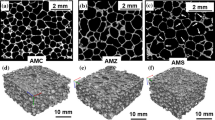

Metallic foams with a high fraction of porosity, low density and high-energy absorption capacity are a rapidly emerging class of novel ultralight weight materials for various engineering applications. In this study, Y-Cr and Ce-Cr-coated Ni-Cr-Fe alloy foams were prepared via the pack cementation method, and the effects of Y and Ce addition on the coating microstructure and oxidation performance were analyzed in order to improve the oxidation resistance of open-cell nickel-based alloy foams. The results show that the Ce-Cr coating is relatively more uniform and has a denser distribution on the surface of the nickel-based alloy foam. The surface grains of the Ce-Cr-coated alloy foam are finer compared to those of the Y-Cr-coated alloy foam. An obvious Ce peak appears on the interface between the coating and the alloy foam strut, which gives rise to a “site-blocking” effect for the short-circuit transport of the cation in the substrate. X-ray diffraction analysis shows that the Y-Cr-coated alloy foam mainly consists of Cr, (Fe, Ni) and (Ni, Cr) phases in the surface layer. The Ce-Cr-coated alloy foam is mainly composed of Cr and (Ni, Cr) phases. Furthermore, the addition of Y and Ce clearly lead to an improvement in the oxidation resistance of the coated alloy foams in the temperature range of 900-1000 °C. The addition of Ce is especially effective in enhancing the diffusion of chromium to the oxidation front, thus, accelerating the formation of a Cr2O3 layer.

Similar content being viewed by others

References

A.A. Aal and M.S. Aly, Electroless Ni-Cu-P Plating Onto Open Cell Stainless Steel Foam, Appl. Surf. Sci., 2009, 255, p 6652–6655

J. Banhart, Manufacture, Characterisation and Application of Cellular Metals and Metal Foams, Prog. Mater Sci., 2001, 46, p 559–632

J. Nowacki and K. Moraniec, Evaluation of Methods of Soldering AlSi and AlSi-SiC Particle Composite Al Foams, J. Mater. Eng. Perform., 2015, 24, p 426–433

I. Unver, H.O. Gulsoy, and B. Aydemir, Ni-625 Superalloy Foam Processed by Powder Space-Holder Technique, J. Mater. Eng. Perform., 2013, 22, p 3735–3741

M.F. Ashby, A.G. Evans, N.A. Fleck, L.J. Gibson, J.W. Hutchinson, and H.N.G. Wadley, Metal Foams: A Design Guide, Butterworth-Heinemann, Oxford, 2000, p 195

O. Smorygo, V. Mikutski, A. Leonov, A. Marukovich, and Y. Vialiuha, Nickel Foams with Oxidation-Resistant Coatings Formed by Combustion Synthesis, Scripta Mater., 2008, 58, p 910–913

Y. Boonyongmaneerat and D.C. Dunand, Ni-Mo-Cr Foams Processed by Casting Replication of Sodium Aluminate Preforms, Adv. Eng. Mater., 2008, 10, p 379–383

D. Hochauer, C. Mitterer, M. Penoy, C. Michotte, H.P. Martinz, and M. Kathrein, Thermal Stability of Doped CVD K-Al2O3 Coatings, Surf. Coat. Technol., 2010, 204, p 3713–3722

H.Y. Yue, E.J. Guo, W.D. Fei, Z.M. Yu, and L.P. Wang, Effects of Cr2O3 Coating of Whiskers on the Tensile Properties and Thermal Stability of Aluminum Borate Whiskers Reinforced 2024Al Composite, Mater. Sci. Eng., A, 2012, 533, p 33–37

A.M. Hodge and D.C. Dunand, Synthesis of Nickel-Aluminide Foams by Pack-Aluminization of Nickel Foams, Intermetallics, 2001, 9, p 581–589

Y. Boonyongmaneerat, C.A. Schuh, and D.C. Dunand, Mechanical Properties of Reticulated Aluminum Foams with Electrodeposited Ni-W Coatings, Scripta Mater., 2008, 59, p 336–339

H. Choe and D.C. Dunand, Mechanical Properties of Oxidation-Resistant Ni-Cr Foams, Mater. Sci. Eng., A, 2004, 384, p 184–193

R. Cueff, H. Buscail, E. Caudron, F. Riffard, C. Issartel, and S.E.I. Messki, Effect of Reactive Element Oxide Coating on the High Temperature Oxidation Behaviour of FeCrAl Alloys, Appl. Surf. Sci., 2004, 229, p 233–241

Y. Wang and W. Chen, Microstructures, Properties and High-Temperature Carburization Resistances of HVOF Thermal Sprayed NiAl Intermetallic-Based Alloy Coatings, Surf. Coat. Technol., 2004, 183, p 18–28

S. Chevalier and J.P. Larpin, Influence of Reactive Element Oxide Coatings on the High Temperature Cyclic Oxidation of Chromia-Forming Steels, Mater. Sci. Eng., A, 2003, 363, p 116–125

Q. Pang, G.H. Wu, Z.Y. Xiu, L.T. Jiang, and D.L. Sun, Microstructure, Oxidation Resistance and High-Temperature Strength of a New Class of 3D Open-Cell Nickel-Based Foams, Mater. Charact., 2012, 70, p 125–136

M.S. Aly, Tensile Properties Of Open-Cell Nickel Foams, Mater. Des., 2010, 31, p 2237–2240

N.M. Lin, F.Q. Xie, T. Zhong, X.Q. Wu, and W. Tian, Influence of Adding Various Rare Earths on Microstructures and Corrosion Resistance of Chromizing Coatings Prepared Via Pack Cementation on P110 Steel, J. Rare Earths, 2010, 28, p 301–304

H. Zhang, X. Peng, J. Zhao, and F. Wang, Prior Electrodeposition of Nanocrystalline Ni-CeO2 Film Fabricating an Oxidation-Resistant Chromized Coating on Carbon Steels, Electrochem. Solid-State Lett., 2007, 10, p 12–15

L. Zhu, X. Peng, J. Yan, and F. Wang, Oxidation of a Novel Chromium Coating with CeO2 Dispersions, Oxid. Met., 2004, 62, p 411–426

N.C. Huang and S.J. Hu, Surface Modification by REE and Its Applications, National Defense Industry Press, Beijing, 2007, p 8–77

J. Yan, X. Peng, and F. Wang, Oxidation of a Novel CeO2-Dispersion-Strengthened Chromium Coating in Simulated Coal-Combustion Gases, Mater. Sci. Eng., A, 2006, 426, p 266–273

B.A. Pint, Experimental Observations in Support of the Dynamic-Segregation Theory to Explain the Reactive-Element Effect, Oxid. Met., 1996, 45, p 1–37

A. Barty, S. Marchesini, H.N. Chapman, C. Cui, M.R. Howells, and D.A. Shapiro, Three-Dimensional Coherent x-Ray Diffraction Imaging of a Ceramic Nanofoam: Determination of Structural Deformation Mechanisms, Phys. Rev. Lett., 2008, 101, p 1–4

J.L. Murray, ASM Handbook-Alloy Phase Diagrams, Vol 3, ASM International, Materials Park, 1990, p 312–322

R. Bianco, R.A. Rapp, and N.S. Jacobson, Volatile Species in Halide-Activated Diffusion Coating Packs, Oxid. Met., 1992, 38, p 33–43

A. Chyrkin, S.L. Schulze, J. Pirón-Abellán, W. Bleck, L. Singheiser, and W.J. Quadakkers, Oxidation Limited Lifetime of Ni-Base Metal Foams in the Temperature Range 700-900°C, Adv. Eng. Mater., 2010, 9, p 873–883

Q. Pang, Z.Y. Xiu, G.H. Wu, L.T. Jiang, D.L. Sun, and Z.L. Hu, Synthesis and Properties Of Open-Cell Ni-Cr-Fe-Al Alloy Foams by Pack Co-Deposition Process, J. Mater. Process. Technol., 2012, 212, p 2219–2227

Q. Pang, G.H. Wu, D.L. Sun, Z.Y. Xiu, and L.T. Jiang, A Dual-Layer Ce-Cr/Al Oxidation Resistant Coating for 3D Open-Cell Nickel Based Foams by a Two-Step Pack Cementation, Mater. Sci. Eng., A, 2013, 568, p 228–238

T.P. Li, High Temperature Oxidation and Thermal Corrosion of Metal, Chemical Industry Press, Beijing, 2003, p 33–215

P.J. Blau, T.M. Brummett, and B.A. Pint, Effects of Prior Surface Damage on High-Temperature Oxidation of Fe-, Ni-, and Co-Based Alloys, Wear, 2009, 267, p 380–386

Y.B. Zhou, H. Chen, and H. Zhang, Preparation and Oxidation of an Y2O3-Dispersed Chromizing Coating by Pack Cementation at 800°C, Vacuum, 2008, 82, p 748–753

Y.J. Liang and Y.C. Che, Thermodynamic Data Handbook of Inorganic Substances, Northeastern University Press, Shengyang, 1994

X. Song, L. Wang, and Y. Liu, Effects of Temperature and Rare Earth Content on Oxidation Resistance of Ni-Based Superalloy, Prog. Nat. Sci., 2011, 21, p 227–235

N.B. Pilling and R.E. Bedworth, The Oxidation of Metals at High Temperatures, J. Inst. Metals, 1923, 29, p 529–582

Acknowledgment

This study is financially supported by National Natural Science Foundation of China (Grant No. 51501133) and the Universities of Hubei Province outstanding young scientific and technological innovation team plans (Project No.T201629). The authors would like to take this opportunity to express their sincere appreciation.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Pang, Q., Hu, Z.L. & Wu, G.H. Preparation and Oxidation Performance of Y and Ce-Modified Cr Coating on open-cell Ni-Cr-Fe Alloy Foam by the Pack Cementation. J. of Materi Eng and Perform 25, 5189–5200 (2016). https://doi.org/10.1007/s11665-016-2362-3

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-016-2362-3