Abstract

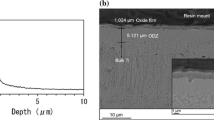

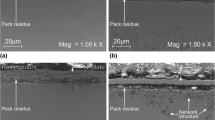

In the research presented, the corrosion and tribocorrosion characteristics of pack-carburized titanium with limited oxygen diffusion (PCOD-Ti) have been investigated using a 0.9% NaCl solution. The carburization treatment was undertaken using a service temperature of 925 °C for duration of 20 h. The treatment resulted in the creation of a titanium carbide network layer atop an extended oxygen diffusion zone (α-Ti(O)). Electrochemical testing indicated that the treated titanium surface offered slightly enhanced corrosion resistance over that of untreated titanium. Tribocorrosion testing of the PCOD-Ti was conducted by sliding the titanium against an alumina counter-face under a contact load of 20 N, with various anodic and cathodic potentials applied. The testing showed a dramatic reduction in the wear rate for the treated titanium. Wear rates were reduced by an order of magnitude when compared with the untreated samples. During testing, an interesting cathodic protection was encountered. When subjected to high negative charge the wear rates of the treated titanium were reduced further. This reduced wear was attributed to the formation of titanium hydride within the wear track.

Similar content being viewed by others

References

Qi PY, Li XY, Dong H, Bell T (2002) Characterisation of the palladium-modified thermal oxidation-treated titanium. Mater Sci Eng A 326(2):330–342

Kumar S, Narayanan TSNS, Raman SGS (2010) Thermal oxidation of CP Ti—an electrochemical and structural characterization. Mater Charact 61(6):589–597

Martin É, Azzi M, Salishchev GA, Szpunar J (2010) Influence of microstructure and texture on the corrosion and tribocorrosion behavior of Ti–6Al–4V. Tribol Int 43(5):918–924

Gilabert-Chirivella E, Pérez-Feito R, Ribeiro C, Ribeiro S, Correia DM, González-Martín ML, Manero JM, Lanceros-Méndez S, Ferrer GG, Gómez-Ribelles JL (2017) Chitosan patterning on titanium implants. Prog Org Coat 111(1):23–28

Liu X, Chu PK, Ding C (2004) Surface modification of titanium, titanium alloys, and related materials for biomedical applications. Mater Sci Eng R Rep 47(3):49–121

Vieira AC, Ribeiro AR, Rocha LA, Celis JP (2006) Influence of pH and corrosion inhibitors on the tribocorrosion of titanium in artificial saliva. Wear 261(9):994–1001

Revathi A, Borrás AD, Muñoz AI, Richard C, Manivasagam G (2017) Degradation mechanisms and future challenges of titanium and its alloys for dental implant applications in oral environment. Mater Sci Eng C 76(1):1354–1368

Schmidmaier G, Kerstan M, Schwabe P, Südkamp N, Raschke M (2017) Clinical experiences in the use of a gentamicin-coated titanium nail in tibia fractures and revisions. Injury 48(10):2235–2241

Bull SJ, Moharrami N, Langton D (2016) Mechanistic study of the wear of ceramic heads by metallic stems in modular implants. J Bio Tribo Corros 3(1):7

Pohrelyuk IM, Sheykin SE, Dub SM, Mamalis AG, Rostotskii IY, Tkachuk OV, Lavrys SM (2016) Increasing of functionality of cp titanium/UHMWPE tribo-pairs by thermodiffusion nitriding of titanium component. Biotribology 7(1):38–45

Dearnley PA, Dahm KL, Çimenoǧlu H (2004) The corrosion–wear behaviour of thermally oxidised CP-Ti and Ti–6Al–4V. Wear 256(5):469–479

Albayrak Ç, Hacısalihoğlu İ, Vangölü SY, Alsaran A (2013) Tribocorrosion behavior of duplex treated pure titanium in simulated body fluid. Wear 302(1):1642–1648

Fernandes AC, Vaz F, Ariza E, Rocha LA, Ribeiro ARL, Vieira AC, Rivière JP, Pichon L (2006) Tribocorrosion behaviour of plasma nitrided and plasma nitrided + oxidised Ti6Al4V alloy. Surf Coat Technol 200(22):6218–6224

Eyre TS, Alsalim H (1977) Effect of boronising on adhesive wear of titanium alloys. Tribol Int 10(5):281–285

Wen M, Wen C, Hodgson P, Li Y (2014) Improvement of the biomedical properties of titanium using SMAT and thermal oxidation. Colloids Surf B 116(1):658–665

Bailey R, Sun Y (2015) Corrosion and tribocorrosion performance of thermally oxidized commercially pure titanium in a 0.9% NaCl solution. J Mater Eng Perform 24(4):1669–1678

Luo Y, Ge S, Zhang D, Wang Q, Liu H (2011) Fretting wear of carburized titanium alloy against ZrO2 under serum lubrication. Tribol Int 44(11):1471–1475

Luo Y, Ge S, Liu H, Jin Z (2009) Microstructure analysis and wear behavior of titanium cermet femoral head with hard TiC layer. J Biomech 42(16):2708–2711

Tsuji N, Tanaka S, Takasugi T (2009) Effects of combined plasma-carburizing and shot-peening on fatigue and wear properties of Ti–6Al–4V alloy. Surf Coat Technol 203(10):1400–1405

Dong H, Li XY (2000) Oxygen boost diffusion for the deep-case hardening of titanium alloys. Mater Sci Eng A 280(2):303–310

Bailey R, Sun Y (2015) Pack carburisation of commercially pure titanium with limited oxygen diffusion for improved tribological properties. Surf Coat Technol 261(1):28–34

Brama M, Rhodes N, Hunt J, Ricci A, Teghil R, Migliaccio S, Rocca CD, Leccisotti S, Lioi A, Scandurra M, De Maria G, Ferro D, Pu F, Panzini G, Politi L, Scandurra R (2007) Effect of titanium carbide coating on the osseointegration response in vitro and in vivo. Biomaterials 28(4):595–608

Veronesi F, Giavaresi G, Fini M, Longo G, Ioannidu CA, Scotto d’Abusco A, Superti F, Panzini G, Misiano C, Palattella A, Selleri P, Di Girolamo N, Garbarino V, Politi L, Scandurra R (2017) Osseointegration is improved by coating titanium implants with a nanostructured thin film with titanium carbide and titanium oxides clustered around graphitic carbon. Mater Sci Eng C 70(1):264–271

CES selector softwear (2016) 16.1.22, Cambridge, UK: Granta Design Limited

Toptan F, Alves AC, Pinto AMP, Ponthiaux P (2017) Tribocorrosion behavior of bio-functionalized highly porous titanium. J Mech Behav Biomed Mater 69(Supplement C):144–152

Fazel M, Salimijazi HR, Golzar MA, Jazi MRG (2015) A comparison of corrosion, tribocorrosion and electrochemical impedance properties of pure ti and Ti6Al4V alloy treated by micro-arc oxidation process. Appl Surf Sci 324(Supplement C):751–756

Barril S, Mischler S, Landolt D (2005) Electrochemical effects on the fretting corrosion behaviour of Ti6Al4V in 0.9% sodium chloride solution. Wear 259(1):282–291

Sun Y, Dearnley P, Mallia B (2017) Response of duplex Cr(N)/S and Cr(C)/S coatings on 316L stainless steel to tribocorrosion in 0.89% NaCl solution under plastic contact conditions. J Biomed Mater Res Part B 105(6):1503–1513

Oláh N, Fogarassy Z, Furkó M, Balázsi C, Balázsi K (2015) Sputtered nanocrystalline ceramic TiC/amorphous C thin films as potential materials for medical applications. Ceram Int 41(4):5863–5871

Avgustinik AI, Drozdetskaya GV, Ordan’yan SS (1967) Reaction of titanium carbide with water. Sov Powder Metall Metal Ceram 6(6):470–473

Raja KS, Jones DA (2006) Effects of dissolved oxygen on passive behavior of stainless alloys. Corros Sci 48(7):1623–1638

Sun Y (2010) Depth-profiling electrochemical measurements of low temperature plasma carburised 316L stainless steel in 1M H2SO4 solution. Surf Coat Technol 204(16):2789–2796

Qiao YX, Zheng YG, Ke W, Okafor PC (2009) Electrochemical behaviour of high nitrogen stainless steel in acidic solutions. Corros Sci 51(5):979–986

Schneider M, Kremmer K, Lämmel C, Sempf K, Herrmann M (2014) Galvanic corrosion of metal/ceramic coupling. Corros Sci 80(1):191–196

Tsai W, Ju C, Wen Y, Lee J (1987) Hydride formation during the cathodic polarization of titanium in artificial sea water. Surf Coat Technol 31(4):401–408

Bernstein IM, Thompson AW (1974) Hydrogen in metals. In: Proceedings of an international conference on the effects of hydrogen on materials properties and selection and structural design. American Society for Metals, Ohio, USA

Millenbach P, Givon M (1982) The electrochemical formation of titanium hydride. J Less Common Met 87(2):179–184

Shih DS, Robertson IM, Birnbaum HK (1988) Hydrogen embrittlement of α titanium: in situ TEM studies. Acta Metall 36(1):111–124

Lee SC, Ho WY, Chen TM (1994) Prevention of hydrogen degradation in titanium by deposition of TiN thin film. J Mater Eng Perform 3(6):740–743

Vieira AC, Rocha LA, Papageorgiou N, Mischler S (2012) Mechanical and electrochemical deterioration mechanisms in the tribocorrosion of Al alloys in NaCl and in NaNO3 solutions. Corros Sci 54(1):26–35

Pina VG, Dalmau A, Devesa F, Amigó V, Muñoz AI (2015) Tribocorrosion behavior of beta titanium biomedical alloys in phosphate buffer saline solution. J Mech Behav Biomed Mater 46:59–68

Acknowledgements

One of the authors (RB) would like to acknowledge the financial support of De Montfort University for providing a Ph.D. scholarship. Special thanks are also due to The Alderman Newton’s Educational Foundation, The Sidney Perry Foundation, and The Wyvernian Foundation for providing additional financial support during the course of this work.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

On behalf of all authors, the corresponding author states there is no conflict of interest.

Rights and permissions

About this article

Cite this article

Bailey, R., Sun, Y. Corrosion and Tribocorrosion Performance of Pack-Carburized Commercially Pure Titanium with Limited Oxygen Diffusion in a 0.9% NaCl Solution. J Bio Tribo Corros 4, 6 (2018). https://doi.org/10.1007/s40735-017-0123-y

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s40735-017-0123-y