Abstract

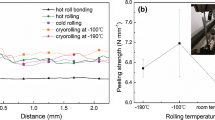

The effect of rolling parameters on microstructure, texture and mechanical properties of Al/Mg/Al laminated composites was investigated. The results showed that the development of microstructure through the thickness of Al and Mg layers was inhomogeneous. The surface layer of Al possessed the highest hardness, and it decreased as the measured position moved from the surface layer toward the interface of Al/Mg. At the center of Mg layer, the volume fraction of recrystallized grains increased with increasing rolling reduction and temperature, while the fully dynamic recrystallization occurred at the interface of Mg layer. The surface and center of Al layer exhibited stronger r-cube and γ-fiber shear textures compared to the interface layer. The tensile strength of the Al/Mg/Al laminated composites increased with increasing rolling reduction and decreasing rolling temperature, whereas the elongation decreased. The bonding strength increased with increasing rolling reduction. With increasing rolling temperature, the bonding strength increased to a maximum value at 450 °C and then decreased.

taken from the peeling surfaces of (a and c) Al and (b and d) Mg sides in the Al/Mg/Al laminated composites fabricated at different rolling temperatures and reductions

Similar content being viewed by others

References

J. Wadsworth and D.R. Lesuer, Ancient and Modern Laminated Composites-from the Great Pyramid of Gizeh to Y2K, Mater. Charact., 2000, 45, p 289–313.

H.S. Liu, B. Zhang and G.P. Zhang, Enhanced Toughness and Fatigue Strength of Cold Roll Bonded Cu/Cu Laminated Composites with Mechanical Contrast, Scripta Mater., 2011, 65, p 891–894.

W.A. Spitzig, A.R. Pelton and F.C. Laabs, Characterization of the Strength and Microstructure of Heavily Cold Worked Cu-Nb Composites, Acta Metall., 1987, 35, p 2427–2442.

M. Ma, P. Huo, W.C. Liu, G.J. Wang and D.M. Wang, Microstructure and Mechanical Properties of Al/Ti/Al Laminated Composites Prepared by Roll Bonding, Mater. Sci. Eng. A, 2015, 636, p 301–310.

M. Movahedi, A.H. Kokabi and S.M.S. Reihani, Investigation on the Bond Strength of Al-1100/St-12 Roll Bonded Sheets, Optimization and Characterization, Mater. Des., 2011, 32, p 3143–3149.

X.B. Li, G.Y. Zu, M.M. Ding, Y.L. Mu and P. Wang, Interfacial Microstructure and Mechanical Properties of Cu/Al clad Sheet Fabricated by Asymmetrical Roll Bonding and Annealing, Mater. Sci. Eng., A, 2011, 529, p 485–491.

G. Heness, R. Wuhrer and W.Y. Yeung, Interfacial Strength Development of Roll-Bonded Aluminium/copper Metal Laminates, Mater. Sci. Eng., A, 2008, 483, p 740–742.

H. Chang, M.Y. Zheng, C. Xu, G.D. Fan, H.G. Brokmeier and K. Wu, Microstructure and Mechanical Properties of the Mg/Al Multilayer Fabricated by Accumulative Roll Bonding (ARB) at Ambient Temperature, Mater. Sci. Eng., A, 2012, 543, p 249–256.

K. Wu, H. Chang, E. Maawad, W.M. Gan, H.G. Brokmeier and M.Y. Zheng, Microstructure and Mechanical Properties of the Mg/Al Laminated Composite Fabricated by Accumulative Roll Bonding (ARB), Mater. Sci. Eng., A, 2010, 527, p 3073–3078.

X. Qiao, X. Li, X. Zhang, Y. Chen, M. Zheng, I.S. Golovin and M.J. Starink, Intermetallics Formed at Interface of Ultrafine Grained Al/Mg bi-layered Disks Processed by High Pressure Torsion at Room Temperature, Mater. Lett., 2016, 181, p 187–190.

L.M. Zhao and Z.D. Zhang, Effect of Zn alloy Interlayer on Interface Microstructure and Strength of Diffusion-Bonded Mg-Al Joints, Scripta Mater., 2008, 58, p 283–286.

G. Mahendran, V. Balasubramanian and T. Senthilvelan, Developing Diffusion Bonding Windows for Joining AZ31B Magnesium-AA2024 Aluminium Alloys, Mater. Des., 2009, 30, p 1240–1244.

L. Xu, Y.Y. Cui, Y.L. Hao and R. Yang, Growth of Intermetallic Layer in Multi-Laminated Ti/Al Diffusion Couples, Mater. Sci. Eng., A, 2006, 435, p 638–647.

X.P. Zhang, T.H. Yang, S. Castagne and J.T. Wang, Microstructure; Bonding Strength and Thickness Ratio of Al/Mg/Al Alloy Laminated Composites Prepared by Hot Rolling, Mater. Sci. Eng., A, 2011, 528, p 1954–1960.

X.B. Liu, R.S. Chen and E.H. Han, Preliminary Investigations on the Mg-Al-Zn/Al Laminated Composite Fabricated by Equal Channel Angular Extrusion, J. Mater. Process. Technol., 2009, 209, p 4675–4681.

Y.B. Yan, Z.W. Zhang, W. Shen, J.H. Wang, L.K. Zhang and B.A. Chin, Microstructure and Properties of Magnesium AZ31B-Aluminum 7075 Explosively Welded Composite Plate, Mater. Sci. Eng., A, 2010, 527, p 2241–2245.

G.Y. Li, W.M. Jiang, W.C. Yang, Z.L. Jiang, F. Guan, H.X. Jiang and Z.T. Fan, New Insights into the Characterization and Formation of the Interface of A356/AZ91D Bimetallic Composites Fabricated by Compound Casting, Metall. Mater. Trans. A., 2019, 50, p 1076–1090.

Z. Zhang, W.M. Jiang, G.Y. Li, J.L. Wang, F. Guan, G.L. Jie and Z.T. Fan, Effect of La on Microstructure, Mechanical Properties and Fracture Behavior of Al/Mg Bimetallic Interface Manufactured by Compound Casting, J. Mater. Sci. Technol., 2022, 105, p 214–225.

Y.C. Chen and K. Nakata, Friction Stir Lap Joining Aluminum and Magnesium Alloys, Scripta Mater., 2008, 58, p 433–436.

X.P. Zhang, M.J. Tan, T.H. Yang, X.J. Xu and J.T. Wang, Bonding Strength of Al/Mg/Al Alloy Tri-Metallic Laminates Fabricated by Hot Rolling, Bull. Mater. Sci., 2011, 34, p 805–810.

M. Abbasi and S.A. Sajjadi, Mechanical Properties and Interface Evaluation of Al/AZ31 Multilayer Composites Produced by ARB at Different Rolling Temperatures, J. Mater. Eng. Perform., 2018, 27, p 3508–3520.

Y.D. Zhao, Z.M. Ding and Y. Chen, Crystallographic Orientations of Intermetallic Compounds of a Multi-Pass Friction Stir Processed Al/Mg Composite Materials, Mater. Charact., 2017, 128, p 156–164.

Y. Wang and P.B. Prangnell, The Significance of Intermetallic Compounds formed during Interdiffusion in Aluminum and Magnesium Dissimilar Welds, Mater. Charact., 2017, 134, p 84–95.

G.Y. Li, W.M. Jiang, F. Guan, J.W. Zhu, Z. Zhang and Z.T. Fan, Microstructure, Mechanical Properties and Corrosion Resistance of A356 Aluminum/AZ91D Magnesium Bimetal prepared by a Compound Casting Combined with a Novel Ni-Cu Composite Interlayer, J. Mater. Process. Technol., 2021, 288, p 116874.

X.P. Zhang, T.H. Yang, J.Q. Liu, X.F. Luo and J.T. Wang, Mechanical Properties of an Al/Mg/Al Trilaminated Composite Fabricated by Hot Rolling, J. Mater. Sci., 2010, 45, p 3457–3464.

F.T. Kong, Y.Y. Chen and D.L. Zhang, Interfacial Microstructure and Shear Strength of Ti-6Al-4V/TiAl Laminate Composite Sheet Fabricated by Hot Packed Rolling, Mater. Des., 2011, 32, p 3167–3172.

H.J. Bunge, Texture Analysis in Materials Science, Vol 11 Butterworths, London, 1982.

W.C. Liu and J.G. Morris, Comparison of the Texture Evolution in Cold Rolled DC and SC AA 5182 Aluminum Alloys, Mater. Sci. Eng., A, 2003, 339, p 183–193.

W.C. Liu and J.G. Morris, Quantitative Analysis of Texture Evolution in Cold-Rolled, Continuous-Cast AA 5xxx-Series Aluminum Alloys, Metall. and Mater. Trans. A., 2004, 35, p 265–277.

A. Macwan, X.Q. Jiang, C. Li and D.L. Chen, Effect of Annealing on Interface Microstructures and Tensile Properties of Rolled Al/Mg/Al tri-layer Clad Sheets, Mater. Sci. Eng., A, 2013, 587, p 344–351.

J.W. Tang, L. Chen, G.Q. Zhao, C.S. Zhang and J.Q. Yu, Study on Al/Mg/Al Sheet Fabricated by Combination of Porthole die Co-Extrusion and Subsequent Hot Rolling, J. Alloy. Compd., 2019, 784, p 727–738.

M. Movahedi, H.R. Madaah-Hosseini and A.H. Kokabi, The Influence of Roll Bonding Parameters on the Bond Strength of Al-3003/Zn Soldering Sheets, Mater. Sci. Eng., A, 2008, 487, p 417–423.

R. Jamaati and M.R. Toroghinejad, Investigation of the Parameters of the Cold Roll Bonding (CRB) Process, Mater. Sci. Eng., A, 2010, 527, p 2320–2326.

H.D. Manesh and A.K. Taheri, The Effect of Annealing Treatment on Mechanical Properties of Aluminum Clad Steel Sheet, Mater. Des., 2003, 24, p 617–622.

W. Truszkowski, J. Król and B. Major, Inhomogeneity of Rolling Texture in f.c.c Metals, Metall. Trans. A, 1980, 11, p 749–758.

W. Truszkowski, J. Król and B. Major, On Penetration of Shear Texture into the Rolled Aluminum and Copper, Metall. Trans. A, 1982, 13, p 665–669.

B. Major, Texture, Microstructure, and Stored Energy Inhomogeneity in Cold Rolled Commercial Purity Aluminium and Copper, Mater. Sci. Technol., 1992, 8, p 510–515.

C.H. Choi, J.W. Kwon, K.H. Oh and D.N. Lee, Analysis of Deformation Texture Inhomogeneity and Stability Condition of Shear Components in f.c.c Metals, Acta Mater., 1997, 45, p 5119–5128.

O. Engler, C.N. Tomé and M.Y. Huh, A Study of Through-Thickness Texture Gradients in Rolled Sheets, Metall. and Mater. Trans. A., 2000, 31, p 2299–2315.

C.G. Kang, H.G. Kang, H.C. Kim, M.Y. Huh and H.G. Suk, Formation of Shear Texture Components during Hot Rolling of AA 1050, J. Mater. Process. Technol., 2007, 187, p 542–545.

M. Hölscher, D. Raabe and K. Lücke, Relationship Between Rolling Textures and Shear Textures in f.c.c and bcc Metals, Acta Metall. Et Mater., 1994, 42, p 879–886.

O.V. Mishin, B. Bay, G. Winther and D.J. Jensen, The Effect of Roll Gap Geometry on Microstructure in Cold-Rolled Aluminum, Acta Mater., 2004, 52, p 5761–5770.

H.P. Yang, Y.H. Sha, F. Zhang and L. Zuo, Through-Thickness Shear Strain Control in Cold Rolled Silicon Steel by the Coupling Effect of Roll Gap Geometry and Friction, J. Mater. Process. Technol., 2010, 210, p 1545–1550.

O.V. Mishin, B. Bay and D.J. Jensen, Through-Thickness Texture Gradients in Cold-Rolled Aluminum, Metall. and Mater. Trans. A., 2000, 31, p 1653–1662.

H.O. Asbeck and H. Mecking, Influence of Friction and Geometry of Deformation on Texture Inhomogeneities during Rolling of Cu Single Crystals as an Example, Mater. Sci. Eng., 1978, 34, p 111–119.

R.E. Bauer, H. Mecking and K. Lücke, Textures of Copper Single Crystals after Rolling at Room Temperature, Mater. Sci. Eng., 1977, 27, p 163–180.

H.P. Kneijnsberg, C.A. Verbraak and M.J. Ten Bouwhuijs, Determination of Texture Distributions in Inhomogeneously Rolled Al Single Crystals using a Topographical X-Ray method, Acta Metall., 1985, 33, p 1759–1767.

J.K. Kim, Y.K. Jee, M.Y. Huh and H.T. Jeong, Formation of Textures and Microstructures in Asymmetrically Cold Rolled and Subsequently Annealed Aluminum Alloy 1100 Sheets, J. Mater. Sci., 2004, 39, p 5365–5369.

C.S. Lee and B.J. Duggan, A Simple Theory for the Development of Inhomogeneous Rolling Extures, Metall. Trans. A, 1991, 22, p 2637–2643.

O.V. Mishin, D.J. Jensen and N. Hansen, Evolution of Microstructure and Texture during Annealing of Aluminum AA1050 Cold Rolled to High and Ultrahigh Strains, Metall. Mater. Trans. A., 2010, 41, p 2936–2948.

M. Eizadjou, H.D. Manesh and K. Janghorban, Investigation of Roll Bonding between Aluminum Alloy Strips, Mater. Des., 2008, 29, p 909–913.

H. Yan and J.G. Lenard, A Study of Warm and Cold Roll-Bonding of an Aluminium Alloy, Mater. Sci. Eng., A, 2004, 385, p 419–428.

X.K. Peng, G. Heness and W.Y. Yeung, Effect of Rolling Temperature on Interface and Bond Strength Development of Roll Bonded Copper/Aluminium Metal Laminates, J. Mater. Sci., 1999, 34, p 277–281.

Acknowledgments

This work was supported by the National Natural Science Foundation of China (Grant No. 52001274).

Author information

Authors and Affiliations

Corresponding authors

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Sun, H.Y., Zhang, D.H., Ma, M. et al. Effect of Rolling Parameters on Microstructure, Texture, and Mechanical Properties of Al/Mg/Al Laminated Composites. J. of Materi Eng and Perform 31, 7624–7640 (2022). https://doi.org/10.1007/s11665-022-06777-6

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-022-06777-6