Abstract

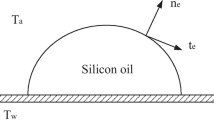

This study investigates the effect of substrate size on the supersonic jet flow regime, particle acceleration and temperature distribution within the substrate in cold spraying. A computational fluid dynamics approach is employed in the present work to achieve this objective. The simulated results show that substrate diameter has some effect on the gas flow regime and the consequent particle motion. When the substrate diameter is smaller than the nozzle exit diameter, the thickness of the bow shock formed in front of the substrate is rather small, which contributes to increase the particle impact velocity. With increasing the substrate diameter, the bow shock thickness increases gradually up to the point at which the substrate diameter is beyond the nozzle exit diameter. A further increase beyond this has almost no effect on the flow regime and the bow shock thickness. Besides, the current numerical work also reveals that the temperature distribution within the substrate can be significantly influenced by substrate thickness. With an increase in substrate thickness, the substrate temperature presents a downward trend, which means that higher inlet temperature may be required for thick substrate to achieve the same preheating effect.

Similar content being viewed by others

References

H. Tabbara and S. Gu, Computational Simulation of Liquid-Fuelled HVOF Thermal Spraying, Surf. Coat. Technol., 2009, 204(5), p 676-684

H. Tabbara, S. Gu, and D.G. McCartney, Computational Modelling of Titanium Particles in Warm Spray, Comput. Fluids, 2011, 44(1), p 358-368

A.N. Papyrin, Cold Spray Technology, Adv. Mater. Process., 2001, 159(9), p 49-51

H. Assadi, F. Gärtner, T. Stoltenhoff, and H. Kreye, Bonding Mechanism in Cold Gas Spraying, Acta Mater., 2003, 51(15), p 4379-4394

T. Schmidt, F. Gärtner, H. Assadi, and H. Kreye, Development of a Generalized Parameter Window for Cold Spray Deposition, Acta Mater., 2006, 54(3), p 729-742

G. Bae, Y. Xiong, S. Kumar, K. Kang, and C. Lee, General Aspects of Interface Bonding in Kinetic Sprayed Coatings, Acta Mater., 2008, 56(17), p 4858-4868

S. Yin, X.F. Wang, W.Y. Li, and B.P. Xu, Numerical Investigation on Effects of Interactions Between Particles on Coating Formation in Cold Spraying, J. Therm. Spray Technol., 2009, 18(4), p 686-693

M. Grujicic, C.L. Zhao, W.S. DeRosset, and D. Helfritch, Adiabatic Shear Instability Based Mechanism for Particles/Substrate Bonding in the Cold-Gas Dynamic-Spray Process, Mater. Des., 2004, 25(8), p 681-688

W.Y. Li, S. Yin, and X.F. Wang, Numerical Investigations of the Effect of Oblique Impact on Particle Deformation in Cold Spraying by the SPH Method, Appl. Surf. Sci., 2010, 256(12), p 3725-3734

R.C. Dykhuizen and M.F. Smith, Gas Dynamic Principles of Cold Spray, J. Therm. Spray Technol., 1998, 7(2), p 205-212

W.Y. Li and C.J. Li, Optimal Design of a Novel Cold Spray Gun Nozzle at a Limited Space, J. Therm. Spray Technol., 2005, 14(3), p 391-396

W.Y. Li, H. Liao, H.T. Wang, C.J. Li, G. Zhang, and C. Coddet, Optimal Design of Convergent-Barrel Cold Spray Nozzle by Numerical Method, Appl. Surf. Sci., 2006, 253(2), p 708-713

H. Tabbara, S. Gu, D.G. McCartney, T.S. Price, and P.H. Shipway, Study on Process Optimization of Cold Gas Spraying, J. Therm. Spray Technol., 2011, 20(3), p 608-620

S. Yin, X.F. Wang, and W.Y. Li, Computational Analysis of the Effect of Nozzle Cross-Section Shape on Gas Flow and Particle Acceleration in Cold Spraying, Surf. Coat. Technol., 2011, 205(8-9), p 2970-2977

T.C. Jen, L.J. Li, W.-Z. Cui, Q.H. Chen, and X.M. Zhang, Numerical Investigations on Cold Gas Dynamic Spray Process with Nano- and Microsize Particles, Int. J. Heat Mass Transf., 2005, 48(21-22), p 4384-4396

S. Yin, X.F. Wang, W.Y. Li, and B.P. Xu, Numerical Study on the Effect of Substrate Angle on Particle Impact Velocity and Normal Velocity Component in Cold Gas Dynamic Spraying Based on CFD, J. Therm. Spray Technol., 2010, 19(6), p 1155-1162

J. Pattison, S. Celotto, A. Dhan, and W. O’Neill, Standoff Distance and Bow Shock Phenomena in the Cold Spray Process, Surf. Coat. Technol., 2008, 202(8), p 1443-1454

M. Fukumoto, H. Wada, K. Tanabe, M. Yamada, E. Yamaguchi, A. Niwa, M. Sugimoto, and M. Izawa, Effect of Substrate Temperature on Deposition Behavior of Copper Particles on Substrate Surfaces in the Cold Spray Process, J. Therm. Spray Technol., 2007, 16(5-6), p 643-650

P.C. King, G. Bae, S.H. Zahiri, M. Jahedi, and C. Lee, An Experimental and Finite Element Study of Cold Spray Copper Impact onto Two Aluminum Substrates, J. Therm. Spray Technol., 2010, 19(3), p 620-634

J.G. Legoux, E. Irissou, and C. Moreau, Effect of Substrate Temperature on the Formation Mechanism of Cold-Sprayed Aluminum, Zinc and Tin Coatings, J. Therm. Spray Technol., 2007, 16(5-6), p 619-626

D. Zhang, P.H. Shipway, and D.G. McCartney, Cold Gas Dynamic Spraying of Aluminum: The Role of Substrate Characteristics in Deposit Formation, J. Therm. Spray Technol., 2005, 14(1), p 109-116

S. Yin, X.F. Wang, W.Y. Li, and H.E. Jie, Effect of Substrate Hardness on the Deformation Behavior of Subsequently Incident Particles in Cold Spraying, Surf. Coat. Technol., 2011, 57(11), p 7560-7565

P.H. Gao, C.J. Li, G.J. Yang, Y.G. Li, and C.X. Li, Influence of Substrate Hardness Transition on Built-Up of Nanostructured WC-12Co by Cold Spraying, Appl. Surf. Sci., 2010, 256(7), p 2263-2268

V.F. Kosarev, S.V. Klinkov, A.P. Alkhimov, and A.N. Papyrin, On Some Aspects of Gas Dynamics of the Cold Spray Process, J. Therm. Spray Technol., 2003, 12(2), p 265-281

S. Yin, X.F. Wang, W.Y. Li, and X.P. Guo, Examination on Substrate Pre-heating Process in Cold Gas Dynamic Spraying, J. Therm. Spray Technol., 2011, 20(4), p 852-859

W.Y. Li, S. Yin, X.P. Guo, H.L. Liao, X.F. Wang, and C. Coddet, An Investigation on Temperature Distribution Within the Substrate and Nozzle Wall in Cold Spraying by Numerical and Experimental Methods, J. Therm. Spray Technol. (in press). doi:10.1007/s11666-011-9685-2

FLUENT Inc., Fluent 6.2 User Guide, 1999

R. Nickel, K. Bobzin, E. Lugscheider, D. Parkot, W. Varava, H. Olivier, and X. Luo, Numerical Studies of the Application of Shock Tube Technology for Cold Gas Dynamic Spray Process, J. Therm. Spray Technol., 2007, 16(5-6), p 729-735

T. Han, B.A. Gillispie, and Z.B. Zhao, An Investigation on Powder Injection in the High-Pressure Cold Spray Process, J. Therm. Spray Technol., 2009, 18(3), p 320-330

S.A. Morsi and A.J. Alexander, An Investigation of Particle Trajectories in Two-Phase Flow Systems, J. Fluid Mech., 1972, 55(2), p 193-208

J. Lee and S.J. Lee, The Effect of Nozzle Configuration on Stagnation Region Heat Transfer Enhancement of Axisymmetric Jet Impingement, Int. J. Heat Mass Transf., 2000, 43(4), p 555-575

Acknowledgments

The research was mainly supported by the National Natural Science Foundation of China (No. 50476075). The authors also would like to acknowledge the financial support by the Chinese Ministry of Education’s Academic Award for Outstanding Doctoral Student.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Yin, S., Wang, Xf., Li, Wy. et al. Numerical Study on the Effect of Substrate Size on the Supersonic Jet Flow and Temperature Distribution Within the Substrate in Cold Spraying. J Therm Spray Tech 21, 628–635 (2012). https://doi.org/10.1007/s11666-011-9711-4

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11666-011-9711-4