Abstract

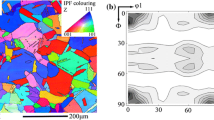

The influence of friction on the mechanical properties, physical properties, and microstructure of the processed billets by equal-channel angular pressing (ECAP) was investigated in this work. Selecting the lubricants from different available lubricants which were the agents to change the friction in the process was based on the ring compression test. Simple tensile tests showed that ductility was improved more than 16%, which was accompanied with almost constant yield strength and ultimate strength by increasing the friction coefficient. In addition, about 4.6% more impact energy was absorbed in the impact test. Microhardness values were recorded on the longitudinal and cross-sectional planes of each billet to evaluate the degree of the homogeneity of the mechanical properties. The results obtained from microhardness measurement confirmed that there was a little enhancement in the homogeneity of the work-piece on its longitudinal plane by increasing the friction. However, the homogeneity of the work-piece on its cross-sectional plane decreased by increasing the friction coefficient. Assessment of the microstructure of different samples showed considerable influence of the ECAP process on the elimination of pores and cavities in the billets. In addition, density measurements indicated that the size of the pores within the bulk material was decreased as the friction was increased.

Similar content being viewed by others

References

V.M. Segal, Materials Processing by Simple Shear, Mater. Sci. Eng. A, 1995, 197(2), p 157–164

E. López-Chipres, E. García-Sanchez, E. Ortiz-Cuellar, M.A.L. Hernandez-Rodriguez, and R. Colás, Optimization of the Severe Plastic Deformation Processes for the Grain Refinement of Al6060 Alloy Using 3D FEM Analysis, J. Mater. Eng. Perform., 2010, doi:10.1007/s11665-010-9783-1

H.G. Salem and J.S. Lyons, Effect of Equal Channel Angular Extrusion on the Microstructure and Superplasticity of an Al-Li Alloy, J. Mater. Eng. Perform., 2002, 11(4), p 384–391

K. Narooei and A. Karimi Taheri, A New Model for Prediction the Strain Field and Extrusion Pressure in ECAE Process of Circular Cross Section, Appl. Math. Model., 2010, 34(7), p 1901–1917

J. Alkorta and J. Gil Sevillano, A Comparison of FEM and Upper-Bound Type Analysis of Equal-Channel Angular Pressing (ECAP), J. Mater. Process. Technol., 2003, 141(3), p 313–318

H.J. Hu, Simulations of Isothermal ECAE for Magnesium Alloy Using FEM Software and Experimental Validations, J. Mater. Process. Technol., 2012, 14(3), p 181–187

R. Luri, C.J. Luis Pérez, D. Salcedo, I. Puertas, J. León, I. Pérez, and J.P. Fuertes, Evolution of Damage in AA-5083 Processed by Equal Channel Angular Extrusion Using Different Die Geometries, J. Mater. Process. Technol., 2011, 211(1), p 48–56

N.E. Mahallawy, F.A. Shehata, M.A.E. Hameed, M.I.A.E. Aal, and H.S. Kim, 3D FEM Simulations for the Homogeneity of Plastic Deformation in Al-Cu Alloys During ECAP, Mater. Sci. Eng. A, 2010, 527(6), p 1404–1410

E. Cerri, P.P. De Marco, and P. Leo, FEM and Metallurgical Analysis of Modified 6082 Aluminium Alloys Processed by Multipass ECAP: Influence of Material Properties and Different Process Settings on Induced Plastic Strain, J. Mater. Process. Technol., 2009, 209(3), p 1550–1564

S. Wang, W. Liang, Y. Wang, L. Bian, and K. Chen, A Modified Die for Equal Channel Angular Pressing, J. Mater. Process. Technol., 2009, 209(7), p 3182–3186

A.V. Nagasekhar, S.C. Yoon, Y. Tick-Hon, and H.S. Kim, An Experimental Verification of the Finite Element Modelling of Equal Channel Angular Pressing, Comput. Mater. Sci, 2009, 46(2), p 347–351

R.B. Figueiredo, P.R. Cetlin, and T.G. Langdon, The Evolution of Damage in Perfect-Plastic and Strain Hardening Materials Processed by Equal-Channel Angular Pressing, Mater. Sci. Eng. A, 2009, 518(1-2), p 124–131

S.C. Yoon, M.H. Seo, and H.S. Kim, Preform Effect on the Plastic Deformation Behavior of Workpieces in Equal Channel Angular Pressing, Scripta Mater., 2006, 55(2), p 159–162

C.J. Luis-Pérez, R. Luri-Irigoyen, and D. Gastón-Ochoa, Finite Element Modelling of an Al-Mn Alloy by Equal Channel Angular Extrusion (ECAE), J. Mater. Process. Technol., 2004, 153-154, p 846–852

C.J. LuisPérez, P. González, and Y. Garcés, Equal Channel Angular Extrusion in a Commercial Al-Mn Alloy, J. Mater. Process. Technol., 2003, 143-144, p 506–511

C. Xu, T. Langdon, Z. Horita, and M. Furukawa, Using Equal-Channel Angular Pressing for the Production of Superplastic Aluminum and Magnesium Alloys, J. Mater. Eng. Perform., 2004, 13(6), p 683–690

P.B. Prangnell, C. Harris, and S.M. Roberts, Finite Element Modelling of Equal Channel Angular Extrusion, Scripta Mater., 1997, 37(7), p 983–989

Y.-L. Yang and S. Lee, Finite Element Analysis of Strain Conditions After Equal Channel Angular Extrusion, J. Mater. Process. Technol., 2003, 140(1-3), p 583–587

S. Li, M.A.M. Bourke, I.J. Beyerlein, D.J. Alexander, and B. Clausen, Finite Element Analysis of the Plastic Deformation Zone and Working Load in Equal Channel Angular Extrusion, Mater. Sci. Eng. A, 2004, 382(1-2), p 217–236

T. Suo, Y. Li, Y. Guo, and Y. Liu, The Simulation of Deformation Distribution During ECAP Using 3D Finite Element Method, Mater. Sci. Eng. A, 2006, 432(1-2), p 269–274

S. Xu, G. Zhao, X. Ma, and G. Ren, Finite Element Analysis and Optimization of Equal Channel Angular Pressing for Producing Ultra-fine Grained Materials, J. Mater. Process. Technol., 2007, 184(1-3), p 209–216

H.S. Kim, Finite Element Analysis of Equal Channel Angular Pressing Using a Round Corner Die, Mater. Sci. Eng. A, 2001, 315(1-2), p 122–128

B.S. Altan, G. Purcek, and I. Miskioglu, An Upper-Bound Analysis for Equal-Channel Angular Extrusion, J. Mater. Process. Technol., 2005, 168(1), p 137–146

A.V. Nagasekhar, Y. Tick-Hon, S. Li, and H.P. Seow, Stress and Strain Histories in Equal Channel Angular Extrusion/Pressing, Mater. Sci. Eng. A, 2006, 423(1-2), p 143–147

F. Djavanroodi and M. Ebrahimi, Effect of Die Channel Angle, Friction and Back Pressure in the Equal Channel Angular Pressing Using 3D Finite Element Simulation, Mater. Sci. Eng. A, 2010, 527(4-5), p 1230–1235

T. Robinson, H. Ou, and C.G. Armstrong, Study on Ring Compression Test Using Physical Modelling and FE Simulation, J. Mater. Process. Technol., 2004, 153-154, p 54–59

M. Prell, C. Xu, and T.G. Langdon, The Evolution of Homogeneity on Longitudinal Sections During Processing by ECAP, Mater. Sci. Eng. A, 2008, 480(1-2), p 449–455

S. Dumoulin, H.J. Roven, J.C. Werenskiold, and H.S. Valberg, Finite Element Modeling of Equal Channel Angular Pressing: Effect of Material Properties, Friction and Die Geometry, Mater. Sci. Eng. A, 2005, 410-411, p 248–251

I. Balasundar and T. Raghu, Effect of Friction Model in Numerical Analysis of Equal Channel Angular Pressing Process, Mater. Des., 2010, 31(1), p 449–457

F. Djavanroodi and M. Ebrahimi, Effect of Die Parameters and Material Properties in ECAP with Parallel Channels, Mater. Sci. Eng. A, 2010, 527(29-30), p 7593–7599

A.R. Eivani and A. Karimi Taheri, The Effect of Dead Metal Zone Formation on Strain and Extrusion Force During Equal Channel Angular Extrusion, Comput. Mater. Sci., 2008, 42(1), p 14–20

J.K. Kim, H.K. Kim, J.W. Park, and W.J. Kim, Large Enhancement in Mechanical Properties of the 6061 Al Alloys After a Single Pressing by ECAP, Scripta Mater., 2005, 53(10), p 1207–1211

P.W.J. McKenzie and R. Lapovok, ECAP with Back Pressure for Optimum Strength and Ductility in Aluminium Alloy 6016. Part 2: Mechanical Properties and Texture, Acta Mater., 2010, 58(9), p 3212–3222

I.-H. Son, J.-H. Lee, and Y.-T. Im, Finite Element Investigation of Equal Channel Angular Extrusion with Back Pressure, J. Mater. Process. Technol., 2006, 171(3), p 480–487

N. Medeiros, J.F.C. Lins, L.P. Moreira, and J.P. Gouvêa, The Role of the Friction During the Equal Channel Angular Pressing of an IF-Steel Billet, Mater. Sci. Eng. A, 2008, 489(1-2), p 363–372

A. Shan, I.-G. Moon, and J.-W. Park, Estimation of Friction During Equal Channel Angular (ECA) Pressing of Aluminum Alloys, J. Mater. Process. Technol., 2002, 122(2-3), p 255–259

A. Shokuhfar and O. Nejadseyfi, A Comparison of the Effects of Severe Plastic Deformation and Heat Treatment on the Tensile Properties and Impact Toughness of Aluminum Alloy 6061, Mater. Sci. Eng. A, 2014, 594, p 140–148

Acknowledgments

The authors would like to thank the Iran Nanotechnology Initiative Council (INIC) and K.N. Toosi University of Technology, Tehran, Iran, for the financial support and research facilities used in this work. Also, they acknowledge the help of Mr. Naeem who was in-charge of machine-shop, at that university for performing the experimental tests.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Shokuhfar, A., Nejadseyfi, O. The Influence of Friction on the Processing of Ultrafine-Grained/Nanostructured Materials by Equal-Channel Angular Pressing. J. of Materi Eng and Perform 23, 1038–1048 (2014). https://doi.org/10.1007/s11665-013-0849-8

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-013-0849-8