Abstract

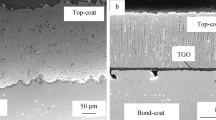

Lutetium and yttrium silicates, enriched with an additional secondary zirconia phase, environmental barrier coatings were synthesized by the solution precursor plasma spraying process on silicon carbide substrates. A custom-made oven was designed for thermal cycling and water vapor corrosion testing. The oven can test four specimens simultaneously and allows to evaluate environmental barrier performances under similar corrosion kinetics compared to turbine engines. Coatings structural evolution has been observed by SEM on the polished cross sections, and phase composition has been analyzed by XRD. All coatings have been thermally cycled between 1300 °C and the ambient temperature, without spallation, due to their porosity and the presence of additional secondary phase which increases the thermal cycling resistance. During water vapor exposure at 1200 °C, rare earth disilicates showed a good stability, which is contradictory with the literature, due to impurities—such as Si- and Al-hydroxides—in the water vapor jets. The presence of vertical cracks allowed the water vapor to reach the substrate and then to corrode it. It has been observed that thin vertical cracks induced some spallation after 24 h of corrosion.

Similar content being viewed by others

References

P. Baldus, M. Jansen, and D. Sporn, Ceramic Fibres for Matrix Composites in High-Temperature Engine Applications, Science, 1999, 80(699), p 699-703. doi:10.1126/science.285.5428.699

M. Belmonte, Advanced Ceramic Materials for High Temperature Applications, Adv. Eng. Mater., 2006, 8, p 693-703. doi:10.1002/adem.200500269

A.G. Evans and D.B. Marshall, The Mechanical Behavior of Ceramic Matrix Composites, Acta Met., 1989, 37, p 2567-2583

Y. Katoh, S.M. Dong, and A. Kohyama, Thermo-Mechanical Properties Carbide Composites Fabricated and Microstructure of Silicon by Nano-Infiltrated Transient Eutectoid Process, Fusion Eng. Des., 2002, 61-2, p 723-731

R. Naslain, Design, Preparation and Properties of Non-oxide CMCs for Application in Engines and Nuclear Reactors: An overview, Compos. Sci. Technol., 2004, 64, p 155-170. doi:10.1016/S0266-3538(03)00230-6

R.R. Naslain, Ceramic Matrix Composites: Matrices and Processing, Encylopedia Sci. Technol. Mater., 2000, doi:10.1016/B978-0-12-803581-8.02317-1

A. Misra, 12—Composite Materials for Aerospace Propulsion Related to Air and Space Transportation A2—Njuguna, J BT—Lightweight Composite Structures in Transport, Light. Compos. Struct. Transp., 2016, doi:10.1016/B978-1-78242-325-6.00012-8

S.N. Basu and V.K. Sarin, Thermal and Environmental Barrier Coatings for Si-Based Ceramics, Elsevier, 2014, doi:10.1016/B978-0-08-096527-7.00036-2

N.P. Padture, Advanced Structural Ceramics in Aerospace Propulsion, Nat. Mater., 2016, 15, p 804-809. doi:10.1038/nmat4687

H.E. Eaton and G.D. Linsey, Accelerated Oxidation of SiC CMC’s by Water Vapor and Protection via Environmental Barrier Coating Approach, J. Eur. Ceram. Soc., 2002, 22, p 2741-2747. doi:10.1016/S0955-2219(02)00141-3

N. Al Nasiri, N. Patra, N. Ni, D.D. Jayaseelan, and W.E. Lee, Oxidation Behaviour of SiC/SiC Ceramic Matrix Composites in Air, J. Eur. Ceram. Soc., 2016, 36, p 3293-3302. doi:10.1016/j.jeurceramsoc.2016.05.051

N.S. Jacobson, Corrosion of Silicon-Based Ceramics in Combustion Environments, J. Am. Ceram. Soc., 1993, 76, p 3-28. doi:10.1111/j.1151-2916.1993.tb03684.x

E.J. Opila, Oxidation and Volatilization of Silica Formers in Water Vapor, J. Am. Ceram. Soc., 2003, 86, p 1238-1248. doi:10.1111/j.1151-2916.2003.tb03459.x

P.J. Meschter, E.J. Opila, and N.S. Jacobson, Water Vapor-Mediated Volatilization of High-Temperature Materials, Annu. Rev. Mater. Res., 2013, 43, p 559-588. doi:10.1146/annurev-matsci-071312-121636

P.F. Tortorelli and K.L. More, Effects of High Water-Vapor Pressure on Oxidation of Silicon Carbide at 1200 °C, J. Am. Ceram. Soc., 2003, 86, p 1249-1255. doi:10.1111/j.1151-2916.2003.tb03460.x

E.J. Opila and R.E. Hann, Paralinear Oxidation of CVD SiC in Water Vapor, J. Am. Ceram. Soc., 1997, 80, p 197-205. doi:10.1111/j.1151-2916.1997.tb02810.x

E. Courcot, F. Rebillat, F. Teyssandier, From the Volatility of Simple Oxides to that of Mixed Oxides: Thermodynamic and Experimental Approaches, in: Ceram. Trans., 2010: pp. 235–244

E. Courcot, F. Rebillat, F. Teyssandier, and C. Louchet-Pouillerie, Thermochemical Stability of the Y2O3–SiO2 System, J. Eur. Ceram. Soc., 2010, 30, p 905-910. doi:10.1016/j.jeurceramsoc.2009.09.007

N. Maier, K.G. Nickel, and G. Rixecker, High Temperature Water Vapour Corrosion of Rare Earth Disilicates (Y, Yb, Lu)2Si2O7 in the Presence of Al(OH)3 Impurities, J. Eur. Ceram. Soc., 2007, 27, p 2705-2713

Y. Wang and J. Liu, First-Principles Investigation on the Corrosion Resistance of Rare Earth Disilicates in Water Vapor, J. Eur. Ceram. Soc., 2009, 29, p 2163-2167

J. Liu, L. Zhang, Q. Liu, L. Cheng, and Y. Wang, Structure Design and Fabrication of Environmental Barrier Coatings for Crack Resistance, J. Eur. Ceram. Soc., 2014, 34, p 2005-2012. doi:10.1016/j.jeurceramsoc.2013.12.049

B.T. Richards, K.A. Young, F. De Francqueville, S. Sehr, M.R. Begley, and H.N.G. Wadley, Response of Ytterbium Disilicate-Silicon Environmental Barrier Coatings to Thermal Cycling in Water Vapor, Acta Mater., 2016, 106, p 1-14. doi:10.1016/j.actamat.2015.12.053

F. Stolzenburg, P. Kenesei, J. Almer, K.N. Lee, M.T. Johnson, and K.T. Faber, The Influence of Calcium-Magnesium-Aluminosilicate Deposits on Internal Stresses in Yb2Si2O7 Multilayer Environmental Barrier Coatings, Acta Mater., 2016, 105, p 189-198. doi:10.1016/j.actamat.2015.12.016

K.N. Lee, D.S. Fox, and N.P. Bansal, Rare Earth Silicate Environmental Barrier Coatings for SiC/SiC Composites and Si3N4 Ceramics, J. Eur. Ceram. Soc., 2005, 25, p 1705-1715. doi:10.1016/j.jeurceramsoc.2004.12.013

Z. Tian, L. Zheng, J.J. Wang, P. Wan, J. Li, and J.J. Wang, Theoretical and Experimental Determination of the Major Thermo-Mechanical Properties of RE2SiO5 (RE = Tb, Dy, Ho, Er, Tm, Yb, Lu, and Y) for Environmental and Thermal Barrier Coating Applications, J. Eur. Ceram. Soc., 2016, 36, p 189-202. doi:10.1016/j.jeurceramsoc.2015.09.013

S. Ueno, D. Doni Jayaseelan, H. Kita, T. Ohji, and H.-T. Lin, Comparison of Water Vapor Corrosion Behaviors of Ln2Si2O7 (Ln = Yb and Lu) and ASiO4 (A = Ti, Zr and Hf) EBC’s, Key Eng. Mater., 2006, 317–318, p 557-560

S. Ueno, D.D. Jayaseelan, and T. Ohji, Water Vapor Corrosion Behavior of Lutetium Silicates at High Temperature, Ceram. Int., 2006, 32, p 451-455. doi:10.1016/j.ceramint.2005.03.022

S. Ueno, D.D. Jayaseelan, T. Ohji, and H.T. Lin, Recession Mechanism of Lu2Si2O7 Phase in High Speed Steam Jet Environment at High Temperatures, Ceram. Int., 2006, 32, p 775-778. doi:10.1016/j.ceramint.2005.05.014

N.S. Jacobson, D.S. Fox, J.L. Smialek, E.J. Opila, C. Dellacorte, and K.N. Lee, Performance of Ceramics in Severe Environments. ASM Handbook, Corros. Mater., 2005, doi:10.1361/asmhba0003842

J. Karthikeyan, C.C. Berndt, J. Tikkanen, S. Reddy, and H. Herman, Plasma spray Synthesis of Nanomaterial Powders and Deposits, Mater. Sci. Eng., A, 1997, 238, p 275-286. doi:10.1016/S0921-5093(96)10568-2

Y. Shen, V.A.B. Almeida, and F. Gitzhofer, Preparation of Nanocomposite GDC/LSCF Cathode Material for IT-SOFC by Induction Plasma Spraying, J. Therm. Spray Technol., 2011, 20, p 145-153. doi:10.1007/s11666-010-9583-z

E.H. Jordan, C. Jiang, and M. Gell, The Solution Precursor Plasma Spray (SPPS) Process: A Review with Energy Considerations, J. Therm. Spray Technol., 2015, 24, p 1153-1165. doi:10.1007/s11666-015-0272-9

C. Jiang, E.H. Jordan, A.B. Harris, M. Gell, and J. Roth, Double-Layer Gadolinium Zirconate/Yttria-Stabilized Zirconia Thermal Barrier Coatings Deposited by the Solution Precursor Plasma Spray Process, J. Therm. Spray Technol., 2015, 24, p 895-906. doi:10.1007/s11666-015-0283-6

P. Fauchais, A. Vardelle, Advanced Plasma Spray Applications, in: H. Salimi Jazi (Ed.), Adv. Plasma Spray Appl., InTech, 2012, p 149-188. doi:10.5772/1921.

E.H. Jordan, L. Xie, M. Gell, N.P. Padture, B. Cetegen, A. Ozturk et al., Superior Thermal Barrier Coatings using Solution Precursor Plasma Spray, J. Therm. Spray Technol., 2004, 13, p 57-65. doi:10.1361/10599630418121

G. Bertolissi, C. Chazelas, G. Bolelli, L. Lusvarghi, M. Vardelle, and A. Vardelle, Engineering the Microstructure of Solution Precursor Plasma-sprayed Coatings, J. Therm. Spray Technol., 2012, 21, p 1148-1162. doi:10.1007/s11666-012-9789-3

É. Darthout and F. Gitzhofer, Structure Stabilization by Zirconia Pinning Effect of Y2Si2O7 Environmental Barrier Coatings Synthesized by Solution Precursor Plasma Spraying Process, Surf. Coatings Technol., 2017, 309, p 1081-1088. doi:10.1016/j.surfcoat.2016.10.015

L. Xie, X. Ma, A. Ozturk, E.H. Jordan, N.P. Padture, B.M. Cetegen et al., Processing Parameter Effects on Solution Precursor Plasma Spray Process Spray Patterns, Surf. Coatings Technol., 2004, 183, p 51-61. doi:10.1016/j.surfcoat.2003.09.071

P. Fauchais, V. Rat, J.F. Coudert, R. Etchart-Salas, and G. Montavon, Operating Parameters for Suspension and Solution Plasma-Spray Coatings, Surf. Coatings Technol., 2008, 202, p 4309-4317. doi:10.1016/j.surfcoat.2008.04.003

E. Darthout, A. Quet, N. Braidy, and F. Gitzhofer, Lu2O3-SiO2-ZrO2 Coatings for Environmental Barrier Application by Solution Precursor Plasma Spraying and Influence of Precursor Chemistry, J. Therm. Spray Technol., 2014, 23, p 325-332. doi:10.1007/s11666-013-9987-7

É. Darthout, G. Laduye, and F. Gitzhofer, Processing Parameter Effects and Thermal Properties of Y2Si2O7 Nanostructured Environmental Barrier Coatings Synthesized by Solution Precursor Induction Plasma Spraying, J. Therm. Spray Technol., 2016, 25, p 1264-1279. doi:10.1007/s11666-016-0450-4

X.Q. Cao, R. Vassen, and D. Stoever, Ceramic Materials for Thermal Barrier Coatings, J. Eur. Ceram. Soc., 2004, 24, p 1-10. doi:10.1016/S0955-2219(03)00129-8

C.M. Weyant, K.T. Faber, J. Almer, and J.V. Guiheen, Residual Stress and Microstructural Evolution in Tantalum Oxide Coatings on Silicon Nitride, J. Am. Ceram. Soc., 2005, 88, p 2169-2176. doi:10.1111/j.1551-2916.2005.00396.x

W.D. Kingery, Factors Affecting Thermal Stress Resistance, J. Am. Ceram. Soc., 1955, 38, p 3-15. doi:10.1111/j.1151-2916.1955.tb14545.x

J.C. Han, Thermal Shock Resistance of Ceramic Coatings, Acta Mater., 2007, 55, p 3573-3581. doi:10.1016/j.actamat.2007.02.007

A. Saha, S. Seal, B. Cetegen, E. Jordan, A. Ozturk, and S. Basu, Thermo-Physical Processes in Cerium Nitrate Precursor Droplets Injected into High Temperature Plasma, Surf. Coatings Technol., 2009, 203, p 2081-2091. doi:10.1016/j.surfcoat.2008.09.018

I. Castillo and R.J. Munz, Transient Heat, Mass and Momentum Transfer of an Evaporating Stationary Droplet Containing Dissolved Cerium Nitrate in a RF Thermal Argon-oxygen Plasma Under Reduced Pressure, Int. J. Heat Mass Transf., 2007, 50, p 240-256. doi:10.1016/j.ijheatmasstransfer.2006.06.023

G.L. Messing, S.-C. Zhang, and G.V. Jayanthi, Ceramic Powder Synthesis, J. Am. Ceram. Soc., 1993, 76, p 2707-2726. doi:10.1111/j.1151-2916.1993.tb04007.x

M.I. Boulos, RF Induction Plasma Spraying: State-of-the-art Review, J. Therm. Spray Technol., 1992, 1, p 33-40. doi:10.1007/BF02657015

J.D’Errico, Surface Fitting Using Gridfit, MATLAB Cent. File Exch. (2005). http://fr.mathworks.com/matlabcentral/fileexchange/8998-surface-fitting-using-gridfit

R.C. Robinson and J.L. Smialek, SiC Recession Caused by SiO2 Scale Volatility under Combustion Conditions: I, Experimental Results and Empirical Model, J. Am. Ceram. Soc., 1999, 82, p 1817-1825. doi:10.1111/j.1151-2916.1999.tb02004.x

J.L. Smialek, R.C. Robinson, E.J. Opila, D.S. Fox, and N.S. Jacobson, SiC and Si3N4 Recession Due to SiO2 Scale Volatility Under Combustor Conditions, Adv. Compos. Mater., 1999, 8, p 33-45. doi:10.1163/156855199X00056

E.J. Opila, D.S. Fox, and N.S. Jacobson, Mass Spectrometric Identification of Si-O-H(g) Species from the Reaction of Silica with Water Vapor at Atmospheric Pressure, J. Am. Ceram. Soc., 1997, 12, p 1009-1012. doi:10.1111/j.1151-2916.1997.tb02935.x

J. Welty, G.L. Rorrer, and D.G. Foster, Fundamentals of Momentum, Heat, and Mass Transfer, Wiley, Hoboken, 2014

R.A. Svehla, Estimated Viscosities and Thermal Conductivities of Gases At High Temperatures, 1962.

J.O. Hirschfelder, R.B. Bird, and E.L. Spotz, The Transport Properties of Gases and Gaseous Mixtures, Chem. Rev., 1949, 44, p 205-231

V. Angelici Avincola, D. Cupid, and H.J. Seifert, Thermodynamic Modeling of the Silica Volatilization in Steam Related to Silicon Carbide Oxidation, J. Eur. Ceram. Soc., 2015, 35, p 3809-3818. doi:10.1016/j.jeurceramsoc.2015.05.036

N.S. Jacobson, E.J. Opila, D.L. Myers, and E.H. Copland, Thermodynamics of Gas Phase Species in the Si-O-H System, J. Chem. Thermodyn., 2005, 37, p 1130-1137. doi:10.1016/j.jct.2005.02.001

A. Hashimoto, The Effect of H2O Gas on Volatilities of Planet-Forming Major Elements: I. Experimental Determination of Thermodynamic Properties of Ca-, Al-, and Si-hydroxide Gas Molecules And its Application to the Solar Nebula, Geochim. Cosmochim. Acta, 1992, 56, p 511-532. doi:10.1016/0016-7037(92)90148-C

R.A. Golden and E.J. Opila, A Method for Assessing the Volatility of Oxides in High-temperature High-velocity Water Vapor, J. Eur. Ceram. Soc., 2016, 36, p 1135-1147. doi:10.1016/j.jeurceramsoc.2015.11.016

S.L. Dos Santos, E. Lucato, O.H. Sudre, and D.B. Marshall, A Method for Assessing Reactions of Water Vapor with Materials in High-speed, High-temperature Flow, J. Am. Ceram. Soc., 2011, 94, p s186-s195. doi:10.1111/j.1551-2916.2011.04556.x

A.G. Evans and J.W. Hutchinson, The Thermomechanical Integrity of Thin Films and Multilayers, Acta Metall. Mater., 1995, 43, p 2507-2530. doi:10.1016/0956-7151(94)00444-M

J. Kováčik, Correlation Between Young’s Modulus and Porosity in Porous Materials, J. Mater. Sci. Lett., 1999, 18, p 1007-1010. doi:10.1023/A:1006669914946

B. Himmel, T. Gerber, W. Heyer, and W. Blau, X-ray Diffraction Analysis of SiO2 Structure, J. Mater. Sci., 1987, 22, p 1374-1378. doi:10.1007/BF01233136

R.L. Withers, J.G. Thompson, and T.R. Welberry, The Structure and Microstructure of α-Cristobalite and Its Relationship to β-Cristobalite, Phys. Chem. Miner., 1989, 16, p 517-523. doi:10.1007/BF00202206

R.C. Breneman, J.W. Halloran, and A. Arbor, Hysteresis Upon Repeated Cycling Through the Beta-Alpha Cristobalite Transformation, J. Ceram. Sci. Technol., 2015, 62, p 55-61. doi:10.4416/JCST2014-00048

K.N. Lee, D.S. Fox, J.I. Eldridge, D. Zhu, R.C. Robinson, N.P. Bansal et al., Upper Temperature Limit of Environmental Barrier Coatings Based on Mullite and BSAS, J. Am. Ceram. Soc., 2003, 86, p 1299-1306. doi:10.1111/j.1151-2916.2003.tb03466.x

C.V. Cojocaru, D. Lévesque, C. Moreau, and R.S. Lima, Performance of Thermally Sprayed Si/mullite/BSAS Environmental Barrier Coatings Exposed to Thermal Cycling in Water Vapor Environment, Surf. Coatings Technol., 2013, 216, p 215-223. doi:10.1016/j.surfcoat.2012.11.043

B.T. Richards, M.R. Begley, and H.N.G. Wadley, Mechanisms of Ytterbium Monosilicate/Mullite/Silicon Coating Failure During Thermal Cycling in Water Vapor, J. Am. Ceram. Soc., 2015, 98, p 4066-4075. doi:10.1111/jace.13792

C.S. Tedmon, The Effect of Oxide Volatilization on the Oxidation Kinetics of Cr and Fe-Cr Alloys, J. Electrochem. Soc., 1966, 113, p 766. doi:10.1149/1.2424115

D.L. Poerschke, R.W. Jackson, and C.G. Levi, Silicate Deposit Degradation of Engineered Coatings in Gas Turbines: Progress Toward Models and Materials Solutions, Annu. Rev. Mater. Res., 2016, 46, p 235-262

S. Ueno, T. Ohji, and H.T. Lin, Recession Behavior of Lu2SiO5 Under a High Speed Steam Jet at High Temperatures, Ceram. Int., 2011, 37, p 1185-1189. doi:10.1016/j.ceramint.2010.11.029

S. Ueno, D.D. Jayaseelan, T. Ohji, N. Kondo, and S. Kanzaki, Comparison of Water Vapor Corrosion Mechanisms of Polycrystalline and Eutectic Lu2Si2O7, J. Ceram. Process. Res., 2004, 5, p 153-156

B.T. Richards and H.N.G. Wadley, Plasma Spray Deposition of Tri-Layer Environmental Barrier Coatings, J. Eur. Ceram. Soc., 2014, 34, p 3069-3083. doi:10.1016/j.jeurceramsoc.2014.04.027

S. Ueno, D.D. Jayaseelan, and T. Ohji, Development of Oxide-Based EBC for Silicon Nitride, Int. J. Appl. Ceram. Technol., 2004, 1, p 362-373

S. Ueno, T. Ohji, and H.-T. Lin, Corrosion and Recession of Mullite in Water Vapor Environment, J. Eur. Ceram. Soc., 2008, 28, p 431-435. doi:10.1016/j.jeurceramsoc.2007.03.006

M. Fritsch, H. Klemm, M. Herrmann, and B. Schenk, Corrosion of Selected Ceramic Materials in Hot Gas Environment, J. Eur. Ceram. Soc., 2006, 26, p 3557-3565. doi:10.1016/j.jeurceramsoc.2006.01.015

E.J. Opila and D.L. Myers, Alumina Volatility in Water Vapor at Elevated Temperatures, J. Am. Ceram. Soc., 2004, 87, p 1701-1705. doi:10.1111/j.1551-2916.2004.01701.x

M. Fritsch and H. Klemm, The Water–Vapour hot Gas Corrosion Behavior of Al2O3-Y2O3 Materials, Y2SiO5 and Y3Al5O12-Coated Alumina in a Combustion Environment. in: A.W. and E.L.-C.D. Zhu, U. Schulz (Eds.), Adv. Ceram. Coatings Interfaces Ceram. Eng. Sci. Proc., John Wiley, John Wiley & Sons, Inc., Hoboken, NJ, USA, 2006, p 148-159. doi:10.1002/9780470291320.ch14.

K.N. Lee, Environmental Barrier Coatings for SiCf/SiC, in: Ceram. Matrix Compos. Mater. Model. Technol., John Wiley & Sons, Inc., 2014: pp. 430–451. doi:10.1002/9781118832998.ch15.

W. Richerson, Modern Ceramic Engineering: Properties, Processing, and Use in Design, 3rd ed., CRC, Boca Raton, 2006

Z. Sun, Y. Zhou, J. Wang, and M. Li, Thermal Properties and Thermal Shock Resistance of γ-Y2Si2O7, J. Am. Ceram. Soc., 2008, 91, p 2623-2629. doi:10.1111/j.1551-2916.2008.02470.x

Z. Sun, M. Li, and Y. Zhou, Thermal Properties of Single-Phase Y2SiO5, J. Eur. Ceram. Soc., 2009, 29, p 551-557. doi:10.1016/j.jeurceramsoc.2008.07.026

H. Le Chatelier, La Silice et les Silicates, A. Hermann, Paris, 1914

Acknowledgments

The authors would like to thank Kossi E. Béré for its technical support during the plasma spray process. They are also grateful to the Center of Characterization of Materials (Sherbrooke, QC, CA) and to NACOMAT partners (Bordeaux, France) for financial support.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Darthout, É., Gitzhofer, F. Thermal Cycling and High-Temperature Corrosion Tests of Rare Earth Silicate Environmental Barrier Coatings. J Therm Spray Tech 26, 1823–1837 (2017). https://doi.org/10.1007/s11666-017-0635-5

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11666-017-0635-5