Abstract

The resistance spot welding between titanium and mild steel was carried out with and without an interlayer of Nb foil. The effect of interlayer Nb on the microstructure and performance of the joint was analyzed by comparing the two types of joints with and without interlayer. The results reveal that the part of the interlayer Nb disappeared when the welding current was above 8 kA in the selected interlayer Nb thickness of 0.1 mm. In the resistance spot welding between titanium and mild steel, the addition of the interlayer Nb can improve the microstructure and tensile shear load of the joint. When the welding current is 7 kA, the tensile shear load of the Ti/Nb/Q235 joint reaches the maximum value of 4.3 kN.

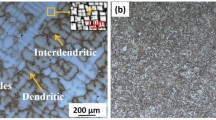

taken from A1, B1, C1, A2, B2 and C2 in Fig. 1, respectively

taken from D3, E3, F3 and G3 in Fig. 3, respectively

Similar content being viewed by others

References

Y. Zhang, Y. Bi, J. Zhou, D. Sun and X. Gu, Butt Laser Welding of TC4 Titanium Alloy and 304 Stainless Steel with Ag-Base Filler Metal Based on a Hybrid Connection Mechanism, Opt. Laser Technol., 2020, 124, p 105957.

N.K. Adomako, J.O. Kim, S.H. Lee, K.H. Noh and J.H. Kim, Dissimilar Welding Between Ti–6Al–4V and 17–4PH Stainless Steel Using a Vanadium Interlayer, Mater. Sci. Eng. A, 2018, 732, p 378–397.

H. Liu and H. Fujii, Ultralow Rotation Speed Produces High-Quality Joint in Dissimilar Friction Welding of Ti–6Al–4V Alloy and SUS316L Stainless Steel, Mater. Sci. Eng. A, 2021, 800, p 140303.

N. Kahramana, B. Gülen and F. Findik, Joining of Titanium/Stainless Steel by Explosive Welding and Effect on Interface, J. Mater. Process. Technol., 2005, 169(2), p 127–133.

X.J. Yuan, G.M. Sheng, B. Qin, W.Z. Huang and B. Zhou, Impulse Pressuring Diffusion Bonding of Titanium Alloy to Stainless Steel, Mater. Charact., 2008, 59(7), p 930–936.

L. Jhe-Yu, N. Shoichi and K. Toshihiko, Interfacial Phenomena During Ultrasonic Welding of Ultra-Low-Carbon Steel and Pure Ti, Scripta Mater., 2020, 178, p 218–222.

Y. Zhang, Y. Chen, J. Zhou, D. Sun and X. Gu, Forming Mechanism and Mechanical Property of Pulsed Laser Welded Ti Alloy and Stainless Steel Joint Using Copper as Interlayer, J. Mater. Res. Technol., 2020, 9(2), p 1425–1433.

W. Ting, Z. Binggang and F. Jicai, Influences of Different Filler Metals on Electron Beam Welding of Titanium Alloy to Stainless Steel, Trans. Nonferrous Metals Soc. China, 2014, 24(1), p 108–114.

Yu. Xiaohua, D. Xiang, Li. Ruyan, Z. Kaomin, Z. Yan, Ge. Jie and L. Shuhe, Interface Analysis of Ti-304SS Clad Plate by Transient Liquid Phase Diffusion Bonding, Rare Metal Mater. Eng., 2017, 46(10), p 3156–3189.

M. Gao, S.W. Mei, Z.M. Wang, X.Y. Li and X.Y. Zeng, Characterisation of Laser Welded Dissimilar Ti/Steel Joint Using Mg Interlayer, Sci. Technol. Weld. Joining, 2012, 17(4), p 269–276.

A. Evren and K. Nizamettin, Diffusion Bonding of Commercially Pure Titanium to Low Carbon Steel Using a Silver Interlayer, Mater. Charact., 2008, 59(10), p 1481–1490.

Lu. Zhang Pengxian and C.P. Jianqiang, Type and Thickness of Copper Foil on Microstructure and Properties of Resistance Spot Welded Joints of Titanium/Steel, Mater. Mech. Eng., 2021, 45(3), p 46–51.

Li. Yongbing, L. Zhongqin, L. Xinmin and C. Guanlong, Analysis of Nugget Formation Process in Resistance Spot Welding Based on Magnetic Fluid Dynamics Theory, Trans. China Weld. Inst., 2006, 27(7), p 41–44.

R. Qiu, S. Satonaka and C. Iwamoto, Mechanical Properties and Microstructures of Magnesium Alloy AZ31B Joint Fabricated by Resistance Spot Welding With Cover Plates [J], Sci. Technol. Weld. Joining, 2009, 14(8), p 691–697.

Acknowledgments

The authors gratefully acknowledge funding from the International Cooperation Project of Henan Province (Grant No. 182102410066).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Liu, C., Zhang, J., Shi, H. et al. Influence of Interlayer Nb on the Performance of Joint Between Titanium and Steel Welded by Resistance Spot Welding. J. of Materi Eng and Perform 31, 1155–1162 (2022). https://doi.org/10.1007/s11665-021-06229-7

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-021-06229-7