Abstract

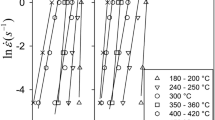

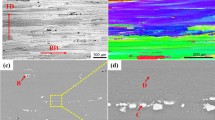

A constitutive model that includes the effect of Mg2Si dissolution during pre-deformation heating and holding has been developed for the prediction of the hot flow stress behavior of AA6063 aluminum alloy. The deformation behavior of homogenized AA6063 aluminum alloy was studied by performing compression tests on a Gleeble 3500 thermomechanical simulator at temperatures ranging from 400 to 550 °C and strain rates from 0.01 to 10 s−1. A one-dimensional model of particle dissolution in spherical coordinate system was developed to determine the Mg-Si solute content during pre-deformation heating and holding. Using the Mg solute content determined from the particle dissolution model, the flow stress during the deformation of AA6063 aluminum alloy at specific temperatures and strain rates was predicted using a modified hyperbolic sine equation. The constitutive model developed was found to be in good agreement with experimental measurements in this study as well as other experimental and model results published in the literature. A 14% increase in flow stress of the alloy was observed for an increase in hold time from 60 to 1500 s at 450 °C. This is due to increased deformation resistance of the alloy as the Mg-Si solute content increases. The modified hyperbolic sine equation developed in this study clearly shows that accounting for Mg-Si solute content improves the ability to accurately predict the flow stress behavior of AA6063 aluminum alloy.

Similar content being viewed by others

References

R.A. Siddiqui, H.A. Abdullah, and K.R. Al-Belushi, Influence of Aging Parameters on the Mechanical Properties of 6063 Aluminum Alloy, J. Mater. Process. Technol., 2000, 102, p 234–240

J.-P. Bourget, M. Fafard, H. Shakeri, and T. Cote, Optimization of Heat Treatment In Cold-Drawn 6063 Aluminium Tubes, J. Mater. Process. Technol., 2009, 209, p 5035–5041

“Azom,” Aalco, 2013. www.azom.com/article.aspx?articleID=2813#application_of_aluminum

O. Reiso, Extrusion of AlMgSi Alloys, Mater. Forum, 2004, 28, p 32–46

Y. Lin, M. Chen, and J. Zhong, Constitutive Modeling of Elevated Temperature Flow Behavior of 42CrMo Steel, Comput. Mater. Sci., 2008, 42, p 470–477

J. Van de Langkruis, R. Bergwerf, S. Van der Zwaag, and W. Kool, Linking Plane Strain Compression Tests on AA6063 to Laboratory Scale Extrusion Via Constitutive Equations, Mater. Sci. Forum, 2000, 331–337, p 565–570

N. Anjabin, A. Taheri, and H. Kim, Constitutive Modeling of Hot Deformation Behavior of the AA6063 Alloy with Different Precipitates, Metall. Mater. Trans. A, 2013, 44A, p 5853–5860

H. Espedal, H. Gjestland, N. Ryum, and H. McQueen, Hot Deformation of Al-Mg-Si Alloys, Scand. J. Metall., 1989, 18, p 131–136

J. Van de Langkruis, W. Kool, and S. Van der Zwaag, Modification of a Thermomechanical Model to Predict Constitutive Behavior of Al-Mg-Si Alloys, J. Mater. Eng. Perform., 2006, 15(6), p 632–639

J. Van de Langkruis, W. Kool, C. Sellars, M. Van der Winden, and S. Van der Zwaag, The Effect of β, βI, and βII, Precipitates in a Homogenized AA6063 Alloy on the Hot Deformability and the Peak Hardness, Mater. Sci. Eng. A, 2001, 299, p 105–115

J. Van de Langkruis, N. Kuijpers, W. Kool, F. Vermolen and S. Van der Zwaag, Modelling Mg2Si Dissolution in an AA6063 Alloy During Pre-heating to the Extrusion Temperature, International Aluminum Extrusion Technology Seminar, Chicago, 2000.

E. Kelesoglu, Y. Ersalan, and G. Ozer, Deformation Character of the Aluminum Alloy AA6063 Depending on the Homogenization State, Mater. Test., 2009, 51(6), p 390–394

F. Vermolen, K. Vuik, and S. Van der Zwaag, A Mathematical Model for the Dissolution Kinetics of Mg2Si-Phases in Al-Mg-Si Alloys During Homogenization Under Industrial Conditions, Mater. Sci. Eng. A, 1991, 254, p 13–32

R. Davies, A. Dinsdale, and J. Gisby, MTDATA-Thermodynamic and Phase Equilibrium Software from the National Physical Laboratory, Calphad, 2002, 26(2), p 229–271

J. Jonas, C. Sellars, and M. Tegart, Strength and Structure Under Hot Working Conditions, Metall. Rev., 1969, 14, p 1–24

J. Van de Langkruis, W. Kool, and S. Van der Zwaag, Assessment of Constitutive Equations in Modelling the Hot Deformability of Some Overaged Al-Mg-Si Alloys with Varying Solute Contents, Mater. Sci. Eng. A, 1999, 266, p 135–145

H. Wei, G. Liu, X. Xiao, H. Zhao, H. Ding, and R. Kang, Characterization of Hot Deformation Behavior of a New Microalloyed C-Mn-Al High Strength Steel, Mater. Sci. Eng. A, 2013, 564, p 140–146

G. Mrówka-Nowotnik, J. Sieniawski, S. Kotowski, A. Nowotnik, and M. Motyka, Hot Deformation of 6xxx Series Aluminum Alloys, Arch. Metall. Mater., 2015, 60(2), p 1079–1084

E. Puchi and M. Staia, Mechanical Behavior of Aluminum Under Hot Working Conditions, Metall. Mater. Trans. A, 1995, 26, p 2895–2910

Z. Chen, S. Xu, and X. Dong, Deformation Behavior of AA6063 Aluminum Alloy After Removing Friction Effect Under Hot Working Conditions, Acta Metall. Sin. (Engl. Lett.), 2008, 21(6), p 451–458

S. Tangen, Deformation and Annealing Behavior of Commercial Non-heat Treatable Aluminum Alloys: An Experimental Investigation, Norges, Trondheim, 2004, p 123

P. Olaffson, S. Sandstrom, and A. Karlsson, Comparison of Experimental, Calculated and Observed Values for Electrical and Thermal Conductivity of Aluminum Alloys, J. Mater. Sci., 1997, 32, p 4383–4390

M. Wang, Z. He, X. Wu, C. Li, and G. Li, Deformation Simulation of Low Temperature High Speed Extrusion for 6063 Al Alloy, J. Cent. South Univ. Technol., 2010, 17(5), p 881–887

H. Zhu, M. Couper, and A. Dahle, Effect of Process Variables on Mg-Si Particles and Extrudability of 6XXX Series Aluminum Extrusions, J. Miner. Met. Mater. Soc. TMS, 2011, 63(11), p 66–71

Acknowledgment

The authors acknowledge Canada’s Natural Science and Engineering Research Council (NSERC) automotive partnership for Canada for the financial support provided. Authors also thank the staff of the engineering machine shop at University of Waterloo for machining Gleeble samples.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Odoh, D., Mahmoodkhani, Y., Whitney, M. et al. Prediction of the Hot Flow Stress Behavior of AA6063 Including Mg2Si Dissolution. J. of Materi Eng and Perform 26, 1186–1194 (2017). https://doi.org/10.1007/s11665-017-2557-2

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-017-2557-2