Abstract

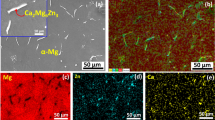

In the present study, a new pack carburization technique for titanium has been investigated. The aim of this treatment is to produce a titanium carbide/oxycarbide layer atop of an extended oxygen diffusion zone [α-Ti(O)]. The effects of treatment temperature and pack composition have been investigated in order to determine the optimal conditions required to grant the best tribological response. The resulting structural features were investigated with particular interest in the carbon and oxygen concentrations across the samples cross section. The optimization showed that a temperature of 925 °C with a pack composition of 1 part carbon to 1 part energizer produced surface capable of withstanding a contact pressure of ≈ 1.5 GPa for 1 h. The process resulted in TiC surface structure which offers enhanced hardness (2100 HV) and generates a low friction coefficient (μ ≈ 0.2) when in dry sliding contact with an alumina (Al2O3) ball. The process also produced an extended oxygen diffusion zone that helps to improve the load bearing capacity of the substrate.

Similar content being viewed by others

References

S. Kumar, T.S.N.S. Narayanan, S.G.S. Raman, and S.K. Seshadri, Fretting Corrosion Behaviour of Thermally Oxidized CP-Ti in Ringer’s Solution, Corros Sci, 2010, 52, p 711–721

É. Martin, M. Azzi, G.A. Salishchev, and J. Szpunar, Influence of Microstructure and Texture on the Corrosion and Tribocorrosion Behavior of Ti-6Al-4V, Tribol Int, 2010, 43, p 918–924

D.G. Bansal, O.L. Eryilmaz, and P.J. Blau, Surface Engineering to Improve the Durability and Lubricity of Ti-6Al-4V Alloy, Wear, 2011, 271, p 2006–2015

A. Bloyce, Surface Engineering of Titanium Alloys for Wear Protection, Proc Inst Mech Eng J, 1998, 212, p 467–476

H. Dong and T. Bell, Enhanced Wear Resistance of Titanium Surfaces by a New Thermal Oxidation Treatment, Wear, 2000, 238, p 131–137

C. Lee, A. Sanders, N. Tikekar, and K.S.R. Chandran, Tribology of Titanium Boride-Coated Titanium Balls Against Alumina Ceramic: Wear, Friction, and Micromechanisms, Wear, 2008, 265, p 375–386

B. Sarma, N.M. Tikekar, and K.S.R. Chandran, Kinetics of Growth of Superhard Boride Layers During Solid State Diffusion of Boron into Titanium, Ceram Int, 2012, 38, p 6795–6805

S. Barril, S. Mischler, and D. Landolt, Triboelectrochemical Investigation of the Friction and Wear Behaviour of TiN Coatings in a Neutral Solution, Tribol Int, 2001, 34, p 599–608

A. Zhecheva, W. Sha, S. Malinov, and A. Long, Enhancing the Microstructure and Properties of Titanium Alloys Through Nitriding and Other Surface Engineering Methods, Surf Coat Technol, 2005, 200, p 2192–2207

A. Ashrafizadeh and F. Ashrafizadeh, Structural Features and Corrosion Analysis of Thermally Oxidized Titanium, J Alloy Compd, 2009, 480, p 849–852

R. Bailey and Y. Sun, Unlubricated Sliding Friction and Wear Characteristics of Thermally Oxidized Commercially Pure Titanium, Wear, 2013, 308, p 61–70

M. Jamesh, T.S.N.S. Narayanan, and P.K. Chu, Thermal Oxidation of Titanium: Evaluation of Corrosion Resistance as a Function of Cooling Rate, Mater Chem Phys, 2013, 138, p 565–572

P.A. Dearnley, K.L. Dahm, and H. Çimenoğlu, The Corrosion-Wear Behaviour of Thermally Oxidised CP-Ti and Ti-6Al-4V, Wear, 2004, 256, p 469–479

Y. Luo, H. Jiang, G. Cheng, and H. Liu, Effect of Carburization on the Mechanical Properties of Biomedical Grade Titanium Alloys, J Bionic Eng, 2011, 8, p 86–89

A. Haseeb, M.F. Islam, M.O. Alam and S. Tofail, Surface Hardening Behavior of Titanium Alloys in Carburization, Proceedings of the 1997, 126th Conference on TMS Annual Meeting, Indianapolis, IN, 1997

N. Makuch, M. Kulka, P. Dziarski, and D. Przestacki, Laser Surface Alloying of Commercially Pure Titanium with Boron and Carbon, Opt Lasers Eng, 2014, 57, p 64–81

L. Qin, C. Liu, K. Yang, and B. Tang, Characteristics and Wear Performance of Borided Ti6Al4V Alloy Prepared by Double Glow Plasma Surface Alloying, Surf Coat Technol, 2013, 225, p 92–96

G. Kartal, S. Timur, M. Urgen, and A. Erdemir, Electrochemical Boriding of Titanium for Improved Mechanical Properties, Surf Coat Technol, 2010, 204, p 3935–3939

H. Dong and X.Y. Li, Oxygen Boost Diffusion for the Deep-Case Hardening of Titanium Alloys, Mater Sci Eng A, 2000, 280, p 303–310

R. Bailey and Y. Sun, Pack Carburisation of Commercially Pure Titanium with Limited Oxygen Diffusion for Improved Tribological Properties, Surf Coat Technol, 2015, 261, p 28–34

R.C. Sharma, Principles of Heat Treatment of Steels, New Age International, New Delhi, 2003

H. Dong, A. Bloyce, P.H. Morton, and T. Bell, Surface Engineering to Improve Tribological Performance of Ti-6Al-4V, Surf Eng, 1997, 13, p 402–406

E. Bucur and F.C. Wagner, Rate of Diffusion of Carbon in Alpha and in Beta Titanium as a Function of the Temperature and Concentration. Final technical report for period December 12, 1952-July 1, 1954, Horizons, Inc. 1954

F. Borgioli, E. Galvanetto, F.P. Galliano, and T. Bacci, Air Treatment of Pure Titanium by Furnace and Glow-Discharge Processes, Surf Coat Technol, 2001, 141, p 103–107

R. Bailey and Y. Sun, Corrosion and Tribocorrosion Performance of Pack-Carburized Commercially Pure Titanium with Limited Oxygen Diffusion in a 0.9% NaCl Solution, J Bio- Tribo-Corros, 2018, 4, p 6

L. Meier, N. Schaal, and K. Wegener, In-Process Measurement of the Coefficient of Friction on Titanium, Proc CIRP, 2017, 58, p 163–168

I. Arvanitidis, D. Siche, and S. Seetharaman, A Study of the Thermal Decomposition of BaCO3, Metall Mater Trans B, 1996, 27, p 409–416

A.K. Galwey and M.E. Brown, Thermal Decomposition of Ionic Solids: Chemical Properties and Reactivities of Ionic Crystalline Phases, Elsevier Science, Amsterdam, 1999

J. Kim and H. Lee, Thermal and Carbothermic Decomposition of Na2CO3 and Li2CO3, Metall Mater Trans B, 2001, 32, p 17–24

B.V. L’vov, Thermal Decomposition of Solids and Melts: New Thermochemical Approach to the Mechanism, Kinetics and Methodology, Springer, Dordrecht, 2007

S. Kumar, T.S.N.S. Narayanan, S.G.S. Raman, and S.K. Seshadri, Evaluation of Fretting Corrosion Behaviour of CP-Ti for Orthopaedic Implant Applications, Tribol Int, 2010, 43, p 1245–1252

A.R. Shankar, N.S. Karthiselva, and U.K. Mudali, Thermal Oxidation of Titanium to Improve Corrosion Resistance in Boiling Nitric Acid Medium, Surf Coat Technol, 2013, 235, p 45–53

A. Maitre, D. Tetard, and P. Lefort, Role of some Technological Parameters During Carburizing Titanium Dioxide, J Eur Ceram Soc, 2000, 20, p 15–22

R.J. Van Thyne, E.S. Bumps, H.D. Kessler, and M. Hansen, Phase Diagrams of the Titanium-Aluminum, Titanium-Chromium-Iron, and Titanium-Oxygen Alloy Systems, WADC Tech Rep, 1952, 52–16, p 96

L.H. Van Vlack, Materials Science for Engineers, World Student Series, Addison-Wesley, Reading, MA, 1974, p 171–173

Acknowledgments

I (RB) would like to acknowledge the financial support of De Montfort University for providing a Ph.D. scholarship. Special thanks are also due to The Alderman Newton’s Educational Foundation, The Sidney Perry Foundation, and The Wyvernian Foundation for providing additional financial support during the course of this work.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Bailey, R., Sun, Y. An Investigation into the Effects of Process Conditions on the Tribological Performance of Pack Carburized Titanium with Limited Oxygen Diffusion. J. of Materi Eng and Perform 27, 3091–3101 (2018). https://doi.org/10.1007/s11665-018-3382-y

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-018-3382-y