Abstract

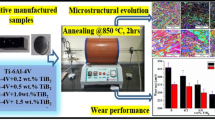

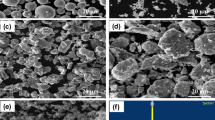

Selective laser melting (SLM) technique was used to fabricate in situ Ti-6Al-4V+TiB titanium matrix composite (TMC) samples by addition of sub-micron TiB2 ceramic particles in Ti-6Al-4V powder. The TMC samples were further subjected to annealing treatment at 900 °C for 30 minutes in an inert atmosphere. The influence of annealing treatment on the microstructure development was characterized using optical microscope and field emission scanning electron microscope (FESEM). The addition of TiB2 (0.2, 0.5 and 1.0 wt.%) induces drastic changes in the morphology of the as-built TMC samples. After annealing, a complete phase transformation occurred in pure Ti-6Al-4V alloy to lamellar shaped alpha and globular beta phase. In TMC samples, the increase in the weight fraction of TiB2 ceramic particles resulted in substantial grain refinement; however, grain coarsening was observed upon annealing treatment. Refinement in microstructure was associated with pinning effect of TiB whiskers. Coarsening of TiB whiskers also occurred with predominant increase in length as compared to width. Development in tribological performance was attributed to microstructure refinement.

Similar content being viewed by others

References

D. Banerjee and J.C. Williams, Perspectives on Titanium Science and Technology, Acta Mater., 2013 https://doi.org/10.1016/j.actamat.2012.10.043

R.R. Boyer, An Overview on the Use of Titanium in the Aerospace Industry, Mater. Sci. Eng. A., 1996 https://doi.org/10.1016/0921-5093(96)10233-1

I. Inagaki, T. Takechi, Y. Shirai, N. Ariyasu, Application and Features of Titanium for the Aerospace Industry. Nippon Steel Sumitomo Met. Tech. Rep. (2014).

A. Molinari, G. Straffelini, B. Tesi and T. Bacci, Dry Sliding Wear Mechanisms of the Ti6Al4V Alloy, Wear, 1997, 208, p 105–112. https://doi.org/10.1016/S0043-1648(96)07454-6

H. Dong, Tribological properties of titanium-based alloys, Surf. Eng. Light Alloy. Alum. Magnes. Titan. Alloy, 2010 https://doi.org/10.1533/9781845699451.1.58

O.M. Ivasishin, D.G. Savvakin, I.S. Bielov, V.S. Moxson, V.A. Duz, R. Davies, C. Lavender, BEPM Synthesis of Ti-6Al-4V Alloy Using Hydrogenated Titanium, Euro PM 2005 Powder Metall. Congr. Exhib. 1, 115–120 (2005)

M.A. Xavior and J.P.A. Kumar, Machinability of Hybrid Metal Matrix Composite - A Review, Procedia Eng., 2017 https://doi.org/10.1016/j.proeng.2017.01.264

S.C. Tjong and Z.Y. Ma, Microstructural and Mechanical Characteristics of In Situ Metal Matrix Composites, Mater. Sci. Eng. R Reports., 2000 https://doi.org/10.1016/S0927-796X(00)00024-3

S. Dadbakhsh, R. Mertens, L. Hao, J. Van Humbeeck and J.P. Kruth, Selective Laser Melting to Manufacture “In Situ” Metal Matrix Composites: A Review, Adv. Eng. Mater., 2019 https://doi.org/10.1002/adem.201801244

K.B. Panda and K.S. Ravi Chandran, Synthesis of Ductile Titanium-Titanium Boride (Ti-TiB) Composites with a Beta-Titanium Matrix: The Nature of TiB Formation and Composite Properties, Mater. Trans. A Phys. Metall. Mater. Sci, 2003 https://doi.org/10.1007/s11661-003-0249-z

A.S. Patil, V.D. Hiwarkar, P.K. Verma and R.K. Khatirkar, Effect of TiB2 Addition on the Microstructure and Wear Resistance of Ti-6Al-4V Alloy Fabricated Through Direct Metal Laser Sintering (DMLS), J. Alloys Compd., 2019, 777, p 165–173. https://doi.org/10.1016/j.jallcom.2018.10.308

P.K. Verma, S. Warghane, U. Nichul, P. Kumar, A. Dhole and V. Hiwarkar, Effect of Boron Addition on Microstructure, Hardness and Wear Performance of Ti-6Al-4 V Alloy Manufactured by Laser Powder Bed Fusion Additive Manufacturing, Mater. Charact., 2021 https://doi.org/10.1016/j.matchar.2020.110848

C. Cai, C. Radoslaw, J. Zhang, Q. Yan, S. Wen, B. Song and Y. Shi, In-Situ Preparation and Formation of TiB/Ti-6Al-4V Nanocomposite Via Laser Additive Manufacturing: Microstructure Evolution and Tribological Behavior, Powder Technol., 2019, 342, p 73–84. https://doi.org/10.1016/j.powtec.2018.09.088

M. Forming, Near Net Shape Manufacturing Processes, Springer International Publishing, Cham, 2019. https://doi.org/10.1007/978-3-030-10579-2

Y. Huang, M.C. Leu, J. Mazumder and A. Donmez, Additive Manufacturing: Current State, Future Potential, Gaps and Needs, and Recommendations, J. Manuf. Sci. Eng., 2015, 137, 014001. https://doi.org/10.1115/1.4028725

D. Herzog, V. Seyda, E. Wycisk and C. Emmelmann, Additive Manufacturing of Metals, Acta Mater., 2016, 117, p 371–392. https://doi.org/10.1016/j.actamat.2016.07.019

S. Bremen, W. Meiners and A. Diatlov, Selective Laser Melting: A Manufacturing Technology for the Future?, Laser Tech. J., 2012, 9, p 33–38. https://doi.org/10.1002/latj.201290018

H. Attar, M. Bönisch, M. Calin, L.C. Zhang, S. Scudino and J. Eckert, Selective Laser Melting of In Situ Titanium-Titanium Boride Composites: Processing, Microstructure and Mechanical Properties, Acta Mater., 2014, 76, p 13–22. https://doi.org/10.1016/j.actamat.2014.05.022

L. Parry, I.A. Ashcroft and R.D. Wildman, Understanding the Effect of Laser Scan Strategy on Residual Stress in Selective Laser Melting Through Thermo-Mechanical Simulation, Addit. Manuf., 2016 https://doi.org/10.1016/j.addma.2016.05.014

L. Bertini, F. Bucchi, F. Frendo, M. Moda and B.D. Monelli, Residual Stress Prediction in Selective Laser Melting: A Critical Review of Simulation Strategies, Int. J. Adv. Manuf. Technol., 2019 https://doi.org/10.1007/s00170-019-04091-5

Q. Peng, S. Dong, S. Yan, P. Men, B. Wang, An Overview of Defects in Laser Melting Deposition Forming Products and the Corresponding Controlling Methods. Cailiao Daobao/Materials Rev. (2018). https://doi.org/10.11896/j.issn.1005-023X.2018.15.019.

J. Song, W. Wu, L. Zhang, B. He, L. Lu, X. Ni, Q. Long and G. Zhu, Role of Scanning Strategy on Residual Stress Distribution in Ti-6Al-4V Alloy Prepared by Selective Laser Melting, Optik (Stuttg)., 2018 https://doi.org/10.1016/j.ijleo.2018.05.128

W. Xiong, L. Hao, Y. Li, D. Tang, Q. Cui, Z. Feng and C. Yan, Effect of Selective Laser Melting Parameters on Morphology, Microstructure, Densification and Mechanical Properties of Supersaturated Silver Alloy, Mater. Des., 2019 https://doi.org/10.1016/j.matdes.2019.107697

R. Sharma and A. Kumar, Track-Scale Simulations of Selective Laser Melting to Investigate Development and Mitigation of Thermal Stresses, Lasers Manuf. Mater. Process., 2019 https://doi.org/10.1007/s40516-019-00103-0

A. Saboori, D. Gallo, S. Biamino, P. Fino and M. Lombardi, An Overview of Additive Manufacturing of Titanium Components by Directed Energy Deposition: Microstructure and Mechanical Properties, Appl. Sci., 2017 https://doi.org/10.3390/app7090883

L. Thijs, F. Verhaeghe, T. Craeghs, J. Van Humbeeck and J.P. Kruth, A Study of the Microstructural Evolution During Selective Laser Melting of Ti-6Al-4V, Acta Mater., 2010 https://doi.org/10.1016/j.actamat.2010.02.004

J. Yang, H. Yu, J. Yin, M. Gao, Z. Wang and X. Zeng, Formation and Control of Martensite in Ti-6Al-4V Alloy Produced by Selective Laser Melting, Mater. Des., 2016 https://doi.org/10.1016/j.matdes.2016.06.117

Y. Cui, K. Aoyagi, Y. Zhao, K. Yamanaka, Y. Hayasaka, Y. Koizumi, T. Fujieda and A. Chiba, Manufacturing of a Nanosized TiB Strengthened Ti-Based Alloy Via Electron Beam Powder Bed Fusion, Addit. Manuf., 2020 https://doi.org/10.1016/j.addma.2020.101472

Y. Liu, Y. Yang and D. Wang, A Study on the Residual Stress During Selective Laser Melting (SLM) of Metallic Powder, Int. J. Adv. Manuf. Technol., 2016 https://doi.org/10.1007/s00170-016-8466-y

G. Vastola, G. Zhang, Q.X. Pei and Y.W. Zhang, Controlling of Residual Stress in Additive Manufacturing of Ti6Al4V by Finite Element Modeling, Addit. Manuf., 2016 https://doi.org/10.1016/j.addma.2016.05.010

P. Mercelis and J.P. Kruth, Residual Stresses in Selective Laser Sintering and Selective Laser Melting, Rapid Prototyp. J., 2006 https://doi.org/10.1108/13552540610707013

A.M. Khorasani, I. Gibson, M. Goldberg and G. Littlefair, On the Role of Different Annealing Heat Treatments on Mechanical Properties and Microstructure of Selective Laser Melted and Conventional Wrought Ti-6Al-4V, Rapid Prototyp. J., 2017 https://doi.org/10.1108/RPJ-02-2016-0022

B. Vrancken, L. Thijs, J.P. Kruth and J. Van Humbeeck, Heat Treatment of Ti6Al4V produced by Selective Laser Melting: Microstructure and Mechanical Properties, J. Alloys Compd., 2012 https://doi.org/10.1016/j.jallcom.2012.07.022

W.C. Oliver and G.M. Pharr, An Improved Technique for Determining Hardness and Elastic Modulus Using Load and Displacement Sensing Indentation Experiments, J. Mater. Res., 1992 https://doi.org/10.1557/jmr.1992.1564

M. Dao, N. Chollacoop, K.J. Van Vliet, T.A. Venkatesh and S. Suresh, Computational Modeling of the Forward and Reverse Problems in Instrumented Sharp Indentation, Acta Mater., 2001, 49, p 3899–3918. https://doi.org/10.1016/S1359-6454(01)00295-6

S. Roy, S. Suwas, S. Tamirisakandala, D.B. Miracle and R. Srinivasan, Development of Solidification Microstructure in Boron-Modified Alloy Ti–6Al–4V–0.1B, Acta Mater., 2011, 59, p 5494–5510. https://doi.org/10.1016/j.actamat.2011.05.023

O.O. Bilous, L.V. Artyukh, A.A. Bondar, T.Y. Velikanova, M.P. Burka, M.P. Brodnikovskyi, O.S. Fomichov, N.I. Tsyganenko and S.O. Firstov, Effect of Boron on the Structure and Mechanical Properties of Ti–6Al and Ti–6Al–4V, Mater. Sci. Eng. A., 2005, 402, p 76–83. https://doi.org/10.1016/j.msea.2005.05.011

R. Banerjee, P.C. Collins, A. Genç and H.L. Fraser, Direct Laser Deposition of In Situ Ti–6Al–4V–TiB Composites, Mater. Sci. Eng. A., 2003, 358, p 343–349. https://doi.org/10.1016/S0921-5093(03)00299-5

W.O. Soboyejo, R.J. Lederich and S.M.L. Sastry, Mechanical Behavior of Damage Tolerant TiB Whisker-Reinforced In Situ Titanium Matrix Composites, Acta Metall. Mater., 1994 https://doi.org/10.1016/0956-7151(94)90199-6

M.J. Bermingham, S.D. McDonald, D.H. StJohn and M.S. Dargusch, Beryllium as a Grain Refiner in Titanium Alloys, J. Alloys Compd., 2009 https://doi.org/10.1016/j.jallcom.2009.03.016

Z. Fan, Z.X. Guo and B. Cantor, The Kinetics and Mechanism of Interfacial Reaction in Sigma Fibre-Reinforced Ti MMCs, Compos. Part A Appl. Sci. Manuf., 1997 https://doi.org/10.1016/S1359-835X(96)00105-4

M. Mrotzek and E. Nembach, Ostwald Ripening of Precipitates During Two Successive Heat Treatments Performed at Different Temperatures, Acta Mater., 2008, 56, p 150–154. https://doi.org/10.1016/j.actamat.2007.09.024

V.P. Zhdanov, Ostwald Ripening on a Composite Support, Phys. A Stat. Mech. Its Appl., 2020, 547, 124431. https://doi.org/10.1016/j.physa.2020.124431

P. Streitenberger and D. Zöllner, The Envelope of size Distributions in Ostwald Ripening and Grain Growth, Acta Mater., 2015, 88, p 334–345. https://doi.org/10.1016/j.actamat.2015.01.035

H. Feng, Y. Zhou, D. Jia, Q. Meng and J. Rao, Growth Mechanism of In Situ TiB Whiskers in Spark Plasma Sintered TiB/Ti Metal Matrix Composites, Cryst. Growth Des., 2006, 6, p 1626–1630. https://doi.org/10.1021/cg050443k

Y.Z. Hailiang Li, D. Jia, Z. Yang, X. Liao, H. Jin and D. Cai, Effect of Heat Treatment on Microstructure Evolution and Mechanical Properties of Selective Laser Melted Ti–6Al–4V and TiB/Ti–6Al–4V Composite: A Comparative Study, Mater. Sci. Eng. A., 2021 https://doi.org/10.1016/j.msea.2020.140415

A. Baldan, Progress in Ostwald Ripening Theories and Their Applications to the γ′-Precipitates in Nickel-Base Superalloys Part II: Nickel-Base Superalloys, J. Mater. Sci., 2002, 37, p 2379–2405. https://doi.org/10.1023/A:1015408116016

C. Mateo-Mateo, C. Vázquez-Vázquez, M. Pérez-Lorenzo, V. Salgueiriño and M.A. Correa-Duarte, Ostwald Ripening of Platinum Nanoparticles Confined in a Carbon Nanotube/Silica-Templated Cylindrical Space, J. Nanomater., 2012 https://doi.org/10.1155/2012/404159

W.O. Soboyejo, R.J. Lederich and S.M.L. Sastry, Mechanical Behavior of Damage Tolerant TiB Whisker-Reinforced In Situ Titanium Matrix Composites, Acta Metall. Mater., 1994, 42, p 2579–2591. https://doi.org/10.1016/0956-7151(94)90199-6

T. Chen, S. Koyama and L. Yu, Improvement of Mechanical, Tribological, and Fricative Reduction Properties of Pure Titanium by Boriding, Appl. Sci., 2021 https://doi.org/10.3390/app11114862

S. Liu and Y.C. Shin, Additive Manufacturing of Ti6Al4V Alloy: A Review, Mater. Des., 2019 https://doi.org/10.1016/j.matdes.2018.107552

R.A. Gaisin, V.M. Imayev, R.M. Imayev and E.R. Gaisina, Microstructure and Hot Deformation Behavior of Two-Phase Boron-Modified Titanium Alloy VT8, Phys. Met. Metallogr., 2013, 114, p 339–347. https://doi.org/10.1134/S0031918X13040042

R.A. Gaisin, V.M. Imayev and R.M. Imayev, Microstructure and Mechanical Properties of a Near-α-Titanium-Alloy/TiB Composite Prepared in situ by Casting and Subjected to Deformation and Heat Treatment, Phys. Met. Metallogr., 2018, 119, p 907–916. https://doi.org/10.1134/S0031918X18090041

J. Tiley, T. Searles, E. Lee, S. Kar, R. Banerjee, J.C. Russ and H.L. Fraser, Quantification of Microstructural Features in α/β Titanium Alloys, Mater. Sci. Eng. A., 2004, 372, p 191–198. https://doi.org/10.1016/J.MSEA.2003.12.008

Z.C. Cordero, B.E. Knight and C.A. Schuh, Six Decades of the Hall-Petch Effect – a Survey of Grain-Size Strengthening Studies on Pure Metals, Int. Mater. Rev., 2016 https://doi.org/10.1080/09506608.2016.1191808

B.K.C. Ganesh, N. Ramanaih and P.V. Chandrasekhar Rao, Dry Sliding Wear Behavior of Ti-6Al-4V Implant Alloy Subjected to Various Surface Treatments, Trans. Indian Inst. Met., 2012, 65, p 425–434. https://doi.org/10.1007/s12666-012-0147-4

T.M.T. Godfrey, P.S. Goodwin and C.M. Ward-Close, Titanium Particulate Metal Matrix Composites: Reinforcement, Production Methods, and Mechanical Properties, Adv. Eng. Mater., 2000 https://doi.org/10.1002/(sici)1527-2648(200003)2:3%3c85::aid-adem85%3e3.0.co;2-u

W. Xiang, M. Xuliang, L. Xinlin, D. Lihua and W. Mingjia, Effect of Boron Addition on Microstructure and Mechanical Properties of TiC/Ti6Al4V Composites, Mater. Des., 2012, 36, p 41–46. https://doi.org/10.1016/j.matdes.2011.10.040

J. Yang, W. Gu, L.M. Pan, K. Song, X. Chen and T. Qiu, Friction and Wear Properties of In Situ (TiB2+TiC)/Ti3SiC2 Composites, Wear, 2011, 271, p 2940–2946. https://doi.org/10.1016/j.wear.2011.06.017

Acknowledgments

The authors would like to acknowledge the use of National facility of Texture and OIM (A DST-IRPHA project) and Nanoindentation lab of IIT Bombay. The corresponding author would like to acknowledge VRDE Ahmednagar for supporting the research.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Verma, P.K., Warghane, S., Nichul, U. et al. Heat Treatment Behaviour of SLM-Built Titanium Matrix Composite: Microstructure and Tribological Performance. J. of Materi Eng and Perform 31, 9586–9595 (2022). https://doi.org/10.1007/s11665-022-06981-4

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-022-06981-4