Abstract

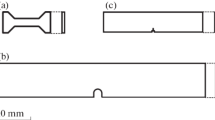

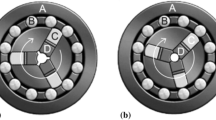

Commercially pure titanium strengthened by severe plastic deformation constitutes an alternative to the use of complex Ti alloys in many medical or industrial applications. In this research, rods of grade 2 Ti were processed by up to six passes using Equal-channel angular pressing (ECAP) at 573 K followed by cold rolling at room or subzero temperatures. After four passes of ECAP, the grain size was refined down to the submicrometer scale and subsequent rolling led to further refinement. The microstructure was characterized by taking Vickers microhardness measurements and tensile testing was performed both at room temperature and in the temperature range of 573–773 K. The results show that at all temperatures the tensile strength is significantly improved by means of these processing techniques. At room temperature, the ultimate tensile strength of pure Ti after ECAP plus subzero rolling is close to that of the traditional Ti-6Al-4V alloy while maintaining adequate levels of elongation to failure.

Similar content being viewed by others

References

Valiev RZ, Langdon TG (2006) Prog Mater Sci 51:881

Valiev RZ, Estrin Y, Horita Z, Langdon TG, Zehetbauer MJ, Zhu YT (2006) JOM 58(4):33

Stolyarov VV, Zhu YT, Alexandrov IV, Lowe TC, Valiev RZ (2003) Mater Sci Eng A343:45

Zhao X, Fu W, Yang X, Langdon TG (2008) Scr Mater 59:542

Fan Z, Jiang H, Sun X, Song J, Zhang X, Xie C (2009) Mater Sci Eng A527:45

McKay GC, Mcnair R, MacDonald C, Grant MH (1996) Biomaterials 17:1339

Furukawa M, Iwahashi Y, Horita Z, Nemoto M, Langdon TG (1998) Mater Sci Eng A257:328

Iwahashi Y, Wang J, Horita Z, Nemoto M, Langdon TG (1996) Scr Mater 35:143

Esteban L, Elizalde MR, Ocana L (2007) J Mater Proc Technol (2007) 183:390

Jia D, Wang YM, Ramesh KT, Ma E, Zhu YT, Valiev RZ (2001) Appl Phys Lett 79:611

Ko YG, Shin DH, Park K, Lee CS (2006) Scr Mater 54:1785

Chen Y, Li Y, He L, Lu C, Ding H, Li Q (2008) Mater Lett 62:2821

Wang Y, Chen M, Zhou F, Ma E (2008) Nature 419:912

Ahn SH, Chun YB, Yu SH, Kim KH, Hwang SK (2010) Mater Sci Eng A528:165

Kalidindi SR, Salem AA, Doherty RD (2003) Adv Eng Mater 5:229

Zherebtsov SV, Dyakonov GS, Salem AA, Malysheva SP, Salishchev GA, Semiatin SL (2011) Mater Sci Eng A528:3474

Shin DH, Kim I, Kim J, Kim YS, Semiatin SL (2003) Acta Mater 51:983

Stolyarov VV, Zhu YT, Lowe TC, Islamgaliev RK, Valiev RZ (1999) Nanostruct Mater 11:947

Stolyarov VV, Zhu YT, Lowe TC, Valiev RZ (2001) Mater Sci Eng A303:82

Kang DH, Kim TW (2010) Mater Des 31:554

Zhao X, Yang X, Liu X, Wang X, Langdon TG (2010) Mater Sci Eng A527:6335

Mendes Filho AA, Sordi VL, Kliauga AM, Ferrante M (2010) J Phys Conf Ser 240:012130

Zhang Y, Figueiredo RB, Alhajeri SN, Wang JT, Gao N, Langdon TG (2011) Mater Sci Eng A528:7708

Stolyarov VV, Zhu YT, Alexandrov IV, Lowe TC, Valiev RZ (2001) Mater Sci Eng A299:59

Mendes AA (2010) Increasing mechanical strength of commercially pure titanium by equal-channel angular pressing: application in orthopaedic implants. Dissertation, Federal University of Sao Carlos

Hoppel HW, Kautz M, Xu C, Murashkin M, Langdon TG, Valiev RZ, Mughrabi H (2006) Intl J Fatigue 28:1001

Acknowledgements

V.L. Sordi thanks FAPESP (Fundação de Apoio à Pesquisa no Estado de São Paulo) for financial support. This research was supported in part by the National Science Foundation of the United States under Grant No. DMR-0855009 (MK and TGL) and by the European Research Council under ERC Grant Agreement No. 267464-SPDMETALS (TGL).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Sordi, V.L., Ferrante, M., Kawasaki, M. et al. Microstructure and tensile strength of grade 2 titanium processed by equal-channel angular pressing and by rolling. J Mater Sci 47, 7870–7876 (2012). https://doi.org/10.1007/s10853-012-6593-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-012-6593-x