Abstract

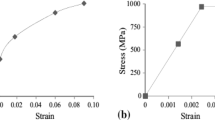

The objective of this research was to investigate the mechanical behavior of metal matrix composites (MMCs) 6061 aluminum, reinforced with silicon carbide particles, under unidirectional tensile loading by finite element analysis. The effects of particle’s shape, size and content on the tensile properties of the composites were studied and compared with each other. In addition, stress and strain distributions and possible particle fracture or debonding were investigated. It was found that, among different shapes, a certain shape of reinforcement particle provided better tensile properties for MMCs and, within each shape category, composites with smaller particle size and higher particle content (20%) also showed better properties. It was also found that when the reinforcement content was 10%, the effects of shape and size of the particles were negligible. Not only interfacial length between the reinforcement and matrix materials, but also state of matrix material, due to the presence of the reinforcement particles, affected the stiffness of the MMCs. In almost all of the cases, except for MMCs with triangular particles, when the stress increased, with the increase in the applied positive displacement, the stress distributions remained unchanged.

Similar content being viewed by others

References

H. Huang and M. Bush, Finite element analysis of mechanical properties in discontinuously reinforced metal matrix composites with ultrafine micro structure, Mater. Sci. Eng. A, 1997, 232(1), p 63–72

M. Rahimian, N. Parvin, and N. Ehsani, Investigation of particle size and amount of alumina on microstructure and mechanical properties of Al matrix composite made by powder metallurgy, Mater. Sci. Eng. A, 2010, 527(4), p 1031–1038

S.B. Prabu, L. Karunamoorthy, and G. Kandasami, A finite element analysis study of micromechanical interfacial characteristics of metal matrix composites, J. Mater. Process. Technol., 2004, 153, p 992–997

Y. Yan, L. Geng, and A. Li, Experimental and numerical studies of the effect of particle size on the deformation behavior of the metal matrix composites, Mater. Sci. Eng. A, 2007, 448(1), p 315–325

V.K. Varma, S.V. Kamat, Y.R. Mahajan, and V.V. Kutumbarao, Effect of reinforcement size on low strain yielding behaviour in Al-Cu-Mg/SiCp composites, Mater. Sci. Eng. A, 2001, 318(1–2), p 57–64

Z. Wang, M. Song, C. Sun, and Y. He, Effects of particle size and distribution on the mechanical properties of SiC reinforced Al-Cu alloy composites, Mater. Sci. Eng. A, 2011, 528(3), p 1131–1137

N. Chawla, C. Andres, J.W. Jones, and J.E. Allison, Effect of SiC volume fraction and particle size on the fatigue resistance of a 2080 Al/SiCp composite, Metall. Mater. Trans. A, 1998, 29(11), p 2843–2854

J.N. Hall, J. Wayne Jones, and A.K. Sachdev, Particle size, volume fraction and matrix strength effects on fatigue behavior and particle fracture in 2124 aluminum-SiCp composites, Mater. Sci. Eng. A, 1994, 183(1–2), p 69–80

V.V. Ganesh and N. Chawla, Effect of reinforcement-particle-orientation anisotropy on the tensile and fatigue behavior of metal-matrix composites, Metall. Mater. Trans. A Phys. Metall Mater. Sci., 2004, 35(1), p 53–61

G. O’Donnell and L. Looney, Production of aluminium matrix composite components using conventional PM technology, Mater. Sci. Eng. A, 2001, 303(1–2), p 292–301

R. Narayanasamy, T. Ramesh, and M. Prabhakar, Effect of particle size of SiC in aluminium matrix on workability and strain hardening behaviour of P/M composite, Mater. Sci. Eng. A, 2009, 504(1–2), p 13–23

A. Pramanik, L. Zhang, and J. Arsecularatne, An FEM investigation into the behavior of metal matrix composites: tool–particle interaction during orthogonal cutting, Int. J. Mach. Tools Manuf., 2007, 47(10), p 1497–1506

A. Pramanik, L. Zhang, and J. Arsecularatne, Micro-indentation of metal matrix composites—an FEM analysis, Key Eng. Mater., 2007, 340, p 341

M.T. Milan and P. Bowen, Tensile and fracture toughness properties of SiCp reinforced Al alloys: effects of particle size, particle volume fraction, and matrix strength, J. Mater. Eng. Perform., 2004, 13(6), p 775–783

A. Pramanik, L. Zhang, and J. Arsecularatne, Deformation mechanisms of MMCs under indentation, Compos. Sci. Technol., 2008, 68(6), p 1304–1312

A.M. Al-Qutub, I.M. Allam, and T.W. Qureshi, Effect of sub-micron Al2O3 concentration on dry wear properties of 6061 aluminum based composite, J. Mater. Process. Technol., 2006, 172(3), p 327–331

N. Chawla and Y.L. Shen, Mechanical behavior of particle reinforced metal matrix composites, Adv. Eng. Mater., 2001, 3(6), p 357–370

C. Sun, M. Song, Z. Wang, and Y. He, Effect of particle size on the microstructures and mechanical properties of SiC-reinforced pure aluminum composites, J. Mater. Eng. Perform., 2011, 20(9), p 1606–1612

C.-Y. Chen and C.-G. Chao, Effect of particle-size distribution on the properties of high-volume-fraction SiC p-Al-based composites, Metall. Mater. Trans. A, 2000, 31(9), p 2351–2359

R. Jamaati, S. Amirkhanlou, M.R. Toroghinejad, and B. Niroumand, Effect of particle size on microstructure and mechanical properties of composites produced by ARB process, Mater. Sci. Eng. A, 2011, 528(4), p 2143–2148

M. Kok, Production and mechanical properties of Al2O3 particle-reinforced 2024 aluminium alloy composites, J. Mater. Process. Technol., 2005, 161(3), p 381–387

T.J.A. Doel and P. Bowen, Tensile properties of particulate-reinforced metal matrix composites, Compos. A Appl. Sci. Manuf., 1996, 27(8), p 655–665

I.A. Ibrahim, F.A. Mohamed, and E.J. Lavernia, Particulate reinforced metal matrix composites—a review, J. Mater. Sci., 1991, 26(5), p 1137–1156

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Paknia, A., Pramanik, A., Dixit, A.R. et al. Effect of Size, Content and Shape of Reinforcements on the Behavior of Metal Matrix Composites (MMCs) Under Tension. J. of Materi Eng and Perform 25, 4444–4459 (2016). https://doi.org/10.1007/s11665-016-2307-x

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-016-2307-x