Abstract

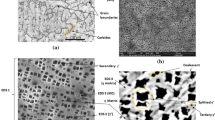

The occurrence of hot cracks in the blades of Ni-based superalloy turbocharger wheels is thought to be closely related to eutectic characteristics. Different alloys that are susceptible to hot tearing, namely K418, K419 and K424, were studied. SEM was used to obtain the microstructure of the alloys. DSC, isothermal solidification quenching process and EPMA were conducted to determine the relationship between the eutectic characteristics and solidification process, segregation behavior and dendrite coalescence. The results show that a large volume fraction of γ/γ′ eutectic indicates a wide-temperature solidification range and severe segregation. A large γ/γ′ eutectic size is a result of element segregation and poor dendrite coalescence. Ti is thought to promote the formation of a large isolated residual liquid pool and lead to a large eutectic size, leading to the poor coalescence behavior of the dendrites. The volume fraction and size of the γ/γ′ eutectic were considered, and a eutectic influence factor (E) was defined to evaluate the effect of eutectic characteristics on hot tearing in cast superalloys. It was found that a high E corresponds to high hot-tearing susceptibility.

Similar content being viewed by others

References

D.S. Wen, S.R. Wang, G.Q. Wang et al., Fabrication Processing and Mechanical Properties of Si3N4 Ceramic Turbocharger Wheel, Ceram. Int., 2018, 44(9), p 10596–10603

J. Grodzki, N. Hartmann, R. Rettig et al., Effect of B, Zr, C on Hot Tearing of a Directionally Solidified Nickel-Based Superalloy, Metall. Mater. Trans. A, 2016, 47(6), p 2914–2926

Z.X. Shi, J.X. Dong, M.C. Zhang et al., Solidification Characteristics and Segregation Behavior of Ni-Based Superalloy K418 for Auto Turbocharger Turbine, J. Alloy. Compd., 2013, 571, p 168–177

G. Liu, J. Salvat-Cantó, S. Winwood et al., The Effects of Microstructure and Microtexture Generated During Solidification on Deformation Micromechanism in IN713C Nickel-Based Superalloy, Acta Mater., 2018, 148, p 391–406

Z.X. Shi, J.X. Dong, M.C. Zhang et al., Solidification Characteristics and Hot Tearing Susceptibility of Ni-Based Superalloys for Turbocharger Turbine Wheel, Trans. Nonferrous Metals Soc. China, 2014, 24(9), p 2737–2751

Z. Zhao, J.X. Dong, M.C. Zhang et al., Microstructure and Susceptibility to Hot Tearing of K424 Nickel-Based Superalloys for Turbocharger Turbine Wheels, Chin. J. Eng., 2016, 38(10), p 1429–1437

J.J. Xu, X. Lin, P.F. Guo et al., The Initiation and Propagation Mechanism of the Overlapping Zone Cracking During Laser Solid Forming of IN-738LC Superalloy, J. Alloy. Compd., 2018, 749, p 859–870

Y. Li, K. Chen, and N. Tamura, Mechanism of Heat Affected Zone Cracking in Ni-Based Superalloy DZ125L Fabricated by Laser 3D Printing Technique, Mater. Des., 2018, 150, p 171–181

S.R. Wang, P.Q. Guo, and L.Y. Yang, Centrifugal Precision cast TiAl Turbocharger Wheel Using Ceramic Mold, J. Mater. Process. Technol., 2008, 204(1–3), p 492–497

A. Szczotok and H. Matysiak, Influence of Constituents of Shell Mold on the Morphology and Chemical Composition of Carbides Occurring in IN 713C Superalloy Castings, J. Mater. Eng. Perform., 2014, 23(8), p 2748–2759

J.W. Liu and S. Kou, Crack Susceptibility of Binary Aluminum Alloys During Solidification, Acta Mater., 2016, 110, p 84–94

H. Akhyar, V. Malau, Suyitno et al., Hot Tearing Susceptibility of Aluminum Alloys Using CRCM-Horizontal Mold, Results Phys., 2017, 7, p 1030–1039

J. Zhang and R.F. Singer, Hot Tearing of Nickel-Based Superalloys During Directional Solidification, Acta Mater., 2002, 50(7), p 1869–1879

G. Agarwal, M. Amirthalingam, S.C. Moon et al., Experimental Evidence of Liquid Feeding During Solidification of A Steel, Scripta Mater., 2018, 146, p 105–109

H.N. Moosavy, M.R. Aboutalebi, S.H. Seyedein et al., A Solidification Model for Prediction of Castability in the Precipitation-Strengthened Nickel-Based Superalloys, J. Mater. Process. Technol., 2013, 213(11), p 1875–1884

M.C. Flemings, Solidification Processing, Mcgraw-Hill College, New York, 1974

T.W. Clyne and G.J. Davies, Influence of composition on solidification cracking susceptibility in binary alloy systems, Br. Foundryman, 1981, 74, p 65–73

K. Heck, R. Blackford, and R.F. Singer, Castability of Directionally Solidified Nickel Base Superalloys, Metal Sci. J., 1999, 15(2), p 213–220

M. Rappaz, A. Jacot, and W.J. Boettinger, Last-Stage Solidification of Alloys: Theoretical Model of Dendrite-Arm And Grain Coalescence, Metall. Mater. Trans. A, 2003, 34(3), p 467–479

Z. Jian, Effect of Ti and Ta on Hot Cracking Susceptibility of Directionally Solidified Ni-Based Superalloy IN792, Scripta Mater., 2003, 48(6), p 677–681

Y.Z. Zhou and A. Volek, Effect of Carbon Additions on Hot Tearing of a Second Generation Nickel-Base Superalloy, Mater. Sci. Eng., A, 2008, 479(1–2), p 324–332

Y.Z. Zhou, A. Volek, and R.F. Singer, Effect of Grain Boundary Characteristics on Hot Tearing in Directional Solidification of Superalloys, J. Mater. Res., 2006, 21(9), p 2361–2370

J. Zhang and R.F. Singer, Effect of Zr and B on Castability of Ni-Based Superalloy IN792, Metall. Mater. Trans. A, 2004, 35(4), p 1337–1342

Y.Z. Zhou and A. Volek, Effect of Dendrite Arm Spacing on Castability of a Directionally Solidified Nickel Alloy, Scripta Mater., 2007, 56(6), p 537–540

Academic Committee of the Superalloys, China Superalloys Handbook, Standards Press of China, Beijing, 2012

L. Cao, L. Yao, Y.Z. Zhou et al., Formation of the Surface Eutectic of a Ni-Base Single Crystal Superalloy, J. Mater. Sci. Technol., 2016, 33(4), p 347–351

F. Wang, D. Ma, J. Zhang et al., Solidification Behavior of a Ni-Based Single Crystal CMSX-4 Superalloy Solidified by Downward Directional Solidification Process, Mater. Charact., 2015, 101, p 20–25

G. Li, B. Chen, Z.H. Du et al., Investigation of Solidification and Segregation Characteristics of Cast Ni-Base Superalloy K417G, J. Mater. Sci. Technol., 2018, 34(3), p 541–550

M. Mostafaei and S.M. Abbasi, Solutioning and Solidification Process Control in Ta-Modified CM247 LC Superalloy, J. Mater. Process. Tech., 2016, 231, p 113–124

S.M. Seo, H.W. Jeong, Y.K. Ahn et al., A Comparative Study of Quantitative Microsegregation Analyses Performed During the Solidification of the Ni-Base Superalloy CMSX-10, Mater. Charact., 2014, 89(3), p 43–55

J.L. Zhang, Z.H. Zhao, Y.H. Kong et al., Crack Initiation and Propagation Mechanisms During Thermal Fatigue in Directionally Solidified Superalloy DZ125, Int. J. Fatigue, 2019, 119, p 355–366

X.F. Yuan, J.T. Wu, J.T. Li et al., Effects of Initial Microstructures on the Microstructural Evolution and Corresponding Mechanical Property of K424 Superalloy after Overheating Exposure, Mater. Sci. Eng., A, 2019, 743, p 40–56

R.A. Hobbs, S. Tin, and C.M.F. Rae, A Castability Model Based on Elemental Solid-Liquid Partitioning in Advanced Nickel-Base Single-Crystal Superalloys, Metall. Mater. Trans. A, 2005, 36(10), p 2761–2773

A. Heckl, R. Rettig, and R.F. Singer, Solidification Characteristics and Segregation Behavior of Nickel-Base Superalloys in Dependence on Different Rhenium and Ruthenium Contents, Metall. Mater. Trans. A, 2010, 41(1), p 202–211

Y.Z. Zhou and A. Volek, Influence of Solidification Conditions on Grain Boundary Cohesion in the Mushy Zone During Directional Solidification of Nickel Base Superalloy, Metal Sci. J., 2007, 23(3), p 297–302

J.C. Lippold, S.D. Kiser, and J.N. Dupont, Welding Metallurgy and Weldability of Nickel-base alloys, Wiley, Hoboken, 2009

E. Chauvet, P. Kontis, E.A. Jägle et al., Hot cracking mechanism affecting a non-weldable Ni-based superalloy produced by Selective Electron Beam Melting, Acta Mater., 2018, 142, p 82–94

F.X. Yang, E.Z. Liu, Z. Zhi et al., Influence of Ti Content on Microstructure, Mechanical Properties and Castability of Directionally Solidified Superalloy DZ125L, Mater. Des., 2014, 61, p 41–49

Y.L. Wang, Z.H. Huang, X.H. Zhao et al., Effect of Elements on Hot Tearing of Directionally Solidified Ni-Based Superalloys, Adv. Mater. Res., 2011, 150–151, p 975–978

Acknowledgments

This work was supported by National Natural Science Foundation of China No. 51571012.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Zhao, Z., Dong, J.X. Effect of Eutectic Characteristics on Hot Tearing of Cast Superalloys. J. of Materi Eng and Perform 28, 4707–4717 (2019). https://doi.org/10.1007/s11665-019-04230-9

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-019-04230-9