Abstract

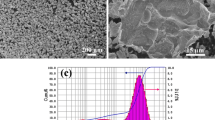

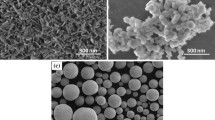

In this study, a Yb2O3 coating was fabricated by the atmospheric plasma spray technique. The phase composition, microstructure, and thermal stability of the coating were examined. The thermal conductivity and thermal expansion behavior were also investigated. Some of the mechanical properties (elastic modulus, hardness, fracture toughness, and flexural strength) were characterized. The results reveal that the Yb2O3 coating is predominantly composed of the cubic Yb2O3 phase, and it has a dense lamellar microstructure containing defects. No mass change and exothermic phenomena are observed in the thermogravimetry and differential thermal analysis curves. The high-temperature x-ray diffraction results indicate that no phase transformation occurs from room temperature to 1500 °C, revealing the good phase stability of the Yb2O3 coating. The coefficient of thermal expansion of the Yb2O3 coating is (7.50-8.67) × 10−6 K−1 in the range of 200-1400 °C. The thermal conductivity is about 1.5 W m−1 K−1 at 1200 °C. The Yb2O3 coating has excellent mechanical properties and good damage tolerant. The unique combination of these properties implies that the Yb2O3 coating might be a promising candidate for T/EBCs applications.

Similar content being viewed by others

References

R.A. Miller, Thermal Barrier Coatings for Aircraft Engines—History and Direction, J. Therm. Spray Technol., 1997, 6(1), p 35-42

X.Q. Cao, R. Vassen, and D. Stoever, Ceramic Materials for Thermal Barrier Coatings, J. Eur. Ceram. Soc., 2004, 24(1), p 1-10

S. Zhu, M. Mizuno, Y. Nagano, J. Cao, Y. Kagawa, and H. Kaya, Creep and Fatigue Behavior in An Enhanced SiC/SiC Composite at High Temperature, J. Am. Ceram. Soc., 1998, 81(9), p 2269-2277

N.S. Jacobson, Corrosion of Silicon-Based Ceramics in Combustion Environments, J. Am. Ceram. Soc., 1993, 76(1), p 3-28

K.N. Lee, Current Status of Environmental Barrier Coatings for Si-based Ceramics, Surf. Coat. Technol., 2000, 133-134, p 1-7

É. Darthout and F. Gitzhofer, Thermal Cycling and High-Temperature Corrosion Tests of Rare Earth Silicate Environmental Barrier Coatings, J. Therm. Spray Technol., 2017, 26(8), p 1823-1837

B.J. Harder, J. Ramírez-Rico, J.D. Almer, K.N. Lee, and K.T. Faber, Chemical and Mechanical Consequences of Environmental Barrier Coating Exposure to Calcium-Magnesium-Aluminosilicate, J. Am. Ceram. Soc., 2011, 94(S1), p S178-S185

D.L. Poerschke, D.D. Hass, S. Eustis, G.G.E. Seward, J.S.V. Sluytman, and C.G. Levi, Stability and CMAS Resistance of Ytterbium-Silicate/Hafnate EBCs/TBC for SiC Composites, J. Am. Ceram. Soc., 2015, 98(1), p 278-286

D.L. Poerschke, R.W. Jackson, and C.G. Levi, Silicate Deposit Degradation of Engineered Coatings in Gas Turbines: Progress Toward Models and Materials Solutions, Annu. Rev. Mater. Res., 2017, 47, p 297-330

D.L. Poerschke, J.S. Van Sluytman, K.B. Wong, and C.G. Levi, Thermochemical Compatibility of Ytterbia-(Hafnia/Silica) Multilayers for Environmental Barrier Coatings, Acta Mater., 2013, 61(18), p 6743-6755

B.T. Richards, S. Sehr, F. de Franqueville, and H.N.G. Wadley, Fracture Mechanisms of Ytterbium Monosilicate Environmental Barrier Coatings During Cyclic Thermal Exposure, Acta Mater., 2016, 103, p 448-460

B.T. Richards, M.R. Begley, and H.N.G. Wadley, Mechanisms of Ytterbium Monosilicate/Mullite/Silicon Coating Failure During Thermal Cycling in Water Vapor, J. Am. Ceram. Soc., 2015, 98(12), p 4066-4075

B.T. Richards, K.A. Young, F.D. Francqueville, S. Sehr, M.R. Begley, and H.N.G. Wadley, Response of Ytterbium Disilicate-Silicon Environmental Barrier Coatings to Thermal Cycling in Water Vapor, Acta Mater., 2016, 106, p 1-14

M.H. Lu, H.M. Xiang, Z.H. Feng, X.Y. Wang, and Y.C. Zhou, Mechanical and Thermal Properties of Yb2SiO5: A promising Material for T/EBCs Applications, J. Am. Ceram. Soc., 2016, 99(4), p 1404-1411

Z.L. Tian, L.Y. Zheng, J.M. Wang, and J.B. Yang, Damage Tolerance and Extensive Plastic Deformation of β-Yb2Si2O7 From Room to High Temperatures, J. Am. Ceram. Soc., 2015, 98(9), p 2843-2851

Z.Q. Sun, Y.C. Zhou, J.Y. Wang, and M.S. Li, Mechanical Properties and Damage Tolerance of Y2SiO5, J. Eur. Ceram. Soc., 2008, 28(15), p 2895-2901

Z.Q. Sun, Y.C. Zhou, J.Y. Wang, and M.S. Li, Γ-Y2Si2O7, A Machinable Silicate Ceramic: Mechanical Properties and Machinability, J. Am. Ceram. Soc., 2007, 90(8), p 2535-2541

H. Yamamura, H. Nishino, and K. Kakinuma, Relationship Between Oxide-Ion Conductivity and Dielectric Relaxation in the Ln2Zr2O7 System Having Pyrochore-Type Compositions (Ln = Yb, Y, Gd, Eu, Sm, Nd, La), J. Phys. Chem. Solids, 2008, 69(7), p 1711-1717

R.L. Jones, Some Aspects of the Hot Corrosion of Thermal Barrier Coatings, J. Therm. Spray Technol., 1997, 6(1), p 77-84

P. Mechnich and W. Braue, Air Plasma-Sprayed Y2O3 Coatings for Al2O3/Al2O3 Ceramic Matrix Composites, J. Eur. Ceram. Soc., 2013, 33(13-14), p 2645-2653

R.A. Golden and E.J. Opila, A Method for Assessing the Volatility of Oxides in High-Temperature High-Velocity Water Vapor, J. Eur. Ceram. Soc., 2016, 36(5), p 1135-1147

E. Courcot, F. Rebillat, F. Teyssandier, and C. Louchet-Pouillerie, Stability of Rare Earth Oxides in a Moist Environment at Elevated Temperatures-Experimental and Thermodynamic Studies Part II: Comparison of the Rare Earth Oxides, J. Eur. Ceram. Soc., 2010, 30(9), p 1911-1917

D.L. Ye, Inorganic Material Thermodynamics, 2nd ed., Metallurgical Industry Press, Beijing, 2002, p 1161-1162

F. Tarasi, M. Medraj, A. Dolatabadi, J. Oberste-Berghaus, and C. Moreau, Phase Formation and Transformation in Alumina/YSZ Nanocomposite Coating Deposited by Suspension Plasma Spray Process, J. Therm. Spray Technol., 2010, 19(4), p 787-795

DOE-National Energy Technology Laboratory, Protective Coatings for Gas Turbines. http://www.netl.doe.gov/File%20Library/Research/Coal/energy%20systems/turbines/handbook/4-4-2.pdf/, 2005. Accessed 12.06.11.

X. Zhong, Y.R. Niu, H. Li, Y. Zeng, X.B. Zheng, C.X. Ding, and J.L. Sun, Microstructure Evolution and Thermomechanical Properties of Plasma-Sprayed Yb2SiO5 Coating During Thermal Aging, J. Am. Ceram. Soc., 2017, 100(5), p 1896-1906

G.E. Youngblood, R.W. Rice, and R.P. Ingel, Thermal Diffusivity of Partially and Fully Stabilized (Yttria) Zirconia Single Crystals, J. Am. Ceram. Soc., 1988, 71(4), p 255-260

D.R. Clarke and S.R. Phillpot, Thermal Barrier Coating Materials, Mater. Today, 2005, 8(6), p 22-29

X.F. Wang, H.M. Xiang, X. Sun, J.C. Liu, F. Hou, and Y.H. Zhou, Mechanical Properties and Damage Tolerance of Bulk Yb3Al5O12 Ceramic, J. Mater. Sci. Technol., 2015, 31(4), p 369-374

S.R. Choi, D.M. Zhu, and R.A. Miller, Mechanical Properties/Database of Plasma-Sprayed ZrO2-8wt% Y2O3 Thermal Barrier Coatings, Int. J. Appl. Ceram. Technol., 2004, 1(4), p 330-342

S.H. Leigh, C.K. Lin, and C.C. Berndt, Elastic Response of Thermal Spray Deposits under Indentation Tests, J. Am. Ceram. Soc., 1997, 80(8), p 2093-2099

K.N. Lee, J.I. Eldridge, and R.C. Robinson, Residual Stresses and Their Effects on the Durability of Environmental Barrier Coatings for SiC Ceramics, J. Am. Ceram. Soc., 2005, 88(12), p 3483-3488

A.R. Boccaccini, Machinability and Brittleness of Glass-Ceramics, J. Mater. Process. Technol., 1997, 65(1-3), p 302-304

Y.W. Bao, C.F. Hu, and Y.C. Zhou, Damage Tolerance of Nanolayer-Grained Ceramic: A Quantitative Estimation, Mater. Sci. Technol., 2006, 22(2), p 227-230

Acknowledgments

This work was supported by the Engineering case study in extreme conditions using system mechanics approach (XDB22010202) and the Youth Innovation Promotion Association of the Chinese Academy of Sciences (2014223).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Zhong, X., Niu, Y., Li, H. et al. Microstructure and Thermomechanical Properties of Atmospheric Plasma-Sprayed Yb2O3 Coating. J Therm Spray Tech 27, 959–967 (2018). https://doi.org/10.1007/s11666-018-0733-z

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11666-018-0733-z