Abstract

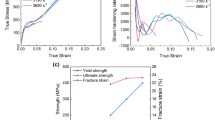

A new severe plastic deformation technique, forward extrusion and twist deformation, was adopted to manufacture magnesium (Mg) alloys at different temperatures. The microstructure evolution and mechanical properties of extruded AQ80 alloy were investigated. The strain distribution in FETD extrusion was simulated with finite element simulation software. The extruded samples exhibit finer grain sizes, weaker basal textures, higher recrystallized volume fractions and higher strengths than the traditional forward extrusion samples. This technology can refine the microstructure and improve the mechanical properties of Mg alloys. At lower temperatures, the grain size is smaller with a finer second phase, which is detected as Mg17AL12. Mg17AL12 has a particle-stimulated nucleation effect and a retarding effect on grain growth, resulting in much finer DRXed grains. Due to the effects of fine-grained strengthening and second phase strengthening, the strength and elongation of AQ80 alloy can be improved significantly.

Similar content being viewed by others

References

Z.R. Zeng, N. Stanforda, C.H.J. Daviesb, J.F. Nie, and N. Birbilis, Magnesium Extrusion Alloys: A Review of Developments and Prospects, Int. Mater. Rev., 2019, 64, p 27–62

D.F. Shi, M.T. Pérez-Prado, and C.M. Cepeda-Jiménez, Effect of Solutes on Strength and Ductility of Mg Alloys, Acta Mater., 2019, 180, p 218–230

E.A.A. Abd, Y. Xu, S. Ha, and S.H. Zhang, Computational Homogenization of Tensile Deformation Behaviors of a Third Generation Al-Li Alloy 2060-T8 Using Crystal Plasticity Finite Element Method, Mater. Sci. Eng. A, 2018, 731, p 583–594

G. Chen, X.S. Chang, J.X. Zhang, Y. Jin, C. Sun, Q. Chen, and Z.D. Zhao, Microstructures and Mechanical Properties of In-Situ Al3Ti/2024 Aluminum Matrix Composites Fabricated by Ultrasonic Treatment and Subsequent Squeeze Casting, Met. Mater. Int., 2019. https://doi.org/10.1007/s12540-019-00396-y

Y. Wang, F. Li, X.W. Li, and W.B. Fang, Unusual Texture Formation and Mechanical Property in AZ31 Magnesium Alloy Sheets Processed by CVCDE, J. Mater. Process. Technol., 2019. https://doi.org/10.1016/j.jmatprotec.2019.116360

Z.R. Zeng, Y.M. Zhu, R.L. Liu, S.W. Xu, C.H.J. Davies, J.F. Nie, and N. Birbilis, Achieving Exceptionally High Strength in Mg-3Al-1Zn-0.3Mn Extrusions Via Suppressing Intergranular Deformation, Acta Mater., 2018, 160, p 97–108

Z.J. Yu, C. Xu, J. Meng, and S. Kamado, Microstructure Evolution and Mechanical Properties of a High Strength Mg-11.7Gd-4.9Y-0.3Zr (wt%) ALLOY prepared by Pre-Deformation Annealing, Hot Extrusion and Ageing, Mater. Sci. Eng. A, 2017, 703, p 348–358

X.Y. Liu, L.W. Lu, K. Sheng, Y. Xiang, and Z.Q. Wu, Effect of Pre-compression on Microstructure Evolution of AQ80 Magnesium Alloy in Forward Extrusion and Twist Deformation, JOM, 2019, 71, p 4726–4736

Z. Yu, Y.D. Huang, X. Qiu, G.F. Wang, F. Meng, N. Hort, and J. Meng, Fabrication of a High Strength Mg-11Gd-4.5Y-1Nd-1.5Zn–0.5Zr (wt%) Alloy by Thermomechanical Treatments, Mater. Sci. Eng. A, 2015, 622, p 121–130

C. Xu, M.Y. Zheng, S.W. Xu, K. Wu, E.D. Wang, S. Kamado, G.J. Wang, and X.Y. Lv, Ultra High-Strength Mg-Gd-Y-Zn-Zr Alloy Sheets Processed by Large-Strain Hot Rolling and Ageing, Mater. Sci. Eng. A, 2012, 547, p 93–98

Y. Huang, Y. Wang, X. Meng, L. Wan, J. Cao, L. Zhou, and J. Feng, Dynamic Recrystallization and Mechanical Properties of Friction Stir Processed Mg-Zn-Y-Zr Alloys, J. Mater. Process. Technol., 2017, 249, p 331–338

K. Narooei and T.A. Karimi, A New Model for Prediction the Strain Field and Extrusion Pressure in ECAE Process of Circular Cross Section, Appl. Math. Model., 2010, 34, p 1901–1917

T. Wang, H. Zheng, R. Wu, J. Yang, X. Ma, and M. Zhang, Preparation of Fine-Grained and High-Strength Mg-8Li-3Al-1Zn Alloy by Accumulative roll Bonding, Adv. Eng. Mater., 2016, 18, p 304–311

Q. Wang, Y. Mu, J. Lin, L. Zhang, and H.J. Roven, Strengthening and Toughening Mechanisms of an Ultrafine Grained Mg-Gd-Y-Zr Alloy Processed by Cyclic Extrusion and Compression, Mater. Sci. Eng. A, 2017, 699, p 26–30

R. Alizadeh, R. Mahmudi, A. Ngan, Y. Huang, and T. Langdon, Super Plasticity of a Nano-Grained Mg-Gd-Y-Zr Alloy Processed by High-Pressure Torsion, Mater. Sci. Eng. A, 2016, 651, p 786–794

T.Z. Han, G.S. Huang, Q.Y. Deng, G.G. Wang, B. Jiang, A. Tang, Y.T. Zhu, and F.S. Pan, Grain Refining and Mechanical Properties of AZ31 Alloy Processed by Accumulated Extrusion Bonding, J. Alloys Compd., 2018, 745, p 599–608

J.T. Wang, R.B. Figueiredo, and T.G. Langdon, Twist Extrusion: Fundamentals and Applications, Mater. Sci. Forum, 2010, 667–669, p 31–37

S.R. Bahadori, S.A. Asghar, and A. Mousavi, The Evolution of Homogeneity in a Transverse Cross Section of Aluminum Alloy Profile Deformed by Twist Extrusion, JOM, 2012, 64, p 593–599

M.I. Latypov, I.V. Alexandrov, Y.E. Beygelzimer, S. Lee, and H.S. Kim, Finite Element Analysis of Plastic Deformation in twist Extrusion, Comp. Mater. Sci., 2012, 60, p 194–201

F. Rahimi, A.R. Eivani, and M. Kiani, Effect of Die Design Parameters on the Deformation Behavior in Pure Shear Extrusion, Mater. Design., 2015, 83, p 144–153

S.A.A. Akbari Mousavi, Sh Ranjbar Bahadori, and A.R. Shahab, Numerical Experimental Studies of the Plastic Strains Distribution Using Subsequent Direct Extrusion After Three Twist Extrusion Passes, Mater. Sci. Eng. A, 2010, 527, p 3967–3974

S.A.A.A. Mousavi and S.R. Bahador, Investigation and Numerical Analysis of Strain Distribution in the Twist Extrusion of Pure Aluminum, JOM, 2011, 63, p 69–76

Y. Liu, F. Li, and H.W. Jiang, Microstructural Analysis and Mechanical Properties of AZ31 Magnesium Alloy Prepared by Alternate Extrusion (AE), Int. J. Adv. Manuf. Technol., 2017, 92, p 4293–4301

Y. Beygelzimer, V. Varyukhin, S. Synkov, and D. Orlov, Useful Properties of Twist Extrusion, Mater. Sci. Eng. A, 2009, 53, p 14–17

V. Varyukhin, Y. Beygelzimer, S. Synkov, and D. Orlov, Application of Twist Extrusion, Mater. Sci. Forum, 2006, 503–504, p 335–339

H.J. Hu, Y.L. Ying, Z.W. Ou, and X.Q. Wang, Comparisons of Microstructures and Texture and Mechanical Properties of Magnesium Alloy Fabricated by Compound Extrusion and Direct Extrusion, Mater. Sci. Eng. A, 2017, 695, p 360–366

R. Yuan, Z. Wu, H. Cai, L. Zhao, and X.P. Zhang, Effects of Extrusion Parameters on Tensile Properties of Magnesium Alloy Tubes Fabricated Via Hydrostatic Extrusion Integrated with Circular ECAP, Mater. Des., 2016, 101, p 131–136

D. Orlov, Y. Beygelzimer, S. Synkov, V. Varyukhin, N. Tsuji, and Z.J. Horita, Plastic Flow, Structure and Mechanical Properties in Pure Al Deformed by Twist Extrusion, Mater. Sci. Eng. A, 2009, 519, p 105–111

L.W. Lu, C.M. Liu, J. Zhao, W.B. Zeng, and Z.C. Wang, Modification of Grain Refinement and Texture in AZ31 Mg Alloy by a New Plastic Deformation Method, J. Alloys Compd., 2015, 628, p 130–134

H. Zendehdel and A. Hassani, Influence of Twist Extrusion Process on Microstructure and Mechanical Properties of 6063 Aluminum Alloy, Mater. Des., 2012, 37, p 13–18

L. Chen, M.C. Liang, G.Q. Zhao, J.X. Zhou, and C.S. Zhang, Microstructure Evolution of AZ91 Alloy During Hot Extrusion Process with Various Ram Velocity, Vacuum, 2018, 150, p 136–143

X. Li, F. Jiao, T. Al-Samman, and G.S. Chowdhury, Influence of Second-Phase Precipitates on the Texture Evolution of Mg-Al-Zn Alloys During Hot Deformation, Scr. Mater., 2012, 66, p 159–162

Y. Chen, R. Zhang, T. Zhou, L. Hu, J. Tu, L.X. Shi, Y. Zhi, and L.W. Lu, Influence of Extrusion Speed on the Microstructure Evolution, Interface Bonding and Mechanical Response of Mg MB26/Al 7075 Composite Rod, Acta. Metall. Sin-Engl., 2019, 32, p 253–262

M.T. Pérez-Prado and O.A. Ruano, Texture Evolution During Grain Growth in Annealed MG AZ61 Alloy, Scr. Mater., 2003, 48, p 59–64

J. Bohlen, S.B. Yi, J. Swiostek, D. Letzig, H.G. Brokmeier, and K.U. Kainer, Microstructure and Texture Development During Hydrostatic Extrusion of Magnesium Alloy AZ31, Scr. Mater., 2005, 53, p 259–264

L.W. Lu, C.M. Liu, Z.R. Yin, J. Zhao, L. Gan, and Z.C. Wang, Double Extrusion of Mg-Al-Zn Alloys, Int. J. Adv. Manuf. Technol., 2017, 89, p 869–875

C. Xu, T. Nakata, G.H. Fan, K. Yamanaka, G.Z. Tang, L. Geng, and S. Kamado, Effect of Partially Substituting Ca with Mischmetal on the Microstructure and Mechanical Properties of Extruded Mg-Al-Ca-Mn-Based Alloys, Acta. Metall. Sin-Engl., 2019, 32, p 205–217

L. Tang, Y. Zhao, R.K. Islamgaliev, C.Y.A. Tsao, R.Z. Valiev, E.J. Lavernia, and Y.T. Zhu, Enhanced Strength and Ductility of AZ80 Mg Alloys by Spray Forming and ECAP, Mater. Sci. Eng., A, 2016, 670, p 280–291

H.K. Lin, J.C. Huang, and T.G. Langdon, Relationship Between Texture and Low Temperature Superplasticity in an Extruded AZ31 Mg Alloy Processed by ECAP, Mater. Sci. Eng., A, 2005, 402, p 250–257

D.L. Yu, D.F. Zhang, Y.X. Luo, J. Sun, J.Y. Xu, and F.S. Pan, Microstructure Evolution During High Cycle Fatigue in Mg-6Zn-1Mn Alloy, Mater. Sci. Eng. A, 2016, 658, p 99–108

Acknowledgments

This work was partly supported by National Natural Science Foundation of China (Grant Nos. 51975207, 51728202), Hunan Provincial Natural Science Foundation for Excellent Young Scholars of China (Grant No. 2019JJ30010) and the Scientific Research Fund of the Hunan Provincial Education Department (Grant No. 17B089).

Author information

Authors and Affiliations

Corresponding authors

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Liu, X., Lu, L., Ma, M. et al. Microstructure Evolution and Mechanical Properties of AQ80 Alloy During Forward Extrusion and Twist Deformation. J. of Materi Eng and Perform 29, 6774–6783 (2020). https://doi.org/10.1007/s11665-020-05104-1

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-020-05104-1