Abstract

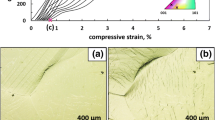

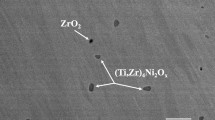

The effect of equal-channel angular pressing (ECAP) in quasi-continuous mode on the structure formation and mechanical and functional properties of a near-equiatomic Ti-Ni shape memory alloy (SMA) was studied in this work. ECAP with channel intersection angles of 110° and 120° was carried out at a temperature of 350-450 °C for 2-7 passes. Optimum deformation temperatures of ECAP in quasi-continuous mode are determined as 400 °C for ECAP with a channel intersection angle of 120° and 450 °C for 110°. ECAP with a channel intersection angle of 110° at a temperature of 450 °C yields high values of strength (yield stress σy = 1,090 MPa, ultimate tensile strength σв = 1,150 MPa) and functional (maximum value of completely recoverable strain of 7.5% after ECAP and 8.4% after the addition of post-deformation annealing (PDA) at 400 °C for 1 h) characteristics. With the increase in the deformation temperature of quasi-continuous ECAP with a channel intersection angle of 110° from 350 to 450 °C, structure-morphological transformation in Ti-Ni SMA occurs. The shape of structural elements (grains and subgrains) changes from elongated to equiaxed; the size of the structural elements increases from less than 100 nm to 100-250 nm.

Similar content being viewed by others

References

V. Brailovski, S.D. Prokoshkin, P. Terriault, F. Trochu, Shape Memory Alloys: Fundamentals, Modeling and Applications, Monreal: ETS Publishing, 2003, 851 p, https://espace2.etsmtl.ca/id/eprint/3754

J.M. Jani, M. Leary, A. Subic and M.A. Gibson, A Review of Shape Memory Alloy Research, Applications and Opportunities, Mater. Des., 2014, 56, p 1078–1113. https://doi.org/10.1016/j.matdes.2013.11.084

N. Resnina and V. Rubanik, Shape Memory Alloys: Properties, Technologies, Opportunities, Trans. Tech. Publications, Praffikon, 2015, p 640

Q. Sun, R. Matsui, K. Takeda, E. Pieczyska, Advances in Shape Memory Materials: In Commemoration of the Retirement of Professor Hisaaki Tobushi. New York: Springer, 2017, 73, 241 p, https://doi.org/https://doi.org/10.1007/978-3-319-53306-3

Z. Zeng, B.Q. Cong, J.P. Oliveira, W.C. Ke, N. Schell, B. Peng, Z.W. Qi, F.G. Gea, W. Zhange and S.S. Ao, Wire and Arc Additive Manufacturing of a Ni-Rich NiTi Shape Memory Alloy: Microstructure and Mechanical Properties, Addit. Manuf., 2020, 32, p 101051. https://doi.org/10.1016/j.addma.2020.101051

J.P. Oliveira, D. Barbosa, F.B. Fernandes and R.M. Miranda, Tungsten Inert Gas (TIG) Welding of Ni-Rich NiTi Plates: Functional Behavior, Smart Mater. Struct., 2016, 25(3), p 03LT01. https://doi.org/10.1088/0964-1726/25/3/03LT01

J.P. Oliveira, A.J. Cavaleiro, N. Schell, A. Stark, R.M. Miranda, J.L. Ocana and F.M. Braz Fernandes, Effects of Laser Processing on the Transformation Characteristics of NiTi: A Contribute to Additive Manufacturing, Scripta Mater., 2018, 152, p 122–126. https://doi.org/10.1016/j.scriptamat.2018.04.024

K.A. Polyakova, E.P. Ryklina and S.D. Prokoshkin, Effect of Grain Size and Ageing-Induced Microstructure on Functional Characteristics of a Ti-507 at% Ni Alloy, Shape Memory and Superelasticity, 2020, 6, p 139–147. https://doi.org/10.1007/s40830-020-00269-z

E.P. Ryklina, K.A. Polyakova, NYu. Tabachkova, N.N. Resnina and S.D. Prokoshkin, Effect of B2 Austenite Grain Size and Aging Time on Microstructure and Transformation Behavior of Thermomechanically Treated Titanium Nickelide, J. Alloys Compd., 2018, 764, p 626–638. https://doi.org/10.1016/j.jallcom.2018.06.102

D. Gunderov, A. Churakova, A. Lukyanov, E. Prokofiev, V. Pushin, A. Kreitcberg and S. Prokoshkin, Features of the Mechanical Behavior of Ultrafine-Grained and Nanostructured TiNi Alloys, Mater. Today: Proc., 2017, 4(3), p 4825–4829. https://doi.org/10.1016/j.matpr.2017.04.078

I. Khmelevskaya, V. Komarov, R. Kawalla, S. Prokoshkin and G. Korpala, Effect of Biaxial Isothermal Quasi-Continuous Deformation on Structure and Shape Memory Properties of Ti-Ni Alloys, J. Mater. Eng. Perform, 2017, 26(8), p 4011–4019. https://doi.org/10.1007/s11665-017-2841-1

S. Prokoshkin, I. Khmelevskaya, V. Andreev, R. Karelin, V. Komarov and A. Kazakbiev, Manufacturing of Long-Length Rods of Ultrafine-Grained Ti-Ni Shape Memory Alloys, Mater. Sci. Forum, 2018, 918, p 71–76.

A.A. Churakova and D.V. Gunderov, Microstructure and Mechanical Properties of the Ultrafine-Grained TiNi Alloy After Multiple Martensitic Transformations and Subsequent Aging, IOP Conf. Ser. Mater. Sci. Eng, 2019 https://doi.org/10.1088/1757-899X/672/1/012025

V. Komarov, I. Khmelevskaya, R. Karelin, R. Kawalla, G. Korpala, U. Prahl, V. Yusupov and S. Prokoshkin, Deformation Behavior, Structure, and Properties of an Aging Ti-Ni Shape Memory Alloy after Compression Deformation in a Wide Temperature Range, JOM, 2021 https://doi.org/10.1007/s11837-020-04508-7

R.Z. Valiev, A.V. Korznikov and R.R. Mulyukov, Structure and Properties of Ultrafine-Grained Materials Produced by Severe Plastic Deformation, Mater. Sci. Eng. A., 1993, 168(2), p 141–148. https://doi.org/10.1016/0921-5093(93)90717-S

R. Valiev, Y. Estrin, Z. Horita, T. Langdon, M. Zehetbauer and Y. Zhu, Producing Bulk Ultrafine-Grained Materials by Severe Plastic Deformation, JOM, 2006, 58, p 33–39. https://doi.org/10.1007/s11837-006-0213-7

I. Sabirov, N. Enikeev, M. Murashkin, R. Valiev, Bulk Nanostructured Materials with Multifunctional Properties, New York: Springer, 2015, 118 p, https://doi.org/https://doi.org/10.1007/978-3-319-19599-5

V. Brailovski, S. Prokoshkin, I. Khmelevskaya, K. Inaekyan, V. Demers, S. Dobatkin and E. Tatyanin, Structure and Properties of the Ti-500 at% Ni Alloy After Strain Hardening and Nanocrystallizing, Mater. Trans, 2006 https://doi.org/10.2320/matertrans.47.795

V. Komarov, I. Khmelevskaya, R. Karelin, S. Prokoshkin, M. Zaripova, M. Isaenkova, G. Korpala and R. Kawalla, Effect of Biaxial Cyclic Severe Deformation on Structure and Properties of Ti-Ni Alloys, J. Alloys Compd, 2019, 797, p 842–848. https://doi.org/10.1016/j.jallcom.2019.05.127

IYu. Khmelevskaya, R. Kawalla, S.D. Prokoshkin and V.S. Komarov, Effect of Multiaxial Deformation Max-Strain on the Structure and Properties of Ti-Ni Alloy, IOP Conf. Ser. Mater. Sci. Eng., 2014, 63, p 012108. https://doi.org/10.1088/1757-899X/63/1/012108

I. Khmelevskaya, V. Komarov, R. Kawalla, S. Prokoshkin and G. Korpala, Features of Ti-Ni Alloy Structure Formation Under Multi-Axial Quasi-Continuous Deformation and Post-Deformation Annealing, Mater. Today: Proc., 2017, 4(3), p 4830–4835. https://doi.org/10.1016/j.matpr.2017.04.079

R.Z. Valiev and T.G. Langdon, Principles of Equal-Channel Angular Pressing as a Processing Tool for Grain Refinement, Prog. Mater Sci., 2006, 51, p 881–981. https://doi.org/10.1016/j.pmatsci.2006.02.003

H. Shahmir, M. Nili-Ahmadabadi, M. Mansouri-Arani and T.G. Langdon, The Processing of NiTi Shape Memory Alloys by Equal-Channel Angular Pressing at Room Temperature, Mater. Sci. Eng. A., 2013, 576, p 178–184. https://doi.org/10.1016/j.msea.2013.04.001

IYu. Khmelevskaya, R.D. Karelin, S.D. Prokoshkin, M.G. Isaenkova, Yu.A. Perlovich, V.A. Fesenko, V.S. Komarov and M.M. Zaripova, Features of Nanostructure and Functional Properties Formation in Ti-Ni Shape Memory Alloys Subjected to Quasi-Continuous Equal Channel Angular Pressing, IOP Conf. Ser. Mater. Sci. Eng, 2019 https://doi.org/10.1088/1757-899X/503/1/012024

G. Raab, The Innovation Potential of ECAP Techniques of Severe Plastic Deformation, IOP Conf Ser. Mater. Sci. Eng, 2014 https://doi.org/10.1088/1757-899X/63/1/012009

S.N. Lezhnev, I.E. Volokitina and D.V. Kuis, Evolution of Microstructure and Mechanical Properties of Composite Aluminum-Based Alloy during ECAP, Phys. Met. Metallogr., 2018, 119(8), p 810–815. https://doi.org/10.1134/S0031918X18040129

V.G. Pushin, R.Z. Valiev, Y.T. Zhu, S.D. Prokoshkin, D.V. Gunderov and L.I. Yurchenko, Effect of Equal-Channel Angular Pressing and Repeated Rolling on Structure Phase Transformations and Properties of TiNi Shape Memory Alloys, Mater. Sci. Forum, 2006, 503–504, p 539–544.

IYu. Khmelevskaya, S.D. Prokoshkin, I.B. Trubitsyna, M.N. Belousov, S.V. Dobatkin, E.V. Tatyanin, A.V. Korotitskiy, V. Brailovski, V.V. Stolyarov and E.A. Prokofiev, Structure and Properties of Ti–Ni-Based Alloys After Equal-Channel Angular Pressing and High-Pressure Torsion, Mater. Sci. Eng. A, 2008, 481–482, p 119–122. https://doi.org/10.1016/j.msea.2007.02.157

V.V. Stolyarov, E.A. Prokofyev, S.D. Prokoshkin, S.V. Dobatkin, I.B. Trubitsyina, I.Y. Khmelevskaya, V.G. Pushin and R.Z. Valiev, Structure Features, Mechanical Properties and Shape Memory Effect in Ti-Ni Alloy, Processed by ECAP, Phys. Met. Metallogr, 2005, 100, p 608–618.

IYu. Khmelevskaya, R.D. Karelin, S.D. Prokoshkin, V.A. Andreev, V.S. Yusupov, M.M. Perkas, V.V. Prosvirnin, A.E. Shelest and V.S. Komarov, Effect of the Quasi-Continuous Equal-Channel Angular Pressing on the Structure and Functional Properties of Ti-Ni-Based Shape-Memory Alloys, Phys. Met. Metallogr, 2017, 118, p 279–287. https://doi.org/10.1134/S0031918X17030073

H.C. Lin and S.K. Wu, Strengthening Effect on Shape Recovery Characteristic of the Equiatomic TiNi Alloy, Scripta Metall. Mater, 1992, 26, p 59–62. https://doi.org/10.1016/0956-716X(92)90369-P

V.G. Pushin, A.I. Lotkov, Y.R. Kolobov, R.Z. Valiev, E.F. Dudarev, N.N. Kuranova, A.P. Dyupin, D.V. Gunderov and G.P. Bakach, On the Nature of Anomalously High Plasticity of High-Strength Titanium Nickelide Alloys with Shape-Memory Effects: I. Initial Structure and Mechanical Properties, Phys. Met. Metallogr, 2008, 106(5), p 520–530. https://doi.org/10.1134/S0031918X08110124

E.F. Dudarev, R.Z. Valiev, Yu.R. Kolobov, A.I. Lotkov, V.G. Pushin, G.P. Bakach, D.V. Gunderov, A.P. Dyupin and N.N. Kuranova, On the Nature of Anomalously High Plasticity of High-Strength Titanium Nickelide Alloys with Shape-Memory Effects: II. Mechanisms of Plastic Deformation Upon Isothermal Loading, Phys. Met. Metallogr, 2009, 107(3), p 298–311. https://doi.org/10.1134/S0031918X09030120

E.P. Ryklina, S.D. Prokoshkin and A.A. Chernavina, Peculiarities of Implementation of Abnormally High Shape Memory Effects in Thermomechanically Treated Ti-Ni Alloys, Inorg. Mater. Appl. Res., 2013, 4(4), p 348–355. https://doi.org/10.1134/S2075113313040096

E. Ryklina, S. Prokoshkin and A. Kreytsberg, Abnormally High Recovery Strain in Ti–Ni-Based Shape Memory Alloys, J. Alloys Compd., 2013, 577(1), p 255–258. https://doi.org/10.1016/j.jallcom.2012.02.138

S. Prokoshkin, V. Brailovski, K. Inaekyan, V. Demers, I. Khmelevskaya, S. Dobatkin and E. Tatyanin, Structure and Properties of Severely Cold-Rolled and Annealed Ti-Ni Shape Memory Alloys, Mater. Sci. Eng. A., 2008, 481–482, p 114–118. https://doi.org/10.1016/j.msea.2007.02.150

Acknowledgments

The work was carried out with the support of the Ministry of Science and Higher Education of the Russian Federation in the framework of the State Task (project code 0718-2020-0030).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Karelin, R.D., Khmelevskaya, I.Y., Komarov, V.S. et al. Effect of Quasi-Continuous Equal-Channel Angular Pressing on Structure and Properties of Ti-Ni Shape Memory Alloys. J. of Materi Eng and Perform 30, 3096–3106 (2021). https://doi.org/10.1007/s11665-021-05625-3

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-021-05625-3