Abstract

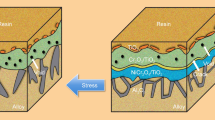

In this study, satellited CoNiCrAlY/nano-Al2O3 feedstocks with 2 wt.% of oxide nanoparticles and pure CoNiCrAlY powder were deposited by the HVOF and LPPS processes on Inconel738 superalloy substrates. Microstructure and phase composition of powders and coatings were characterized by FESEM and XRD, respectively. The early-stage oxidation test was done at 1050 °C for 10 min. The results showed that the satelliting seems to be a promising method to produce nano-particles dispersed composite powders suitable for thermal spraying. Adding α-Al2O3 nanoparticles increased the porosity of the HVOF and LPPS coatings from 0.6 to 1 and from 2 to 2.45 vol.%, respectively. In the HVOF-sprayed CoNiCrAlY/nano-Al2O3, coating including γ-Co,Ni,Cr, β-(Co,Ni)Al, and α-Al2O3, the growth of non-protective NiO and spinel oxides was significantly limited and a dense α-Al2O3 oxide layer was promoted after the early-stage of oxidation. However, for the LPPS-deposited CoNiCrAlY/nano-Al2O3 coating consisting of γ-Co,Ni,Cr and γ-Al2O3, after oxidation, the presence of Al-rich oxides like θ-Al2O3 whiskers and porous transformed α-Al2O3 were observed on the coating. The correlation between microstructure, phase composition, and early-stage oxidation was discussed in detail.

Similar content being viewed by others

References

U. Dragos, M. Gabriela, B. Waltraut, and C. Ioan, Improvement of the Oxidation Behavior of Electron Beam Remelted MCrAlY Coatings, Solid State Sci., 2005, 7, p 459–464. https://doi.org/10.1016/j.solidstatesciences.2005.01.003

J.G. Thakare, C. Pandey, M.M. Mahapatra, and R.S. Mulik, Thermal Barrier Coatings—A State of the Art Review, Met. Mater. Int., 2021, 27, p 1947–1968. https://doi.org/10.1007/s12540-020-00705-w

A. Khezrloo, M. Afshar, S. Baghshahi, and A.A. Amadeh, Optimizing Nanostructured Yttria-Stabilized Zirconia Electrophoretic Coatings on MCrAlY Bond-Coated Inconel 738LC Superalloy, Trans. Indian Ceram. Soc., 2023 https://doi.org/10.1080/0371750X.2022.2152369

F. Ghadami, A.S. Aghdam, and S. Ghadami, Microstructural Characteristics and Oxidation Behavior of the Modified MCrAlX Coatings: A Critical Review, Vacuum., 2021, 185, p 109980. https://doi.org/10.1016/j.vacuum.2020.109980

M.F. Smith, A.C. Hall, J.D. Fleetwood, and P. Meyer, Very Low Pressure Plasma Spray—A Review of an Emerging Technology in the Thermal Spray Community, Coatings, 2011, 1, p 117–132. https://doi.org/10.3390/coatings1020117

M. Mohammadi, S. Javadpour, S.A. Jahromi, K. Shirvani, and A. Kobayashi, Characterization and Hot Corrosion Performance of LVPS and HVOF-CoNiCrAlYSi Coatings, Vacuum, 2012, 86, p 1458–1464. https://doi.org/10.1016/j.vacuum.2012.02.030

A.C. Karaoglanli, Y. Ozgurluk, and K.M. Doleker, Comparison of Microstructure and Oxidation Behavior of CoNiCrAlY Coatings Produced by APS, SSAPS, D-gun, HVOF and CGDS Techniques, Vacuum., 2020, 180, p 109609. https://doi.org/10.1016/j.vacuum.2020.109609

A. Scrivani, U. Bardi, L. Carrafiello, A. Lavacchi, F. Niccolai, and G.A. Rizzi, Comparative Study of High Velocity Oxygen Fuel, Vacuum Plasma Spray, and Axial Plasma Spray for the Deposition of CoNiCrAlY Bond Coat Alloy, J Therm. Spray Technol., 2003, 12, p 504–507. https://doi.org/10.1361/105996303772082242

M. Shibata, S. Kuroda, H. Murakami, M. Ode, M. Watanabe, and Y. Sakamoto, Comparison of Microstructure and Oxidation Behavior of CoNiCrAlY Bond Coatings Prepared by Different Thermal Spray Processes, Mater. Trans., 2006, 47, p 1638–1642. https://doi.org/10.2320/matertrans.47.1638

J.A. Cabral-Miramontes, C. Gaona-Tiburcio, F. Almeraya-Calderón, F.H. Estupiñan-Lopez, G.K. Pedraza-Basulto, and C.A. Poblano-Salas, Parameter Studies on High-Velocity oxy-Fuel Spraying of CoNiCrAlY Coatings Used in the Aeronautical Industry, Int. J. Corros., 2014 https://doi.org/10.1155/2014/703806

H. Vasudev, L. Thakur, H. Singh, and A. Bansal, A Study on Processing and Hot Corrosion Behaviour of HVOF Sprayed Inconel718-nano Al2O3 Coatings, Mater. Today Commun., 2020, 25, p 101626. https://doi.org/10.1016/j.mtcomm.2020.101626

P. Zamani, R. Ghasemi, S. Torabi, B. Mirjani, M. Memari, M. Alizadeh, and H. Khaledi, Characterization and High-Temperature Fretting Wear Resistance of HVOF-Sprayed Cr3C2-NiCr, CoCrWC and CoCrWNiC Hardfacing Coatings, J. Therm. Spray Technol., 2022, 31, p 2157–2171. https://doi.org/10.1007/s11666-022-01431-y

M. Bai, B. Song, L. Reddy, T. Hussain, HVOF Thermal Sprayed MCrAlY-Alumina Composite Coatings for High Temperature Applications. In ITSC2018 (pp. 16-23). ASM International. 2018. https://doi.org/10.31399/asm.cp.itsc2018p0016.

P. Zamani and Z. Valefi, Comparative Investigation of Microstructure and High-Temperature Oxidation Resistance of High-Velocity Oxy-Fuel Sprayed CoNiCrAlY/Nano-Al2O3 Composite Coatings Using Satellited Powders, Int. J. Miner. Metall. Mater., 2023, 30, p 1779–1791. https://doi.org/10.1007/s12613-023-2630-9

A. Zakeri, E. Bahmani, A. Sabour, and Rouh Aghdam, Impact of MCrAlY Feedstock Powder Modification by High-Energy Ball Milling on the Microstructure and High-Temperature Oxidation Performance of HVOF-Sprayed Coatings Surf, Coat. Technol., 2020, 395, p 125935. https://doi.org/10.1016/j.surfcoat.2020.125935

T. Huang, J. Bergholz, G. Mauer, R. Vassen, D. Naumenko, and W.J. Quadakkers, Effect of Test Atmosphere Composition on High-Temperature Oxidation Behaviour of CoNiCrAlY Coatings Produced from Conventional and ODS Powders, Mater. High Temp., 2018, 35, p 97–107. https://doi.org/10.1080/09603409.2017.1389422

M. Bai, B. Song, L. Reddy, and T. Hussain, Preparation of MCrAlY– Al2O3 Composite Coatings with Enhanced Oxidation Resistance Through a Novel Powder Manufacturing Process, J. Therm. Spray Technol., 2019, 28, p 433–443. https://doi.org/10.1007/s11666-019-00830-y

J. Bergholz, B.A. Pint, K.A. Unocic, and R. Vaßen, Fabrication of Oxide Dispersion Strengthened Bond Coats with Low Al2O3 Content, J. Therm. Spray Technol., 2017, 26, p 868–879. https://doi.org/10.1007/s11666-017-0550-9

H. Vasudev, L. Thakur, H. Singh, and A. Bansal, Effect of Addition of Al2O3 on the High-Temperature Solid Particle Erosion Behaviour of HVOF Sprayed Inconel-718 Coatings, Mater. Today Commun., 2022, 30, p 103017. https://doi.org/10.1016/j.mtcomm.2021.103017

I.G. Wright, Dispersed Phases in Powder Metallurgically-Produced Alloys: Contributions to High-Temperature Oxidation Behavior, Mater. High Temp., 2022, 1, p 1–28. https://doi.org/10.1080/09603409.2022.2113709

K.S. Al-Hamdani, J.W. Murray, T. Hussain, A. Kennedy, and A.T. Clare, Cold Sprayed Metal-Ceramic Coatings Using Satellited Powders, Mater. Lett., 2017, 198, p 184–187. https://doi.org/10.1016/j.matlet.2017.03.175

M. Simonelli, N.T. Aboulkhair, P. Cohen, J.W. Murray, A.T. Clare, C. Tuck, and R.J. Hague, A comparison of Ti-6Al-4V In-Situ Alloying in Selective Laser Melting Using Simply-Mixed and Satellited Powder Blend Feedstocks, Mater. Charact., 2018, 143, p 118–126. https://doi.org/10.1016/j.matchar.2018.05.039

A. Clare and A. Kennedy, Additive Manufacturing, U.S. Patent Application 15/022,344, filed September 29, 2016.

H. Tan, D. Hao, K. Al-Hamdani, F. Zhang, Z. Xu, and A.T. Clare, Direct Metal Deposition of TiB2/AlSi10Mg Composites Using Satellited Powders, Mater. Lett., 2018, 214, p 123–126. https://doi.org/10.1016/j.matchar.2018.05.039

K.E. Schneider, V. Belashchenko, M. Dratwinski, S. Siegmann, and A. Zagorski, Thermal Spraying for Power Generation Components, Wiley, New York, 2006.

M. I. Boulos, P. L. Fauchais, E. Pfender, Handbook of Thermal Plasmas, Springer International Publishing, New York, NY, 2019. https://doi.org/10.1007/978-3-319-12183-3 .

H. Chen, Effects of Internal Oxide Contents on the Oxidation and β-Phase Depletion Behavior in HOVF CoNiCrAlY Coatings, Surf. Coat. Technol., 2021, 424, p 127666. https://doi.org/10.1016/j.surfcoat.2021.127666

H. Aghajani, Z. Valefi, and P. Zamani, Phase Composition, Microstructure, Mechanical Properties, and Wear Performance of Nanostructured Al2O3 and Al2O3-Y2O3 Coatings Deposited by Plasma Spraying, Appl. Surf. Sci., 2022, 585, p 152754. https://doi.org/10.1016/j.surfcoat.2017.03.022

S. Dhakar and K. Chatterjee, Sabiruddin, Phase Stabilization of Plasma-Sprayed Alumina Coatings by Spraying Mechanically Blended Alumina–Chromia Powders, Mater. Manuf. Process., 2017, 32, p 355–364. https://doi.org/10.1080/10426914.2016.1198028

T. Diana, W. Brandl, and U. Köster, Studies on the Transient Stage of Oxidation of VPS and HVOF Sprayed MCrAlY Coatings, Surf. Coat. Technol., 1999, 120, p 8–15. https://doi.org/10.1016/S0257-8972(99)00332-1

Y. Hosseini, A. Kermanpur, F. Ashrafizadeh, and A. Keyvani, Oxidation Behavior of Overlay NiCoCrAlY and Diffusion Aluminide Coatings Deposited on a Directionally Solidified Nickel-Based Superalloy: A Comparative Study, JOM., 2023, 75, p 64–75. https://doi.org/10.1007/s11837-022-05575-8

M. Mohammadi, S. Javadpour, S.A.J. Jahromi, and K. Shirvani, Characterization and Hot Corrosion Performance of LVPS and HVOF-CoNiCrAlYSi Coatings, Vacuum, 2012, 86, p 1458–1464. https://doi.org/10.1016/j.vacuum.2012.02.030

J. Sun, S.B. Liu, W. Li, H.J. Yu, and S.M. Jiang, Hot Corrosion Behaviour of Pt Modified Aluminized NiCrAlYSi Coating on a Ni-Based Single Crystal Superalloy, Corros. Sci., 2019, 149, p 207–217. https://doi.org/10.1016/j.corsci.2019.01.014

S. Lamouri, M. Hamidouche, and N. Bouaouadja, Control of the γ-Alumina to α-Alumina Phase Transformation for an Optimized Alumina Densification, Boletín de la Sociedad Española de cerámica y vidrio., 2017, 56, p 47–54. https://doi.org/10.1016/j.bsecv.2016.10.001

X. Ren and F. Wang, High-Temperature Oxidation and Hot-Corrosion Behavior of a Sputtered NiCrAlY Coating With and Without Aluminizing, Surf. Coat. Technol., 2006, 201, p 30–37. https://doi.org/10.1016/j.surfcoat.2005.10.042

P. Bowen and C. Carry, From Powders to Sintered Pieces: Forming, Transformations and Sintering of Nanostructured Ceramic Oxides, Powder Technol., 2002, 128, p 248–255. https://doi.org/10.1016/S0032-5910(02)00183-3

B.A. Pint, Experimental Observations in Support of the Dynamic-Segregation Theory to Explain the Reactive-Element Effect, Oxid. Met., 1996, 45, p 1–37. https://doi.org/10.1007/BF01046818

S. Shabani, S.M. Mirkazemi, H. Rezaie, Y. Vahidshad, and S. Trasatti, A Comparative Study on the Thermal Stability, Textural, and Structural Properties of Mesostructured γ-Al2O3 Granules in the Presence of La, Sn, and B Additives, Ceram. Int., 2022, 48, p 6638–6648. https://doi.org/10.1016/j.ceramint.2021.11.213

W. Sloof and T. Nijdam, On the High-Temperature oxidaTion of MCrAlY Coatings, Int. J. Mater. Res., 2009, 100, p 1318–1330. https://doi.org/10.3139/146.110201

N. Birks, G.H. Meier, and F.S. Pettit, Introduction to the High Temperature Oxidation of Metals, Chapter 5: Oxidation of Alloys, Cambridge University Press, Cambridge, 2006.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Zamani, P., Valefi, Z. Characterization and Early-Stage Oxidation Behavior of CoNiCrAlY/Nano-Al2O3 Composite Coatings Using Satellited Powders Deposited by HVOF and LPPS Processes. J Therm Spray Tech 32, 2525–2538 (2023). https://doi.org/10.1007/s11666-023-01650-x

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11666-023-01650-x