Abstract

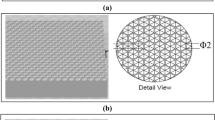

Corrosion and metal release characteristics of cobalt-based alloys are important factors influential on their biomedical applications. This study fabricated a porous Vitallium (CoCrMo) alloy and then coated with a 58S bioglass coating by applying the sol-gel dipping method with 3, 4 and 5 cycles to examine the corrosion and ion release performance of this alloy. For this purpose, potentiodynamic polarization, electrochemical impedance spectroscopy (EIS) and immersion tests were conducted in the simulated body fluid (SBF) at 37 °C. Also, the released ion measurements were performed by inductive coupled plasma optical emission spectrometry (ICP-OES). SEM examinations on the porous substrate indicated that this porous scaffold exhibited the porosity of 37% and the content of small porosities was decreased; however, the macrospores on the surface were intact after applying bioglass coatings. Furthermore, increasing the dipping cycles led to enhancing the corrosion potential from − 191 mV (in the uncoated porous sample) to − 98 mV (in the coated porous sample dipped 5 cycles in the bioglass sols). EIS results in SBF demonstrated that the corrosion performance of the coatings was improved by increasing the dipping cycles from 0 to 5. ICP-OES results also proved that the presence of the 58 S bioglass coating on the porous Vitallium decreased the release of cobalt and chromium ions, while it enriched Ca and P, thereby improving the bioactivity of the samples.

Similar content being viewed by others

References

E. Mahlooji, M. Atapour and S. Labbaf, Electrophoretic Deposition of Bioactive Glass–Chitosan Nanocomposite Coatings on Ti-6Al-4V for Orthopedic Applications, Carbohydr. Polym., 2019, 226, p 115299. https://doi.org/10.1016/j.carbpol.2019.115299

M. Alaei, M. Atapour and S. Labbaf, Electrophoretic Deposition of Chitosan-Bioactive Glass Nanocomposite Coatings on AZ91 Mg Alloy for Biomedical Applications, Prog. Org. Coat., 2020, 147, p 105803. https://doi.org/10.1016/j.porgcoat.2020.105803

A. Nouri and C. Wen, 1 - Introduction to surface coating and modification for metallic biomaterials, in Surface Coating and Modification for Metallic Biomaterials, (Woodhead Publishing, 2015), pp. 3–60

T. Narushima and K. Ueda, Alfirano, Co-Cr Alloys as Effective Metallic, Biomaterials, 2015 https://doi.org/10.1007/978-3-662-46836-4_7

M.R. Haftbaradaran-Esfahani, M. Ahmadian and A.H. Nassajpour-Esfahani, Fabrication and Characterization of Porous Biomedical Vitallium Alloy with 58S Bioglass Coating Prepared By Sol-Gel Method, Appl. Surf. Sci., 2020, 506, p 144959. https://doi.org/10.1016/J.APSUSC.2019.144959

R.H. Oskouei, M.R. Barati, H. Farhoudi, M. Taylor and L.B. Solomon, A New Finding on the In-Vivo Crevice Corrosion Damage in a CoCrMo Hip Implant, Mater. Sci. Eng. C., 2017, 79, p 390–398. https://doi.org/10.1016/j.msec.2017.05.086

E. Krasicka-Cydzik, Z. Oksiuta and J.R. Dabrowski, Corrosion Testing of Sintered Samples made of the Co-Cr-Mo Alloy for Surgical Applications, J. Mater. Sci. Mater. Med., 2005, 16, p 197–202. https://doi.org/10.1007/s10856-005-6680-5

M. Ren, S. Cai, G. Xu, X. Ye, Y. Dou, K. Huang and X. Wang, Influence of Heat Treatment on Crystallization and Corrosion Behavior of Calcium Phosphate Glass Coated AZ31 Magnesium Alloy by Sol–Gel Method, J. Non. Cryst. Solids, 2013, 369, p 69–75. https://doi.org/10.1016/j.jnoncrysol.2013.03.022

S.C. Cachinho and R.N. Correia, Titanium Scaffolds for Osteointegration: Mechanical, In Vitro and Corrosion Behaviour, J. Mater. Sci. Mater. Med., 2008, 19, p 451–457. https://doi.org/10.1007/s10856-006-0052-7

K. Huang, S. Cai, G. Xu, M. Ren, X. Wang, R. Zhang, S. Niu and H. Zhao, Sol–Gel Derived Mesoporous 58S Bioactive Glass Coatings on AZ31 Magnesium Alloy and In Vitro Degradation Behavior, Surf. Coat. Technol., 2014, 240, p 137–144. https://doi.org/10.1016/j.surfcoat.2013.12.026

T.F. Zhang, Q.Y. Deng, B. Liu, B.J. Wu, F.J. Jing, Y.X. Leng and N. Huang, Wear and Corrosion Properties of Diamond Like Carbon (DLC) Coating on Stainless Steel, CoCrMo and Ti6Al4V Substrates, Surf. Coat. Technol., 2015, 273, p 12–19.

B.X. de Freitas, C.A. Nunes and C. dos Santos, Sintering Behaviour of Co-28%Cr-6%Mo Compacted Blocks for Dental Prosthesis, J. Mater. Res. Technol., 2019, 8, p 2052–2062. https://doi.org/10.1016/j.jmrt.2018.12.020

W.C. Rodrigues, L.R. Broilo, L. Schaeffer, G. Knörnschild and F.R.M. Espinoza, Powder Metallurgical Processing of Co–28%Cr–6%Mo for Dental Implants: Physical, Mechanical and Electrochemical Properties, Powder Technol., 2011, 206, p 233–238. https://doi.org/10.1016/j.powtec.2010.09.024

G.L. Turdean, A. Craciun, D. Popa and M. Constantiniuc, Study of Electrochemical Corrosion of Biocompatible Co–Cr and Ni–Cr Dental Alloys in Artificial Saliva. Influence of pH of the Solution, Mater. Chem. Phys., 2019, 233, p 390–398. https://doi.org/10.1016/j.matchemphys.2019.05.041

Y. Say and B. Aksakal, Enhanced Corrosion Properties of Biological NiTi Alloy by Hydroxyapatite and Bioglass Based Biocomposite Coatings, J. Mater. Res. Technol., 2020, 9, p 1742–1749. https://doi.org/10.1016/j.jmrt.2019.12.005

C. García, S. Ceré and A. Durán, Bioactive Coatings Prepared by Sol–Gel on Stainless Steel 316L, J. Non. Cryst. Solids, 2004, 348, p 218–224. https://doi.org/10.1016/j.jnoncrysol.2004.08.172

M.M.M. López, J. Fauré, M.I.E. Cabrera and M.E.C. García, Structural Characterization and Electrochemical Behavior of 45S5 Bioglass Coating on Ti6Al4V Alloy for Dental Applications, Mater. Sci. Eng. B., 2016, 206, p 30–38. https://doi.org/10.1016/j.mseb.2015.09.003

V. Swaminathan and J.L. Gilbert, Potential and Frequency Effects on Fretting Corrosion of Ti6Al4V and CoCrMo Surfaces, J. Biomed. Mater. Res. Part A., 2013, 101A, p 2602–2612. https://doi.org/10.1002/jbm.a.34564

A.C. Lewis, M.R. Kilburn, I. Papageorgiou, G.C. Allen and C.P. Case, Effect of Synovial Fluid, Phosphate-Buffered Saline Solution, and Water on the Dissolution and Corrosion Properties of CoCrMo Alloys as Used in Orthopedic Implants, J. Biomed. Mater. Res. Part A., 2005, 73A, p 456–467. https://doi.org/10.1002/jbm.a.30368

ASTM C20-00, in Standard Test Methods for Apparent Porosity, Water Absorption, Apparent Specific Gravity, and Bulk Density of Burned Refractory Brick and Shapes by Boiling Water, 2015th ed., (ASTM International, West Conshohocken, PA, 2015). https://doi.org/10.1520/C0020-00R15.

M.T. Dehaghani and M. Ahmadian, Porous Vitalium-Base Nano-Composite for Bone Replacement: Fabrication, Mechanical, and In Vitro Biological Properties, J. Mech. Behav. Biomed. Mater., 2016, 57, p 297–309. https://doi.org/10.1016/j.jmbbm.2016.01.026

M. Bahrami, M.H. Fathi and M. Ahmadian, The Effect of Nanobioceramic Reinforcement on Mechanical and Biological Properties of Co-Base Alloy/Hydroxyapatite Nanocomposite, Mater. Sci. Eng. C., 2015, 48, p 572–578. https://doi.org/10.1016/j.msec.2014.12.017

M. Taghian Dehaghani, M. Ahmadian and M. Fathi, Effect of Ball Milling on the Physical and Mechanical Properties of the Nanostructured Co–Cr–Mo Powders, Adv. Powder Technol., 2014, 25, p 1793–1799. https://doi.org/10.1016/j.apt.2014.07.009

G. Ryan, A. Pandit and D.P. Apatsidis, Fabrication Methods of Porous Metals for use in Orthopaedic Applications, Biomaterials, 2006, 27, p 2651–2670. https://doi.org/10.1016/j.biomaterials.2005.12.002

S. Fujino, H. Tokunaga, E. Saiz and A.P. Tomsia, Fabrication and Characterization of Bioactive Glass Coatings on Co-Cr Implant Alloys, Mater. Trans., 2004, 45, p 1147–1151.

J. Liu and X. Miao, Sol–gel Derived Bioglass as a Coating Material for Porous Alumina Scaffolds, Ceram. Int., 2004, 30, p 1781–1785. https://doi.org/10.1016/j.ceramint.2003.12.120

D.-M. Liu, Q. Yang and T. Troczynski, Sol–gel Hydroxyapatite Coatings on Stainless Steel Substrates, Biomaterials, 2002, 23, p 691–698.

J. Gallardo, A. Durán and J.J. de Damborenea, Electrochemical and In Vitro Behaviour of Sol–Gel Coated 316L Stainless Steel, Corros. Sci., 2004, 46, p 795–806. https://doi.org/10.1016/S0010-938X(03)00185-9

Y. Liu and B. Chen, In Vivo Corrosion of CoCrMo Alloy and Biological Responses: A Review, Mater. Technol., 2018, 33, p 127–134. https://doi.org/10.1080/10667857.2017.1408929

E. Liverani, A. Balbo, C. Monticelli, A. Leardini, C. Belvedere and A. Fortunato, Corrosion Resistance and Mechanical Characterization of Ankle Prostheses Fabricated Via Selective Laser Melting, Procedia CIRP., 2017, 65, p 25–31.

S. Karimi and A.M. Alfantazi, Ion Release and Surface Oxide Composition of AISI 316L, Co–28Cr–6Mo, and Ti–6Al–4V Alloys Immersed in Human Serum Albumin Solutions, Mater. Sci. Eng. C., 2014, 40, p 435–444.

B. Stojanović, C. Bauer, C. Stotter, T. Klestil, S. Nehrer, F. Franek and M. Rodríguez Ripoll, Tribocorrosion of a CoCrMo Alloy Sliding Against Articular Cartilage and the Impact of Metal Ion Release on Chondrocytes, Acta Biomater., 2019, 94, p 597–609. https://doi.org/10.1016/j.actbio.2019.06.015

S. Pourhashem and A. Afshar, Double Layer Bioglass-Silica Coatings on 316L Stainless Steel by Sol–Gel Method, Ceram. Int., 2014, 40, p 993–1000. https://doi.org/10.1016/j.ceramint.2013.06.096

D. Mareci, D. Sutiman, A. Cailean and G. Bolat, Comparative Corrosion Study of Ag-Pd and Co-Cr Alloys Used in Dental Applications, Bull. Mater. Sci., 2010, 33, p 491–500.

D.C. Romonţi, J. Iskra, M. Bele, I. Demetrescu and I. Milošev, Elaboration and Characterization of Fluorohydroxyapatite and Fluoroapatite Sol−Gel Coatings on CoCrMo Alloy, J. Alloys Compd., 2016, 665, p 355–364.

F. Baino, E. Fiume, M. Miola and E. Verné, Bioactive Sol-Gel Glasses: Processing, Properties, and Applications, Int. J. Appl. Ceram. Technol., 2018, 15, p 841–860. https://doi.org/10.1111/ijac.12873

J.R. Jones, Review of Bioactive Glass: From Hench to Hybrids, Acta Biomater., 2013, 9, p 4457–4486. https://doi.org/10.1016/j.actbio.2012.08.023

I.R. Oliveira, A.M. Barbosa, K.W. Santos, M.C. Lança, M.M.R.A. Lima, T. Vieira, J.C. Silva and J.P. Borges, Properties of Strontium-Containing BG 58S Produced by Alkali-Mediated Sol-Gel Process, Ceram. Int., 2022 https://doi.org/10.1016/j.ceramint.2022.01.002

M. Maximov, O.-C. Maximov, L. Craciun, D. Ficai, A. Ficai and E. Andronescu, Bioactive Glass—An Extensive Study of the Preparation and Coating Methods, Coatings, 2021, 11, p 1386. https://doi.org/10.3390/coatings11111386

S. Wu, X. Liu, T. Hu, J. Jiang, P.K. Chu, K.W.K. Yeung, C.Y. Chung, C.L. Chu, Z. Xu, W.W. Lu, K.M.C. Cheung and K.D.K. Luk, Electrochemical Stability of Orthopedic Porous NiTi Shape Memory Alloys Treated by Different Surface Modification Techniques, J. Electrochem. Soc., 2009, 156, p C187. https://doi.org/10.1149/1.3110945

S. Barison, S. Cattarin, S. Daolio, M. Musiani and A. Tuissi, Characterisation of Surface Oxidation of Nickel–Titanium Alloy by Ion-Beam and Electrochemical Techniques, Electrochim. Acta., 2004, 50, p 11–18.

A.W.E. Hodgson, Y. Mueller, D. Forster and S. Virtanen, Electrochemical Characterisation of Passive Films on Ti Alloys Under Simulated Biological Conditions, Electrochim. Acta., 2002, 47, p 1913–1923.

S. Karimi, T. Nickchi and A. Alfantazi, Effects of Bovine Serum Albumin on the Corrosion Behaviour of AISI 316L, Co–28Cr–6Mo, and Ti–6Al–4V Alloys in Phosphate Buffered Saline Solutions, Corros. Sci., 2011, 53, p 3262–3272.

M.İ Coşkun, İH. Karahan and T.D. Golden, Computer Assisted Corrosion Analysis of Hydroxyapatite Coated CoCrMo Biomedical Alloys, Surf. Coatings Technol., 2015, 275, p e1–e9. https://doi.org/10.1016/j.surfcoat.2015.05.037

U. Türkan, O. Öztürk and A.E. Eroğlu, Metal Ion Release From TiN Coated CoCrMo Orthopedic Implant Material, Surf. Coat. Technol., 2006, 200, p 5020–5027.

Y. Okazaki and E. Gotoh, Comparison of Metal Release from Various Metallic Biomaterials In Vitro, Biomaterials, 2005, 26, p 11–21. https://doi.org/10.1016/j.biomaterials.2004.02.005

X. Wang and C. Wen, Corrosion Protection of Mesoporous Bioactive Glass Coating on Biodegradable Magnesium, Appl. Surf. Sci., 2014, 303, p 196–204.

G. Herranz, C. Berges, J.A. Naranjo, C. García and I. Garrido, Mechanical Performance, Corrosion and Tribological Evaluation of a Co–Cr–Mo Alloy Processed by MIM for Biomedical Applications, J. Mech. Behav. Biomed. Mater., 2020, 105, p 103706. https://doi.org/10.1016/J.JMBBM.2020.103706

Acknowledgment

Isfahan University of Technology (IUT) is acknowledged for providing the technical supports.

Author information

Authors and Affiliations

Corresponding authors

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Haftbaradaran-Esfahani, M.R., Ahmadian, M. & Atapour, M. Corrosion and Metal Release Investigation of a Porous Biomedical Vitallium Alloy Coated with 58S Sol-Gel Bioactive Glass. J. of Materi Eng and Perform 31, 10010–10020 (2022). https://doi.org/10.1007/s11665-022-07017-7

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-022-07017-7