Abstract

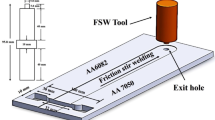

This paper aims at investigating how fracture toughness and other mechanical and microstructural properties of two 2mm-thicked Al 6061 sheets are evolving under different FS-Welding conditions. Hence, three principal FSW parameters, including pin geometry, welding, and rotating speeds, each changing in three levels, have been chosen. Therefore, the number of corresponding trials was reduced from 27 to 9 by employing L9 Taguchi orthogonal array. Besides utilizing Digital Image Correlation to study the fracture toughness of the FS-Welded specimens for more accuracy, samples’ microstructure, including their grain size, was also examined under an optical microscope. It has been concluded that higher rates of rotational speed to welding speed lead to coarser and larger grains and confirmed welded samples’ weak or strong performance. In terms of Vickers micro-hardness and ultimate tensile strength, while results show the positive effect of the welding speed, the rotational speed negatively impacts values. Results have also revealed that the highest DIC-aided measured fracture toughness has belonged to the weld conducted using a square-shaped pin, having welding and rotating speeds of 80mm/min and 1600 RPM, respectively. Finally, correlations between input and output variables have been achieved in regression equations, utilizing response surface methodology.

Similar content being viewed by others

References

R.P. Mahto, R. Kumar, S.K. Pal and S.K. Panda, A Comprehensive Study on Force, Temperature, Mechanical Properties and Micro-structural Characterizations in Friction Stir Lap Welding of Dissimilar Materials (AA6061-T6 & AISI304), J. Manuf. Process., 2018, 31, p 624–639.

B. Gungor, E. Kaluc, E. Taban and A. Sik, Mechanical, Fatigue and Microstructural Properties of Friction Stir Welded 5083–H111 and 6082–T651 Aluminum Alloys, Mater. Des. (1980-2015), 2014, 56, p 84–90.

H. Demir and S. Gündüz, The Effects of Aging on Machinability of 6061 Aluminium Alloy, Mater. Des., 2009, 30, p 1480–1483.

V. Sarila, S. Muthukumaran, S. Yalagi and S. Kailas, Failure Modes and Fatigue Behavior of Conventional and Refilled Friction Stir Spot Welds in AA 6061–T6 Sheets, Int. J. Fatigue, 2014, 61, p 93–100.

R. Singh, S. Chauhan and P.C. Gope, Influence of Notch Radius and Strain Rate on the Mechanical Properties and Fracture Behavior of TIG-welded 6061 Aluminum Alloy, Arch. Civil Mech. Eng., 2016, 16, p 513–523.

R.S. Mishra and Z.Y. Ma, Friction Stir Welding and Processing, Mater. Sci. Eng. R Rep., 2005, 50, p 1–78.

A. Heidarzadeh, S. Mironov, R. Kaibyshev, G. Çam, A. Simar, A. Gerlich et al., Friction Stir Welding/Processing of Metals and Alloys: A Comprehensive Review on Microstructural Evolution, Progress Mater. Sci., 2021, 117, p 100752.

X. Meng, Y. Huang, J. Cao, J. Shen and dos J. F. Santos, Recent Progress on Control Strategies for Inherent Issues in Friction Stir Welding, Progress Mater. Sci., 2021, 115, p 100706.

A. Simar, Y. Bréchet, B. de Meester, A. Denquin, C. Gallais and T. Pardoen, Integrated Modeling of Friction Stir Welding of 6xxx Series Al Alloys: Process, Microstructure and Properties, Progress Mater. Sci., 2013, 57, p 95–183.

D.G. Moghadam and K. Farhangdoost, Influence of Welding Parameters on Fracture Toughness and Fatigue Crack Growth Rate in Friction Stir Welded Nugget of 2024–T351 Aluminum Alloy Joints, Trans. Nonferrous Metals Soc. China, 2016, 26, p 2567–2585.

M. Raturi, A. Garg and A. Bhattacharya, Tensile Strength and Failure of Dissimilar Friction Stir Welded Joints between 6061–T6 and 2014–T6 Aluminum Alloys, Procedia Struct. Integrity, 2019, 17, p 495–502.

H.R. Majidi, A.R. Torabi, M. Zabihi, S.M.J. Razavi and F. Berto, Energy-based Ductile Failure Predictions in Cracked Friction-Stir Welded Joints, Eng. Failure Anal., 2019, 102, p 327–337.

N. Kumbhar and K. Bhanumurthy, Friction Stir Welding of Al 5052 with Al 6061 Alloys, J. Metall., 2012, 2012, p 1269.

N.E. Dowling, Mechanical Behavior of Materials: Engineering Methods for Deformation, Fracture, and Fatigue, Pearson, London, 2012.

J. Bian and Z. Ge, Material Test on Strain Fracture and Crack Opening Displacement Based on Digital Image Correlation Method, Arch. Civil Eng., 2016, 62, p 10239.

H. Coules, G. Horne, K.A. Venkata and T. Pirling, The effects of residual stress on elastic-plastic fracture propagation and stability, Mater. Des., 2018, 143, p 10269.

A.R. Torabi, M.H. Kalantari, M.R.M. Aliha and S.M.N. Ghoreishi, Pure mode II Fracture Analysis of Dissimilar Al-Al and Al-Cu Friction Stir Welded Joints using the Generalized MTS Criterion, Theor. Appl. Fracture Mech., 2019, 104, p 102369.

A. Pirondi, L. Collini and D. Fersini, Fracture and Fatigue Crack Growth Behaviour of PMMC Friction Stir Welded Butt Joints, Eng. Fracture Mech., 2008, 75, p 4333–4342.

A. Çınar, Image-Based Fracture Mechanics with Digital Image Correlation and Digital, Vol Correlation University of Sheffield, London, 2019.

G. Gao, W. Yao, K. Xia and Z. Li, Investigation of the Rate Dependence of Fracture Propagation in Rocks using Digital Image Correlation (DIC) Method, Eng. Fracture Mech., 2015, 138, p 146–155.

D. Rahmatabadi, M. Ahmadi, M. Pahlavani and R. Hashemi, DIC-based Experimental Study of Fracture Toughness through R-curve Tests in a Multi-layered Al-Mg (LZ91) Composite Fabricated by ARB, J. Alloys Comp., 2021, 883, p 160843.

A.K. Lakshminarayanan and V. Balasubramanian, Process Parameters Optimization for Friction Stir Welding of RDE-40 Aluminium Alloy using Taguchi Technique, Trans. Nonferrous Metals Soc. China, 2008, 18, p 548–554.

M.H. Shojaeefard, M. Akbari, A. Khalkhali, P. Asadi and A.H. Parivar, Optimization of Microstructural and Mechanical Properties of Friction Stir Welding Using the Cellular Automaton and Taguchi Method, Mater. Des., 2014, 64, p 660–666.

Y. Javadi, S. Sadeghi and M.A. Najafabadi, Taguchi Optimization and Ultrasonic Measurement of Residual Stresses in the Friction Stir Welding, Mater. Des., 2014, 55, p 27–34.

M. Shunmugasundaram, A.P. Kumar, L.P. Sankar and S. Sivasankar, Optimization of Process Parameters of Friction Stir Welded Dissimilar AA6063 and AA5052 Aluminum Alloys by Taguchi Technique, Mater. Today Proc., 2020, 2, p 1369.

F.C. Liu, Y. Hovanski, M.P. Miles, C.D. Sorensen and T.W. Nelson, A Review of Friction Stir Welding of Steels: Tool, Material Flow, Microstructure, and Properties, J. Mater. Sci. Technol., 2018, 34, p 39–57.

S. Madhavarao, R.V. Penmetsa, G.S.V.S. Kumar, C.R. Raju and K.T. Kumar, Investigation on Mechanical Properties of Friction Stir Welded Aa7075 & Aa6061 Joints, Mater. Today Proc., 2019, 18, p 2288–2297.

ASTM E8 / E8M-16ae1, Standard Test Methods for Tension Testing of Metallic Materials, ASTM International, West Conshohocken, PA, 2016, www.astm.org

ASTM E647-15e1, Standard Test Method for Measurement of Fatigue Crack Growth Rates, ASTM International, West Conshohocken, PA, 2015, www.astm.org

M. Pahlavani, J. Marzbanrad, D. Rahmatabadi, R. Hashemi and A. Bayati, A Comprehensive Study on the Effect of Heat Treatment on the Fracture Behaviors and Structural Properties of Mg-Li Alloys using RSM, Mater. Res Express, 2019, 6, p 076554.

A.K. Lakshminarayanan and V. Balasubramanian, Comparison of RSM with ANN in Predicting Tensile Strength of Friction Stir Welded AA7039 Aluminium Alloy Joints, Trans. Nonferrous Metals Soc. China, 2009, 19, p 9–18.

D.C. Montgomery, Design and Analysis of Experiments, Wiley, New York, 2008.

M. Rahimi, S. Shahhosseini and S. Movahedirad, Continuous-Flow Ultrasound Assisted Oxidative Desulfurization (UAOD) Process: An Efficient Diesel Treatment by Injection of the Aqueous Phase, Ultrasonics Sonochem., 2017, 39, p 611–622.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Appendix

Appendix

See Table 10 .

Rights and permissions

About this article

Cite this article

Ahmadi, M., Pahlavani, M., Rahmatabadi, D. et al. An Exhaustive Evaluation of Fracture Toughness, Microstructure, and Mechanical Characteristics of Friction Stir Welded Al6061 Alloy and Parameter Model Fitting Using Response Surface Methodology. J. of Materi Eng and Perform 31, 3418–3436 (2022). https://doi.org/10.1007/s11665-021-06461-1

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-021-06461-1