Abstract

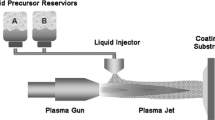

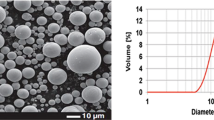

The thin film low pressure plasma spray process (LPPS-TF) has been developed with the aim of efficient depositing uniform and thin coatings with large area coverage by plasma spraying. At high power input (~150 kW) and very low pressure (~100 Pa) the plasma jet properties change considerably and it is even possible to evaporate the powder feedstock material providing advanced microstructures of the deposits. This relatively new technique bridges the gap between conventional plasma spraying and physical vapor deposition. In addition, the resulting microstructures are unique and can hardly be obtained by other processes. In this paper, microstructures made by LPPS-TF are shown and the columnar layer growth by vapor deposition is demonstrated. In addition to the ceramic materials TiO2, Al2O3 or MgAl2O4, the focus of the research was placed on partially yttria-stabilized zirconia. Variations of the microstructures are shown and discussed concerning potential coating applications.

Similar content being viewed by others

References

J.L. Dorier, M. Gindrat, C. Hollenstein, M. Loch, A. Refke, A. Sailto, and G. Barbezat, Plasma Jet Properties in a New Spraying Process at Low Pressure for Large Area Thin Film Deposition, International Thermal Spray Conference, C.C. Berndt, K.A. Khor, and E.F. Lugscheider, Ed. (Singapore), ASM International, Materials Park, 2001

E. Muehlberger and P. Meyer, LPPS—Thin Film Processes: Overview of Origin and Future Possibilities. International Thermal Spray Conference, B. Marple, M. Hyland, Y.-C. Lau, C.-Y. Li, R. Lima, and G. Montavon, Ed. (Las Vegas), ASM International, Materials Park, 2009

A. Refke, M. Gindrat, and K. von Niessen, LPPS Thin Film: A Hybrid Coating Technology between Thermal Spray and PVD for Functional Thin Coatings and Large Area Applications, International Thermal Spray Conference, B.R. Marple, M.M. Hyland, Y.-C. Lau, C.-J. Li, R.S. Lima, and G. Montavon, Ed. (Beijing), ASM International, Materials Park, 2007

K. von Niessen, M. Gindrat, and A. Refke, Vapor Phase Deposition Using Plasma Spray-PVD, J. Therm. Spray Technol., 2010, 19(1), p 502-509

M. Gindrat, A. Refke, and R. Schmid, Process Characterization of LPPS Thin Film Processes with Optical Diagnostics, International Thermals Spray Conference, B.R. Marple, M.M. Hyland, Y.-C. Lau, C.-J. Li, R.S. Lima, and G. Montavon, Ed. (Beijing), ASM International, Materials Park, 2007

A. Hospach, U. Maier, and R. Vaßen, Development of a Thermally Sprayed Insulation Layer for SOFCs, European SOFC Forum, U. Bossel, Ed., European Fuel Cell Forum, Luzern, 2008

B. Pateyron, M.-F. Elchinger, G. Delluc, and P. Fauchais, Thermodynamic and Transport Properties of Ar-H2 and Ar-He Plasma Gases Used for Spraying at Atmospheric Pressure. I: Properties of the Mixtures, Plasma Chem. Plasma Process., 1992, 12(4), p 421-448

J. Aubreton, M.F. Elchinger, P. Fauchais, V. Rat, and P. Andre, Thermodynamic and Transport Properties of a Ternary Ar-H2-He Mixture Out of Equilibrium up to 30000 K at Atmospheric Pressure, J. Phys. D, 2004, 37(16), p 2232-2246

A. Refke, D. Hawley, J. Doesburg, and R.K. Schmid, LPPS Thin Film Technology for the Application of TBC Systems, International Thermal Spray Conference, E.F. Lugscheider, Ed. (Basel), DVS-Verlag, Düsseldorf, 2005

A. Hospach, G. Mauer, R. Vaßen, and D. Stöver, Columnar-Structured Thermal Barrier Coatings (TBCs) by Thin Film Low-Pressure Plasma Spraying (LPPS-TF), J. Therm. Spray Technol., 2011, 20, p 116-120

R. Vaßen, D. Hathiramani, J. Mertens, V.A.C. Haanappel, and I.C. Vinke, Manufacturing of High Performance Solid Oxide Fuel Cells (SOFCs) with Atmospheric Plasma Spraying (APS), Surf. Coat. Technol., 2007, 202(3), p 499-508

T. Yoshida, Toward a New Era of Plasma Spray Processing, Pure Appl. Chem., 2006, 78(6), p 1093-1107

A. Shinozawa, K. Eguchi, M. Kambara, and T. Yoshida, Feather-Like Structured YSZ Coatings at Fast Rates by Plasma Spray Physical Vapor Deposition, Proc. Therm. Spray Conf., 2009, 2009, p 1140-1145

K. Wada, N. Yamaguchi, and H. Matsubara, Crystallographic Texture Evolution in ZrO2-Y2O3 Layers Produced by Electron Beam Physical Vapor Deposition, Surf. Coat. Technol., 2004, 184(1), p 55-62

U. Schulz, B. Saruhan, K. Fritscher, and C. Leyens, Review on Advanced EB-PVD Ceramic Topcoats for TBC Applications, Int. J. Appl. Ceram. Technol., 2004, 1(4), p 302-315

M. Matsumoto, K. Wada, N. Yamaguchi, T. Kato, and H. Matsubara, Effects of Substrate Rotation Speed During Deposition on the Thermal Cycle Life of Thermal Barrier Coatings Fabricated by Electron Beam Physical Vapor Deposition, Surf. Coat. Technol., 2008, 202(15), p 3507-3512

J.R. Nicholls, K.J. Lawson, A. Johnstone, and D.S. Rickerby, Methods to Reduce the Thermal Conductivity of EB-PVD TBCs, Surf. Coat. Technol., 2002, 151-152, p 383-391

D.E. Wolfe, J. Singh, R.A. Miller, J.I. Eldridge, and D.-M. Zhu, Tailored Microstructure of EB-PVD 8YSZ Thermal Barrier Coatings with Low Thermal Conductivity and high Thermal Reflectivity for Turbine Applications, Surf. Coat. Technol., 2005, 190(1), p 132-149

A. Flores Renteria, B. Saruhan, U. Schulz, H.-J. Raetzer-Scheibe, J. Haug, and A. Wiedenmann, Effect of Morphology on Thermal Conductivity of EB-PVD PYSZ TBCs, Surf. Coat. Technol., 2006, 201(6), p 2611-2620

M.J. Kelly, D.E. Wolfe, J. Singh, J.I. Eldridge, D.-M. Zhu, and R.A. Miller, Thermal Barrier Coatings Design with Increased Reflectivity and Lower Thermal Conductivity for High-Temperature Turbine Applications, Int. J. Appl. Ceram. Technol., 2006, 3(2), p 81-93

G.M. Ingo and T. de Caro, Origin of Darkening in 8 wt% Yttria-Zirconia Plasma-Sprayed Thermal Barrier Coatings, J. Am. Ceram. Soc., 1991, 74(2), p 381-386

L. Xie, M. Dorfman, A. Patel, and I. Aguilar, Factors Affecting the Appearance of Air Plasma Sprayed Thermal Barrier Coatings, International Thermal Spray Conference, B.R. Marple, M.M. Hyland, Y.-C. Lau, R.S. Lima, and J. Voyer, Ed. (Seattle), ASM International, Materials Park, 2006

L.-M. Berger, Titanium Oxide—New Opportunities for an Established Coating Material, International Thermal Spray Conference, E.F. Lugscheider, and D. von Hofe, Ed. (Osaka), DVS-Verlag, , Düsseldorf, 2004

Author information

Authors and Affiliations

Corresponding author

Additional information

This article is an invited paper selected from presentations at the 2011 International Thermal Spray Conference and has been expanded from the original presentation. It is simultaneously published in Thermal Spray 2011: Proceedings of the International Thermal Spray Conference, Hamburg, Germany, September 27-29, 2011, Basil R. Marple, Arvind Agarwal, Margaret M. Hyland, Yuk-Chiu Lau, Chang-Jiu Li, Rogerio S. Lima, and André McDonald, Ed., ASM International, Materials Park, OH, 2011.

Rights and permissions

About this article

Cite this article

Hospach, A., Mauer, G., Vaßen, R. et al. Characteristics of Ceramic Coatings Made by Thin Film Low Pressure Plasma Spraying (LPPS-TF). J Therm Spray Tech 21, 435–440 (2012). https://doi.org/10.1007/s11666-012-9748-z

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11666-012-9748-z