Abstract

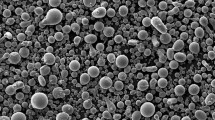

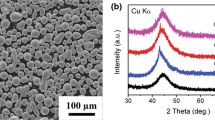

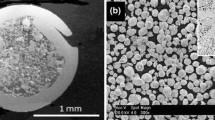

The goal of this study is to investigate the influence of the powder size on the coating properties and to gain insights into the underlying mechanisms. Therefore, FeCrB/WC-Co coatings were produced by HVAF spraying using different powder sizes. The used FeCrB/WC-Co feedstock materials exhibit an identical chemical composition with varying powder sizes of − 45 + 11 (Bobzin et al. (in Proceedings of ITSC—international thermal spray conference and exposition, Düsseldorf, pp. 339–345, 2017. ISBN: 978-3-96144-000-9), − 32 + 11 (Bobzin et al. in Proceedings of 20. WTK—Werkstofftechnisches Kolloquium, Chemnitz, 2018. ISBN: 978-3-00-058901-0) and − 20 + 3 µm. These coatings were subsequently analyzed with regard to their microstructure and phase composition, as well as their wear and corrosion behavior. All HVAF-sprayed FeCrB/WC-Co coatings exhibited a very dense microstructure. It was observed that coatings, which were produced with a finer powder size and identical chemical composition, showed reduced crack formation in the coating at high powder feed rates and lower current densities at high polarizations. Furthermore, the presented HVAF-sprayed FeCrB/WC-Co coatings exhibited an increased sliding wear and corrosion resistance compared to a sealed wire-arc-sprayed reference coating. The investigation also revealed that the powder size of the FeCrB/WC-Co feedstock material influences the microstructure and the phase composition of the resulting coating. It is assumed that the finer powder size of the HVAF-sprayed FeCrB/WC-Co coatings results in partly amorphous coatings, which might improve the corrosion resistance.

Similar content being viewed by others

References

A. Verstak and V. Baranovski, AC-HVAF Sprayed Tungsten Carbide: Properties and Applications, in Proceedings of ITSC—International Thermal Spray Conference & Exposition, May 2006, Seattle, pp. 643/648

A. Salman, B. Gabbitas, P. Cao, and D. Zhang, Tribological Properties of Ti(AlO/Al2O3) Composite Coating by Thermal Spraying, Int. J. Mod. Phys. B, 2009, 23(6 & 7), p 1407-1412. https://doi.org/10.1142/S0217979209061019

Q. Wang, S. Zhang, Y. Cheng, and J. Xiang, Wear and Corrosion Performance of WC-10Co4Cr Coatings Deposited by Different HVOF and HVAF Spraying Processes, Surf. Coat. Technol., 2013, 218(I), p 117-123. https://doi.org/10.1016/j.surfcoat.2012.12.041

R.Q. Guo, C. Zhang, Q. Chen, and Y. Yang, Study of Structure and Corrosion Resistance of Fe-Based Amorphous Coatings Prepared by HVAF and HVOF, Corros. Sci., 2011, 53(7), 2351-2356. https://doi.org/10.1016/j.corsci.2010.12.022

G. Bolelli, L.M. Berger, T. Boerner, and H. Koivuluoto, Tribology of HVOF- and HVAF-Sprayed WC-10Co4Cr Hardmetal Coatings: A Comparative Assessment, Surf. Coat. Technol., 2015, 265, 125-144. https://doi.org/10.1016/j.surfcoat.2015.01.048

I. Hulka, V.A. Serban, K. Niemi, and P. Vuoristo, Comparison of Structure and Wear Properties of Fine-Structured WC-CoCr Coatings Deposited by HVOF and HVAF Spraying Processes, Sol. St. Phen., 2017, 188, p 422-427. https://doi.org/10.4028/www.scientific.net/SSP.188.422

G. Bolelli, I. Hulka, H. Koivuluoto, and L. Lusvarghi, Properties of WC-FeCrAl Coatings Manufactured by Different High Velocity Thermal Spray Processes, Surf. Coat. Technol., 2014, 247, p 74-89. https://doi.org/10.1016/j.surfcoat.2014.03.021

S. Hashmi, Comprehensive Materials Processing: Thermal Spray Coating Process, (Newnes 2014), pp. 233-266. ISBN: 978-0-0809-6532-1.

K. Bobzin, M. Öte, T.F. Linke, and K.A. Malik, Wear and Corrosion Resistance of Fe-Based Coatings Reinforced by TiC Particles for Application in Hydraulic Systems, J. Therm. Spray Technol., 2016, 25(1-2), p 365-374. https://doi.org/10.1007/s11666-015-0316-1

K. Bobzin, L. Zhao, M. Öte, and T. Königstein, Novel Fe-Based Wear and Corrosion Resistant Coatings By Three-Cathode Plasma Technology, Surf. Coat. Technol., 2017, 318, p 288-292. https://doi.org/10.1016/j.surfcoat.2016.08.041

A. Schwenk, HVOF-K2-Spritzen von Eisenbasislegierungen für Anwendungen in der Druckindustrie, in Proceedings of. 8. HVOF-Kolloquium, Erding, October 2009

A. Osamanda, A. Battenbough, and A. Staines, Fe-Cr and Fe-Cr-Ni Based HVOF Coating Systems Customised for Wear and Corrosion Protection, Thermal Spray Bull., 2012, 64(2), p 117-122

P. Vuoristo and P. Nylén, Industrial and Research Activities in Thermal Spray Technology in the Nordic Region of Europe, J. Therm. Spray Technol., 2007, 16, p 466-471. https://doi.org/10.1007/s11666-007-9136-2

H.S. Jazi, Thermal Sprayed Coatings Used Against Corrosion and Corrosive Wear. IntechOpen (2012), ISBN: 978-953-51-0349-3

C. Perdikaris, Methods of Coating Yankee Dryer Drums, E.U. Patent 1,158,066A1

J. Tenkula, B. Hellman, and J. Majava, Yankee Clyinder with Plasma Sprayed Carbide Coating, U.S. Patent 5,123,152A.

K. Bobzin, M. Öte, M.A. Knoch, and J. Sommer, Influence of Powder Feed Rate on Corrosion and Wear Properties of Fe-Based HVAF Coatings, in Proceedings of 20. WTK—Werkstofftechnisches Kolloquium, Chemnitz, March 2018. ISBN: 978-3-00-058901-0

N. Espallargas, Future Development of Thermal Spray Coatings. Woodhead Publishing (2015), ISBN: 978-0-85709-769-9

P. Vuoristo, Thermal Spray Coating Processes, Comprehensive Material Processing 1st Edition, Elsevier (Amsterdam, 2014), pp. 229-276

G.E. Totten, Friction, Lubrication, and Wear Technology. ASM Handbook Vol. 18

K. Bobzin, M. Öte, M.A. Knoch, and J. Sommer, Development of HVAF-Sprayed Novel Fe-Based Coatings for Large Area Applications, in Proceedings of ITSC—International Thermal Spray Conference & Exposition, Düsseldorf, June 2017, pp. 339-345. ISBN: 978-3-96144-000-9

J.A. Picas, A. Forn, and G. Matthäus, HVOF Coatings as an Alternative to Hard Chrome for Pistons and Valves, Wear, 2006, 261, p 477-484. https://doi.org/10.1016/j.wear.2005.12.005

T. Warda, Thermisch gespritzt eisenbasierte Feinstpulverschichtsysteme für Verschleiß- und Korrosionsschutzanwendungen, Shaker Verlag (Aachen, 2013). ISBN: 978-3-8440-1833-2

E. Sadeghimeresht, N. Markocsan, and P. Nylén, Microstructural Characteristics and Corrosion Behavior of HVAF- and HVOF-Sprayed Fe-Based Coatings, Surf. Coat. Technol., 2017, 318, p 365-373. https://doi.org/10.1016/j.surfcoat.2016.11.088

J. Nebel, W. Tillmann, W. Piotrowski, and I.A. Laemmerhirt, Influence of Fine Powder Feedstock (− 10 +2 µm) on the HVOF Spraying Characteristics, Coating Morphology and Properties of WC-CoCr 86-10-4, in Proceedings of ITSC—Inernational Thermal Spray Conference & Exposition, Houston, TX, May 2012, pp. 403-408. ISBN: 978-1-62708-010-1

W. Tillmann, E. Vogli, I. Baumann, G. Matthaeus, and T. Ostrowski, Influence on the HVOF Gas Composition on the Thermal Spraying of WC-Co Submicron Powders (-8 +1 µm) to Produce Superfine Structured Cermet Coatings, J. Therm. Spray Technol., 2008, 14(3), p 405-413. https://doi.org/10.1007/s11666-008-9234-9

A. Milanti, V. Matikainen, G. Bolelli, H. Koivuluoto, L. Lusvarghi, and P. Vuoristo, Microstructure and Sliding Wear Behavior of Fe-Based Coatings Manufactured with HVOF and HVAF Thermal Spray Processes, J. Therm. Spray Technol., 2016, 25(5), p 1040-1055. https://doi.org/10.1007/s11666-016-0410-z

L. Milanti, V. Matikainen, H. Koivuluoto, G. Bolelli, L. Lusvarghi, and P. Vuoristo, Effect of Spraying Parameters on the Microstructural and Corrosion Properties of HVAF-Sprayed Fe-Cr-Ni-B-C Coatings, Surf. Coat. Technol., 2015, 277, p 81-90. https://doi.org/10.1016/j.surfcoat.2015.07.018

E. Sadeghimeresht, N. Markoscan, and P. Nylén, A Comparative Study of Corrosion Resistance for HVAF-Sprayed Fe- and Co-Based Coatings, Coatings, 2016, https://doi.org/10.3390/coatings6020016

G. Bolelli, T. Börner, A. Milanti, L. Lusvarghi, J. Laurila, H. Koivuluoto, K. Niemi, and P. Vuoristo, Tribological Behavior of HVOF- and HVAF-Sprayed Composite Coatings Based on Fe-Alloy + WC–12% Co, Surf. Coat. Technol., 2014, 248, p 104-112. https://doi.org/10.1016/j.surfcoat.2014.03.037

A. Milanti, H. Koivuluoto, and P. Vuoristo, Influence of the Spray Gun Type on Microstructure and Properties of HVAF Sprayed Fe-Based Corrosion Resistant Coatings, J. Therm. Spray Technol., 2015, 24, p 1312-1322. https://doi.org/10.1007/s11666-015-0298-z1059-9630/$19.00

M. Miller and P. Liaw, Bulk Metallic Glasses, Springer, Berlin, 2008, ISBN 978-0-387-48920-9

J. Liu, R.E. Saw, and Y.-H. Kian, Calculation of Effective Penetration Depth in X-Ray Diffraction for Pharmaceutical Solids, J. Pharm. Sci., 2010, 99(9), p 3807-3814. https://doi.org/10.1002/jps.22202

V. Hauk and H. Behnken, Structural and Residual Stress Analysis by Nondestructive Methods, Elsevier, Amsterdam, 2006, ISBN 0444824766

J.H. Hubbell and S.M. Seltzer, Standard Reference Database 126: X-Ray Mass Attenuation Coefficients. Tables of X-Ray Mass Attenuation Coefficients and Mass Energy-Absorption Coefficients from 1 keV to 20 MeV for Elements Z = 1 to 92 and 48 Additional Substances of Dosimetric Interest, Stand vom 07.2004. U.S. Department of Commerce: https://www.nist.gov/pml/x-ray-mass-attenuation-coefficients. Accessed 12 Sept 2018

L. Liu and C. Zhang, Fe-Based Amorphous Coatings: Structures and Properties, Thin Solid Films, 2014, 561, p 70-86. https://doi.org/10.1016/j.tsf.2013.08.029

Acknowledgments

This work based on the DFG project BO 1979/45-1 “Resource efficient production of novel Fe-based coatings for large-area applications by AC-HVAF coating process.” The authors gratefully acknowledge the financial support of the German Research Foundation (DFG).

Author information

Authors and Affiliations

Corresponding author

Additional information

This article is an invited paper selected from presentations at the 2018 International Thermal Spray Conference, held May 7-10, 2018, in Orlando, Florida, USA, and has been expanded from the original presentation.

Rights and permissions

About this article

Cite this article

Bobzin, K., Öte, M., Knoch, M.A. et al. Influence of Powder Size on the Corrosion and Wear Behavior of HVAF-Sprayed Fe-Based Coatings. J Therm Spray Tech 28, 63–75 (2019). https://doi.org/10.1007/s11666-018-0819-7

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11666-018-0819-7