Abstract

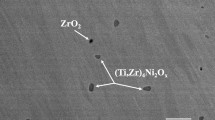

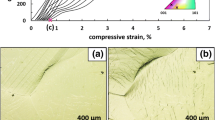

The effect of severe plastic deformation by equal-channel angular pressing (ECAP) under normal and quasi-continuous regimes on the structure and the mechanical and functional properties of a Ti–50.2 at % Ni shape-memory alloy (SMA) has been studied. ECAP was carried out at an angle of intersection of channels of 120° in the normal regime with heating between passes at 450°C for 20 passes and in the quasi-continuous regime at the temperature of 400°C for three, five, and seven passes. The hot screw rolling with subsequent annealing at 750°C for 30 min and cooling in water was used as a control treatment (CT). A mixed submicrocrystalline and nanosubgrained structure was formed. The increase in the number of passes from three to seven led to a decrease in the average size of structural elements from 115 ± 5 to 103 ± 5 nm and to an increase in the fraction of grains/subgrains having a size less than 100 nm. After ECAP (seven passes) and post-deformation annealing at the temperature of 400°C for 1 h, a completely recoverable strain was 9.5%; after normal ECAP, 7.2%; after CT, 4.0%.

Similar content being viewed by others

References

R. Z. Valiev and I. V. Aleksandrov, Nanostructural Materials Obtained by Severe Plastic Deformation (Integratsiya, Moscow, 2000).

R. Z. Valiev, “Nanomaterial advantage,” Nature 419, 887–889 (2002).

I. Yu. Khmelevskaya, S. D. Prokoshkin, S. V. Dobatkin, and V. V. Stolyarov, “Structure and properties of severely deformed Ti–Ni-based shape memory alloys,” J. Phys. 4, 819–822 (2003).

I. Yu. Khmelevskaya, I. B. Trubitsyna, S. D. Prokoshkin, S. V. Dobatkin, E. V. Tatyanin, V. V. Stolyarov, and E. A. Prokofiev, “Thermomechanical treatment of Ti–Ni–based shape memory alloys using severe plastic deformation,” Mater. Sci. Forum 426–432, 2765–2770 (2003).

S. D. Prokoshkin, I. Yu. Khmelevskaya, S. V. Dobatkin, I. B. Trubitsyna, V. V. Stolyarov, and E. A. Prokofiev, “Structure evolution upon severe plastic deformation of TiNi-based shape–memory alloys,” Phys. Met. Metallogr. 97, 619–625 (2005).

S. D. Prokoshkin, I. Y. Khmelevskaya, S. V. Dobatkin, I. B. Trubitsyna, E. V. Tatyanin, V. V. Stolyarov, and E. A. Prokofiev, “Alloy composition, deformation temperature, pressure and post–deformation annealing effects in severely deformed Ti–Ni based shape memory alloys,” Act. Mater. 53, 2703–2714 (2005).

I. B. Trubitsina, Structure Formation and Functional Properties of Ti–Ni Alloys after Severe Plasric Deformation (NITU MISiS, Moscow, 2005) [in Russian].

V. M. Segal, “Plastic treatment of metals by simple shear,” Izv. Akad. Nauk SSSR, Met., No. 1, 115–123 (1981).

V. M. Segal, “Development of material treatment by severe plastic deformation,” Russ. Metall. (Metally) 2004, 2–9 (2004).

R. Z. Valiev and T. G. Langdon, “Principles of equalchannel angular pressing as a processing tool for grain refinement,” Progr. Mater. Sci. 51, 881–981 (2006).

G. Raab, “The innovation potential of ECAP techniques of severe plastic deformation,” Mater. Sci. Eng. 63, 012009 (2014).

R. Kocich, L. Kuncická, and A. Machácková, “Twist channel multi-angular pressing (TCMAP) as a new SPD process: Numerical and experimental study,” Mater. Sci. Eng., A 612, 445–455 (2014).

A. V. Botkin, “Scientific-Methodological Foundations of Designing Angular-Pressing Processes,” Doctoral (Eng.) Dissertation (UGATU, Ufa, 2013).

D. V. Gunderov, A. V. Polykov, and I. P. Semenova, “Evaluation of microstructure, macrostructure and mechanical properties of commercially pure Ti during ECAP-conform processing and drawing,” Mater. Sci. Eng., A 562, 128–136 (2013).

V. V. Stolyarov, E. A. Prokof’ev, S. D. Prokoshkin, S. V. Dobatkin, I. B. Trubitsyna, I. Yu. Khmelevskaya, V. G. Pushin, and R. Z. Valiev,”Structural features, mechanical properties, and the shape-memory effect in TiNi alloys subjected to equal-channel singular pressing,” Phys. Met. Metallogr. 100, 608–612 (2005).

V. Brailovski, S. Prokoshkin, I. Khmelevskaya, K. Inaekyan, V. Demers, S. Dobatkin, and E. Tatyanin, “Structure and properties of the Ti–50.0 at % Ni alloy after strain hardening and nanocrystallizing thermomechanical processing,” Mater. Trans. 47, 795–804 (2006).

V. Demers, V. Brailovski, S. Prokoshkin, K. Inaekyan, E. Bastarash, I. Khmelevskaya, and S. Dobatkin, “Functional properties of nanostructured Ti–50.0 at % Ni alloy,” J. ASTM Int. (JAI) 3(6), 1–11 (2006).

S. D. Prokoshkin, V. Brailovskii, I. Yu. Khmelevskaya, S. V. Dobatkin, K. E. Inaekyan, V. Demers, and E. V. Tat’yanin, “Formation of nanocrystalline structure upon severe rolling plastic deformation and annealing and improvement of set of functional properties of Ti–Ni alloys,” Bull. Russ. Acad. Sci.: Phys. 70, 1536–1541 (2006).

V. G. Pushin, R. Z. Valiev, Y. T. Zhu, S. D. Prokoshkin, D. V. Gunderov, and L. I. Yurchenko, “Effect of equal channel angular pressing and repeated rolling on structure phase transformations and properties of TiNi shape memory alloys,” Mater. Sci. Forum 503–504, 539–544 (2006).

I. Yu. Khmelevskaya, S. D. Prokoshkin, S. V. Dobatkin, E. V. Tatyanin, and I. B. Trubitsyna, “Studies of composition, deformation temperature and pressure effects on structure formation in severely deformed TiNi–based alloy,” Mater. Sci. Eng., A 438–440, 472–475 (2006).

I. Yu. Khmelevskaya, S. D. Prokoshkin, I. B. Trubitsyna, M. N. Belousov, S. V. Dobatkin, E. V. Tatyanin, A. V. Korotitskiy, V. Brailovski, V. V. Stolyarov, and E. A. Prokofiev, “Structure and properties of Ti–Ni-based alloys after equal-channel angular pressing and high-pressure torsion,” Mater. Sci. Eng., A 481–482, 119–122 (2008).

D. Gunderov, D. Lukyanov, E. Prokofiev, A. Churakova, V. Pushin, S. Prokoshkin, V. Stolyarov, and R. Valiev, “Microstructure and mechanical properties of the SPD-processed TiNi alloys,” Mater. Sci. Forum 738–739, 486–490 (2013).

D. Yu. Zhapova, “Microstructure Evolution and Its Effect on Martensitic Transformations and Nonelastic Properties of Titanium Nickelide-Based Binary Alloys upon Warm Deformation,” Candidate Sci. (Eng.) Dissertation (IFPM SO RAN, Tomsk, 2013).

A. A. Churakova and D. V. Gundarev, “Effect of thermocycling on the temperatures of phase transformations, structure, and properties of the Ti50.0Ni50.0 equiatomic alloy,” Phys. Met. Metallogr. 117, 96–106 (2016).

H. S. Kim, “Prediction of temperature rise in equal channel angular pressing,” Mater. Trans. 42, 536–538 (2001).

H. Shahmir, M. Nili-Ahmadabadi, M. Mansouri- Arani, and T. G. Langdon, “The processing of NiTi shape memory alloys by equal-channel angular pressing at room temperature,” Mater. Sci. Eng., A 576, 178–184 (2013).

A. V. Korotitskii, “Express-estimation of parameters of form restoration of shape-memory alloys after deformation induced by bending,” in Proc. 5th Eur.-Asia Sci.Tech. Conf. “Strength of inhomogeneous Structures” PROST 2010 (MISiS, Moscow, 2010).

V. Brailovski, S. D. Prokoshkin, P. Terriault, and F. Trochu, Shape Memory Alloys: Fundamentals, Modeling and Applications (ETS Publ., Monreal, 2003).

S. V. Oleinikova, S. D. Prokoshkin, L. M. Kaputkina, I. Yu. Khmelevskaya, A. A. Kadnikov, and L. A. Zaitseva, “Effect of ageing on mechanical behavior of Ti–50.7% Ni alloy,” Tekhnol. Legk. Splavov, No. 4, 28–34 (1990).

V. Brailovski, S. Prokoshkin, K. Inaekyan, and V. Demers, “Functional properties of nanocrystalline, submicrocrystalline and polygonized Ti–Ni alloys processed by cold rolling and post-deformation annealing,” J. Alloys Compd. 509, 2066–2075 (2011).

K. A. Polyakova-Vachiyan, E. P. Ryklina, S. D. Prokoshkin, and S. M. Dubinskii, “Dependence of the functional characteristics of thermomechanically processed titanium nickelide on the size of the structural elements of austenite,” Phys. Met. Metallogr. 117, 817–827 (2016).

S. D. Prokoshkin, V. Brailovskii, A. V. Korotitskii, K. E. Inaekyan, and A. M. Glezer, “Specific features of the formation of the microstructure of titanium nickelide upon thermomechanical treatment including cold plastic deformation to degrees from moderate to severe,” Phys. Met. Metallogr. 110, 289–303 (2010).

S. D. Prokoshkin, I. Yu. Khmelevskaya, V. Brailovski, F. Trochu, and V. Y. Turilina, “Structure and deformation diagrams of NiTi alloys subjected to a low-temperature thermomechanical treatment with postdeformation heating,” Phys. Met. Metallogr. 91, 423–431 (2001).

A. Kreitcberg, V. Brailovski, S. Prokoshkin, D. Gunderov, M. Khomutov, and K. Inaekyan, “Effect of the grain/subgrain size on the strain-rate sensitivity and deformability of Ti–50 at %Ni alloy,” Mater. Sci. Eng., A 622, 21–29 (2015).

Author information

Authors and Affiliations

Corresponding author

Additional information

Original Russian Text © I.Yu. Khmelevskaya, R.D. Karelin, S.D. Prokoshkin, V.A. Andreev, V.S. Yusupov, M.M. Perkas, V.V. Prosvirnin, A.E. Shelest, V.S. Komarov, 2017, published in Fizika Metallov i Metallovedenie, 2017, Vol. 118, No. 3, pp. 293–300.

Rights and permissions

About this article

Cite this article

Khmelevskaya, I.Y., Karelin, R.D., Prokoshkin, S.D. et al. Effect of the quasi-continuous equal-channel angular pressing on the structure and functional properties of Ti–Ni-based shape-memory alloys. Phys. Metals Metallogr. 118, 279–287 (2017). https://doi.org/10.1134/S0031918X17030073

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S0031918X17030073