Abstract

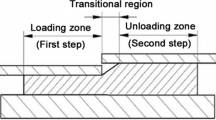

The size parameters of 6061 aluminum alloy rib-web forging were optimized by using hot-processing map and finite element method (FEM) based on high-temperature compression data. The results show that the stress level of the alloy can be represented by a Zener-Holloman parameter in a hyperbolic sine-type equation with the hot deformation activation energy of 343.7 kJ/mol. Dynamic recovery and dynamic recrystallization concurrently preceded during high-temperature deformation of the alloy. Optimal hot-processing parameters for the alloy corresponding to the peak value of 0.42 are 753 K and 0.001 s−1. The instability domain occurs at deformation temperature lower than 653 K. FEM is an available method to validate hot-processing map in actual manufacture by analyzing the effect of corner radius, rib width, and web thickness on workability of rib-web forging of the alloy. Size parameters of die forgings can be optimized conveniently by combining hot-processing map and FEM.

Similar content being viewed by others

References

R. Raj, Development of a Processing Map for Use in Warm-Forming and Hot Forming Processes, Metall. Trans., 1981, 12, p 1089–1097

Y.V.R.K. Prasad, H.L. Gegel, S.M. Doravelu, J.C. Malas, J.T. Morgan, K.A. Lark, and D.R. Barker, Modeling of Dynamic Material Behavior in Hot Deformation: Forging of Ti-6242, Metall. Trans. A, 1984, 15, p 1883–1892

J.S. Jin, H.E. Hu, and J.C. Xia, High-Temperature Deformation Behavior and Processing Map of 7050 Aluminum Alloy, Met. Mater. Int., 2012, 18, p 69–75

Y.-N. Kwon, Y.S. Lee, and J.H. Lee, Deformation Behavior of Al-Mg-Si Alloy at the Elevated Temperature, J. Mater. Proc. Technol., 2007, 187-188, p 533–536

J. Talamantes-Silva, M.F. Abbod, E.S. Puchi Cabrera, I.C. Howard, J.H. Beynon, C.M. Sellars, and D.A. Linkens, Microstructure Modeling of Hot Deformation of Al-1%Mg Alloy, Mater. Sci. Eng. A, 2009, 525, p 147–158

B.H. Lee, S.M. Kim, and E.M. Mohamed, Effect of stress state on the high temperature workability of AZ31 Mg alloy, Met. Mater. Int., 2010, 16, p 197–203

F.A. Slooff, J.S. Dzwonczyk, J. Zhou, J. Duszczyk, and L. Katgerman, Hot Workability Analysis of Extruded AZ Magnesium Alloys with Processing Maps, Mater. Sci. Eng. A, 2010, 527, p 735–744

N. Srinivasan, Y.V.R.K. Prasad, and P.R. Rao, Hot Deformation Behaviour of Mg-3Al Alloy-A Study Using Processing Map, Mater. Sci. Eng. A, 2007, 476, p 146–156

I. Philippart and H.J. Rack, High Temperature High Strain Deformation Behavior of Ti-6.8Mo-4.5Fe-1.5Al, Mater. Sci. Eng. A, 1998, 254, p 253–267

M. Rajamuthamilselvan and S. Ramanathan, Development of Processing Map for 7075 Al/20% SiCp Composite, J. Mater. Eng. Perform., 2012, 21, p 191–196

H.T. Zhou, R.R. Liu, Z.C. Liu, X. Zhou, Q.Z. Peng, F.H. Zhong, and Y. Peng, Hot Deformation Characteristics of GH625 and Development of a Processing Map, J. Mater. Eng. Perform., 2013, 22, p 2515–2521

B.F. Guo, H.P. Ji, X.G. Liu, L. Gao, R.G. Dong, and Q.H. Zhang, Research on Flow Stress During Hot Deformation Process and Processing Map for 316LN Austenitic Stainless Steel, J. Mater. Eng. Perform., 2012, 21, p 1455–1461

A. Amiri, M.H. Sadeghi, and G.R. Ebrahimi, Characterization of Hot Deformation Behavior of AMS 5708 Nickel-Based Superalloy Using Processing Map, J. Mater. Eng. Perform., 2013, 22, p 3940–3945

Y.H. Duan, Hot Deformation and Processing Map of Pb-Mg-10Al-1B Alloy, J. Mater. Eng. Perform., 2013, 22, p 3049–3054

J.G. Kaufman, Introduction to Aluminum Alloys and Tempers, ASM International, Materials Park, OH, 2000

S. Dziaszyk, E.J. Payton, F. Friedel, V. Marx, and G. Eggeler, On the Characterization of Recrystallized Fraction Using Electron Backscatter Diffraction: A Direct Comparison to Local Hardness in an IF Using Nanoindentation, Mater. Sci. Eng. A, 2010, 527, p 7854–7864

Ph Gerber, J. Tarasiuk, R. Chiron, and B. Bacroix, Estimation of the Recrystallized Volume Fraction From Local Misorientation Calculations, Arch. Metall. Mater., 2005, 50, p 747–755

H. Lu, P. Sivaprasad, and C.H.J. Davies, Treatment of Misorientation Data to Determine the Fraction of Recrystallized Grains in a Partially Recrystallized Metal, Mater. Charact., 2003, 51, p 293–300

B. Wu, M.Q. Li, and D.W. Ma, The Flow Behavior and Constitutive Equations in Isothermal Compression of 7050 Aluminum Alloy, Mater. Sci. Eng. A, 2012, 542, p 79–87

N. Haghdadi, A. Zarei-Hanzaki, and H.R. Abedi, The Flow Behavior Modeling of Cast A356 Aluminum Alloy at Elevated Temperatures Considering the Effect of Strain, Mater. Sci. Eng. A, 2012, 535, p 252–257

O.D. Sherby, R.H. Klundt, and A.K. Miller, Flow Stress, Subgrain Size, and Subgrain Stability at Elevated Temperature, Metall. Mater. Trans. A, 1977, 8(6), p 843–850

H.J. McQueen and O.C. Celliers, Application of Hot Workability Studies to Extrusion Processing: Part III. Physical and Mechanical Metallurgy of Al-Mg-Si and Al-Zn-Mg Alloys, Can. Metall. Q., 1997, 36, p 73–86

H. Zhang, L.X. Li, Y. Deng, and D.S. Peng, Hot Deformation Behavior of the New Al-Mg-Si-Cu Aluminum Alloy During Compression at Elevated Temperatures, Mater. Charact., 2007, 58, p 168–173

J.D. Whittenberger, R.D. Noebe, and J. Darolia, Elevated Temperature Creep Deformation in Solid Solution Strengthened <001> NiAl-3.6Ti Single Crystals, Mater. Sci. Eng. A, 2004, 367, p 143–151

S.V.S.N. Murty and B.N. Rao, On the Development of Instability Criteria During Hotworking with Reference to IN 718, Mater. Sci. Eng. A, 1998, 254, p 76–82

S.V.S.N. Murty, B.N. Rao, and B.P. Kashyap, Development and Validation of a Processing Map for AFNOR 7020 Aluminium Alloy, Mater. Sci. Technol., 2004, 20(6), p 772–782

Acknowledgments

This research is supported by the NSFC (51105373) and NCET-11-0185.

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Hu, H.E., Wang, X.Y. & Deng, L. An Approach to Optimize Size Parameters of Forging by Combining Hot-Processing Map and FEM. J. of Materi Eng and Perform 23, 3887–3895 (2014). https://doi.org/10.1007/s11665-014-1182-6

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-014-1182-6