Abstract

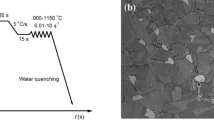

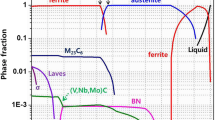

The hot deformation behavior of a Fe-11Mn-10Al-0.9C duplex low-density steel has been investigated, based on a series of isothermal compression tests at temperatures of 800-1100 °C and strain rates of 0.001-10 s−1. At relatively lower temperatures, with austenite decomposing, continuous dynamic recrystallization of ferrite and the formation of inter-granular κ-carbide were responsible for significant softening. At high deformation temperature where austenite was a dominant phase, dynamic recrystallization (DRX) is the restoration mechanism. Processing maps were developed at different plastic strains employing dynamic materials model and further verified through microstructural characterization. The optimal hot deformation condition at a large strain (0.7) was identified as deformation temperature of 950-1100 °C and strain rate of 0.01-1.0 s−1. In this domain, the original coarse grains could be replaced by the fine and uniform recrystallized grains, indicating that the high efficiency was dissipated by DRX. Meanwhile, two instable regions resulted from the formation of inter-granular κ-carbides and necklace structure should be avoided during hot processing.

Similar content being viewed by others

References

S.S. Sohn, H. Song, B. Suh, J.H. Kwak, B.J. Lee, N.J. Kim, and S. Lee, Novel Ultra-High-Strength (Ferrite + Austenite) Duplex Lightweight Steels Achieved by Fine Dislocation Substructures (Taylor Lattices) Grain Refinement, and Partial Recrystallization, Acta Mater., 2015, 96, p 301–310

H. Song, J. Yoo, S.H. Kim, S.S. Sohn, M. Koo, N.J. Kim, and S. Lee, Novel Ultra-High-Strength Cu-Containing Medium-Mn Duplex Lightweight Steels, Acta Mater., 2017, 135, p 215–225

N. Kisku, A. Sarkar, K.K. Ray, and S. Mandal, Development and Characterization of a Novel Ti-Modified High-Si Medium-Mn Steel Possessing Ultra-High Strength and Reasonable Ductility After Hot Rolling, J. Mater. Eng. Perform., 2018, 27, p 4077–4089

L. Zhang, X. Huang, Y. Wang, Y. Guo, G. Dai, and D. Li, Achieving Excellent Strength-Ductility and Impact Toughness Combination by Cyclic Quenching in Medium Mn TRIP-Aided Steel, J. Mater. Eng. Perform., 2018, 27, p 5769–5777

K. Choi, C. Seo, H. Lee, S.K. Kim, J.H. Kwak, K.G. Chin, K.T. Park, and N.J. Kim, Effect of Aging on the Microstructure and Deformation Behavior of Austenite Base Lightweight Fe-28Mn-9Al-0.8C Steel, Scripta Mater., 2010, 63, p 1028–1031

G. Frommeyer and U. Brüx, Microstructures and Mechanical Properties of High-Strength Fe-Mn-Al-C Light-Weight TRIPLEX Steels, Steel Res. Int., 2006, 77, p 627–633

W.K. Choo, J.H. Kim, and J.C. Yoon, Microstructural Change in Austenitic Fe-30.0 wt%Mn-7.8 wt%Al-1.3 wt%C Initiated by Spinodal Decomposition and Its Influence on Mechanical Properties, Acta Mater., 1997, 45, p 4877–4885

D. Liu, M. Cai, H. Ding, and D. Han, Control of Inter/Intra-Granular κ-Carbides and Its Influence on Overall Mechanical Properties of a Fe-11Mn-10Al-1.25C Low Density Steel, Mater. Sci. Eng., A, 2018, 715, p 25–32

S.Y. Han, S.Y. Shin, S.G. Lee, N.J. Kim, J.H. Kwak, and K.G. Chin, Effect of Carbon Content on Cracking Phenomenon Occurring during Cold Rolling of Three Light-weight Steel Plates, Metall. Mater. Trans. A, 2012, 42, p 138–146

S.S. Sohn, B.-J. Lee, S. Lee, and J.-H. Kwak, Effects of Aluminum Content on Cracking Phenomenon Occurring during Cold Rolling of Three Ferrite-Based Lightweight Steel, Acta Mater., 2013, 61, p 5626–5635

J.D. Yoo and K. Park, Microband-Induced Plasticity in a High Mn-Al-C Light Steel, Mater. Sci. Eng., A, 2008, 496, p 417–424

O.A. Zambrano, J. Valdés, Y. Aguilar, J.J. Coronado, S.A. Rodríguez, and R.E. Logé, Hot Deformation of a Fe-Mn-Al-C Steel Susceptible of κ-Carbide Precipitation, Mater. Sci. Eng., A, 2017, 689, p 269–285

B.H. Sun, H. Aydin, F. Fzaeli, and S. Yue, Microstructure Evolution of a Medium Manganese Steel during Thermomechanical Processing, Metall. Mater. Trans. A, 2016, 47, p 1782–1791

Y.P. Li, R.B. Song, E.D. Wen, and F.Q. Yang, Hot Deformation and Dynamic Recrystallization Behavior of Austenite-Based Low-density Fe-Mn-Al-C Steel, Acta Metall. Sin. (Engl. Lett.), 2016, 29, p 441–449

T. Siegmund, E. Werner, and F.D. Fischer, On the Thermomechanical Deformation Behavior of Duplex-Type Materials, J. Mech. Phys. Solids, 1995, 43, p 495–532

A. Mohamadizadeh, A. Zarei-Hanzaki, H.R. Abedi, S. Mehtonen, and D. Porter, Hot Deformation Characterization of Duplex Low-density Steel through 3D Processing Map Development, Mater. Charact., 2015, 107, p 293–301

P. Cizek, The Microstructure Evolution and Softening Processes during High Temperature Deformation of a 21Cr-10Ni-3Mo Duplex Stainless Steel, Acta Mater., 2016, 106, p 129–143

M.C. Li, H. Chang, P.W. Kao, and D. Gan, The Effect of Mn and Al Contents on the Solvus of κ Phase in Austenitic Fe-Mn-Al-C Alloys, Mater. Chem. Phys., 1999, 59, p 96–99

R. Raj, Development of a Processing Map for Use in Warm-forming and Hot-forming Processes, Metall. Trans. A, 1981, 12, p 1089–1097

K.A. Babu, S. Mandal, C.N. Athreya, B. Shakthipriya, and V.S. Sarma, Hot Deformation Characteristics and Processing Map of a Phosphorous Modified Super Austenitic Stainless Steel, Mater. Design, 2017, 115, p 262–275

M.K. Mishra, I. Balasundar, A.G. Rao, B.P. Kashyap, and N. Prabhu, On the High Temperature Deformation Behaviour of 2507 Super Duplex Stainless Steel, J. Mater. Eng. Perform., 2017, 26, p 802–812

N. Park, A. Shibata, D. Terada, and N. Tsuji, Flow Stress Analysis for Determining the Critical Condition of Dynamic Ferrite Transformation in 6Ni-0.1C Steel, Acta Mater., 2013, 61, p 163–173

W. Zhang, S. Sun, D. Zhao, B. Wang, Z. Wang, and W. Fu, Hot Deformation Behavior of a Nb-containing 316LN Stainless Steel, Mater. Design, 2011, 32, p 4173–4179

D. Ponge and G. Gottstein, Necklace Formation during Dynamic Recrystallization: Mechanisms and Impact on Flow Behavior, Acta Mater., 1998, 46, p 69–80

A. Momeni and K. Dehghani, Hot Working Behavior of 2205 Austenite-Ferrite Duplex Stainless Steel Characterized by Constitutive Equations and Processing Maps, Mater. Sci. Eng., A, 2011, 528, p 1448–1454

F.J. Humphreys and M. Hatherly, Recrystallization and Related Annealing Phenomena, 2nd ed., Elsevier Science, New York, 2004

B. Eghbali, Effect of Strain Rate on the Microstructural Development through Continuous Dynamic Recrystallization in a Microalloyed Steel, Mater. Sci. Eng., A, 2010, 527, p 3402–3406

Y.V.R.K. Prasad, T. Seshacharyulu, S.C. Medeiros, and W.G. Frazier, Effect of Prior β-Grain Size on the Hot Deformation Behavior of Ti-6Al-4 V: Coarse vs Coarser, J. Mater. Eng. Perform., 2000, 9, p 153–160

S.A. Sajjadi, A. Chaichi, H.R. Ezatpour, A. Maghsoudlou, and M.A. Kalaie, Hot Deformation Processing Map and Microstructural Evaluation of the Ni-Based Superalloy IN-738LC, J. Mater. Eng. Perform., 2016, 25, p 1269–1275

Y. Lou, H. Chen, C. Ke, and M. Long, Hot Tensile Deformation Characteristics and Processing Map of Extruded AZ80 Mg Alloys, J. Mater. Eng. Perform., 2014, 23, p 1904–1914

Y. Xiao, H. Liu, D. Yi, J. Le, H.Z. Jiang, X. Zhao, Z. Chen, J. Wang, and Q. Gao, High-Temperature Deformation Behavior of Ti-6Al-2Sn-4Zr-2Mo Alloy with Lamellar Microstructure Under Plane-Strain Compression, J. Mater. Eng. Perform., 2018, 27, p 4941–4954

E. Pu, W. Zheng, J. Xiang, Z. Song, and J. Li, Hot Deformation Characteristic and Processing Map of Superaustenitic Stainless Steel S32654, Mater. Sci. Eng., A, 2014, 598, p 174–182

S. Tan, Z. Wang, S. Cheng, Z. Liu, J. Han, and W. Fu, Processing Maps and Hot Workability of Super304H Austenitic Heat-Resistant Stainless Steel, Mater. Sci. Eng., A, 2009, 517, p 312–315

Y.V.R.K. Prasad and T. Seshacharyulu, Modelling of Hot Deformation for Microstructural Control, Int. Mater. Rev., 1998, 43, p 243–258

R. Ebrahimi and A. Najafizadeh, A New Method for Evaluation of Friction in Bulk Metal Forming, J. Mater. Process. Tech., 2004, 152, p 136–143

J. Seol, D. Raabe, P. Choi, H.S. Park, J.H. Kwak, and C.G. Park, Direct Evidence for the Formation of Ordered Carbides in a Ferrite-Based Low-Density Fe-Mn-Al-C Alloy Studied by Transmission Electron Microscopy and Atom Probe Tomography, Scripta Mater., 2013, 68, p 348–353

H. Ahamed and V. Senthilkumar, Hot Deformation Behavior of Mechanically Alloyed Al6063/0.75Al2O3/0.75Y2O3 Nano-Composite—A Study Using Constitutive Modeling and Processing Map, Mater. Sci. Eng., A, 2012, 539, p 349–359

M. Jafari and A. Najafizadeh, Correlation Between Zener-Hollomon Parameter and Necklace DRX during Hot Deformation of 316 Stainless Steel, Mater. Sci. Eng., A, 2009, 501, p 16–25

Acknowledgment

This work was financially supported by the Natural and Scientific Foundation of China (Grant No. 51474062 & U1760205).

Author information

Authors and Affiliations

Corresponding authors

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Liu, D., Ding, H., Cai, M. et al. Hot Deformation Behavior and Processing Map of a Fe-11Mn-10Al-0.9C Duplex Low-Density Steel Susceptible to κ-Carbides. J. of Materi Eng and Perform 28, 5116–5126 (2019). https://doi.org/10.1007/s11665-019-04200-1

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-019-04200-1