Abstract

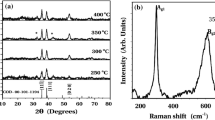

Electrical double-layer capacitors owe their large capacitance to the formation of a double-layer at the electrode/electrolyte interface of high surface area carbon-based electrode materials. Greater electrical energy storage capacity has been attributed to transition metal oxides/nitrides that undergo fast, reversible redox reactions at the electrode surface (pseudo-capacitive behavior) in addition to forming electrical double-layers. Solution Precursor Plasma Spray (SPPS) has shown promise for depositing porous, high surface area transition metal oxides. This investigation explored the potential of SPPS to fabricate α-MoO3 coatings with micro-structures suitable for use as super-capacitor electrodes. The effects of number of spray passes, spray distance, solution concentration, flow rate and spray velocity on the chemistry and micro-structure of the α-MoO3 deposits were examined. DTA/TGA, SEM, XRD, and electrochemical analyses were performed to characterize the coatings. The results demonstrate the importance of post-deposition heating of the deposit by subsequent passes of the plasma on the coating morphology.

Similar content being viewed by others

References

L. Pawlowski, Suspension and Solution Thermal Spray Coatings, Surf. Coat. Technol., 2009, 203(19), p 2807-2829

T. Bhatia, A. Ozturk, L. Xie, E.H. Jordan, B.M. Cetegen, M. Gell, X. Ma, and N.P. Padture, Mechanisms of Ceramic Coating Deposition in Solution-Precursor Plasma Spray, J. Mater. Res., 2002, 17(9), p 2363-2372

Y. Wang and T.W. Coyle, Optimization of Solution Precursor Plasma Spray Process by Statistical Design of Experiment, J. Therm. Spray Technol., 2008, 17(5-6), p 692-699

D. Chen, E. Jordan, and M. Gell, Effect of Solution Concentration on Splat Formation and Coating Microstructure Using the Solution Precursor Plasma Spray Process, Surf. Coat. Technol., 2007, 202, p 2132-2138

S. Basu and B.M. Cetegen, Modeling of Thermo-Physical Processes in Liquid Ceramic Precursor Droplets Injected into a Plasma Jet, Int. J. Heat Mass Transfer, 2007, 50(17-18), p 3278-3290

K. Chien, M. Golozar, and T.W. Coyle, Effect of Solution Chemistry on Coating Microstructure by Solution Precursor Plasma Spraying, Proceedings of the 20th International Symposium on Plasma Chemistry, July 24-29, 2011 (Philadelphia), 2011

M. Golozar, K. Chien, and T.W. Coyle, Deposition of Lath-Shaped α-MoO3 Particles by Solution Precursor Plasma Spray, Proceedings of the 20 th International Symposium on Plasma Chemistry, July 24-29, 2011 (Philadelphia), 2011

T. Brezesinski, J. Wang, S.H. Tolbert, and B. Dunn, Ordered Mesoporous α-MoO3 with Iso-Oriented Nanocrystalline Walls for Thin-Film Pseudocapacitors, Nat. Mater., 2010, 9(2), p 146-151

P. Simon and Y. Gogotsi, Materials for Electrochemical Capacitors, Nat. Mater., 2008, 7(11), p 845-854

L. Chen, L. Pershin, and J. Mostaghimi, A New Highly Efficient High-Power DC Plasma Torch, IEEE Trans. Plasma Sci., 2008, 36(4), p 1068-1069

L. Pershin, L. Chen, and J. Mostaghimi, Comparison of Molecular and Argon Gases for Plasma Spraying, Thermal Spray 2007: Global Coating Solutions, B.R. Marple, M.M. Hyland, Y.-C. Lau, C.-J. Li, R.S. Lima, and G. Montavon, Ed., ASM International, Materials Park, OH, 2007, p 266-269

L. Chen, J. Mostaghimi, and L. Pershin, Numerical Simulations of Cascaded Plasma Torch Using Ar and Molecular Gases, Thermal Spray 2007: Global Coating Solutions, B.R. Marple, M.M. Hyland, Y.-C. Lau, C.-J. Li, R.S. Lima, and G. Montavon, Ed., ASM International, Materials Park, OH, 2007, p 158-162

L. Pershin, L. Chen, and J. Mostaghimi, Deposition of YSZ Coatings by a High Efficiency DC Plasma Torch, Surface Modification Technologies XXI, T.S. Sudarshan and M. Jeandin, Ed., ASM International, Paris, 2007,

E. Shimao, Structure of the Mo7O24 6− Ion in a Crystal of Ammonium Heptamolybdate Tetrahydrate, Nature Materials, 1967, 214, p 170-171

C. Li, H. Zhang, K. Wang, Y. Miao, and Q. Xin, FT-IR Emission Spectroscopic Studies of the Thermal Decomposition of Ammonium Molybdate, Vanadate, and Tungstate, Appl. Spectrosc., 1993, 47(1), p 56-61

J. Wienold, R.E. Jentoft, and T. Ressler, Structural Investigation of the Thermal Decomposition of Ammonium Heptamolybdate by In Situ XAFS and XRD, Eur. J. Inorg. Chem., 2003, 6, p 1058-1071

Z.L. Yin, X.H. Li, Q.S. Zhao, S.Y. Chen, G.R. Liu, and S.Q. Wang, Study on the Thermal Decomposition of a Commercial Polyphase Ammonium Tetramolybdate, Thermochim. Acta, 1994, 244, p 283-289

R.S. Patil, M.D. Uplane, and P.S. Patil, Electrosynthesis of Electrochromic Molybdenum Oxide Thin Films with Rod-Like Features, Int. J. Electrochem. Sci., 2008, 3, p 259-265

T.M. McEvoy, K.J. Stevenson, J.T. Hupp, and X. Dang, Electrochemical Preparation of Molybdenum Trioxide Thin Films: Effect of Sintering on Electrochromic and Electroinsertion Properties, Langmuir, 2003, 19(10), p 4316-4326

E.A. Gulbransen, K.F. Andrew, and F.A. Brassart, Vapor Pressure of Molybdenum Trioxide, J. Electrochem. Soc., 1963, 110(3), p 242-243

P.E. Blackburn, M. Hoch, and H.L. Johnston, The Vaporization of Molybdenum and Tungsten Oxides, J. Phys. Chem., 1958, 62(7), p 769-773

M.S. Samant, A.S. Kerkar, S.R. Bharadwaj, and S.R. Dharwadkar, Thermodynamic Investigation of the Vaporization of Molybdenum Trioxide, J. Alloys Compd., 1992, 187, p 373-379

J. Berkowitz, M.G. Inghram, and W.A. Chupka, Polymeric Gaseous Species in the Sublimation of Molybdenum Trioxide, J. Chem. Phys., 1957, 26(4), p 842-846

Acknowledgments

The authors would like to express their gratitude to Dr. Larry Pershin in our laboratory, Centre for Advanced Coating Technologies (CACT), for his contributions to the SPPS experiments. A special thanks to Miss Sanaz Ketabi from Flexible Energy and Electronics Laboratory for assisting us with the electrochemical analysis of the coatings. Also, a special thanks to Mr. Emil Cocirla from Can-Am Instruments Ltd. for his time and support with regards to the viscosity measurements of the solutions.

Author information

Authors and Affiliations

Corresponding author

Additional information

This article is an invited paper selected from presentations at the 2011 International Thermal Spray Conference and has been expanded from the original presentation. It is simultaneously published in Thermal Spray 2011: Proceedings of the International Thermal Spray Conference, Hamburg, Germany, September 27-29, 2011, Basil R. Marple, Arvind Agarwal, Margaret M. Hyland, Yuk-Chiu Lau, Chang-Jiu Li, Rogerio S. Lima, and André McDonald, Ed., ASM International, Materials Park, OH, 2011.

Rights and permissions

About this article

Cite this article

Golozar, M., Chien, K. & Coyle, T.W. Orthorhombic α-MoO3 Coatings with Lath-Shaped Morphology Developed by SPPS: Applications to Super-Capacitors. J Therm Spray Tech 21, 469–479 (2012). https://doi.org/10.1007/s11666-012-9759-9

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11666-012-9759-9