Abstract

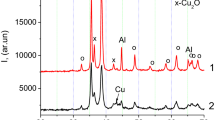

In order to elucidate the decomposition mechanism of Na2CO3 and Li2CO3 in mold-powder systems employed in the continuous casting of steel, decompositions of Na2CO3 and Li2CO3 were investigated using thermogravimetric (TG) and differential scanning calorimetric (DSC) methods at temperatures up to 1200 °C, under a flow of argon gas. For the case of pure Na2CO3, the thermal decomposition started from its melting point and continued as the temperature was increased, but at a very slow rate. For Li2CO3, however, the decomposition occurred at much faster rates than that for Na2CO3. When carbon black was added to the carbonate particles, the decomposition rates of both Na2CO3 and Li2CO3 were significantly enhanced. From mass-balanced calulations and X-ray diffraction (XRD) analyses of the reaction products, it is concluded that decompositions of Na2CO3 and Li2CO3 with carbon black take place according to the respective reactions of Na2CO3 (1) + 2C (s) = 2Na (g) + 3CO (g) and Li2CO3 (l) + C (s) = Li2O (s) + 2CO (g). It was found that liquid droplets of Na2CO3 were initially isolated due to carbon particles surrounding them, but, as the carbon particles were consumed, the liquid droplets were gradually agglomerated. This effected a reduction of the total surface area of the carbonate, resulting in a dependence of the decomposition rate on the amount of carbon black. For the case of Li2CO3, on the other hand, hardly any agglomeration occurred up to the completion of decomposition, and, hence, the rate was almost independent of the amount of carbon black mixed. The apparent activation energies for the decomposition of Na2CO3 and Li2CO3 with carbon black were found to be similar and were estimated to be 180 to 223 kJ mole−1.

Similar content being viewed by others

References

J.A. Moore, R.J. Phillips, and T.R. Gibbs: Steel making Conf. Proc., ISS, Warrendale, PA, 1991, vol. 74, pp. 615–21.

T. Wada, M. Suzuki, and T. Mori: Iron Steelmaker, Sept. 1987, pp. 31–38.

M. Kawamoto, K. Nakajima, T. Kanajawa, and K. Nakai: Iron Steel Inst. Jpn. Int., 1994, vol. 34 (7), pp. 593–98.

O. Knacke, O. Kubaschewski, and K. Hesselmann: Thermochemical Properties of Inorganic Substances, 2nd ed., Springer-Verlag, New York, NY, 1991.

K. Motzfeldt: J. Phys. Chem., 1955, vol. 59, pp. 139.

Y. Nakamura, K. Harashima, Y. Hukuda, N. Tokumitsu, and S. Yamamoto: Tetsu-to-Hagané, 1980, vol. 66, pp. 2023–31.

Phase Diagrams for Ceramists, American Ceramic Society, 1981, vol. 4, p. 311, Figure 5572.

R. Inoue and H. Suito: Tetsu-to-Hagané, 1979, vol. 65, pp. 1838–47.

E.S. Freeman and B Caroll: J. Phys. Chem., 1958, vol. 62, p. 394.

Liu Zhaogang and Ma Ying: Chin. J. Nonferrous Met., 1998, vol. 8(2), p. 299.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Kim, JW., Lee, HG. Thermal and carbothermic decomposition of Na2CO3 and Li2CO3 . Metall Mater Trans B 32, 17–24 (2001). https://doi.org/10.1007/s11663-001-0003-0

Received:

Issue Date:

DOI: https://doi.org/10.1007/s11663-001-0003-0