989)

M. Ebadi, H. Shahriari, A process capability index for simple linear profile. Int. J. Adv. Manuf. Technol. 64(5), 857–865 (2013)

A. Kumar, P.B. Nair, A.J. Keane, S. Shahpar, Robust design using bayesian Monte Carlo. Int. J. Numer. Meth. Eng. 73(11), 1497–1517 (2008)

J.M. Juran, Quality Control Handbook (McGraw-Hill, New York, 1974)

E. Kane, Victor, process capability indices. J. Qual. Technol. 38(4), 884–904 (1986)

L.K. Chang, S.W. Cheng, F. Spiring, A new measure of process capability. J. Qual. Technol. 20(3), 162–175 (1988)

W.L. Pearn, S. Kotz, N.L. Johnson, Distribution and inferential properties of process capability indexes. J. Qual. Technol. 24(4), 216–231 (1992)

W. Taam, P. Subbaiah, J.W. Liddy, A note on multivariate capability indices. J Appl Stat 20(3), 339–351 (1993)

D.P. Karl, J. Morisette, W. Taam, Some applications of a multivariate capability index in geometric dimensioning and tolerancing. Qual. Eng. 6(4), 649–665 (1994)

B. Wu, M.F. Li, Mechanical Parts and System Reliability Model (Chemical Industry Press, Beijing, 2003)

X.T. Liu, H.Z. Qi, X.L. Wang, Y.S. Wang, C.C. Li, M.L. Wang, Reliability analysis and evaluation of differential system based on low load strengthening model. Qual. Reliab. Eng. Int. 32(2), 647–662 (2015)

P.K. Singh, P.K. Jain, S.C. Jain, Important issues in tolerance design of mechanical assemblies, part 1: tolerance analysis. Proc. Inst. Mech. Eng. J J. Eng. 223(10), 1249–1287 (2009)

D.C. Montgomery, Introduction to Statistical Quality Control (Wiley, New Jersey, 2007)

S.S. Rao, L. Berke, Analysis of uncertain structural systems using interval analysis. AIAA J. 35(4), 727–735 (1997)

L. Tenuti, N. Anselmi, P. Rocca, M. Salucci, A. Massa, Minkowski sum method for planar arrays sensitivity analysis with uncertain-but-bounded excitation tolerances. IEEE Trans. Antennas Propag. 65(1), 167–177 (2017)

N. Anselmi, M. Salucci, P. Rocca, A. Massa, Power pattern sensitivity to calibration errors and mutual coupling in linear arrays through circular interval arithmetics. Sensors 16(6), 791 (2016)

Acknowledgments

This work is supported by the National Natural Science Foundation of China (51675324).

Author information

Authors and Affiliations

Corresponding author

Appendices

Appendix A: Notation

- \( C_{{\rm p}} \) :

-

Process capability index

- d :

-

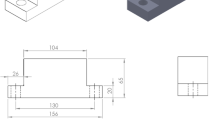

Diameter of transmission shaft

- \( d_{0} \) :

-

Target diameter

- \( d_{i} \) :

-

Diameter of the ith sample shaft

- M T :

-

Torque

- \( \mu_{{M_{{\rm T}} }} \) :

-

Mean value of the torque

- \( n\hat{p}_{i} \) :

-

Excepted frequency

- \( \hat{p}_{i} \) :

-

Probability estimation

- R :

-

Reliability

- \( S_{{\rm d}} \) :

-

Sample standard deviation

- \( S_{{\rm T}} \) :

-

Shear stress

- \( \mu_{{S_{{\rm T}} }} \) :

-

Mean value of the shear stress

- T :

-

Dimensional tolerance

- \( T_{{\rm l}} \) :

-

Lower bound of the dimensional tolerance

- \( T_{{\rm u}} \) :

-

Upper bound of the dimensional tolerance

- \( W_{{\rm T}} \) :

-

Torsional section modulus

- \( Z_{{\rm R}} \) :

-

Coupling coefficient

- \( \alpha \) :

-

Positive constant in the range [0, 1]

- \( \beta \) :

-

Significance level

- \( \delta_{{\rm S}} \) :

-

Yield strength

- \( \mu_{{\delta_{{\rm S}} }} \) :

-

Mean value of the yield strength

- \( \delta_{{\rm T}} \) :

-

Shear static strength

- \( \mu_{{\delta_{{\rm T}} }} \) :

-

Mean value of the shear static strength

- \( \Delta d \) :

-

Diameter tolerance

- \( \mu_{{\rm d}} \) :

-

Mean value of the sample shafts diameters

- \( \nu_{i} \) :

-

Actual frequency

- \( \sigma \) :

-

Overall standard deviation

- \( \sigma_{{\rm d}} \) :

-

Standard deviation of the diameter

- \( \sigma_{{M_{{\rm T}} }} \) :

-

Standard deviation of the torque

- \( \sigma_{{S_{{\rm T}} }} \) :

-

Standard deviation of the shear stress

- \( \sigma_{{\delta_{{\rm S}} }} \) :

-

Standard deviation of the yield strength

- \( \sigma_{{\delta_{{\rm T}} }} \) :

-

Standard deviation of the shear static strength

- \( \phi ( \cdot ) \) :

-

Density function of standard normal distribution

- \( \chi^{2} \) :

-

Test statistic

Appendix B: The Definition of Interval

Many engineering design problems involve imprecision or approximation or uncertainty to varying degrees. Depending on the nature of imprecision, the analysis and design of the system can be conducted using interval analysis [26], defined as follows:

where \( [x] \) is an non-empty bounded set of real numbers, \( \bar{x} \) and \( \underset{\raise0.3em\hbox{$\smash{\scriptscriptstyle-}$}}{x} \) are the upper and lower bounds of the interval, respectively.

Appendix C: Interval Arithmetic

For any intervals \( [a] = [\underset{\raise0.3em\hbox{$\smash{\scriptscriptstyle-}$}}{a} ,\;\bar{a}] \) and \( [b] = [\underset{\raise0.3em\hbox{$\smash{\scriptscriptstyle-}$}}{b} ,\;\bar{b}] \), the interval arithmetic operations are defined as follows [26]:

Appendix D: Universal Gray Mathematics

Based on gray system theory, universal gray mathematics is introduced to solve engineering problems with uncertainty and defined as follows [13]:

where g is a universal number, x is an observed value and \( [\underset{\raise0.3em\hbox{$\smash{\scriptscriptstyle-}$}}{\mu } ,\bar{\mu }] \) is the gray information section of x.

For any universal numbers \( [g_{i} ] = (x_{i} ,\;[\underset{\raise0.3em\hbox{$\smash{\scriptscriptstyle-}$}}{\mu }_{i} ,\bar{\mu }_{i} ])\;(i = 1,2) \), the universal number arithmetic operations are defined as follows [13]:

Rights and permissions

About this article

Cite this article

Wu, Q., Liu, X., Liang, Z. et al. Research on Diameter Tolerance of Transmission Shaft Based on Interval Analysis. J Fail. Anal. and Preven. 19, 154–160 (2019). https://doi.org/10.1007/s11668-019-00584-3

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11668-019-00584-3