Abstract

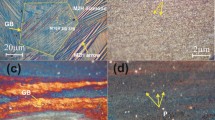

This paper introduces an adapted high-speed high pressure torsion (HS-HPT) method of severe plastic deformation applied for obtaining shape memory alloy (SMA) active elements with revolution symmetry, able to develop axial displacement/force. Billets with circular crown forms were cut from Fe-28Mn-6Si-5Cr (mass%) SMA ingots and, by means of HS-HPT technology, were directly turned into modules, with truncated cone shell configurations. This process was performed, during time intervals of seconds, under the effect of high pressure (up to 1 GPa) cumulated with high rotation speed (hundreds of rotations per minute) applied on the active surfaces of sintered-carbide anvils, specially designed for this purpose. Due to pressure and friction, generated by rotation, the entire sample volume is heated and simultaneously deformed to final shape. During the process, microstructure fragmentation occurred enabling to obtain (ultra)fine grains and nanocrystalline areas, in spite of the heat developed by friction, which was removed by conduction at the contact surface between sample and anvils, before the occurrence of any recrystallization phenomena. When compressed between flat surfaces, the truncated cone modules developed a superelastic-like response, unique among Fe-Mn-Si base SMAs and, when heated in compressed state, they were able to develop either axial strokes or recovery forces by either free or constrained recovery shape memory effect (SME), respectively. By means of optical (OM) and scanning electron microscopy (SEM) marked structural changes caused by HT-HPT were revealed, along with fine and ultrafine crystalline grains. The presence of stress-induced ε-hexagonal close-packed (hcp) martensite, together with nanocrystalline areas were confirmed by x-ray diffraction.

Similar content being viewed by others

References

P.W. Bridgman, On Torsion Combined with Compression, J. Appl. Phys., 1946, 17, p 692–697

A.P. Zhilyaev and T.G. Langdon, Using High-Pressure Torsion for Metal Processing: Fundamentals and Applications, Prog. Mater. Sci., 2008, 53, p 893–979

R.Z. Valiev, Y. Estrin, Z. Horita, T.G. Langdon, M.J. Zechetbauer, and Y.T. Zhu, Producing bulk ultrafine-grained materials by severe plastic deformation, JOM, 2006, 58(4), p 33–39

Y. Estrin and A. Vinogradov, Extreme Grain Refinement by Severe Plastic Deformation: A Wealth of Challenging Science, Acta Mater., 2013, 61, p 782–817

F.M. Braz Fernandes, K.K. Mahesh, R.J.C. Silva, C. Gurau, and G. Gurau, XRD Study of the Transformation Characteristics of Severely Plastic Deformed Ni-Ti SMAs, Phys. Status Solidi C, 2010, 7(5), p 1348–1350

K.K. Mahesh, F.M. Braz Fernandes, and G. Gurau, Phase Transformation in Ni-Ti Shape Memory and Superelastic Alloys Subjected to High Pressure Torsion, Adv. Mater. Res., 2010, 123–125, p 1007–1010

K.K. Mahesh, F.M. Braz Fernandes, R.J.C. Silva, and G. Gurau, Phase Transformation and Structural Study on the Severely Plastic Deformed Ni-Ti Alloys, Phys. Procedia, 2010, 10, p 22–27

D.N.A. Shri, K. Tsuchiya, and A. Yamamoto, Surface Characterization of TiNi Deformed by High-Pressure Torsion, Appl. Surf. Sci., 2014, 289, p 338–344

Y.B. Wang, X.Z. Liao, Y.H. Zhao, E.J. Lavernia, S.P. Ringer, Z. Horita, T.G. Langdon, and Y.T. Zhu, The Role of Stacking Faults and Twin Boundaries in Grain Refinement of a Cu-Zn Alloy Processed by High-Pressure Torsion, Mater. Sci. Eng. A, 2010, 527(18–19), p 4959–4966

R. Chulist, W. Skrotzki, C.-G. Oertel, A. Böhm, T. Lippmann, and E. Rybacki, Microstructure and Texture in Ni50Mn29Ga21 Deformed by High-Pressure Torsion, Scripta Mater., 2010, 62(9), p 650–653

J.L. Proft and T.W. Duerig, The Mechanical Aspects of Constraint Recovery, Engineering Aspects of Shape Memory Alloys, T.W. Duerig, K.N. Melton, D. Stöckel, and C.M. Wayman, Ed., Butterworth-Heinemann, London, 1990, p 115–129

S. Kajiwara, A.L. Baruj, T. Kikuchi, and N. Shinya, Low-Cost High-Quality Fe-Based Shape Memory Alloys Suitable for Pipe Joints, Proc. SPIE, 2003, 5053, p 251–261

T. Maruyama, T. Kurita, S. Kozaki, K. Andou, S. Farjami, and H. Kubo, Innovation in Producing Crane Rail Fishplate Using Fe-Mn-Si-Cr Based Shape Memory Alloy, Mater. Sci. Technol., 2008, 24, p 908–912

W.J. Lee, B. Weber, G. Feltrin, C. Czaderski, M. Motavalli, and C. Leinenbach, Stress Recovery Behaviour of an Fe-Mn-Si-Cr-Ni-VC Shape Memory Alloy Used for Prestressing, Smart Mater. Struct., 2013, 22, p 125037

C.M. Wayman, Deformations, Mechanisms and Other Characteristics of Shape Memory Alloys, Shape Memory Effects in Alloys, J. Perkins, Ed., Plenum Press, New York, 1975, p 1–27

C. Gurău, G. Gurau, and L. G. Bujoreanu, High Pressure Torsion Effects on Shape Memory Behavior of Fe-Mn-Si-Cr alloys, Proceedings of the SMST, 2013, p 65–67

M. Kawasaki, J. Foissey, and T.G. Langdon, Development of Hardness Homogeneity and Superplastic Behavior in an Aluminum-Copper Eutectic Alloy Processed by High-Pressure Torsion, Mater. Sci. Eng. A, 2013, 561, p 118–125

D. Rao, K. Huber, J. Heerens, J.F. dos Santos, and N. Huber, Asymmetric Mechanical Properties and Tensile Behaviour Prediction of Aluminium Alloy 5083 Friction Stir Welding Joints, Mater. Sci. Eng. A, 2013, 565, p 44–50

F.M.J. Starink, X. Cheng, and S. Yang, Hardening of Pure Metals by High-Pressure Torsion: A Physically Based Model Employing Volume-Averaged Defect Evolutions, Acta Mater., 2013, 61, p 183–192

G.B. Rathmayr, A. Hohenwarter, and R. Pippan, Influence of Grain Shape and Orientation on the Mechanical Properties of High Pressure Torsion Deformed Nickel, Mater. Sci. Eng. A, 2013, 560, p 224–231

H. Otsuka, H. Yamada, T. Maruyama, H. Tanahashi, S. Matsuda, and M. Murakami, Effects of Alloying Additions on Fe-Mn-Si Shape Memory Alloys, ISIJ Int., 1990, 30, p 674–679

T. Maki, Ferrous Shape Memory Alloys, Shape Memory Materials, K. Otsuka and C.M. Wayman, Ed., University Press, Cambridge, 1998, p 117–132

X. Sauvage, G. Wilde, S.V. Divinski, Z. Horita, and R.Z. Valiev, Grain Boundaries in Ultrafine Grained Materials Processed by Severe Plastic Deformation and Related Phenomena, Mater. Sci. Eng. A, 2012, 539, p 22–29

S. Jiang, Y. Zhang, L. Zhao, and Y. Zheng, Influence of Annealing on NiTi Shape Memory Alloy Subjected to Severe Plastic Deformation, Intermetallics, 2013, 32, p 344–351

S. Ozaki, K. Tsuda, and J. Tominaga, Analyses of Static and Dynamic Behavior of Coned Disk Springs: Effects of Friction Boundaries, Thin Walled Struct., 2012, 59, p 132–143

M. Peterlechner, T. Waitz, and H.P. Karnthaler, Nanoscale Amorphization of Severely Deformed NiTi Shape Memory Alloys, Scripta Mater., 2009, 60, p 1137–1140

S. Kajiwara, Characteristic Features of Shape Memory Effect and Related Transformation Behavior in Fe-Based Alloys, Mater. Sci. Eng. A, 1999, 273–275, p 67–88

Y. Zhang, S. Jiang, L. Hub, and Y. Liang, Deformation Mechanism of NiTi Shape Memory Alloy Subjected to Severe Plastic Deformation at Low Temperature, Mater. Sci. Eng. A, 2013, 559, p 607–614

M. Koyama, M. Murakami, K. Ogawa, T. Kikuchi, and T. Sawaguchi, Influence of Al on Shape Memory Effect and Twinning Induced Plasticity of Fe-Mn-Si-Al System Alloy, Mater. Trans., 2007, 48(10), p 2729–2734

T. Sawaguchi, L.-G. Bujoreanu, T. Kikuchi, K. Ogawa, M. Koyama, and M. Murakami, Mechanism of Reversible Transformation-Induced Plasticity of Fe-Mn-Si Shape Memory Alloys, Scripta Mater., 2008, 59, p 826–829

K.K. Mahesh, F.M. Braz Fernandes, and G. Gurău, Stability of Thermal-Induced Phase Transformations in the Severely Deformed Equiatomic Ni-Ti Alloys, J. Mater. Sci., 2012, 47, p 6005–6014

G. Gurău, L.-G. Bujoreanu, and R. I. Comăneci, Novel Method to Obtain Superelastic-Like Response in Fe-Mn-Si Based Shape Memory Alloys, J Mater Design, to be published

L.G. Bujoreanu, V. Dia, S. Stanciu, M. Susan, and C. Baciu, Study of Tensile Constrained Recovery Behavior of a Fe-Mn-Si Shape Memory Alloy, Eur. Phys. J. Spec. Top., 2008, 158, p 15–20

Acknowledgments

This research work was supported by the Project PN.II-PT-PCCA-2011-3.1-0174, Contract 144/2012.

Author information

Authors and Affiliations

Corresponding author

Additional information

This article is an invited paper selected from presentations at the International Conference on Shape Memory and Superelastic Technologies 2013, held May 20-24, 2013, in Prague, Czech Republic, and has been expanded from the original presentation.

Rights and permissions

About this article

Cite this article

Gurău, G., Gurău, C., Potecaşu, O. et al. Novel High-Speed High Pressure Torsion Technology for Obtaining Fe-Mn-Si-Cr Shape Memory Alloy Active Elements. J. of Materi Eng and Perform 23, 2396–2402 (2014). https://doi.org/10.1007/s11665-014-1060-2

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-014-1060-2