Abstract

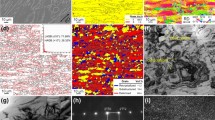

The heat treatment and cold rolling combinations have been carried out on titanium alloy Ti6Al2V2Zr1.5Mo, and microstructure evolution and mechanical behavior have been studied. Solution treatment below the β-transus temperature, followed by air cooling, resulted in higher microhardness/strength as compared to the same with water quenching. A sudden drop in microhardness/strength is observed in sample solution heat-treated above β-transus temperature followed by air cooling. The former is attributed to the additional presence of fine secondary α-phase formed by dynamic aging during air cooling as compared to water-quenched samples which did not have fine secondary α-phase. Solution treatment above β-transus temperature resulted in Widmanstatten microstructure with no significant fine secondary α in air-cooled samples. Among the studied conditions of cold rolling (CR), gain in strength of the alloy from annealed condition is significant with first 15% reduction and thereafter it is marginal for 30% reduction. Initiation of cracks at the edges has been observed in 30% CR. The microstructure of cold-rolled samples confirms the fragmentation of α-plates with the presence of high dislocation density. Heat treatment of cold-rolled samples resulted in significant reduction in strength from the as-cold-rolled conditions. The marginally lower strength than the as-received (annealed) or heat-treated alloy samples is due to the recrystallization in CR samples and the formation of Widmanstatten microstructure in air-cooled samples. The alloy does not have fine secondary α or regions with large dislocation density in this condition. The microstructure in the samples heat-treated (with air cooling) below as well as above β-transus temperature (after CR) is similar to air-cooled samples (without prior CR) with heat treatment above β-transus temperature. This indicates the reduction in recrystallization temperature with cold working, which is substantiated with the reduction in strength as well.

Similar content being viewed by others

References

M.J. Donachie, Jr., Titanium: A Technical Guide, ASM International, Metals Park, 2000

V.N. Moiseyev, Titanium Alloys, Russian Aircraft and Aerospace Applications, Taylor and Francis Group, Milton Park, 2006, p 80–82

S. Tamirisakandala, B.V. Vedam, and R.B. Bhat, Recent Advances in the Deformation Processing of Titanium Alloys, J. Mater. Eng. Perform., 2003, 12, p 661–673

D.R.N. Correa, F.B. Vicente, R.O. Araujo, M.L. Lourenco, P.A.B. Kuroda, M.A.R. Buzalaf, and C.R. Grandini, Effect of Substitutional Elements on the Microstructure of the Ti-15Mo-Zr and Ti-15Zr-Mo Systems Alloys, J. Mater. Res. Technol., 2015, 4(2), p 180–185

C. Huang, Y. Zhao, S. Xin, C.S. Tan, W. Zhou, Q. Li, and W. Zeng, High Cycle Fatigue Behavior of Ti-5Al-5Mo-5V-3Cr-1Zr Titanium Alloy with Lamellar Microstructure, Mater. Sci. Eng. A, 2017, 68, p 107–116

C. Veiga, J.P. Davim, and A.J.R. Loureiro, Properties and Applications of Titanium Alloy A Brief review, Rev. Adv. Mater. Sci., 2012, 32, p 133–148

H.M. Li, M.Q. Li, J. Luo, and K. Wang, Microstructure & Mechanical Properties of Heat Treated Ti-5Al-2Sn-2Zr-4Mo-4Cr, Trans. Non ferrous Met. Soc. China, 2015, 25, p 2893–2900

R. Charlie, Brooks: Heat Treatment, Structure and Properties of Nonferrous Alloys, American Society For Metals, Ohio, 1982

M.A. Imam, A.C. Fraker: Titanium Alloys as Implant Materials in Medical Applications of Titanium and its Alloys (STP 1272, S.A. Brown and J.E. Lemons American Society for Testing and Materials, 1996)

F. Wagner, N. Bozzolo, O. Van Landuyt, and T. Grosdidier, Evolution of Recrystallization Texture and Microstructure in Low Alloyed Titanium Sheets, Acta Mater., 2002, 50, p 1245–1259

F.M. Güçlü and H. Çimenoğlu, The Recrystallization Behaviour of CP-Titanium, Mater. Sci. For., 2004, 467–470, p 459–464

M. Li, Y. Geng, C. Chen, S. Pang, and T. Zhang, Effects of Cold-rolling Reduction on Microstructure and Mechanical Properties of Ti50Zr30Nb10Ta10 Alloy, Mater. Sci. For., 2016, 849, p 376–382

R.K. Gupta, V. Anil Kumar, C. Mathew, and G. Sudarshana Rao, Strain Hardening of Titanium Alloys Ti6Al4V Sheets with Prior Heat Treatment & Cold Working, Mater. Sci. Eng. A, 2016, 662, p 537–550

G. Choi and K. Lee, Effect of Cold Rolling on the Microstructural Evolution of New β-typed Ti-6Mo-6V-5Cr-3Sn-2.5Zr Alloys, Mater. Char., 2017, 123, p 67–74

J. Babu, A. Dutta, and A. Kumaraswamy, Experimental Studies on Effect of Temperature and Strain Rate on Deformation Behavior of Ti-6Al-4V Using Taguchi Method, Procedia Mater. Sci., 2014, 2014(6), p 1121–1130

G.E. Dieter, H.A. Kuhn, and S.L. Semiatin, Handbook of Workability and Process Design, ASM International, Materials Park, 2003

V.I. Muravev, A.V. Yakimov, and A.V. Chernyshev, Effect of Deformation, Welding and Electro Contact Heating on the Properties of Titanium Alloy VT20 in Pressed and Welded Structures, Met. Sci. Heat Treat., 2003, 45, p 419–422

V. Anil Kumar, R.K. Gupta, J. Paul Murugan, J. Srinath, Sushant K. Manwatkar, and S.V.S. Narayana Murty, Effect of Cooling Medium on Solution Treatment Response of Titanium Alloy Ti-5Al-5V-2Mo, Mater. Sci. For., 2015, 830–831, p 123–126

R.K. Gupta, V. Anil Kumar, U.V. Gururaja, K. Subramani, U. Prakash, K.V.A. Chakravarthi, P. Ramkumar, and P. Sarkar, Solution Treatment and Aging of Thick Rings from Titanium Alloy Ti6Al4V, Met. Sci. Heat Treat., 2015, 573–574, p 169–174

O.M. Ivasishin, P.E. Markovsy, S.L. Semiatin, and C.H. Ward, Aging Response of Coarse- and Fine- Grained Beta Titanium Alloys, Mater. Sci. Eng. A, 2005, 405, p 296–305

C.J. Boehlert, D.M. Dimiduk, and K.J. Hemker, The Phase Evaluation, Mechanical Behavior, and Microstructural Instability of Fully Lamellar Ti-46Al (at.%) Alloy, Scripta Mater., 2002, 46, p 259–267

A.K. Singh and R.A. Schwarzer, Effects of Mode of Deformation by Rolling on the Development of Texture in Binary Ti-Mn Alloys, Scripta Mater., 2001, 44, p 375–380

Z. Guo, S. Malinov, and W. Sha, Modelling β Transus Temperature of Titanium Alloys using Artificial Neural Network, Comput. Mater. Sci., 2005, 32(1), p 1–12

H. Takebe, K. Mori, K. Takahashi, H. Fujii, Effects of Thickness and Grain Size on Tensile Properties of Pure Titanium Thin Gauge Sheets, in Proceedings of the 13th World Conference on Titanium, The Minerals, Metals and Materials Society (2016), pp. 491–494

T. Fukumaru, H. Hidaka, T. Tsuchiyama, and S. Takaki, Effect of Wire Diameter and Grain Size on Tensile Properties of Austenitic Stainless Steel Wire, Bull Iron Steel Inst. Jpn., 2005, 91, p 828–833

O.D. Lai, W.K. Lu, and C.U.I. Xia, Dynamic Recrystallization of Ti-6Al-2Zr-1Mo-1V in Beta Forging Process, Trans. Nonferrous Met. Soc. China, 2012, 22(4), p 761–767

E.A. Metzbower, Stacking Fault Probability Determinations in HCP Ti-Al Alloys, Metall. Mater. Trans., 1971, 2(11), p 3099–3103

Z. Guo, A.P. Miodownik, N. Saunders, and J.P. Schillé, Influence of Stacking Fault Energy on High Temperature Creep of Alpha Titanium Alloys, Scripta Mater., 2006, 54(12), p 2175–2178

E.A. Holm, K.J. Healey, and C.C. Battaile, Coupled Computer Simulations of Recrystallization in Deformed Polycrystals, Mater. Sci. For., 2004, 467–470, p 641–646

F.J. Humphreys and M. Hatherly, Recrystallization and Related Annealing Phenomena, 2nd ed., Elsevier, New York, 2004

J. Go, W.J. Poole, M. Militzer, and M.A. Wells, Modelling Recovery and Recrystallisation during Annealing of AA 5754 Aluminium Alloy, Mater. Sci. Technol., 2003, 19(10), p 1361–1368

F.J. Humphreys, A Unified Theory of Recovery, Recrystallization and Grain Growth, based on the Stability and Growth of Cellular Microstructures-I. The Basic Model, Acta Mater., 1997, 45(10), p 4231–4240

M. Blicharski, S. Nourbakhsh, and J. Nutting, Structure and Properties of Plastically Deformed α-Ti, Met. Sci., 1979, 13(9), p 516–522

J.W. Won, T. Lee, S. Hong, Y. Lee, J.H. Lee, and C.S. Lee, Role of Deformation Twins in Static Recrystallization Kinetics of High-Purity Alpha Titanium, Met. Mater. Int., 2016, 22(6), p 1041–1048

Acknowledgments

Authors thank IFF and MMG, VSSC, for facility support, DGM/MPA, GM/MMA and DD/MME for guidance, and Director, VSSC, for kind permission to publish the work.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Gupta, R.K., Anil Kumar, V., Gaur, R. et al. Effect of Heat Treatment and Combination of Cold Rolling and Heat Treatment on Microstructure and Mechanical Properties of Titanium Alloy Ti6Al2V2Zr1.5Mo. J. of Materi Eng and Perform 27, 4405–4422 (2018). https://doi.org/10.1007/s11665-018-3576-3

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-018-3576-3