Abstract

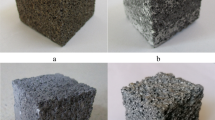

The main focus of the present study is to compare the effect of different alloying elements on Al–Mg alloy foams. Al–Mg15–X10 (X = Cu, Zn and Si) alloy foams were produced via powder metallurgy route by using Mg as a blowing agent. Macro- and microstructural characterisations of the foams were performed using X-ray tomography, X-ray diffraction and scanning electron microscope. Corrosion studies such as weight loss measurement, hydrogen evolution method and potentiodynamic test were conducted. Mechanical properties were evaluated by subjecting the samples to quasi-static compression and microhardness tests. All the alloy foams showed a comparable structure. The Cu-containing foams exhibited the highest strength, while the Zn-containing foams showed the highest expansion. However, the other properties such as brittleness, elastic modulus and burning nature were found to be better for the Si-containing foams.

Similar content being viewed by others

References

Banhart J (2001) Manufacture, characterisation and application of cellular metals and metal foams. Prog Mater Sci 46:559–632. https://doi.org/10.1016/S0079-6425(00)00002-5

Koizumi T, Kido K, Kita K, Mikado K, Gnyloskurenko S, Nakamura T (2011) Foaming agents for powder metallurgy production of aluminum foam. Mater Trans 52:728–733. https://doi.org/10.2320/matertrans.M2010401

Wiehler H, Körner C, Singer RF (2008) High pressure integral foam moulding of aluminium: process technology. Adv Eng Mater 10:171–178. https://doi.org/10.1002/adem.200700267

Banhart J, Vinod-Kumar GS, Kamm PH, Neu TR, García-Moreno F (2016) Light-metal foams: some recent developments. Ciencia Tecnologia dos Materiais 28:1–4. https://doi.org/10.1016/j.ctmat.2016.06.002

Kennedy AR (2002) The effect of TiH2 heat treatment on gas release and foaming in Al–TiH2 preforms. Scr Mater 47:763–767. https://doi.org/10.1016/S1359-6462(02)00281-6

Matijasevic-Lux B, Banhart J, Fiechter S, Gorke O, Wanderka N (2006) Modification of titanium hydride for improved aluminium foam manufacture. Acta Mater 54:1887–1900. https://doi.org/10.1016/j.actamat.2005.12.012

Muduli B, Ramesh T, HariKumar KC, Rajalakshmi N, Mukherjee M (2019) Customised heat treatment of TiH2 for the foaming of aluminium alloys. Materialia 8:100431. https://doi.org/10.1016/j.mtla.2019.100431

Lázaro J, Solórzano E, Rodríguez-Pérez MA, Ramer O, García-Moreno F, Banhart J (2014) Heat treatment of aluminium foam precursors: effects on foam expansion and final cellular structure. Procedia Mater Sci 4:287–292. https://doi.org/10.1016/j.mspro.2014.07.559

Proa-Flores PM, Drew RAL (2008) Production of aluminum foams with Ni-coated TiH2 powder. Adv Eng Mater 10:830–834. https://doi.org/10.1002/adem.200800135

Mukherjee M, Garcia-Moreno F, Banhart J (2010) Defect generation during solidification of aluminium foams. Scr Mater 63:235–238. https://doi.org/10.1016/j.scriptamat.2010.03.064

Vojtìch D, Knotek V (2012) Magnesium alloys for hydrogen storage. Mater Tehnol 46:247–250

Jiménez C, Gracia Moreno F, Banhart J, Zehl G (2008) Effect of relative humidity on pressure-induced foaming (PIF) of aluminium-based precursors. In: Proceedings of 5th international conference on porous metals and metallic foams, pp 59–62

Tuck CDS (1981) Evidence for the formation of magnesium hydride on the grain boundaries Al–Mg and Al–Zn–Mg alloys during their exposure to water vapour. In: Bernstein IM, Thomson AW (eds) Hydrogen effects in metals. The Metallurgical Society of AIME, Warrendale, pp 503–511

Mukherjee M, Garcia-Moreno F, Jiménez C, Banhart J (2010) Al and Zn foams blown by an intrinsic gas source. Adv Eng Mater 12:472–477. https://doi.org/10.1002/adem.201000017

Garcia-Moreno F, Mukherjee M, Jiménez C, Rack A, Banhart J (2011) Metal foaming investigated by X-ray radioscopy. Metals (Basel) 2:10–21. https://doi.org/10.3390/met2010010

Jiménez C, Paeplow M, Kamm PH, Neu TR, Klaus M, Wagener G, Banhart J, Genzel C, Garcia-Moreno F (2018) Simultaneous X-ray radioscopy/tomography and energy-dispersive diffraction applied to liquid aluminium alloy foams. J Synchrotron Radiat 25:1790–1796. https://doi.org/10.1107/S1600577518011657

García-Moreno F, Kamm PH, Neu TR, Bülk F, Mokso R, Schlepütz CM, Stampanoni M, Banhart J (2019) Using X-ray tomoscopy to explore the dynamics of foaming metal. Nat Commun 10:1–9. https://doi.org/10.1038/s41467-019-11521-1

Campana F, Pilone D (2009) Effect of heat treatments on the mechanical behaviour of aluminium alloy foams. Scr Mater 60:679–682. https://doi.org/10.1016/j.scriptamat.2008.12.045

Lehmhus D, Banhart J (2003) Properties of heat-treated aluminium foams. Mater Sci Eng A 349:98–110. https://doi.org/10.1016/S0921-5093(02)00582-8

Lehmhus D, Banhart J, Rodriguez-Perez MA (2002) Adaptation of aluminium foam properties by means of precipitation hardening. Mater Sci Technol 18:474–479. https://doi.org/10.1179/026708302225002182

International Standard I (2011) Mechanical testing of metals. Ductility testing. Compression test for porous and cellular metals. Int Stand ISO 13314

Song G, Atrens A, Suohn D (2001) An hydrogen evolution method for the estimation of the corrosion rate of magnesium alloys. In: Hryn JN (ed) Magnesium technology. Springer, Berlin, pp 255–262

Mukai T, Kanahashi H, Kohzu H, Kanahashi H, Kohzu H, Tanabe S, Higashi K (1999) Enhancement of energy absorption in a closed-cell aluminum by the modification of cellular structures. Scr Mater 41:1055–1060. https://doi.org/10.1016/S13596462(99)00255-9

Ezuber H, El-Houd A, El-Shawesh F (2008) A study on the corrosion behavior of aluminum alloys in seawater. Mater Des 29:801–805. https://doi.org/10.1016/j.matdes.2007.01.021

McCafferty E (2005) Validation of corrosion rates measured by the Tafel extrapolation method. Corros Sci 47:3202–3215. https://doi.org/10.1016/j.corsci.2005.05.046

Shi Z, Liu M, Atrens A (2010) Measurement of the corrosion rate of magnesium alloys using Tafel extrapolation. Corros Sci 52:579–588. https://doi.org/10.1016/j.corsci.2009.10.016

Floyd FL, Tatti S, Provder T (2007) Using DC electrochemical techniques to assess the relative corrosiveness of water-based coatings and their ingredients. J Coat Technol Res 4:111–129. https://doi.org/10.1007/s11998-007-9012-5

Ashby MF, Evans AG, Fleck NA, Gibson LJ, Hutchinson JW, Wadley HN (2000) Metal foams: a design guide. Butterworth-Heinemann, Oxford, p 46

Raj RE, Daniel BSS (2009) Structural and compressive property correlation of closed-cell aluminum foam. J Alloys Compd 467:550–556. https://doi.org/10.1016/j.jallcom.2007.12.040

Baumeister J, Banhart J, Weber M (1997) Aluminium foams for transport industry. Mater Des 18:217–220. https://doi.org/10.1016/s0261-3069(97)00050-2

Szklarska-Smialowska Z (1999) Pitting corrosion of aluminum. Corros Sci 41:1743–1767. https://doi.org/10.1016/S0010-938X(99)00012-8

Birbilis N, Buchheit RG (2005) Electrochemical characteristics of intermetallic phases in aluminum alloys: an experimental survey and discussion. J Electrochem Soc 152:140–151. https://doi.org/10.1149/1.1869984

Li J, Dang J (2017) A summary of corrosion properties of Al-rich solid solution and secondary phase particles in al alloys. Metals (Basel) 7:3–5. https://doi.org/10.3390/met7030084

Bethencourt M, Botana FJ, Cano MJ, Marcos M, Sánchez-Amaya JM, González-Rovira L (2009) Behaviour of the alloy AA2017 in aqueous solutions of NaCl Part I: corrosion mechanisms. Corros Sci 51:518–524. https://doi.org/10.1016/j.corsci.2008.12.027

Rodríguez-Diaz RA, Uruchurtu-chavarín J, Cotero-Villegas AM, Valdez S, Juárez-Islas JA (2015) Corrosion behavior of AlMgSi alloy in aqueous saline solution. Int J Electrochem Sci 10:1792–1808

Wang CC, Chou YC, Yen CY (2012) Hydrogen generation from aluminum and aluminum alloys powder. Procedia Eng 36:105–113. https://doi.org/10.1016/j.proeng.2012.03.017

Belitskus D (1970) Reaction of aluminum with sodium hydroxide solution as a source of hydrogen. J Electrochem Soc 117:1097–1099. https://doi.org/10.1149/1.2407730

Song G, Atrens A (2003) Understanding magnesium corrosion. A framework for improved alloy performance. Adv Eng Mater 5:837–858. https://doi.org/10.1002/adem.200310405

Kirkland NT, Birbilis N, Staiger MP (2012) Assessing the corrosion of biodegradable magnesium implants: a critical review of current methodologies and their limitations. Acta Biomater 8:925–936. https://doi.org/10.1016/j.actbio.2011.11.014

Li JF, Ziqiao Z, Na J, Chengyu T (2005) Localized corrosion mechanism of 2×××-series Al alloy containing S(Al2CuMg) and θ′(Al2Cu) precipitates in 4.0% NaCl solution at pH 6.1. Mater Chem Phys 91:325–329. https://doi.org/10.1016/j.matchemphys.2004.11.034

Yasakau KA, Zheludkevich ML, Ferreira MGS (2018) Role of intermetallics in corrosion of aluminum alloys. Smart corrosion protection. In: Mitra R (ed) Intermetallic matrix composites. Elsevier, Amsterdam, pp 425–462. https://doi.org/10.1016/B978-0-85709-346-2.00015-7

Vuelvas S, Valdez S, Gonzalez-Rodriguez JG (2012) Effect of Mg and Sn addition on the corrosion behavior of an Al–Mn alloy in 0.5M H2SO4. Int J Electrochem Sci 7:4171–4181

Zeng FL, Wei ZL, Li JF, Li CX, Tan X, Zhang Z, Zheng ZQ (2011) Corrosion mechanism associated with Mg2Si and Si particles in Al–Mg–Si alloys. Trans Nonferrous Met Soc China (Engl Ed) 21:2559–2567. https://doi.org/10.1016/S1003-6326(11)61092-3

Abdel Rehim SS, Hassan HH, Amin MA (2004) Chronoamperometric studies of pitting corrosion of Al and (Al–Si) alloys by halide ions in neutral sulphate solutions. Corros Sci 46:1921–1938. https://doi.org/10.1016/j.corsci.2003.10.016

Suter T, Eckermann F, Suter T, Uggowitzer PJ, Afseth A, Schmutz P (2008) The influence of MgSi particle reactivity and dissolution processes on corrosion in Al–Mg–Si alloys. Electrochim Acta 54:844–855. https://doi.org/10.1016/j.electacta.2008.05.078

Fassell WM, Gulbransen LB, Lewis JR, Hamilton JH (1951) Ignition temperatures of magnesium and magnesium alloys. JOM 3:522–528. https://doi.org/10.1007/bf03397342

Sudharsan N, Rajasekaran T, Vinod-Kumar GS (2018) Optimizing the hot compaction parameters of Al–Mg–Cu foams processed through elemental powder route. In: IOP conference series: materials science and engineering. https://doi.org/10.1088/1757-899X/402/1/012202

Zayan MH, Jamjoom OM, Razikt NA (1990) High-temperature oxidation of Al–Mg alloys. Oxid Met 34:323–333. https://doi.org/10.1007/BF00665021

Gaskell DR (2003) Introduction to the thermodynamics of materials, 4th edn. Taylor and Francis, London, pp 412–421

Sundman B, Jansson B, Andersson JO (1985) The Thermo-Calc databank system. Calphad 9:153–190. https://doi.org/10.1016/0364-5916(85)90021-5

TCS aluminium-based alloy thermodynamic databases TCAL, Version 5 (2018) Thermo-Calc Software AB, Sweden

Dumitraschkewitz P, Gerstl SSA, Stephenson LT, Uggowitzer PJ, Pogatscher S (2018) Clustering in age-hardenable aluminum alloys. Adv Eng Mater 20:1800255. https://doi.org/10.1002/adem.201800255

Mukherjee M, García-Moreno F, Jiménez C et al (2017) Microporosity in aluminium foams Rack A and Banhart J. Acta Mater 131:156–168. https://doi.org/10.1016/j.actamat.2017.03.039

Simone AE, Gibson LJ (1998) Aluminum foams produced by liquid-state processes. Acta Mater 46:3109–3123. https://doi.org/10.1016/S1359-6454(98)00017-2

Kubelka P, Matz AM, Jost N (2019) Compression behavior of low-pressure casted AMC syntactic foams with high porosity. In: Dukhan N (ed) 11th International conference on porous metals and metallic foams. Springer, Berlin, pp 115–126

Zhang J, Huang YN, Mao C, Peng P (2012) Structural, elastic and electronic properties of θ (Al2Cu) and S (Al2CuMg) strengthening precipitates in Al–Cu–Mg series alloys: first-principles calculations. Solid State Commun 152:2100–2104. https://doi.org/10.1016/j.ssc.2012.09.003

Sugimura Y, Meyer J, He MY, Bart-Smith H, Grenstedt J, Evans AG (1997) On the mechanical performance of closed cell Al alloy foams. Acta Mater 45:5245–5259. https://doi.org/10.1016/S1359-6454(97)00148-1

Simmons G, Wang H (1971) Single crystal elastic constants and calculated aggregate properties, 2nd edn. MIT Press, Cambridge, p 215

Beals JT, Thompson MS (1997) Density gradient effects on aluminium foam compression behaviour. J Mater Sci 32:3595–3600. https://doi.org/10.1023/A:1018670111305

Andrews EW, Gioux G, Onck P, Gibson LJ (2001) Size effects in ductile cellular solids. Part II: experimental results. Int J Mech Sci 43:701–713

Andrews E, Sanders W, Gibson LJ (1999) Compressive and tensile behaviour of aluminum foams. Mater Sci Eng A 270:113–124. https://doi.org/10.1016/S0921-5093(99)00170-7

Bastawros A-F, Bart-Smith H, Evans AG (2000) Experimental analysis of deformation mechanisms in a closed-cell aluminum alloy foam. J Mech Phys Solids 48:301–322. https://doi.org/10.1016/S0022-5096(99)00035-6

Markaki AE, Clyne TW (2001) The effect of cell wall microstructure on the deformation and fracture of aluminium-based foams. Acta Mater 49:1677–1686. https://doi.org/10.1016/S1359-6454(01)00072-6

Mukherjee M, Ramamurty U, Garcia-Moreno F, Banhart J (2010) The effect of cooling rate on the structure and properties of closed-cell aluminium foams. Acta Mater 58:5031–5042. https://doi.org/10.1016/j.actamat.2010.05.039

Dannemann KA, Lankford J (2000) High strain rate compression of closed-cell aluminum foams. Mater Sci Eng A 293:157–164. https://doi.org/10.1016/S0921-5093(00)01219-3

Banhart J, Brinkers W (1999) Fatigue behavior of aluminum foams. J Mater Sci Lett 18:617–619. https://doi.org/10.1023/A:1006646901741

Acknowledgements

The authors are grateful to Arul Kumar Ganapathi and Kallem Shekar Reddy for their support during corrosion tests and thankful to Shaik Jubeda Begum for helping in image analysis. The first and the last authors would like to thank the Naval Research Board of Defence Research and Development Organization, India, for providing partial funding for this study (Project Number NRB-371/MAT/15-16).

Author information

Authors and Affiliations

Corresponding author

Additional information

Handling Editor: Sophie Primig.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Georgy, K., Neelakantan, L., Kumar, K.C.H. et al. Influence of Cu, Zn and Si alloying elements on Al alloy foams produced using Mg blowing agent. J Mater Sci 56, 2612–2630 (2021). https://doi.org/10.1007/s10853-020-05381-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-020-05381-0