Abstract

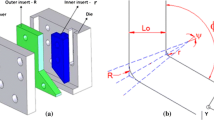

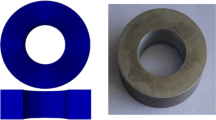

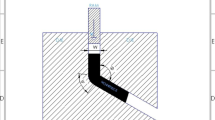

Equal channel angular pressing (ECAP) is one of the advanced manufacturing methods for the production of nanostructured samples. The ECAPed materials showed exceptional mechanical properties with simultaneous high strength and good elongation features. Recently, the application of ECAP method for the production of industrial samples has widely been reported. Due to the required high pressing load in ECAP process, the length of the produced samples is limited. This study investigates the rooms for the reduction in the pressing load by change in frictional surfaces. Here, a novel design of ECAP punch and die is proposed, where most of the friction surfaces are changing from ‘soft sample-to-brittle die’ to ‘brittle die-to-brittle punch’ contact surfaces. By changing the contact surfaces between punch and die, the opportunity for the preparation of frictional surfaces is provided and the total frictional surfaces is reduced. The results of the numerical analysis and experimental measurements showed that about 2.2-9.8% reduction in the maximum required pressing load is feasible. Further reduction is also possible by more surface preparation. Optical microscopy is used to investigate the contact surfaces after the process, and scanning and transmission electron microscopies are used to analyze the rate of the grain refinement of the samples after conventional and novel ECAP processes. The experimental finding is supported by 3D finite element analysis (FEM). The calculated maximum required pressing force in novel and conventional ECAP dies is in good agreement with the experimental measurements. The FEM analysis revealed that the reduction in the pressing load by the modification of frictional surfaces is a practical approach.

Similar content being viewed by others

References

Y. Iwahashi, Z. Horita, M. Nemoto, and T.G. Langdon, An Investigation of Microstructural Evolution During Equal-Channel Angular Pressing, Acta Mater., 1997, 45(11), p 4733–4741.

J. Sun et al., Achieving Excellent Ductility in High-Strength Mg-10.6Gd-2 Ag Alloy via Equal Channel Angular Pressing, J. Alloys Compd., 2020, 817, p 152688.

H.S. Kim, M.H. Seo, and S.I. Hong, On the Die Corner Gap Formation in Equal Channel Angular Pressing, Mater. Sci. Eng. A, 2000, 291(1–2), p 86–90.

A.B. Sankuru, M. Hariram, K. Gudimetla, B. Ravisankar, and S.P. KB, SP KB, Optimization of Processing Temperature and Back Pressure of Equal Channel Angular Pressing for Achieving Crack-Free Fine Grained Magnesium, Mater. Today Proc., 2021, 47, p 4611–4616.

S. Wang, W. Liang, Y. Wang, L. Bian, and K. Chen, A Modified Die for Equal Channel Angular Pressing, J. Mater. Process. Technol., 2009, 209(7), p 3182–3186.

N. Sadasivan, M. Balasubramanian, R. Venkatesh, S. Vigneshram, and T. Sunil, Influence of Equal Channel Angular Pressing in an Acute Angle Die with a Back Pressure Notch on Grain Refinement, Torsion and Mechanical Properties Of Aluminium, Materwiss. Werksttech., 2019, 50(2), p 155–164.

V.S. Rao, B.P. Kashyap, N. Prabhu, and P.D. Hodgson, T-shaped Equi-Channel Angular Pressing of Pb-Sn Eutectic and Its Tensile Properties, Mater. Sci. Eng. A, 2008, 486(1–2), p 341–349.

S. Rusz, L. Čížek, L.A. Dobrzański, and S. Tylšar, ECAP Methods Application on Selected Non-Ferrous Metals and Alloys, Arch. Mater. Sci. Eng., 2010, 43(2), p 69–76.

A. Azushima and K. Aoki, Properties of Ultrafine-Grained Steel by Repeated Shear Deformation of Side Extrusion Process, Mater. Sci. Eng. A, 2002, 337(1–2), p 45–49.

A. Ma, Y. Nishida, K. Suzuki, I. Shigematsu, and N. Saito, Characteristics of Plastic Deformation by Rotary-Die Equal-Channel Angular Pressing, Scr. Mater., 2005, 52(6), p 433–437.

K. Nakashima, Z. Horita, M. Nemoto, and T.G. Langdon, Development of a Multi-pass Facility for Equal-Channel Angular Pressing to High Total Strains, Mater. Sci. Eng. A, 2000, 281(1–2), p 82–87.

A.A. Mukhametgalina et al., Ultrasonic Treatment of Ti-5Al-05 V Alloy Subjected to Equal-Channel Angular Pressing, Met. Mater. Int., 2022, 28(5), p 1257–1263.

Y. Iwahashi, J. Wang, Z. Horita, M. Nemoto, and T.G. Langdon, Principle of Equal-Channel Angular Pressing for the Processing of Ultra-fine Grained Materials, Scr. Mater., 1996, 35(2), p 143–146.

A.I. Rudskoi, A.M. Zolotov, R.A. Parshikov, and E.Y. Raskatov, Friction Problems During ECA-Pressing, Mater. Today Proc., 2020, 30, p 683–687.

M. Eskandarzade and M.N. Ershadi, Experimental and Numerical Investigation of the Frictional Forces in Equal Channel Angular Pressing, Uludağ Univ. J. Fac. Eng., 2021, 26(1), p 65–78.

V.A. de Souza, I. Watanabe, and A. Yanagida, Numerical Estimation of Frictional Effects in Equal Channel Angular Extrusion, Mater. Trans., 2016, 57(9), p 1399–1403.

A. Aminnudin, P. Pratikto, A. Purnowidodo, and Y.S. Irawan, The Analysis of Friction Effect on Equal Channel Angular Pressing (ECAP) Process on Aluminium 5052 to Homogeneity of Strain Distribution, East. Eur. J. Enterp. Technol., 2018, 2(1(92)), p 57–62.

F. Djavanroodi and M. Ebrahimi, Effect of Die Channel Angle, Friction and Back Pressure in the Equal Channel Angular Pressing Using 3D Finite Element Simulation, Mater. Sci. Eng. A, 2010, 527(4–5), p 1230–1235.

J.-P. Mathieu, S. Suwas, A. Eberhardt, L.S. Tóth, and P. Moll, A New Design for Equal Channel Angular Extrusion, J. Mater. Process. Technol., 2006, 173(1), p 29–33.

Z.A. Khan, U. Chakkingal, and P. Venugopal, Analysis of Forming Loads, Microstructure Development and Mechanical Property Evolution During Equal Channel Angular Extrusion of a Commercial Grade Aluminum Alloy, J. Mater. Process. Technol., 2003, 135(1), p 59–67.

M. Eskandarzade, A. Masoumi, and G. Faraji, Numerical and Analytical Investigation of an Ultrasonic Assisted ECAP Process, J. Theor. Appl. Vib. Acoust., 2016, 2(2), p 18.

S. Dumoulin, H.J. Roven, J.C. Werenskiold, and H.S. Valberg, Finite Element Modeling of Equal Channel Angular Pressing: Effect of Material Properties, Friction and Die Geometry, Mater. Sci. Eng. A, 2005, 410, p 248–251.

M. Ebrahimi, Numerical Analysis of Conventional and Modified Equal Channel Angular Pressing, Trans. Indian Inst. Met., 2019, 72(9), p 2263–2273.

R. Bhandari, P. Biswas, A. Pathania, M. Mallik, and M. Kumar Mondal, Equal Channel Angular Pressing Die Design Through Finite Element Analysis Method for Non-strain Hardening Material, Can. Metall. Q., 2022, 61, p 1–20.

S. Nazari Tiji, A. Asgari, H. Gholipour, and F. Djavanroodi, Modeling of Equal Channel Forward Extrusion Force Using Response Surface Approach, Proc. Inst. Mech. Eng. Part. B. J. Eng. Manuf., 2018, 232(4), p 713–719.

M. Ebrahimi, F. Pashmforoush, and C. Gode, Evaluating Influence Degree of Equal-Channel Angular Pressing Parameters Based on Finite Element Analysis and Response Surface Methodology, J. Braz. Soc. Mech. Sci. Eng., 2019, 41(2), p 95.

R.A. Parshikov and A.M. Zolotov, Influence of Contact Friction on the Kinematics of Metal Flow During Equal Channel Angular Pressing, Key Eng. Mater., 2019, 822, p 171–177.

I. Balasundar and T. Raghu, Effect of Friction Model in Numerical Analysis of Equal Channel Angular Pressing Process, Mater. Des., 2010, 31(1), p 449–457.

R. Jivan, M. Eskandarzade, S. Bewsher, M. Leighton, M. Mohammadpour, and S. Saremi-Yarahmadi, Application of Solid Lubricant for Enhanced Frictional Efficiency of Deep Drawing Process, Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci., 2022, 236(1), p 624–634.

A.S. Miavaghi, H. Kangarlou, and M. Eskandarzade, Comparison Between Frictional Behavior of the Soft and Brittle Materials at Different Contact Pressures, Leban. Sci. J., 2017, 18(1), p 98.

A.-E. Jiménez and M.-D. Bermúdez, Friction and wear, in Tribology for Engineers, (Elsevier, 2011), pp. 33–63

Abaqus 6.14, Abaqus Theory Guide (2020)

A.A. Mendes Filho, E.F. Prados, G.T. Valio, J.B. Rubert, V.L. Sordi, and M. Ferrante, Severe Plastic Deformation by Equal Channel Angular Pressing: Product Quality and Operational Details, Mater. Res., 2011, 14(3), p 335–339.

F. Djavanroodi and M. Ebrahimi, Effect of Die Parameters and Material Properties in ECAP with Parallel Channels, Mater. Sci. Eng. A, 2010, 527(29–30), p 7593–7599.

L. Hua, X. Hu, and X. Han, Microstructure Evolution of Annealed 7075 Aluminum Alloy and Its Influence on Room-Temperature Plasticity, Mater. Des., 2020, 196, p 109192.

D.R. Fang et al., Effect of Equal Channel Angular Pressing on Tensile Properties and Fracture Modes of Casting Al-Cu alloys, Mater. Sci. Eng. A, 2006, 426(1–2), p 305–313.

S.R. Kumar, K. Gudimetla, P. Venkatachalam, B. Ravisankar, and K. Jayasankar, Microstructural and Mechanical Properties of Al 7075 Alloy Processed by Equal Channel Angular Pressing, Mater. Sci. Eng. A, 2012, 533, p 50–54.

M. Cabibbo, Microstructure Strengthening Mechanisms in Different Equal Channel Angular Pressed Aluminum Alloys, Mater. Sci. Eng. A, 2013, 560, p 413–432.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

There are no known conflicts of interest associated with this publication, and there has been no significant financial support for this work that could have influenced its outcome.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Abbaszadeh, B., Sheikhi, M.M., Fallah, M.M. et al. Effect of Frictional Contact Surface on Maximum Pressing Load during Equal Channel Angular Pressing Process. J. of Materi Eng and Perform 33, 741–750 (2024). https://doi.org/10.1007/s11665-023-08039-5

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-023-08039-5