Abstract

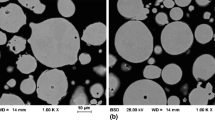

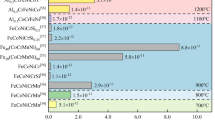

Adopting multi-principal high entropy alloys (HEAs) as wear/corrosion-resistant coatings is a frontier in the field of surface engineering. The eutectic high entropy alloy (EHEA) exhibited excellent mechanical properties, and its dual-phase, lamellar nanostructure effectively prohibited pitting corrosion, making the alloy a potential candidate for wear/corrosion-resistant coatings served in the complicated environments. In the presented study, a dense and non-oxidized CoCrFeNiTaAl EHEA was coated on 304 stainless steel (SUS 304) substrate by a high-velocity air fuel (HVAF) thermal spraying process. The microstructure, corrosion resistance, as well as high temperature wear resistance of the coating were analyzed. The coating consisted of a deformation zone and a solidified zone. The deformation zone had the same structure as the original powders of the hypo-eutectic structure, and the solidified zone exhibited a single-phase solid solution structure. The EHEA coating exhibited an excellent combination of pitting corrosion and room-temperature wear resistance. The wear mechanism of EHEA coatings was abrasive, and oxidation wear at room temperature and 100 °C, while adhesive and oxidation wears occurred at elevated temperatures. The wear resistance decreases as temperature increases.

Similar content being viewed by others

References

N.J. Wagner, W.W. Gerberich and J.V.R. Heberlein, Thermal Plasma Chemical Vapor Deposition of Wear-Resistant, Hard Si-C-N Coatings, Surf. Coat. Technol., 2006, 201(7), p 4168-4173.

K. Hou and Y. Chen, Preparation and Wear Resistance of Pulse Electrodeposited Ni-W/Al2O3 Composite Coatings, Appl. Surf. Sci., 2011, 257(15), p 6340-6346.

F. Movassagh-Alanagh, A. Abdollah-zadeh, M. Aliofkhazraei and M. Abedi, Improving the Wear and Corrosion Resistance of Ti-6Al-4V alloy by Deposition of TiSiN Nanocomposite Coating with Pulsed-DC PACVD, Wear, 2017, 390-391, p 93-103.

Y. Zhang, T.T. Zuo, Z. Tang, M.C. Gao, K.A. Dahmen, P.K. Liaw and Z.P. Lu, Microstructures and Properties of High-Entropy Alloys, Prog. Mater Sci., 2014, 61, p 1-93.

B. Liu, J. Wang, Y. Liu, Q. Fang, Y. Wu, S. Chen and C.T. Liu, Microstructure and Mechanical Properties of Equimolar FeCoCrNi High Entropy Alloy Prepared via Powder Extrusion, Intermetallics, 2016, 75, p 25-30.

B. Cai, B. Liu, S. Kabra, Y. Wang, K. Yan, P.D. Lee and Y. Liu, Deformation Mechanisms of Mo Alloyed FeCoCrNi High Entropy Alloy: In Situ Neutron Diffraction, Acta Mater., 2017, 127, p 471-480.

Y.Y. Chen, U.T. Hong, H.C. Shih, J.W. Yeh and T. Duval, Electrochemical Kinetics of the High Entropy Alloys in Aqueous Environments—A Comparison with type 304 Stainless Steel, Corros. Sci., 2005, 47(11), p 2679-2699.

Y.L. Chou, J.W. Yeh and H.C. Shih, The Effect of Molybdenum on the Corrosion Behaviour of the High-Entropy Alloys Co1.5CrFeNi1.5Ti0.5Mox in Aqueous Environments, Corros. Sci., 2010, 52(8), p 2571-2581.

C.L. Wu, S. Zhang, C.H. Zhang, H. Zhang and S.Y. Dong, Phase Evolution and Cavitation Erosion-Corrosion Behavior of FeCoCrAlNiTix High Entropy Alloy Coatings on 304 Stainless Steel by Laser Surface Alloying, J. Alloys Compd., 2017, 698, p 761-770.

C. Huang, Y. Zhang, R. Vilar and J. Shen, Dry Sliding Wear Behavior of Laser Clad TiVCrAlSi High Entropy Alloy Coatings on Ti-6Al-4V Substrate, Mater. Des., 2012, 41, p 338-343.

W. Wu, L. Jiang, H. Jiang, X. Pan, Z. Cao, D. Deng, T. Wang and T. Li, Phase Evolution and Properties of Al2CrFeNiMoxHigh-Entropy Alloys Coatings by Laser Cladding, J. Therm. Spray Technol., 2015, 24(7), p 1333-1340.

C.L. Wu, S. Zhang, C.H. Zhang, H. Zhang and S.Y. Dong, Phase Evolution and Properties in Laser Surface Alloying of FeCoCrAlCuNix High-Entropy Alloy on Copper Substrate, Surf. Coat. Technol., 2017, 315, p 368-376.

J. Wang, B. Zhang, Y. Yu, Z. Zhang, S. Zhu, X. Lou and Z. Wang, Study of High Temperature Friction and Wear Performance of (CoCrFeMnNi)85Ti15 High-Entropy Alloy Coating Prepared by Plasma Cladding, Surf. Coat. Technol., 2020, 384, p 125337.

M. Löbel, T. Lindner and T. Lampke, High-Temperature Wear Behaviour of AlCoCrFeNiTi0.5 Coatings Produced by HVOF, Surf. Coat. Technol., 2020, 403, p 126379.

D. Zhao, T. Yamaguchi, D. Tusbasa and W. Wang, Fabrication and Friction Properties of the AlFeCrCo Medium-Entropy Alloy Coatings on Magnesium Alloy, Mater. Des., 2020, 193, p 108872.

B. Ren, Z.X. Liu, D.M. Li, L. Shi, B. Cai and M.X. Wang, Corrosion Behavior of CuCrFeNiMn High Entropy Alloy System in 1 M Sulfuric Acid Solution, Mater. Corros., 2015, 63(9), p 828-834.

Y. Guo and Q. Liu, MoFeCrTiWAlNb Refractory High-Entropy Alloy Coating Fabricated by Rectangular-Spot Laser Cladding, Intermetallics, 2018, 102, p 78-87.

L.X. Han, C.M. Wang and H.F. Sun, Microstructure and Anticorrosion Property of High-Entropy alloy AlFeNiCrCoTi0.5Vx, Mater. Trans., 2016, 57(7), p 1134-1137.

X.L. Shang, Z.J. Wang, Q.F. Wu, J.C. Wang, J.J. Li and J.K. Yu, Effect of Mo Addition on Corrosion Behavior of High-Entropy Alloys CoCrFeNiMox in Aqueous Environments, Acta Metall. Sin. (Engl. Lett.), 2019, 32(1), p 41-51.

Y. Lu, Y. Dong, S. Guo, L. Jiang, H. Kang, T. Wang, B. Wen, Z. Wang, J. Jie, Z. Cao, H. Ruan and T. Li, A Promising New Class of High-Temperature Alloys: Eutectic High-Entropy Alloys, Sci. Rep., 2014, 4, p 6200.

Y. Lu, Y. Dong, H. Jiang, Z. Wang, Z. Cao, S. Guo, T. Wang, T. Li and P.K. Liaw, Promising Properties and Future Trend of Eutectic High Entropy Alloys, Scr. Mater., 2020, 187, p 202-209.

S. Shuang, Z.Y. Ding, D. Chung, S.Q. Shi and Y. Yang, Corrosion Resistant Nanostructured Eutectic High Entropy Alloy, Corros. Sci., 2020, 164, p 108315.

Y. Yu, F. He, Z. Qiao, Z. Wang, W. Liu and J. Yang, Effects of Temperature and Microstructure on the Triblogical Properties of CoCrFeNiNbx Eutectic High Entropy Alloys, J. Alloys Compd., 2019, 775, p 1376-1385.

H. Jiang, Study on Composition Design and Mechanical Properties of CoFeNi(Cr)-M Eutectic High Entropy Alloys, Dalian University of Technology, 2018.

L. Han, X. Xu, Z. Li, B. Liu, C.T. Liu and Y. Liu, A Novel Equiaxed Eutectic High-Entropy Alloy with Excellent Mechanical Properties at Elevated Temperatures, Mater. Res. Lett., 2020, 8(10), p 373-382.

D. Lin, N. Zhang, B. He, B. Jin, Y. Zhang, D. Li and F. Dong, Influence of Laser Re-melting and Vacuum Heat Treatment on Plasma-Sprayed FeCoCrNiAl Alloy Coatings, J. Iron. Steel Res. Int., 2017, 24(12), p 1199-1205.

Q. Ye, K. Feng, Z. Li, F. Lu, R. Li, J. Huang and Y.J.A.S.S. Wu, Microstructure and Corrosion Properties of CrMnFeCoNi High Entropy Alloy Coating, Appl. Surf. Sci., 2017, 396(PT.2), p 1420-1426.

T. Li, Y. Liu, B. Liu, W. Guo and L. Xu, Microstructure and Wear Behavior of FeCoCrNiMo0.2 High Entropy Coatings Prepared by Air Plasma Spray and the High Velocity Oxy-Fuel Spray Processes, Coatings, 2017, 7(9), p 151.

L. Chen, K. Bobzin, Z. Zhou, L. Zhao, M. Öte, T. Königstein, Z. Tan and D. He, Wear Behavior of HVOF-Sprayed Al0.6TiCrFeCoNi High Entropy Alloy Coatings at Different Temperatures, Surf. Coat. Technol., 2019, 358, p 215-222.

J. Xiao, Y. Wu, J. Chen and C. Zhang, Microstructure and Tribological Properties of Plasma Sprayed FeCoNiCrSiAlx High Entropy Alloy Coatings, Wear, 2020, 448-449, p 203209.

E. Sadeghimeresht, N. Markocsan and P. Nylén, A Comparative Study on Ni-Based Coatings Prepared by HVAF, HVOF, and APS Methods for Corrosion Protection Applications, J. Therm. Spray Technol., 2016, 25(8), p 1604-1616.

R.E. Kumar, M. Kamaraj, S. Seetharamu and S. Anand Kumar, A Pragmatic Approach and Quantitative Assessment of Silt Erosion Characteristics of HVOF and HVAF Processed WC-CoCr Coatings and 16Cr5Ni Steel for Hydro Turbine Applications, Mater. Des., 2017, 132, p 79-95.

J. Li, W. Jia, J. Wang, H. Kou, D. Zhang and E. Beaugnon, Enhanced Mechanical Properties of a CoCrFeNi High Entropy Alloy by Supercooling Method, Mater. Des., 2016, 95, p 183-187.

L. Avril, B. Courant and J.J. Hantzpergue, Tribological Performance of α-Fe(Cr)-Fe2B-FeB and α-Fe(Cr)-h-BN Coatings Obtained by Laser Melting, Wear, 2006, 260(4), p 351-360.

X. Cui, X. Lin, C. Liu, R. Yang, X. Zheng and M. Gong, Fabrication and Corrosion Resistance of a Hydrophobic Micro-arc Oxidation Coating on AZ31 Mg Alloy, Corros. Sci., 2015, 90, p 402-412.

C. OuYang, X. Liu, Y. Luo, J. Liang, M. Wang and D. Chen, Preparation and High Temperature Tribological Properties of Laser In-Situ Synthesized Self-lubricating Composite Coating on 304 Stainless Steel, J. Market. Res., 2020, 9(4), p 7034-7046.

H. Torres, M. Rodríguez Ripoll and B. Prakash, Tribological Behaviour of Self-lubricating Materials at High Temperatures, Int. Mater. Rev., 2018, 63(5), p 309-340.

Acknowledgments

This research was supported by the Regional Innovation and Development Joint Fund of National Natural Science Foundation of China (No. U20A20236), National Natural Science Foundation of China (No. 51731006, NO.5210110643), Natural Science Foundation of Hunan Province (No. 2020JJ4738), Natural Science Foundation of Shandong Province (No. ZR2020QD081, NO. ZR2020ME130, NO. ZR2020ME131), Green Innovation Science and Technology Plan of Colleges and Universities in Shandong Province (No. 2020KJA014), Open Sharing Fund for the Large-scale Instruments and Equipment of Central South University and 2020 open projects (KLATM202004) of Key Laboratory of Advanced Technologies of Materials, Ministry of Education China, Southwest Jiaotong University.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

This article is part of a special topical focus in the Journal of Thermal Spray Technology on High Entropy Alloy and Bulk Metallic Glass Coatings. The issue was organized by Dr. Andrew S.M. Ang, Swinburne University of Technology; Prof. B.S. Murty, Indian Institute of Technology Hyderabad; Distinguished Prof. Jien-Wei Yeh, National Tsing Hua University; Prof. Paul Munroe, University of New South Wales; Distinguished Prof. Christopher C. Berndt, Swinburne University of Technology. The issue organizers were mentored by Emeritus Prof. S. Ranganathan, Indian Institute of Sciences.

Rights and permissions

About this article

Cite this article

Liu, S., Peng, Y., Zhang, Y. et al. Effect of Nanostructure on Wear and Corrosion Behavior of HVAF-Sprayed Eutectic High-Entropy Alloy Coatings. J Therm Spray Tech 31, 1252–1262 (2022). https://doi.org/10.1007/s11666-022-01342-y

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11666-022-01342-y