Abstract

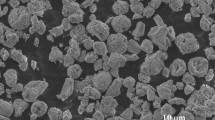

This paper investigates various parameters affecting the thickness of the thermally grown oxide (TGO) layer affecting the lifetime of conventional thermal barrier coatings (TBCs) with two new coatings. The thickness of the TGO layer directly influences the generation of interfacial stresses and delamination of the coating layers. This study examines the effects of the thermal spraying method, time, temperature, and the TC absence on the TGO thickness. In the first new coating, two bond coats are utilized, applied using the high-velocity oxygen fuel (HVOF) and air plasma spraying (APS) methods. The second new coating involves an aluminide diffusion coating applied between the bond coat and substrate. Scanning electron microscope (SEM) analysis of the test samples reveals that the HVOF-applied coating forms a TGO with lower thickness compared to the APS coating. The most extended lifetime of 336 h is achieved by the new coating with a two-layer bond coat, followed by the HVOF coating with 288 h, the diffusion coating with 238 h, and the APS coating with 192 h, respectively. Despite the lower TGO thickness in the HVOF coating compared to the two-layer bond coat, its lifetime is reduced due to severe spinel growth at the interface of TBCs with the HVOF bond coat caused by the faster depletion of aluminum (Al). The diffusion coating increases the concentration of Al in the upper part of the substrate, thereby reducing the depletion of Al from the bond coat through interdiffusion. By retaining the Al in the bond coat for a longer duration, the diffusion coating enhances the lifetime of TBCs.

Similar content being viewed by others

Notes

In this article, the term APS-bond coat refers to the bond coat layer applied by the APS method, and the term HVOF-bond coat refers to the bond coat layer applied by the HVOF method.

References

A. Kebriyaei, M.R. Rahimipour, M. Razavi, and H.A. Alizade, Effect of Solution Precursor on Microstructure and High-Temperature Properties of the Thermal Barrier Coating Made by Solution Precursor Plasma Spray (SPPS) Process, J. Therm. Spray Technol., 2022, 32(1), p 8-28.

X. Qian, P. Yan, X. Wang, and W. Han, Effect of Thermal Barrier Coatings and Integrated Cooling on the Conjugate Heat Transfer and Thermal Stress Distribution of Nickel-Based Superalloy Turbine Vanes, Energy, 2023, 277, p 127774.

N. Kumar, M. Gupta, D.E. Mack, G. Mauer, and R. Vaßen, Columnar Thermal Barrier Coatings Produced by Different Thermal Spray Processes, J. Therm. Spray Technol., 2021, 30(6), p 1437-1452.

T. Hayase, H. Waki, and K. Adachi, Residual Stress Change in Thermal Barrier Coating Due to Thermal Exposure Evaluated by Curvature Method, J. Therm. Spray Technol., 2020, 29(6), p 1300-1312.

J. Rahimi, E. Poursaeidi, F. Montakhabi, M.R.J. Sigaroodi, and Y.Y. Jamalabad, Experimental and Numerical Life Evaluation of TBCs with Different BC and Diffusion Coating under Cyclic Thermal Loading, Int. J. Appl. Ceram. Technol. (2023)

Y. Wu, H. Luo, C. Cai, Y. Wang, Y. Zhou, L. Yang, and G. Zhou, Comparison of CMAS Corrosion and Sintering Induced Microstructural Characteristics of APS Thermal Barrier Coatings, J. Mater. Sci. Technol., 2019, 35(3), p 440-447.

R. Vaßen, E. Bakan, D.E. Mack, and O. Guillon, A Perspective on Thermally Sprayed Thermal Barrier Coatings: Current Status and Trends, J. Therm. Spray Technol., 2022, 31(4), p 685-698.

J. Rahimi, M.R. Sigaroodi, and E. Poursaeidi, Thermal Shock Resistance of Thermal Barrier Coating with Different Bondcoat Types and Diffusion Pre-Coating, Ceram. Int., 2023, 49(2), p 2061-2072.

B. Liu, Y. Liu, C. Zhu, H. Xiang, H. Chen, L. Sun, Y. Gao, and Y. Zhou, Advances on Strategies for Searching for next Generation Thermal Barrier Coating Materials, J. Mater. Sci. Technol., 2019, 35(5), p 833-851.

B. Malvi and M. Roy, Elevated Temperature Erosion of Plasma Sprayed Thermal Barrier Coating, J. Therm. Spray Technol., 2021, 30(4), p 1028-1037.

F. Montakhabi, E. Poursaeidi, J. Rahimi, and M.R. Sigaroodi, Investigation of the Effect of BC Layer Surface Roughness and TC Layer Porosity on Stress Values in Plasma Sprayed Coatings Based on SEM Images, Materials Today Communications., 2022, 33, p 104737.

H. Dong, G. Yang, C. Li, X. Luo, and C. Li, Effect of TGO Thickness on Thermal Cyclic Lifetime and Failure Mode of Plasma-sprayed TBC s, J. Am. Ceram. Soc., 2014, 97(4), p 1226-1232.

K. Torkashvand, E. Poursaeidi, M. Mohammadi, J. Rahimi, and F. Montakhabi, Experimental and Numerical Study of TGO-Induced Stresses of Plasma-Sprayed Thermal Barrier Coating, Mater Today Commun, 2023, 35, p 105977.

A. Rabiei and A.G. Evans, Failure Mechanisms Associated with the Thermally Grown Oxide in Plasma-Sprayed Thermal Barrier Coatings, Acta Mater., 2000, 48(15), p 3963-3976.

A. Abdelgawad, K. Al-Athel, and J. Albinmousa, Analysis of Crack Initiation and Propagation in Thermal Barrier Coatings Using SEM-Based Geometrical Model with Extended Finite Element Method, Ceram. Int., 2021, 47(23), p 33140-33151.

M.R. Sigaroodi, E. Poursaeidi, J. Rahimi, and Y.Y. Jamalabad, Heat Treatment Effect on Coating Shock Resistance of Thermal Barrier Coating System with Different Types of Bond Coat, J. Eur. Ceram. Soc., 2023, 43(8), p 3658-3675.

A.M. Limarga, S. Widjaja, T.H. Yip, and L.K. Teh, Modeling of the Effect of Al2O3 Interlayer on Residual Stress Due to Oxide Scale in Thermal Barrier Coatings, Surf. Coat. Technol., 2002, 153(1), p 16-24.

K.M. Doleker, H. Ahlatci, and A.C. Karaoglanli, Investigation of Isothermal Oxidation Behavior of Thermal Barrier Coatings (TBCs) Consisting of YSZ and Multilayered YSZ/Gd2Zr2O7 Ceramic Layers, Oxid. Met., 2017, 88(1), p 109-119.

G. Boissonnet, G. Bonnet, A. Pasquet, N. Bourhila, and F. Pedraza, Evolution of Thermal Insulation of Plasma-Sprayed Thermal Barrier Coating Systems with Exposure to High Temperature, J. Eur. Ceram. Soc., 2019, 39(6), p 2111-2121.

F. Jing, J. Yang, Z. Yang, and W. Zeng, Critical Compressive Strain and Interfacial Damage Evolution of EB-PVD Thermal Barrier Coating, Mater. Sci. Eng. A, 2020, 776, p 139038.

J. Shi, T. Zhang, B. Sun, B. Wang, X. Zhang, and L. Song, Isothermal Oxidation and TGO Growth Behavior of NiCoCrAlY-YSZ Thermal Barrier Coatings on a Ni-Based Superalloy, J. Alloys Compd., 2020, 844, p 156093.

G. An, W. Li, L. Feng, B. Cheng, Z. Wang, Z. Li, and Y. Zhang, Isothermal Oxidation and TGO Growth Behaviors of YAG/YSZ Double-Ceramic-Layer Thermal Barrier Coatings, Ceram. Int., 2021, 47(17), p 24320-24330.

D.R. Tobergte and S. Curtis, Handbook of Thermal Spray Technology, ASM International: Cleveland, OH, USA, 53 (2013)

W. Nowak, D. Naumenko, G. Mor, F. Mor, D.E. Mack, R. Vassen, L. Singheiser, and W.J. Quadakkers, Effect of Processing Parameters on MCrAlY Bondcoat Roughness and Lifetime of APS–TBC Systems, Surf. Coat. Technol., 2014, 260, p 82-89.

W.R. Chen, X. Wu, B.R. Marple, D.R. Nagy, and P.C. Patnaik, TGO Growth Behaviour in TBCs with APS and HVOF Bond Coats, Surf. Coat. Technol., 2008, 202(12), p 2677-2683.

D. Naumenko, R. Pillai, A. Chyrkin, and W.J. Quadakkers, Overview on Recent Developments of Bondcoats for Plasma-Sprayed Thermal Barrier Coatings, J. Therm. Spray Technol., 2017, 26(8), p 1743-1757.

D. Zheng, Y. Bao, D. Wan, and S. Yi, Determining the Thermal Conductivity of Ceramic Coatings by Relative Method, Int. J. Appl. Ceram. Technol., 2019, 6, p 2299-2305.

Z. Xu, Z. Wang, G. Huang, R. Mu, and L. He, Morphology, Bond Strength and Thermal Cycling Behavior of (Ni, Pt) Al/YSZ EB-PVD Thermal Barrier Coatings, J. Alloys Compnd., 2015, 5(651), p 445-453.

T. Yang, W. Wang, J. Huang, L. Wang, Z. Yang, H. Fang, and D. Ye, Thermal Shock Resistance and Bonding Strength of Novel-Structured Thermal Barrier Coatings with Different Microstructure, J. Therm. Spray Technol., 2022, 31(5), p 1540-1555.

Y. Chen, X. Zhao, and P. Xiao, Effect of Microstructure on Early Oxidation of MCrAlY Coatings, Acta Mater., 2018, 159, p 150-162.

M.J. Pomeroy, Coatings for Gas Turbine Materials and Long Term Stability Issues, Mater. Des., 2005, 26(3), p 223-231.

Y. Guo, L. Wei, Q. He, Y. Deng, W. He, and H. Guo, PS–PVD Alumina Overlayer on Thermal Barrier Coatings Against CMAS Attack, J. Therm. Spray Technol., 2021, 30(4), p 864-872.

J. Krishnasamy, S.A. Ponnusami, S. Turteltaub, and S. van der Zwaag, Numerical Investigation into the Effect of Splats and Pores on the Thermal Fracture of Air Plasma-Sprayed Thermal Barrier Coatings, J. Therm. Spray Technol., 2019, 28(8), p 1881-1892.

R. Eriksson, Thermal Barrier Coatings: Durability Assessment and Life Prediction, Linköping University Electronic Press, (2013)

N.P. Padture, M. Gell, and E.H. Jordan, Thermal Barrier Coatings for Gas-Turbine Engine Applications, Science, 2002, 296(5566), p 280-284.

W.G. Sloof and T.J. Nijdam, On the High-Temperature Oxidation of MCrAlY Coatings, Int. J. Mater. Res., 2009, 100(10), p 1318-1330.

E. Poursaeidi, Y.Y. Jamalabad, J. Rahimi, and M.R.J. Sigaroodi, The Effect of CMAS Penetration on the Microstructure and Failure of the TBCs Applied by APS/APS Method, Surf. Coat. Technol., 2022, 451, p 129053.

W.R. Chen, X. Wu, B.R. Marple, R.S. Lima, and P.C. Patnaik, Pre-Oxidation and TGO Growth Behaviour of an Air-Plasma-Sprayed Thermal Barrier Coating, Surf. Coat. Technol., 2008, 202(16), p 3787-3796.

R.G. Wellman and J.R. Nicholls, A Review of the Erosion of Thermal Barrier Coatings, J. Phys. D Appl. Phys., 2007, 40(16), p R293.

N. Birks, G.H. Meier,, and F.S. Pettit, Introduction to the High Temperature Oxidation of Metals, Second Edition, Introduction to the High Temperature Oxidation of Metals, Second Edition, (2006)

X. Liu, T. Wang, C. Li, Z. Zheng, and Q. Li, Microstructural Evolution and Growth Kinetics of Thermally Grown Oxides in Plasma Sprayed Thermal Barrier Coatings, Prog. Nat. Sci. Mater. Int., 2016, 26(1), p 103-111.

V.K. Tolpygo and D.R. Clarke, Surface Rumpling of a (Ni, Pt)Al Bond Coat Induced by Cyclic Oxidation, Acta Mater., 2000, 48(13), p 3283-3293.

V.K. Tolpygo and D.R. Clarke, On the Rumpling Mechanism in Nickel-Aluminide Coatings, Acta Mater., 2004, 52(17), p 5115-5127.

Z. Zou, L. Jia, L. Yang, X. Shan, L. Luo, F. Guo, X. Zhao, and P. Xiao, Role of Internal Oxidation on the Failure of Air Plasma Sprayed Thermal Barrier Coatings with a Double-Layered Bond Coat, Surf. Coat. Technol., 2017, 319, p 370-377.

D. Renusch, M. Schorr, and M. Schütze, The Role That Bond Coat Depletion of Aluminum Has on the Lifetime of APS-TBC under Oxidizing Conditions, Mater. Corros., 2008, 59(7), p 547-555.

A.H. Heuer, D.B. Hovis, J.L. Smialek, and B. Gleeson, Alumina Scale Formation: A New Perspective, J. Am. Ceram. Soc., 2011, 94, p s146-s153.

M. Kilo, C. Argirusis, G. Borchardt, and R.A. Jackson, Oxygen Diffusion in Yttria Stabilised Zirconia—Experimental Results and Molecular Dynamics Calculations, Phys. Chem. Chem. Phys., 2003, 5(11), p 2219-2224.

L.B. Chen, Yttria-Stabilized Zirconia Thermal Barrier Coatings—A Review, Surf. Rev. Lett., 2006, 05, p 535-544.

T. Beck, M. Białas, P. Bednarz, L. Singheiser, K. Bobzin, N. Bagcivan, D. Parkot, T. Kashko, I. Petković, B. Hallstedt, and S. Nemna, Modeling of Coating Process, Phase Changes, and Damage of Plasma Sprayed Thermal Barrier Coatings on Ni-Base Superalloys, Adv. Eng. Mater., 2010, 3, p 110-126.

V. Postolenko, Failure Mechanisms of Thermal Barrier Coatings for High Temperature Gas Turbine Components under Cyclic Thermal Loading, Fachgruppe für Metallurgie und Werkstofftechnik, (2008)

W.X. Zhang, Y.L. Sun, and T.J. Wang, Effect of Spinel Growth on the Delamination of Thermal Barrier Coatings, Key Eng. Mater., 2011, 462, p 389-394.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Rahimi, J., Poursaeidi, E., Montakhabi, F. et al. Effect of Thermal Spraying Method, Time and Temperature on the Thickness of Thermally Grown Oxide and Lifetime of Thermal Barrier Coatings. J Therm Spray Tech 32, 2580–2602 (2023). https://doi.org/10.1007/s11666-023-01670-7

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11666-023-01670-7