Abstract

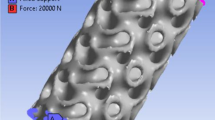

The main purpose of this study is to investigate the effect of microstructuring plus a surface modification method, named SLActive, on mechanical properties and biocompatibility of coarse-grained (CG) titanium grade 2 by in vitro test. In fact, SLActive process is a developed SLA method. To investigate the effects of these two applications on coarse-grained Ti-gr2, this last was grain-refined by the equal channel angular pressing (ECAP). Afterward, SLA and SLActive methods were applied on coarse-grained (CG)-Ti grade 2, ultrafine-grained (UFG)-Ti grade 2, coarse-grained (CG)-Ti grade 4 and Ti-6Al-4 V alloy. Tensile test revealed that mechanical properties of UFG-Ti-gr2 were all developed up to those of Ti-6Al-4 V. Vickers microhardness test showed an increase in hardness of ~162% for UFG-Ti-gr2 compared to CG-Ti-gr2. Surface roughness test indicated the surface of UFG-Ti-gr2 as the roughest among others. The drop test registered an angle of ~0° for all SLActive samples. MTT test represented the highest cell viability and proliferation for SLActive UFG-Ti-gr2 sample. As it was found out from results, the SLActive UFG-Ti-gr2 sample presented the highest potential, among other materials, to be used in dental implant production industries.

Similar content being viewed by others

Data Availability

All the required data was added to text.

References

L. Gaviria, J.P. Salcido, T. Guda, and J.L. Ong, Current Trends in Dental Implants, J. Korean Assoc. Oral Maxillofac. Surg., 2014, 40(2), p 50.

Z.L. Sun, J.C. Wataha, and C.T. Hanks, Effects of Metal Ions on Osteoblast-like Cell Metabolism and Differentiation, J. Biomed. Mater. Res. An Off. J. Soc. Biomater. Japanese Soc. Biomater., 1997, 34(1), p 29–37.

N.J. Hallab, C. Vermes, C. Messina, K.A. Roebuck, T.T. Glant, and J.J. Jacobs, Concentration-and Composition-Dependent Effects of Metal Ions on Human MG-63 Osteoblasts, J. Biomed. Mater. Res., 2002, 60(3), p 420–433.

W.C. Gealh, V. Mazzo, F. Barbi, and E.T. Camarini, Osseointegrated Implant Fracture: Causes and Treatment, J. Oral Implantol., 2011, 37(4), p 499–503.

U.S. Beier, H. Strobl, and M. Dhima, Correction of Esthetic and Biomechanical Outcomes After Maxillary Anterior Single Dental Implant Fracture: A Case Report. Compendium, 35(2), 2014.

P. Kral, J. Dvorak, S. Zherebtsov, G. Salishchev, M. Kvapilova, and V. Sklenicka, Effect of Severe Plastic Deformation on Creep Behaviour of a Ti–6Al–4V Alloy, J. Mater. Sci., 2013, 48(13), p 4789–4795.

V.G. Pushin et al., Effect of Severe Plastic Deformation on the Behavior of Ti–Ni Shape Memory Alloys, Mater. Trans., 2006, 47(3), p 694–697.

A. Jäger, V. Gärtnerova, and K. Tesař, Microstructure and Anisotropy of the Mechanical Properties in Commercially Pure Titanium After Equal Channel Angular Pressing with Back Pressure at Room Temperature, Mater. Sci. Eng. A, 2015, 644, p 114–120.

M. Ensafi, G. Faraji, and H. Abdolvand, Cyclic Extrusion Compression Angular Pressing (CECAP) as a Novel Severe Plastic Deformation Method for Producing Bulk Ultrafine Grained Metals, Mater. Lett., 2017, 197, p 12–16.

M. Eskandarzade, A. Masoumi, G. Faraji, M. Mohammadpour, and X.S. Yan, A New Designed Incremental High Pressure Torsion Process for Producing Long Nanostructured Rod Samples, J. Alloys Compd., 2017, 695, p 1539–1546.

F. Reshadi, G. Faraji, M. Baniassadi, and M. Tajeddini, Surface Modification of Severe Plastically Deformed Ultrafine Grained Pure Titanium by Plasma Electrolytic Oxidation, Surf. Coatings Technol., 2017, 316, p 113–121.

A.E. Medvedev, H.-P. Ng, R. Lapovok, Y. Estrin, T.C. Lowe, and V.N. Anumalasetty, Effect of Bulk Microstructure Of Commercially Pure Titanium on Surface Characteristics and Fatigue Properties After Surface Modification by Sand Blasting and Acid-Etching, J. Mech. Behav. Biomed. Mater., 2016, 57, p 55–68.

R.Z. Valiev and T.G. Langdon, Principles of Equal-Channel Angular Pressing as a Processing Tool for Grain Refinement, Prog. Mater. Sci., 2006, 51(7), p 881–981.

V.V. Stolyarov, Y.T. Zhu, I.V. Alexandrov, T.C. Lowe, and R.Z. Valiev, Grain Refinement and Properties of Pure Ti Processed by Warm ECAP and Cold Rolling, Mater. Sci. Eng. A, 2003, 343(1–2), p 43–50.

P. Luo, D.T. McDonald, W. Xu, S. Palanisamy, M.S. Dargusch, and K. Xia, A Modified Hall-Petch Relationship in Ultrafine-Grained Titanium Recycled from Chips by Equal Channel Angular Pressing, Scr. Mater., 2012, 66(10), p 785–788.

S.J. Ferguson et al., Biomechanical evaluation of the interfacial strength of a chemically modified sandblasted and acid-etched titanium surface, J. Biomed. Mater. Res. Part A An. Off. J. Soc. Biomater. Japanese Soc. Biomater. Aust. Soc. Biomater. Korean Soc. Biomater., 2006, 78(2), p 291–297.

L. Le Guéhennec, A. Soueidan, P. Layrolle, and Y. Amouriq, Surface Treatments of Titanium Dental Implants for Rapid Osseointegration, Dent. Mater., 2007, 23(7), p 844–854.

C.M. Stanford, Surface Modifications of Dental Implants, Aust. Dent. J., 2008, 53, p S26–S33.

R. Junker, A. Dimakis, M. Thoneick, and J.A. Jansen, Effects of Implant Surface Coatings and Composition on Bone Integration: A Systematic Review, Clin. Oral Implants Res., 2009, 20, p 185–206.

C. Han, C.B. Johansson, A. Wennerberg, and T. Albrektsson, Quantitative and Qualitative Investigations of Surface Enlarged Titanium and Titanium Alloy Implants, Clin. Oral Implants Res., 1998, 9(1), p 1–10.

T.J. Webster and J.U. Ejiofor, Increased Osteoblast Adhesion on Nanophase Metals: Ti, Ti6Al4V, and CoCrMo, Biomaterials, 2004, 25(19), p 4731–4739.

J.Y. Martin et al., Effect of Titanium Surface Roughness on Proliferation, Differentiation, and Protein Synthesis of Human Osteoblast-like Cells (MG63), J. Biomed. Mater. Res., 1995, 29(3), p 389–401.

M. Pegueroles et al., Spatial Organization of Osteoblast Fibronectin Matrix on Titanium Surfaces: Effects of Roughness, Chemical Heterogeneity and Surface Energy, Acta Biomater., 2010, 6(1), p 291–301.

A. Wennerberg, S. Galli, and T. Albrektsson, Current Knowledge about the Hydrophilic and Nanostructured SLActive Surface, Clin. Cosmet. Investig. Dent., 2011, 3, p 59.

H.J. Rønold and J.E. Ellingsen, Effect of Micro-Roughness Produced by TiO2 Blasting—Tensile Testing of Bone Attachment by using Coin-Shaped Implants, Biomaterials, 2002, 23(21), p 4211–4219.

H.J. Rønold, S.P. Lyngstadaas, and J.E. Ellingsen, A Study on the Effect of Dual Blasting with TiO2 on Titanium Implant Surfaces on Functional Attachment in Bone, J. Biomed. Mater. Res. Part A An Off. J. Soc. Biomater. Japanese Soc. Biomater. Aust. Soc. Biomater. Korean Soc. Biomater., 2003, 67(2), p 524–530.

H. Schliephake, A. Aref, D. Scharnweber, S. Bierbaum, and A. Sewing, Effect of Modifications of Dual Acid-Etched Implant Surfaces on Peri-Implant Bone Formation. Part I: Organic Coatings, Clin. Oral Implants Res., 2009, 20(1), p 31–37.

A.P. Ross and T.J. Webster, Anodizing Color Coded Anodized Ti6Al4V Medical Devices for Increasing Bone Cell Functions, Int. J. Nanomedicine, 2013, 8, p 109.

D.V. Kilpadi and J.E. Lemons, Surface Energy Characterization of Unalloyed Titanium Implants, J. Biomed. Mater. Res., 1994, 28(12), p 1419–1425.

F. Schwarz et al., Potential of Chemically Modified Hydrophilic Surface Characteristics to Support Tissue Integration of Titanium Dental Implants, J. Biomed. Mater. Res. Part B Appl. Biomater. An Off. J. Soc. Biomater. Japanese Soc. Biomater. Aust. Soc. Biomater. Korean Soc. Biomater., 2009, 88(2), p 544–557.

N. Hansen, Hall–Petch Relation and Boundary Strengthening, Scr. Mater., 2004, 51(8), p 801–806.

J. Gubicza, I. Schiller, N.Q. Chinh, J. Illy, Z. Horita, and T.G. Langdon, The Effect of Severe Plastic Deformation on Precipitation in Supersaturated Al–Zn–Mg Alloys, Mater. Sci. Eng. A, 2007, 460, p 77–85.

Y.G. Ko, D.H. Shin, K.-T. Park, and C.S. Lee, An Analysis of the Strain Hardening Behavior of Ultra-Fine Grain Pure Titanium, Scr. Mater., 2006, 54(10), p 1785–1789. https://doi.org/10.1016/j.scriptamat.2006.01.034

V.L. Sordi, M. Ferrante, M. Kawasaki, and T.G. Langdon, Microstructure and Tensile Strength Of Grade 2 Titanium Processed by Equal-Channel Angular Pressing and by Rolling, J. Mater. Sci., 2012, 47(22), p 7870–7876. https://doi.org/10.1007/s10853-012-6593-x

G.I. Raab, E.P. Soshnikova, and R.Z. Valiev, Influence of Temperature and Hydrostatic Pressure During Equal-Channel Angular Pressing on the Microstructure of Commercial-Purity Ti, Mater. Sci. Eng. A, 2004, 387–389, p 674–677. https://doi.org/10.1016/j.msea.2004.01.137

D.V. Gunderov et al., Evolution of Microstructure, Macrotexture and Mechanical Properties of Commercially Pure Ti During ECAP-Conform Processing and Drawing, Mater. Sci. Eng. A, 2013, 562, p 128–136.

C.N. Elias and L. Meirelles, Improving Osseointegration of Dental Implants, Expert Rev. Med. Devices, 2010, 7(2), p 241–256. https://doi.org/10.1586/erd.09.74

G.R.M. Matos, Surface Roughness of Dental Implant and Osseointegration, J. Maxillofac. Oral Surg., 2021, 20(1), p 1–4. https://doi.org/10.1007/s12663-020-01437-5

T. Albrektsson and A. Wennerberg, On Osseointegration in Relation to Implant Surfaces, Clin. Implant Dent. Relat. Res., 2019, 21(S1), p 4–7. https://doi.org/10.1111/cid.12742

F. Rupp et al., A Review on the Wettability of Dental Implant Surfaces I: Theoretical and Experimental Aspects, Acta Biomater., 2014, 10(7), p 2894–2906. https://doi.org/10.1016/j.actbio.2014.02.040

J. Ganeles, A. Zöllner, J. Jackowski, C. Ten Bruggenkate, J. Beagle, and F. Guerra, Immediate and Early Loading of Straumann Implants with a Chemically Modified Surface (SLActive) in the Posterior Mandible and Maxilla: 1-year Results from a Prospective Multicenter Study, Clin. Oral Implants Res., 2008, 19(11), p 1119–1128. https://doi.org/10.1111/j.1600-0501.2008.01626.x

B. An et al., In vitro and in vivo Studies of Ultrafine-Grain Ti as Dental Implant Material Processed by ECAP, Mater. Sci. Eng. C, 2016, 67, p 34–41.

R.L. Sammons, N. Lumbikanonda, M. Gross, and P. Cantzler, Comparison of Osteoblast Spreading on Microstructured Dental Implant Surfaces and Cell Behaviour in an Explant Model of Osseointegration, Clin. Oral Implants Res., 2005, 16(6), p 657–666. https://doi.org/10.1111/j.1600-0501.2005.01168.x

L. Le Guehennec, M.-A. Lopez-Heredia, B. Enkel, P. Weiss, Y. Amouriq, and P. Layrolle, Osteoblastic Cell Behaviour on Different Titanium Implant Surfaces, Acta Biomater., 2008, 4(3), p 535–543. https://doi.org/10.1016/j.actbio.2007.12.002

M. Geetha, A.K. Singh, R. Asokamani, and A.K. Gogia, Ti based Biomaterials, the Ultimate Choice for Orthopaedic Implants–a Review, Prog. Mater. Sci., 2009, 54(3), p 397–425.

L. Mishnaevsky et al., Nanostructured Titanium-based Materials for Medical Implants: Modeling and Development, Mater. Sci. Eng. R Reports, 2014, 81, p 1–19. https://doi.org/10.1016/j.mser.2014.04.002

F. Schwarz, M. Herten, M. Sager, M. Wieland, M. Dard, and J. Becker, Histological and Immunohistochemical Analysis of Initial and Early Osseous Integration at Chemically Modified and Conventional SLA® Titanium Implants: Preliminary results of a Pilot Study in Dogs, Clin. Oral Implants Res., 2007, 18(4), p 481–488. https://doi.org/10.1111/j.1600-0501.2007.01341.x

P. Jojibabu, B.R. Sunil, T.S.S. Kumar, U. Chakkingal, V. Nandakumar, and M. Doble, Wettability and In Vitro Bioactivity Studies on Titanium Rods Processed by Equal Channel Angular Pressing, Trans. Indian Inst. Met., 2013, 66(4), p 299–304. https://doi.org/10.1007/s12666-013-0281-7

Funding

This research was supported by the University of Tehran.

Author information

Authors and Affiliations

Contributions

All authors contributed to the study conception and design. Material preparation, data collection and analysis were performed by MS and SK. The first draft of the manuscript was written by MS, and all authors commented on previous versions of the manuscript. All authors read and approved the final manuscript.

Corresponding author

Ethics declarations

Conflict of interest

There is no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Sadrkhah, M., Faraji, G., Khorasani, S. et al. Excellent Mechanical Properties, Wettability and Biological Response of Ultrafine-Grained Pure Ti Dental Implant Surface Modified by SLActive. J. of Materi Eng and Perform 32, 11408–11421 (2023). https://doi.org/10.1007/s11665-023-07928-z

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-023-07928-z